- •Preface

- •Imaging Microscopic Features

- •Measuring the Crystal Structure

- •References

- •Contents

- •1.4 Simulating the Effects of Elastic Scattering: Monte Carlo Calculations

- •What Are the Main Features of the Beam Electron Interaction Volume?

- •How Does the Interaction Volume Change with Composition?

- •How Does the Interaction Volume Change with Incident Beam Energy?

- •How Does the Interaction Volume Change with Specimen Tilt?

- •1.5 A Range Equation To Estimate the Size of the Interaction Volume

- •References

- •2: Backscattered Electrons

- •2.1 Origin

- •2.2.1 BSE Response to Specimen Composition (η vs. Atomic Number, Z)

- •SEM Image Contrast with BSE: “Atomic Number Contrast”

- •SEM Image Contrast: “BSE Topographic Contrast—Number Effects”

- •2.2.3 Angular Distribution of Backscattering

- •Beam Incident at an Acute Angle to the Specimen Surface (Specimen Tilt > 0°)

- •SEM Image Contrast: “BSE Topographic Contrast—Trajectory Effects”

- •2.2.4 Spatial Distribution of Backscattering

- •Depth Distribution of Backscattering

- •Radial Distribution of Backscattered Electrons

- •2.3 Summary

- •References

- •3: Secondary Electrons

- •3.1 Origin

- •3.2 Energy Distribution

- •3.3 Escape Depth of Secondary Electrons

- •3.8 Spatial Characteristics of Secondary Electrons

- •References

- •4: X-Rays

- •4.1 Overview

- •4.2 Characteristic X-Rays

- •4.2.1 Origin

- •4.2.2 Fluorescence Yield

- •4.2.3 X-Ray Families

- •4.2.4 X-Ray Nomenclature

- •4.2.6 Characteristic X-Ray Intensity

- •Isolated Atoms

- •X-Ray Production in Thin Foils

- •X-Ray Intensity Emitted from Thick, Solid Specimens

- •4.3 X-Ray Continuum (bremsstrahlung)

- •4.3.1 X-Ray Continuum Intensity

- •4.3.3 Range of X-ray Production

- •4.4 X-Ray Absorption

- •4.5 X-Ray Fluorescence

- •References

- •5.1 Electron Beam Parameters

- •5.2 Electron Optical Parameters

- •5.2.1 Beam Energy

- •Landing Energy

- •5.2.2 Beam Diameter

- •5.2.3 Beam Current

- •5.2.4 Beam Current Density

- •5.2.5 Beam Convergence Angle, α

- •5.2.6 Beam Solid Angle

- •5.2.7 Electron Optical Brightness, β

- •Brightness Equation

- •5.2.8 Focus

- •Astigmatism

- •5.3 SEM Imaging Modes

- •5.3.1 High Depth-of-Field Mode

- •5.3.2 High-Current Mode

- •5.3.3 Resolution Mode

- •5.3.4 Low-Voltage Mode

- •5.4 Electron Detectors

- •5.4.1 Important Properties of BSE and SE for Detector Design and Operation

- •Abundance

- •Angular Distribution

- •Kinetic Energy Response

- •5.4.2 Detector Characteristics

- •Angular Measures for Electron Detectors

- •Elevation (Take-Off) Angle, ψ, and Azimuthal Angle, ζ

- •Solid Angle, Ω

- •Energy Response

- •Bandwidth

- •5.4.3 Common Types of Electron Detectors

- •Backscattered Electrons

- •Passive Detectors

- •Scintillation Detectors

- •Semiconductor BSE Detectors

- •5.4.4 Secondary Electron Detectors

- •Everhart–Thornley Detector

- •Through-the-Lens (TTL) Electron Detectors

- •TTL SE Detector

- •TTL BSE Detector

- •Measuring the DQE: BSE Semiconductor Detector

- •References

- •6: Image Formation

- •6.1 Image Construction by Scanning Action

- •6.2 Magnification

- •6.3 Making Dimensional Measurements With the SEM: How Big Is That Feature?

- •Using a Calibrated Structure in ImageJ-Fiji

- •6.4 Image Defects

- •6.4.1 Projection Distortion (Foreshortening)

- •6.4.2 Image Defocusing (Blurring)

- •6.5 Making Measurements on Surfaces With Arbitrary Topography: Stereomicroscopy

- •6.5.1 Qualitative Stereomicroscopy

- •Fixed beam, Specimen Position Altered

- •Fixed Specimen, Beam Incidence Angle Changed

- •6.5.2 Quantitative Stereomicroscopy

- •Measuring a Simple Vertical Displacement

- •References

- •7: SEM Image Interpretation

- •7.1 Information in SEM Images

- •7.2.2 Calculating Atomic Number Contrast

- •Establishing a Robust Light-Optical Analogy

- •Getting It Wrong: Breaking the Light-Optical Analogy of the Everhart–Thornley (Positive Bias) Detector

- •Deconstructing the SEM/E–T Image of Topography

- •SUM Mode (A + B)

- •DIFFERENCE Mode (A−B)

- •References

- •References

- •9: Image Defects

- •9.1 Charging

- •9.1.1 What Is Specimen Charging?

- •9.1.3 Techniques to Control Charging Artifacts (High Vacuum Instruments)

- •Observing Uncoated Specimens

- •Coating an Insulating Specimen for Charge Dissipation

- •Choosing the Coating for Imaging Morphology

- •9.2 Radiation Damage

- •9.3 Contamination

- •References

- •10: High Resolution Imaging

- •10.2 Instrumentation Considerations

- •10.4.1 SE Range Effects Produce Bright Edges (Isolated Edges)

- •10.4.4 Too Much of a Good Thing: The Bright Edge Effect Hinders Locating the True Position of an Edge for Critical Dimension Metrology

- •10.5.1 Beam Energy Strategies

- •Low Beam Energy Strategy

- •High Beam Energy Strategy

- •Making More SE1: Apply a Thin High-δ Metal Coating

- •Making Fewer BSEs, SE2, and SE3 by Eliminating Bulk Scattering From the Substrate

- •10.6 Factors That Hinder Achieving High Resolution

- •10.6.2 Pathological Specimen Behavior

- •Contamination

- •Instabilities

- •References

- •11: Low Beam Energy SEM

- •11.3 Selecting the Beam Energy to Control the Spatial Sampling of Imaging Signals

- •11.3.1 Low Beam Energy for High Lateral Resolution SEM

- •11.3.2 Low Beam Energy for High Depth Resolution SEM

- •11.3.3 Extremely Low Beam Energy Imaging

- •References

- •12.1.1 Stable Electron Source Operation

- •12.1.2 Maintaining Beam Integrity

- •12.1.4 Minimizing Contamination

- •12.3.1 Control of Specimen Charging

- •12.5 VPSEM Image Resolution

- •References

- •13: ImageJ and Fiji

- •13.1 The ImageJ Universe

- •13.2 Fiji

- •13.3 Plugins

- •13.4 Where to Learn More

- •References

- •14: SEM Imaging Checklist

- •14.1.1 Conducting or Semiconducting Specimens

- •14.1.2 Insulating Specimens

- •14.2 Electron Signals Available

- •14.2.1 Beam Electron Range

- •14.2.2 Backscattered Electrons

- •14.2.3 Secondary Electrons

- •14.3 Selecting the Electron Detector

- •14.3.2 Backscattered Electron Detectors

- •14.3.3 “Through-the-Lens” Detectors

- •14.4 Selecting the Beam Energy for SEM Imaging

- •14.4.4 High Resolution SEM Imaging

- •Strategy 1

- •Strategy 2

- •14.5 Selecting the Beam Current

- •14.5.1 High Resolution Imaging

- •14.5.2 Low Contrast Features Require High Beam Current and/or Long Frame Time to Establish Visibility

- •14.6 Image Presentation

- •14.6.1 “Live” Display Adjustments

- •14.6.2 Post-Collection Processing

- •14.7 Image Interpretation

- •14.7.1 Observer’s Point of View

- •14.7.3 Contrast Encoding

- •14.8.1 VPSEM Advantages

- •14.8.2 VPSEM Disadvantages

- •15: SEM Case Studies

- •15.1 Case Study: How High Is That Feature Relative to Another?

- •15.2 Revealing Shallow Surface Relief

- •16.1.2 Minor Artifacts: The Si-Escape Peak

- •16.1.3 Minor Artifacts: Coincidence Peaks

- •16.1.4 Minor Artifacts: Si Absorption Edge and Si Internal Fluorescence Peak

- •16.2 “Best Practices” for Electron-Excited EDS Operation

- •16.2.1 Operation of the EDS System

- •Choosing the EDS Time Constant (Resolution and Throughput)

- •Choosing the Solid Angle of the EDS

- •Selecting a Beam Current for an Acceptable Level of System Dead-Time

- •16.3.1 Detector Geometry

- •16.3.2 Process Time

- •16.3.3 Optimal Working Distance

- •16.3.4 Detector Orientation

- •16.3.5 Count Rate Linearity

- •16.3.6 Energy Calibration Linearity

- •16.3.7 Other Items

- •16.3.8 Setting Up a Quality Control Program

- •Using the QC Tools Within DTSA-II

- •Creating a QC Project

- •Linearity of Output Count Rate with Live-Time Dose

- •Resolution and Peak Position Stability with Count Rate

- •Solid Angle for Low X-ray Flux

- •Maximizing Throughput at Moderate Resolution

- •References

- •17: DTSA-II EDS Software

- •17.1 Getting Started With NIST DTSA-II

- •17.1.1 Motivation

- •17.1.2 Platform

- •17.1.3 Overview

- •17.1.4 Design

- •Simulation

- •Quantification

- •Experiment Design

- •Modeled Detectors (. Fig. 17.1)

- •Window Type (. Fig. 17.2)

- •The Optimal Working Distance (. Figs. 17.3 and 17.4)

- •Elevation Angle

- •Sample-to-Detector Distance

- •Detector Area

- •Crystal Thickness

- •Number of Channels, Energy Scale, and Zero Offset

- •Resolution at Mn Kα (Approximate)

- •Azimuthal Angle

- •Gold Layer, Aluminum Layer, Nickel Layer

- •Dead Layer

- •Zero Strobe Discriminator (. Figs. 17.7 and 17.8)

- •Material Editor Dialog (. Figs. 17.9, 17.10, 17.11, 17.12, 17.13, and 17.14)

- •17.2.1 Introduction

- •17.2.2 Monte Carlo Simulation

- •17.2.4 Optional Tables

- •References

- •18: Qualitative Elemental Analysis by Energy Dispersive X-Ray Spectrometry

- •18.1 Quality Assurance Issues for Qualitative Analysis: EDS Calibration

- •18.2 Principles of Qualitative EDS Analysis

- •Exciting Characteristic X-Rays

- •Fluorescence Yield

- •X-ray Absorption

- •Si Escape Peak

- •Coincidence Peaks

- •18.3 Performing Manual Qualitative Analysis

- •Beam Energy

- •Choosing the EDS Resolution (Detector Time Constant)

- •Obtaining Adequate Counts

- •18.4.1 Employ the Available Software Tools

- •18.4.3 Lower Photon Energy Region

- •18.4.5 Checking Your Work

- •18.5 A Worked Example of Manual Peak Identification

- •References

- •19.1 What Is a k-ratio?

- •19.3 Sets of k-ratios

- •19.5 The Analytical Total

- •19.6 Normalization

- •19.7.1 Oxygen by Assumed Stoichiometry

- •19.7.3 Element by Difference

- •19.8 Ways of Reporting Composition

- •19.8.1 Mass Fraction

- •19.8.2 Atomic Fraction

- •19.8.3 Stoichiometry

- •19.8.4 Oxide Fractions

- •Example Calculations

- •19.9 The Accuracy of Quantitative Electron-Excited X-ray Microanalysis

- •19.9.1 Standards-Based k-ratio Protocol

- •19.9.2 “Standardless Analysis”

- •19.10 Appendix

- •19.10.1 The Need for Matrix Corrections To Achieve Quantitative Analysis

- •19.10.2 The Physical Origin of Matrix Effects

- •19.10.3 ZAF Factors in Microanalysis

- •X-ray Generation With Depth, φ(ρz)

- •X-ray Absorption Effect, A

- •X-ray Fluorescence, F

- •References

- •20.2 Instrumentation Requirements

- •20.2.1 Choosing the EDS Parameters

- •EDS Spectrum Channel Energy Width and Spectrum Energy Span

- •EDS Time Constant (Resolution and Throughput)

- •EDS Calibration

- •EDS Solid Angle

- •20.2.2 Choosing the Beam Energy, E0

- •20.2.3 Measuring the Beam Current

- •20.2.4 Choosing the Beam Current

- •Optimizing Analysis Strategy

- •20.3.4 Ba-Ti Interference in BaTiSi3O9

- •20.4 The Need for an Iterative Qualitative and Quantitative Analysis Strategy

- •20.4.2 Analysis of a Stainless Steel

- •20.5 Is the Specimen Homogeneous?

- •20.6 Beam-Sensitive Specimens

- •20.6.1 Alkali Element Migration

- •20.6.2 Materials Subject to Mass Loss During Electron Bombardment—the Marshall-Hall Method

- •Thin Section Analysis

- •Bulk Biological and Organic Specimens

- •References

- •21: Trace Analysis by SEM/EDS

- •21.1 Limits of Detection for SEM/EDS Microanalysis

- •21.2.1 Estimating CDL from a Trace or Minor Constituent from Measuring a Known Standard

- •21.2.2 Estimating CDL After Determination of a Minor or Trace Constituent with Severe Peak Interference from a Major Constituent

- •21.3 Measurements of Trace Constituents by Electron-Excited Energy Dispersive X-ray Spectrometry

- •The Inevitable Physics of Remote Excitation Within the Specimen: Secondary Fluorescence Beyond the Electron Interaction Volume

- •Simulation of Long-Range Secondary X-ray Fluorescence

- •NIST DTSA II Simulation: Vertical Interface Between Two Regions of Different Composition in a Flat Bulk Target

- •NIST DTSA II Simulation: Cubic Particle Embedded in a Bulk Matrix

- •21.5 Summary

- •References

- •22.1.2 Low Beam Energy Analysis Range

- •22.2 Advantage of Low Beam Energy X-Ray Microanalysis

- •22.2.1 Improved Spatial Resolution

- •22.3 Challenges and Limitations of Low Beam Energy X-Ray Microanalysis

- •22.3.1 Reduced Access to Elements

- •22.3.3 At Low Beam Energy, Almost Everything Is Found To Be Layered

- •Analysis of Surface Contamination

- •References

- •23: Analysis of Specimens with Special Geometry: Irregular Bulk Objects and Particles

- •23.2.1 No Chemical Etching

- •23.3 Consequences of Attempting Analysis of Bulk Materials With Rough Surfaces

- •23.4.1 The Raw Analytical Total

- •23.4.2 The Shape of the EDS Spectrum

- •23.5 Best Practices for Analysis of Rough Bulk Samples

- •23.6 Particle Analysis

- •Particle Sample Preparation: Bulk Substrate

- •The Importance of Beam Placement

- •Overscanning

- •“Particle Mass Effect”

- •“Particle Absorption Effect”

- •The Analytical Total Reveals the Impact of Particle Effects

- •Does Overscanning Help?

- •23.6.6 Peak-to-Background (P/B) Method

- •Specimen Geometry Severely Affects the k-ratio, but Not the P/B

- •Using the P/B Correspondence

- •23.7 Summary

- •References

- •24: Compositional Mapping

- •24.2 X-Ray Spectrum Imaging

- •24.2.1 Utilizing XSI Datacubes

- •24.2.2 Derived Spectra

- •SUM Spectrum

- •MAXIMUM PIXEL Spectrum

- •24.3 Quantitative Compositional Mapping

- •24.4 Strategy for XSI Elemental Mapping Data Collection

- •24.4.1 Choosing the EDS Dead-Time

- •24.4.2 Choosing the Pixel Density

- •24.4.3 Choosing the Pixel Dwell Time

- •“Flash Mapping”

- •High Count Mapping

- •References

- •25.1 Gas Scattering Effects in the VPSEM

- •25.1.1 Why Doesn’t the EDS Collimator Exclude the Remote Skirt X-Rays?

- •25.2 What Can Be Done To Minimize gas Scattering in VPSEM?

- •25.2.2 Favorable Sample Characteristics

- •Particle Analysis

- •25.2.3 Unfavorable Sample Characteristics

- •References

- •26.1 Instrumentation

- •26.1.2 EDS Detector

- •26.1.3 Probe Current Measurement Device

- •Direct Measurement: Using a Faraday Cup and Picoammeter

- •A Faraday Cup

- •Electrically Isolated Stage

- •Indirect Measurement: Using a Calibration Spectrum

- •26.1.4 Conductive Coating

- •26.2 Sample Preparation

- •26.2.1 Standard Materials

- •26.2.2 Peak Reference Materials

- •26.3 Initial Set-Up

- •26.3.1 Calibrating the EDS Detector

- •Selecting a Pulse Process Time Constant

- •Energy Calibration

- •Quality Control

- •Sample Orientation

- •Detector Position

- •Probe Current

- •26.4 Collecting Data

- •26.4.1 Exploratory Spectrum

- •26.4.2 Experiment Optimization

- •26.4.3 Selecting Standards

- •26.4.4 Reference Spectra

- •26.4.5 Collecting Standards

- •26.4.6 Collecting Peak-Fitting References

- •26.5 Data Analysis

- •26.5.2 Quantification

- •26.6 Quality Check

- •Reference

- •27.2 Case Study: Aluminum Wire Failures in Residential Wiring

- •References

- •28: Cathodoluminescence

- •28.1 Origin

- •28.2 Measuring Cathodoluminescence

- •28.3 Applications of CL

- •28.3.1 Geology

- •Carbonado Diamond

- •Ancient Impact Zircons

- •28.3.2 Materials Science

- •Semiconductors

- •Lead-Acid Battery Plate Reactions

- •28.3.3 Organic Compounds

- •References

- •29.1.1 Single Crystals

- •29.1.2 Polycrystalline Materials

- •29.1.3 Conditions for Detecting Electron Channeling Contrast

- •Specimen Preparation

- •Instrument Conditions

- •29.2.1 Origin of EBSD Patterns

- •29.2.2 Cameras for EBSD Pattern Detection

- •29.2.3 EBSD Spatial Resolution

- •29.2.5 Steps in Typical EBSD Measurements

- •Sample Preparation for EBSD

- •Align Sample in the SEM

- •Check for EBSD Patterns

- •Adjust SEM and Select EBSD Map Parameters

- •Run the Automated Map

- •29.2.6 Display of the Acquired Data

- •29.2.7 Other Map Components

- •29.2.10 Application Example

- •Application of EBSD To Understand Meteorite Formation

- •29.2.11 Summary

- •Specimen Considerations

- •EBSD Detector

- •Selection of Candidate Crystallographic Phases

- •Microscope Operating Conditions and Pattern Optimization

- •Selection of EBSD Acquisition Parameters

- •Collect the Orientation Map

- •References

- •30.1 Introduction

- •30.2 Ion–Solid Interactions

- •30.3 Focused Ion Beam Systems

- •30.5 Preparation of Samples for SEM

- •30.5.1 Cross-Section Preparation

- •30.5.2 FIB Sample Preparation for 3D Techniques and Imaging

- •30.6 Summary

- •References

- •31: Ion Beam Microscopy

- •31.1 What Is So Useful About Ions?

- •31.2 Generating Ion Beams

- •31.3 Signal Generation in the HIM

- •31.5 Patterning with Ion Beams

- •31.7 Chemical Microanalysis with Ion Beams

- •References

- •Appendix

- •A Database of Electron–Solid Interactions

- •A Database of Electron–Solid Interactions

- •Introduction

- •Backscattered Electrons

- •Secondary Yields

- •Stopping Powers

- •X-ray Ionization Cross Sections

- •Conclusions

- •References

- •Index

- •Reference List

- •Index

\456 Chapter 25 · Attempting Electron-Excited X-Ray Microanalysis in the Variable Pressure Scanning Electron Microscope (VPSEM)

|

25.2.3\ Unfavorable Sample Characteristics |

||

25 |

|||

|

|

||

EDS analysis in VPSEM is most problematic for specimens |

|||

|

|||

|

|||

|

consisting of densely packed microscopic features, for exam- |

||

|

ple, most solid materials, natural and synthetic, with a micro- |

||

|

structure. The measured EDS X-ray spectrum in such a case |

||

|

depends very strongly on the VPSEM conditions, the dimen- |

||

|

sions of the target area of interest, and the exact nature of the |

||

|

surrounding microstructure. An example is presented in |

||

|

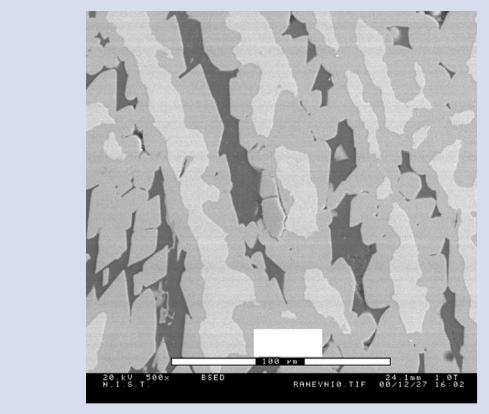

. Fig. 25.14, which shows the microstructure of Raney nickel, |

||

|

an aluminum-nickel catalyst. Based on the contrast in this |

||

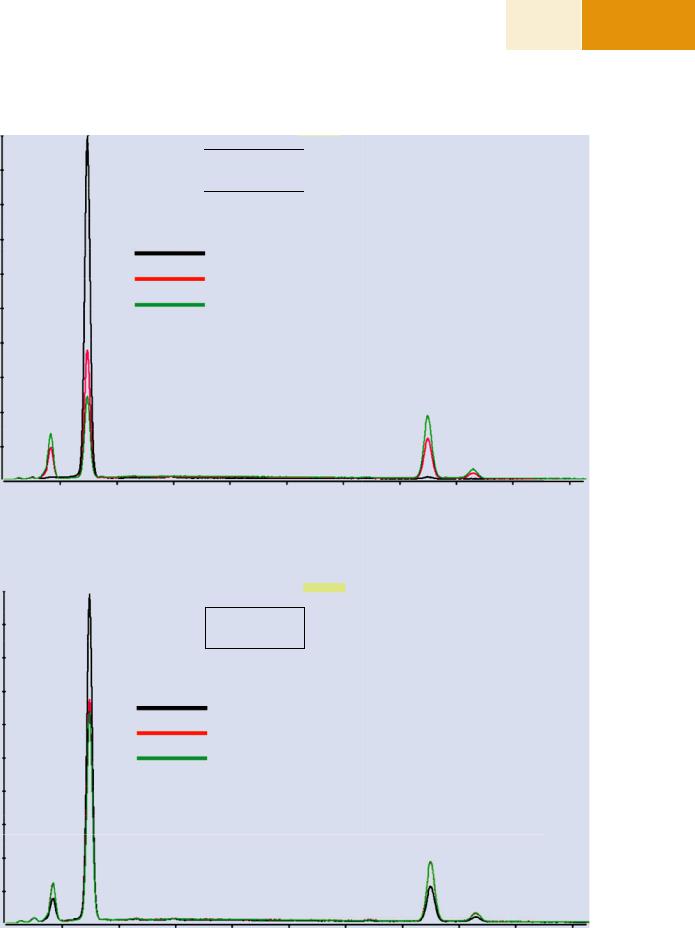

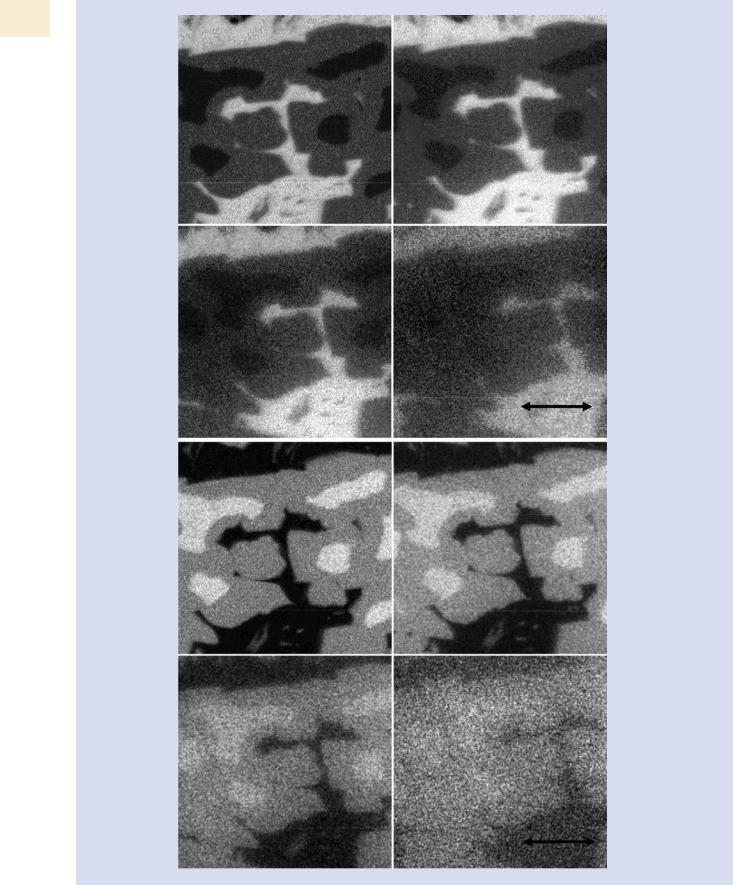

SEM-BSE image, there are three different phases present denoted D, I, and B, with different Al/Ni ratios. The spectral intensities for Al and Ni show differences in the low pressure EDS spectra shown in . Fig. 25.15a that are sufficient to readily distinguish the phases despite the gas scattering (E0 = 20 keV; 50 Pa; water vapor; 6-mm gas path length). When the pressure is increased to 665 Pa, two of the phases can no longer be distinguished in the EDS spectrum shown in . Fig. 25.15b. This loss of phase recognition is also seen as a loss of contrast in X-ray mapping, as seen in the elemental intensity maps shown in . Fig. 25.16a, b.

. Fig. 25.14 SEM-BSE image of Raney nickel in a VPSEM

Raney nickel |

I |

B |

|

D |

|||

|

|||

E0 = 20 keV |

|

||

|

|

||

BSED |

|

|

100 µm

457 |

25 |

25.2 · What Can Be Done To Minimize gas Scattering in VPSEM?

a |

Raney Nickel E0 = 20 keV pressure < 50 Pa (0.4 torr) |

|

|

|

|

|

|

|

||||||||||

57850 |

Ch#: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

279 |

|

Ch kV; |

2.7900 |

|

Work: 318 |

Results: 425 |

Marker: |

|

Ba |

56 |

|

|

|

|

|

|||

|

|

|

|

ALKa |

|

Soec# |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

Counts |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

1 |

510 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

AI-rich phase |

|

|

|

(0.988 AI - 0.012 Ni) |

|

|

|||

|

|

|

|

|

|

|

|

|

Intermediate phase |

|

|

|

(0.588 AI - 0.412 Ni) |

|

|

|||

|

|

|

|

|

|

|

|

|

Ni-rich phase |

|

|

|

(0.429 AI- 0.571 Ni) |

|

|

|||

|

NiLa1 |

|

|

|

|

|

|

|

|

|

|

|

|

NiKa |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NiKb1 |

|

|

0.00 |

|

1.00 |

2.00 |

|

3.00 |

4.00 |

5.00 |

|

|

6.00 |

7.00 |

8.00 |

9.00 |

10.00 |

||||

|

|

|

|

|

|

|

|

|

Photon energy (keV) |

|

|

|

|

|||||

b |

|

Raney Nickel E0 = 20 keV pressure 655 Pa (5 torr) |

|

|

|

|

|

|

|

|||||||||

42649 |

|

|

|

|

|

|

|

Work: 358 |

Results: 458 |

Marker: |

Ba |

56 |

|

|

|

|

||

Ch#: |

388 |

|

Ch kV; |

3.8800 |

|

|

|

|

|

|||||||||

|

|

|

|

ALKa |

|

Soec# |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

Counts |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

1 |

481 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

AI-rich phase |

|

|

|

(0.988 AI - 0.012 Ni) |

|

|

|||

|

|

|

|

|

|

|

|

|

Intermediate phase |

|

|

|

(0.588 AI - 0.412 Ni) |

|

|

|||

|

|

|

|

|

|

|

|

|

Ni-rich phase |

|

|

|

(0.429 AI - 0.571 Ni) |

|

|

|||

|

NiLa1 |

|

|

|

|

|

|

|

|

|

|

|

|

NiKa |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NiKb1 |

|

|

0.00 |

|

1.00 |

2.00 |

3.00 |

4.00 |

5.00 |

|

6.00 |

7.00 |

8.00 |

9.00 |

10.00 |

||||||

|

|

|

|

|

|

|

|

|

Photon energy (keV) |

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

. Fig. 25.15 a EDS spectra obtained at locations “D”, “I,” and “B.” E0 = 20 keV; water vapor; 50 Pa, 6-mm gas path length. b EDS spectra obtained at locations “D,”“I,” and “B.” E0 = 20 keV; water vapor; 665 Pa, 6-mm gas path length

\458 Chapter 25 · Attempting Electron-Excited X-Ray Microanalysis in the Variable Pressure Scanning Electron Microscope (VPSEM)

25 a

AI K-L2

E0 = 20 keV

133 Pa |

665 Pa |

|

1330 Pa |

50 µm |

2000 Pa |

|

||

|

|

b

Ni K-L2

E0 = 20 keV

133 Pa

665 Pa

1330 Pa |

50 |

µm |

2000 Pa |

|

|

|

. Fig. 25.16 a Elemental intensity map for Al K-L2 at various pressures (E0 = 20 keV, water vapor and 6-mm gas path length). b Elemental intensity map for NiKα at various pressures (E0 = 20 keV, water vapor and 6-mm gas path length)