Proceedings of 6th International Conference of Young Scientisis on Solutions of Applied Problems in Control and Communications

..pdf

Fig. 1. As is model

In accordance with the purposes we have to solve the task:

∙ To automate design, development and manufacturing of products with the comprehensive solution T-FLEX.

2. Technology Description

In order to choose suitable automation tools, analysis of CAD/CAM market was conducted.

As result of comparison several CAD/CAM systems is obtained the following table.

Analysis of the CAD/CAM systems

31

All these systems can perform designing and technological tasks; also the systems have functions for preparing NC-code. T-FLEX and ADEM systems have advantages. It is orientation on Russian production structure. The T-FLEX system has the most optimal cost that’s why it’s optimal decision for the enterprise.

The T-FLEX decision combines systems for: engineering design, technological design, NC codes preparing, engineering analysis.

All programs of the suite are functioning on unified information platform of system of technical documents circulation [3].

A feature of this complex is that T-FLEX DOCs has an embedded core of the system T-FLEX CAD. The system T-FLEX technology is built on the core of the system T-FLEX DOCs.

The most obvious advantage of this construction of the system T-FLEX is full implementation of pass-through design.

3. Developments

For now NC-code preparation is conducted in CNC-CAM system. There are two CAM-CNC modules: the first one is module «print CNCcode», where user can write code in the programming language by manually; the second one is graphical module, which uses the principle of graphical plotting and editing of tool paths and machining commands. After implementation T-FLEX decision the process of NC-generation will work like it describe below (Fig. 2).

Fig. 2. The suit T-FLEX

32

At the beginning we have a drawing in the T-FLEX CAD (Fig. 3). The feature of T-FLEX CAM is that it's fully integrated system of T-FLEX CAD, so we just continue to work in CAD using CAM interface.

Fig. 3. T-FLEX CAD. Drawing of sleeve

At this structure of system, a possibility of distorting model geometry is excluded. There is one more plus, it is a simplified modification of model geometry.

Let’s consider the decomposition of NC-code generation in the T-FLEX CAM system (Fig. 4).

Fig. 4. the decomposition of NC-code generation

33

There are 3 main processes:

1) The first one is process of choosing tool. There we can choose the type of tool, length and width and other parameters.

The second one is process of creating tool path. In the 2D drawing, which we got from T-FLEX CAD, we create the tool path (Fig. 5), by means CAM interface.

Fig. 5. The resulting tool path

2) The last one is process of choosing postprocessor. At the stage is necessary to choose a postprocessor, which are suitable for used equipment. T-FLEX CAM provides a large library of postprocessors for all type of machines. The software also includes a postprocessor generator to create and modify table postprocessors.

In order to save resources and time on tooling NC-code on a CNC machine, one can use the emulator program (Fig. 6). The program provides realistic graphical verification, ensuring that codes are correct before being executed. So one can detect collisions and errors before the code is loaded on the machine and also optimize your NC-code for more efficient work.

34

Fig. 6. Emulator program

Results

As results of automation:

1)Reduced time on preparing of NC-codes, using CAD/CAMdecision.

2)Saved resources at the stage of tooling NC-codes, using T-FLEX emulator program.

3)Improved the processes of designing, developing and manufacturing products through implementation of pass-through design.

References

1.Bochkarev S.V., Petrochenkov A.B., Shirtladce A.G. Quality control. – Stary Oskol: TNT, 2012. – 456 p.

2.Shirtladce A.G., Bochkarev S.V., Likov A.N., Boriskin V.P. Technological process automation. – Stary Oskol: TNT, 2 014. – 524 p.

3.T-FLEX. – URL: www.tflex.ru

35

АВТОМАТИЗАЦИЯ ПОДГОТОВКИ УПРАВЛЯЮЩИХ ПРОГРАММ ДЛЯ СТАНКОВ С ЧПУ В МАШИНОСТРОЕНИИ

Егор ОБУХОВ1, Сергей БОЧКАРЕВ2

Пермский национальный исследовательский политехнический университет, Пермь, Россия

(1e-mail:Obuhov2014@bk.ru, 2e-mail: Bochkarev@msa.pstu.ru)

Аннотация. Ключевой стадией технологической подготовки производства является процесс подготовки кодов управляющих программ для станков с ЧПУ. Главный вопрос, который выделен в статье, как сделать более эффективным процесс генерации NC-кода средствами CAD/CAM решения. В этом случае решение T-FLEX является действительно эффективным. Оно позволяет выполнить конструкторские и технологические задачи в одном модуле.

Ключевые слова: подготовка УП, T-FLEX, CAD/CAM, станки с ЧПУ.

36

AUTOMATION OF BUSINESS PROCESSES IN ACCORDANCE WITH SPECIFICATIONS, TECHNICAL REQUIREMENTS

IN THE ENVIRONMENT OF ELECTRONIC DOCUMENT FLOW

Roman POGORAZDOV1, Nikolay KHOROSHEV2

Perm National Research Polytechnic University, Perm, Russia

(1e-mail: rom_pog@mail.ru, 2e-mail: horoshevni@mail.ru)

Abstract. In this article, an example automation business of process in accordance with specifications, technical requirements, in the environment of electronic document flow of «DIRECTUM», at the large industria l enterprise is reviewed.

Keywords: document flow, standard route, business process, specifications, technical requirements.

Introduction

Any enterprise, in the course of its activity, faces processing of a large number of documents. Work with documents is represented by creation, storage, adjustment, coordination, statement, and mailing. These processes are called document flow.

Paper document flow, now brings problems and has low efficiency. Results of work have to be dispatched by mail or carried manually, documents are not always easily found, and if there is a mistake, they have to be reprinted.

We can give the main problems of paper document flow:

−High labor-intensity of processes;

−Long terms of carrying out business processes;

−No process control;

−High risk of document loss;

−Additional expenses.

When the enterprises faced these problems, in the market the software products called by the systems of electronic document flow started appearing.

They completely automate all stages of work with documents, and management of the organization is on a new level.

1. Automation object and its main problems

The industrial enterprise specializing on production of aviation engines, daily faces with big number of documentation. The considerable

37

share from these documents is made by specifications and technical requirements. The main problem consists that specifications, technical requirements are created and coordinated out of information systems and tough regulations. At creation and the circulation of documents, there are cases of losses of documents, not release of documents. To be spent for coordination of these documents a large number of time of performers and heads of all levels. It is necessary to exclude cases of loss of documents, untimely coordination of specifications and technical requirements.

The specification – the initial document for design of technical obj ect (product). This document establishes a basic purpose of the developed object, its technical characteristics, indicators of quality and technical and economic requirements, the instruction on performance of necessary stages of creation of documentation (design, technological, program etc.) and its structure.

Technical requirements – the document establishing technical requirements to which have to satisfy a concrete product, material, substance and so forth or their group. Besides, in them procedures by means of which it is possible to establish have to be specified, whether these requirements are observed.

Proceeding from these main problems it is possible to create the main requirements to automation of processes coordination of specification and technical requirements in system.

1.To provide control of an execution of documents and tasks.

2.To ensure parallel functioning with draft documents at stages of coordination with the corresponding routing and saving of all versions of draft documents.

3.To provide search of documents by the form, date, the contents, the author, the performer.

4.To provide safe storage of documents in an electronic database.

2. Decision of problems

At the solution of this task, at the industrial enterprise the «DIRECTUM» system of electronic document flow is used.

«DIRECTUM» – the system of electronic document flow and management of interaction aimed at increase of overall performance of all staff of the organization in different areas of their joint activity. This system is widely used at the enterprises of Russia and is one of leaders in the domestic market.

38

The «DIRECTUM» system belongs to the class of ECM systems (Enterprise Content Management) and supports full life cycle of management of documents. The system provides the organization and control of business processes based on the «Workflow» technology: coordination of documents, processing of difficult orders, preparation and carrying out meetings, support of a cycle of sales and other processes of interaction.

3. Description of system «DIRECTUM»

Main modules of «DIRECTUM» system:

1.Management of electronic documents. Creation, storage, editing different types of documents (Microsoft Word, Microsoft Excel, Microsoft Visio, CorelDraw), support of storage of different versions of documents and work with digital signatures (at coordination and the statement); structuring documents according to folders; purpose of access rights to documents; work history with documents; search of documents in the name or group of attributes.

2.Management of business processes. Support of processes of coordination and processing of documents at all stages of their life cycle «document flow»; delivery of electronic tasks and control of their execution; interaction between employees during business processes; support of free and rigid routes «workflow».

3.Office. Maintaining the nomenclature of affairs with flexible rules of numbering; mailing and control of location of paper documents; the organization of an exchange of electronic documents with digital signature with other organizations.

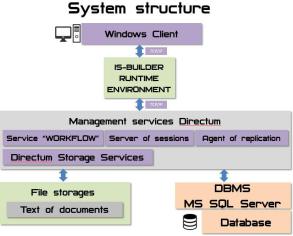

The structure of «DIRECTUM» (Fig. 1) system consists of several components:

−the environment of execution of «IS-Builder» – is r esponsible for business logic and interaction with database management system (DBMS), the server of sessions, «Workflow» service, and file storages under the TCP/IP protocol;

−DBMS – processes inquiries, operates access to a da tabase;

−The «Workflow» service – operates work with tasks o f «DIRECTUM»;

−The server of sessions – operates access to objects of «DIRECTUM» depending on blocking and free license;

39

Fig. 1. Structure of system «DIRECTUM»

−File storages – allow to get access to the text of the electronic documents located in file Windows system;

−The agent of replication – allows to conduct work w ith «DIRECTUM» at remote offices.

4. Realization of algorithm for system of electronic document flow

Flexibility and width of control in system business of logic is the major parameter, which will allow to create and adjust to the enterprise business processes under itself. The «DIRECTUM» system provides to the developer business of processes the flexible and convenient instrument of realization business of processes. These tasks can be realized through creation of algorithms of standard routes which in the form of the logical scheme will reflect algorithm of this or that carrying out process business. Also in system, there is a special environment of development (IS-BUILDER), with the corresponding programming language (ISBL), for modernization of the existing system, and for more exact and convenient creation of work with system.

The standard route represents the logical scheme a set of tasks which execution depends on certain conditions and parameters. Each block – is a specific task, for one user or a group, a further route, depends on decisions of users, or the preset parameters. It can be constructed in the special editor standard routes, which is built in «DIRECTUM» system. Besides blocks of tasks in a route there are logical blocks (conditional, or, i). By means of these blocks and connecting lines the main logic of a route is constructed.

40