- •Модуль 1. Строительные материалы по степени готовности

- •Модуль 2. Строительные материалы по происхождению

- •Модуль 4. Строительные материалы по виду сырья

- •Модуль 6. Строительные смеси

- •Модуль 7. Искусственные строительные изделия

- •Модуль 8. Искусственные строительные материалы

- •Модуль 9. Каменные строительные материалы

- •Модуль 11. Строительные материалы и изделия из древесины

- •Список литературы

Модуль 2. СТРОИТЕЛЬНЫЕ МАТЕРИАЛЫ ПО ПРОИСХОЖДЕНИЮ

Задание 1. Изучите схему. Постройте на ее основе учебный текст на английском языке.

Схема 2. Строительные материалы. Классификация по происхождению

Строительные материалы

Классификация по происхождению

природные |

|

|

искусственные |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

древесина |

|

кирпич |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

||||

природные камни |

|

цемент |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

торф |

|

железобетон |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

||||

природные битумы |

|

стекло |

|

||||

и асфальты |

|

|

|

|

|

||

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

Building materials

Classification according to origins

native, natural |

|

forced, man-made, manufactured, artificial |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

timber, wood |

|

|

brick |

|

||

|

|

|

|

|

|

|

|

|

|

|

|||

rock (natural stone) |

|

|

cement |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

peat, turf |

|

|

ferroconcrete |

|

||

|

|

|

|

|

||

|

|

|

||||

natural bitumen, asphaltic bitumen |

|

glass |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Задание 2. Определите место данных ниже терминов в предложенной выше классификации, постройте дефиниции терминов указанием на принадлежность материала к природным или искусственным материалам.

16

Basalt is a common extrusive igneous (volcanic) rock formed from the rapid cooling of basaltic lava exposed at or very near the surface of a planet or moon. By definition, basalt is an aphanitic igneous rock with less than 20% quartz and less than 10% feldspathoid by volume, and where at least 65% of the feldspar is in the form of plagioclase. (In comparison, granite has more than 20% quartz by volume.) Basalt is usually grey to black in colour, but rapidly weathers to brown or rust-red due to oxidation of its mafic (iron-rich) minerals into rust. It almost always has a finegrained mineral texture due to the molten rock cooling too quickly for large mineral crystals to grow, although it can sometimes be porphyritic, containing the larger crystals formed prior to the extrusion that brought the lava to the surface, embedded in a finer-grained matrix. Basalt with a vesicular or frothy texture is called scoria, and forms when dissolved gases are forced out of solution and form vesicles as the lava decompresses as it reaches the surface.

On Earth, most basalt magmas have formed by decompression melting of the mantle. Basalt commonly erupts on Io, the third largest moon of Jupiter, and has also formed on Earth's Moon, Mars, Venus, and the asteroid Vesta.

The term basalt is at times applied to shallow intrusive rocks with a composition typical of basalt, but rocks of this composition with a phaneritic (coarse) groundmass are generally referred to as diabase (also called dolerite) or gabbro.

Asphalt is a brown to black bituminous substance. Mostnativeasphaltisaresidue from evaporated petroleum. Asphalt is used widely in building for such items as waterproofing roof coverings of many types, exterior wall coverings, and flooring tile.

Sawdust or wood dust is a by-product of cutting, grinding, drilling, sanding, or otherwise pulverizing wood with a saw or other tool; it is composed of fine particles of wood. It is also the byproduct of certain animals, birds and insects which live in wood, such as the woodpecker and carpenter ant. It can present a hazard in manufacturing industries, especially in terms of its flammability. Sawdust is the main component of particleboard. A major use of sawdust is for particleboard; coarse sawdust may be used for wood pulp. Sawdust has a variety of other practical uses, including serving as a mulch, as an alternative to clay cat litter, or as a fuel. Until the advent of refrigeration, it was often used in icehouses to keep ice frozen during the summer. It has been used in artistic displays, and as scatter. It is also sometimes used to soak up liquid spills, allowing the spill to be easily collected or swept aside. As such, it was formerly common on barroom floors. It is used to make Cutler's resin. Mixed with water and frozen, it forms pykrete, a slow-melting, much stronger form of ice.

Sawdust is used in the manufacture of charcoal briquettes. The claim for invention of the first commercial charcoal briquettes goes to Henry Ford who created them from the wood scraps and sawdust produced by his automobile factory.

Plywood is a wood product made by fastening together layers of veneer or a combination of veneer layers and a lumber core. The layers are joined with an adhesive. Adjoining plies are usually laid with grains at right angles to each other, and almost always an odd number of plies are used.

17

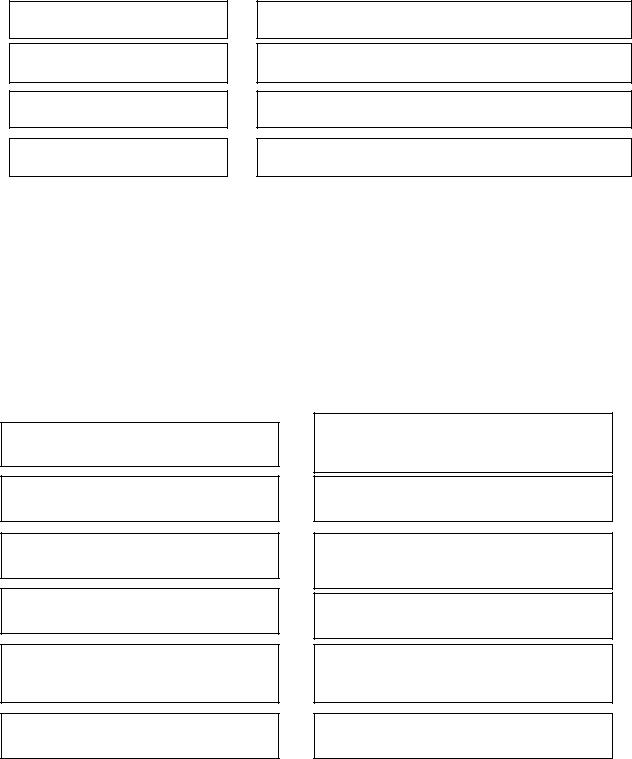

Задание 3. Заполните пустые графы таблицы, пользуясь словарем,

выпишите |

транскрипцию |

терминов. |

Используйте |

полученную |

|

информацию при выполнении следующего задания. |

|

||||

|

|

|

|

||

Сочетаемость |

|

Перевод |

|

||

|

|

|

Армированный бетон |

|

|

|

|

|

Быстротвердеющий бетон |

||

|

|

|

Неармированный бетон |

|

|

|

|

|

Опилочный бетон |

|

|

|

|

|

Строительный бетон |

|

|

|

|

|

Тяжелый бетон (со средней |

||

|

|

|

плотностью 2200-2400 кг/м3) |

||

|

|

|

Ячеистый бетон |

|

|

|

|

|

Бетонирование |

|

|

|

|

|

Бетонировать |

|

|

|

|

|

Бетоновоз (с перемешиванием в |

||

|

|

|

пути) |

|

|

|

|

|

Бетономешалка |

|

|

|

|

|

Бетононасос |

|

|

|

|

|

Пемзобетон |

|

|

|

|

|

Пенобетон |

|

|

|

|

|

Пластобетон, полимербетон |

||

|

|

|

Фибробетон |

|

|

|

|

|

Асфальтобетон |

|

|

|

|

|

Горячий асфальтобетон |

|

|

|

|

|

Холодный асфальтобетон |

||

|

|

|

Аэрированный легкий бетон |

||

blown-out concrete, aerocrete, aerated |

|

|

|

||

concrete, foam(ed) concrete, gas concrete |

|

|

|

||

(gas-)ash concrete |

|

|

|

|

|

gas-ash cilicate |

|

|

|

|

|

reinforced concrete, ferroconcrete |

|

|

|

|

|

light-weight reinforced concrete |

|

|

|

|

|

precast structural concrete |

|

|

|

|

|

heavy reinforced concrete |

|

|

|

|

|

wire-mesh reinforced concrete |

|

|

|

|

|

ceramsite concrete, expanded-clay |

|

|

|

||

concrete |

|

|

|

|

|

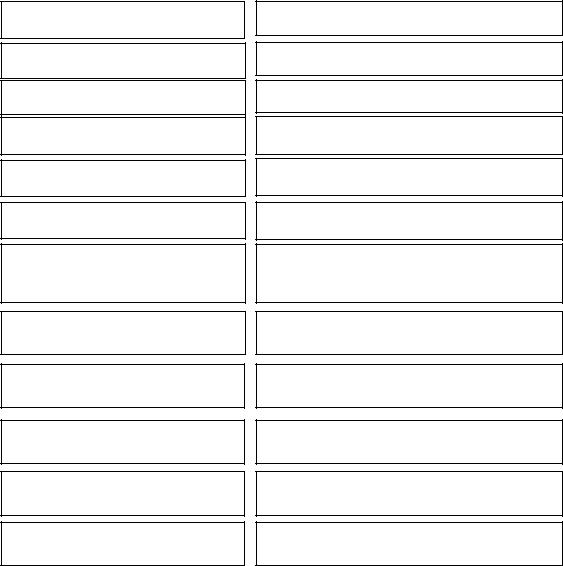

Задание 4. Дайте недостающие толкования понятиям, опираясь на представленный после таблицы текст. Дополните таблицу сведениями из текста. Используйте следующие выражения:

18

группа строительных материалов – group of building materials представлять собой – to be smth

затвердевшая смесь – induration, hardened mixture шлак – ash, slag

различные добавки – different addition agents

уплотненная смесь – compacted mixture тонкоизмельченный – порошок fine powder для устройства полов – for flooring промышленное здание – industrial building

однослойные стеновые панели – single-layer wall panel (building slab) перекрытия и покрытия – coverings and coatings

совмещённые крыши – combined roofs

Definition |

|

|

Translation |

|

|

|

|

|

||

Concrete is a building material, |

Бетон – смесь цемента, песка, гравия |

|||||||||

artificial stone material obtained as a |

или щебня. |

|

|

|

|

|

|

|||

result of hardening of rationally |

Бетоны |

– |

группа |

строительных |

||||||

selected and compacted mixture of |

материалов, |

|

представляющая |

собой |

||||||

binder, |

aggregates, |

water, |

а |

искусственный камень, состоящий из |

||||||

combination of cement and sand, |

затвердевшей |

смеси |

вяжущих |

веществ |

||||||

broken stone, or gravel. It is used for |

(цемент, битум и т. д.), воды, |

|||||||||

foundations, building |

construction, |

заполнителей (песок, гравий, щебень, |

||||||||

walks, and many other purposes |

|

шлак) и различных добавок. По |

||||||||

|

|

|

|

назначению |

бетоны |

подразделяются |

на |

|||

|

|

|

|

конструкционные и специальные |

|

|

||||

|

|

|

|

Асфальтобетон |

– |

строительный |

||||

|

|

|

|

материал, получаемый в результате |

||||||

|

|

|

|

затвердевания |

уплотненной |

смеси |

||||

|

|

|

|

минеральных заполнителей (щебня, песка, |

||||||

|

|

|

|

тонкоизмельченного |

|

минерального |

||||

|

|

|

|

порошка) |

с |

органическим |

вяжущим |

|||

|

|

|

|

(битумом или дегтем). Асфальтобетон |

||||||

|

|

|

|

применяется |

главным |

образом |

для |

|||

|

|

|

|

строительства дорог, а также для |

||||||

|

|

|

|

устройства |

полов |

в |

промышленных |

|||

|

|

|

|

зданиях |

|

|

|

|

|

|

Mix design

Modern concrete mix designs can be complex. The choice of a concrete mix depends on the need of the project both in terms of strength and appearance and in relation to local legislation and building codes.

The design begins by determining the requirements of the concrete. These requirements take into consideration the weather conditions that the concrete will be

19

exposed to in service, and the required design strength. The compressive strength of a concrete is determined by taking standard molded, standard-cured cylinder samples.

Many factors need to be taken into account, from the cost of the various additives and aggregates, to the trade offs between, the "slump" for easy mixing and placement and ultimate performance.

A mix is then designed using cement (Portland or other cementitious material), coarse and fine aggregates, water and chemical admixtures. The method of mixing will also be specified, as well as conditions that it may be used in.

This allows a user of the concrete to be confident that the structure will perform properly.

Various types of concrete have been developed for specialist application and have become known by these names.

Concrete has been used since ancient times. Regular Roman concrete for example was made from volcanic ash (pozzolana), and hydrated lime. Roman concrete was superior from other concrete recipes (for example, those consisting of only sand and lime) used by other nations. Besides volcanic ash for making regular Roman concrete, brick dust can also be utilized. Besides regular Roman concrete, the Romans also invented hydraulic concrete, which they made from volcanic ash and clay.

Regular concrete is the lay term for concrete that is now produced by following the mixing instructions that are commonly published on packets of cement, typically using sand or other common material as the aggregate, and often mixed in improvised containers. The ingredients in any particular mix depends on the nature of the application. Regular concrete can typically withstand a pressure from about 10 MPa (1450 psi) to 40 MPa (5800 psi), with lighter duty uses such as blinding concrete having a much lower MPa rating than structural concrete. Many types of pre-mixed concrete are available which include powdered cement mixed with an aggregate, needing only water.

High-strength concrete has a compressive strength greater than 40 MPa (5800 psi). High-strength concrete is made by lowering the water-cement (W/C) ratio to 0.35 or lower. Often silica fume is added to prevent the formation of free calcium hydroxide crystals in the cement matrix, which might reduce the strength at the cementaggregate bond.

Low W/C ratios and the use of silica fume make concrete mixes significantly less workable, which is particularly likely to be a problem in high-strength concrete applications where dense rebar cages are likely to be used. To compensate for the reduced workability, superplasticizers are commonly added to high-strength mixtures. Aggregate must be selected carefully for high-strength mixes, as weaker aggregates may not be strong enough to resist the loads imposed on the concrete and cause failure to start in the aggregate rather than in the matrix or at a void, as normally occurs in regular concrete.

In some applications of high-strength concrete the design criterion is the elastic modulus rather than the ultimate compressive strength.

20

Stamped concrete is an architectural concrete which has a superior surface finish. After a concrete floor has been laid, floor hardeners (can be pigmented) are impregnated on the surface and a mold which may be textured to replicate a stone / brick or even wood is stamped on to give an attractive textured surface finish. After sufficient hardening the surface is cleaned and generally sealed to give a protection. The wear resistance of stamped concrete is generally excellent and hence found in applications like parking lots, pavements, walkways etc.

High-performance concrete (HPC) is a relatively new term for concrete that conforms to a set of standards above those of the most common applications, but not limited to strength. While all high-strength concrete is also high-performance, not all high-performance concrete is high-strength. Some examples of such standards currently used in relation to HPC are: ease of placement, compaction without segregation, early age strength, long-term mechanical properties, permeability, density, compaction without segregation, heat of hydration, toughness, volume stability, long life in severe environments, depending on its implementation, environmental.

Ultra-high-performance concrete is a new type of concrete that is being developed by agencies concerned with infrastructure protection. UHPC is characterized by being a steel fibre-reinforced cement composite material with compressive strengths in excess of 150 MPa, up to and possibly exceeding 250 MPa. UHPC is also characterized by its constituent material make-up: typically fine-grained sand, silica fume, small steel fibers, and special blends of high-strength Portland cement. Note that there is no large aggregate. The current types in production (Ductal, Taktl, etc.) differ from normal concrete in compression by their strain hardening, followed by sudden brittle failure. Ongoing research into UHPC failure via tensile and shear failure is being conducted by multiple government agencies and universities around the world.

Vacuum concrete, made by using steam to produce a vacuum inside a concrete mixing truck to release air bubbles inside the concrete, is being researched. The idea is that the steam displaces the air normally over the concrete. When the steam condenses into water it will create a low pressure over the concrete that will pull air from the concrete. This will make the concrete stronger due to there being less air in the mixture. A drawback is that the mixing has to be done in a mostly airtight container.

Shotcrete (also known by the trade name Gunite) uses compressed air to shoot concrete onto (or into) a frame or structure. The greatest advantage of the process is that shotcrete can be applied overhead or on vertical surfaces without forming. It is often used for concrete repairs or placement on bridges, dams, pools, and on other applications where forming is costly or material handling and installation is difficult. Shotcrete is frequently used against vertical soil or rock surfaces, as it eliminates the need for formwork. It is sometimes used for rock support, especially in tunneling. Shotcrete is also used for applications where seepage is an issue to limit the amount of water entering a construction site due to a high water table or other subterranean

21

sources. This type of concrete is often used as a quick fix for weathering for loose soil types in construction zones.

There are two application methods for shotcrete.

dry-mix – the dry mixture of cement and aggregates is filled into the machine and conveyed with compressed air through the hoses. The water needed for the hydration is added at the nozzle.

wet-mix – the mixes are prepared with all necessary water for hydration. The mixes are pumped through the hoses. At the nozzle compressed air is added for spraying.

For both methods additives such as accelerators and fiber reinforcement may be used.

Limecrete or lime concrete is concrete where cement is replaced by lime. One successful formula was developed in the mid-1800s by Dr. John E. Park. We know that lime has been used since Roman Times either as mass foundation concretes or as lightweight concretes using a variety of aggregates combined with a wide range of pozzolans (fired materials) that help to achieve increased strength and speed of set. This meant that lime could be used in a much wider variety of applications than previously such as floors, vaults or domes. Over the last decade, there has been a renewed interest in using lime for these applications again. This is because of environmental benefits and potential health benefits, when used with other lime products.

Lime mortars allow other building components such as stone, wood and bricks to be reused and recycled because they can be easily cleaned of mortar/limewash.

Lime enables other natural and sustainable products such as wood (including woodfibre, wood wool boards), hemp, straw etc. to be used because of its ability to control moisture (if cement were used, these buildings would compost!).

Lime plaster is hygroscopic (literally means 'water seeking') which draws the moisture from the internal to the external environment, this helps to regulate humidity creating a more comfortable living environment as well as helping to control condensation and mould growth which have been shown to have links to allergies and asthmas.

Lime plasters and limewash are non-toxic, therefore they do not contribute to indoor air pollution unlike some modern paints.

Roller-compacted concrete, sometimes called rollcrete, is a low-cement-content stiff concrete placed using techniques borrowed from earthmoving and paving work. The concrete is placed on the surface to be covered, and is compacted in place using large heavy rollers typically used in earthwork. The concrete mix achieves a high density and cures over time into a strong monolithic block. Roller-compacted concrete is typically used for concrete pavement, but has also been used to build concrete dams, as the low cement content causes less heat to be generated while curing than typical for conventionally placed massive concrete pours.

The use of recycled glass as aggregate in concrete has become popular in modern times, with large scale research being carried out at Columbia University in New York. This greatly enhances the aesthetic appeal of the concrete. Recent research

22

findings have shown that concrete made with recycled glass aggregates have shown better long-term strength and better thermal insulation due to its better thermal properties of the glass aggregates.

Rapid strength concrete is able to develop high resistance within few hours after being manufactured. This feature has advantages such as removing the formwork early and to move forward in the building process at record time, repair road surfaces that become fully operational in just a few hours.

Polymer concrete is concrete which uses polymers to bind the aggregate. Polymer concrete can gain a lot of strength in a short amount of time. For example, a polymer mix may reach 5000 psi in only four hours. Polymer concrete is generally more expensive than conventional concretes.

A recent innovation is a material called concrete canvas. It is a flexible concrete impregnated fabric that hardens on hydration to form a thin, durable, fire resistant and water proof concrete layer. It consists of a three-dimensional fibre matrix, containing a specially formulated dry concrete mix. A PVC backing on one surface of the Canvas ensures the material is waterproof, while hydrophilic fibers on the opposite surface aid hydration by drawing water into the concrete. Concrete Canvas can be used to create waterproof, fireproof, fibre-reinforced thin concrete forms across a range of applications: water management, erosion control, ditch lining, slope stabilisation, bund lining, cable protective covering, pipeline protection, mining applications, ground re-surfacing, rapid trackway or landing surfaces and rapidly deployable emergency shelters. Concrete canvas is known as concrete cloth in the United States.

Gypsum concrete is a building material used as a floor underlayment used in wood-frame and concrete construction for fire ratings, sound reduction, radiant heating, and floor leveling. It is a mixture of gypsum, Portland cement, and sand.

Задание 5. Прочитайте и переведите текст. Схематично представьте его содержание.

Concrete

Concrete is a composite building material made from the combination of aggregate and a binder such as cement. The most common form of concrete is Portland cement concrete, which consists of mineral aggregate (generally gravel and sand), portland cement and water.

After mixing, the cement hydrates and eventually hardens into a stone-like material. When used in the generic sense, this is the material referred to by the term "concrete".

For a concrete construction of any size, as concrete has a rather low tensile strength, it is generally strengthened using steel rods or bars (known as rebars). This strengthened concrete is then referred to as reinforced concrete. In order to minimise any air bubbles, that would weaken the structure, a vibrator is used to eliminate any air that has been entrained when the liquid concrete mix is poured around the ironwork. Concrete has been the predominant building material in the modern age due to its longevity, formability, and ease of transport. Recent advancements, such as

23

insulating concrete forms, combine the concrete forming and other construction steps (installation of insulation). All materials must be taken in required proportions as described in standards.

Concrete is perhaps the most widely spread building material used nowadays. Concrete is an artificial stone, made by thoroughly mixing such natural ingredients or aggregates as cement, sand and gravel or broken stone together with sufficient water to produce a mixture of the proper consistency. It has many valuable properties. It sets under water, can be poured into moulds so as to get almost any desirable form, and together with steel in reinforced concrete it has very high strength, and also resists fire. Prestressed concrete is most widely used at present while prefabricated blocks are employed on vast scale for skeleton structures.

By the simple definition from the dictionary "aggregates are the materials, such as sand and small stones, that are mixed with cement to form concrete". In other words aggregates (or cushioning materials) can be defined as a mass of practically inert mineral materials, which, when surrounded and bonded together by an active binder, form the rock. This rock is denoted by the general term concrete.

Aggregates have three principal functions in the concrete: they provide a relatively cheap filler for the concreting material, or binder; they provide a mass of particles which are suitable for resisting the action of applied loads, of abrasion, of percolation of moisture through the mass, and of climate factors; they reduce volume changes resulting from the action of the setting and hardening of the concrete mass.

All aggregates, both natural and artificial, which have sufficient strength and resistance to weathering, and which do not contain harmful impurities may be used for making concrete.

As aggregates such natural materials as sand, pebbles, broken stone, broken brick, gravel, slag, cinder, pumice and others can be used.

Prestressed concrete is not a new material. Its successful use has been developed rapidly during the last two decades, chiefly because steel of a more suitable character has been produced. Concrete is strong in compression but weak when used for tensile stresses.

If, therefore, we consider a beam made of plain concrete, and spanning a certain distance, it will at once be realized that the beam's own weight will cause the beam to "sag" or bend. This sagging at once puts the lower edge of the beam in tension, and if the cross-sectional area is small, causes it to break, especially if the span is relatively large.

If, on the other hand, we use a beam of similar cross-section, but incorporate steel bars in the lower portion, the steel will resist the tensile stress derived from the sag of the beam, and thus assist in preventing it from breaking.

In prestressed concrete steel is not used as reinforcement, but as a means of producing a suitable compressive stress in the concrete. Therefore any beam (or member) made of prestressed concrete is permanently under compression, and is consequently devoid of crack under normal loading, or so long as the "elastic limit" is not exceeded.

24

Prestressed concrete is not only used for beams but is now employed extensively for columns, pipes, and cylindrical water towers, storage tanks, etc.

Задание 6. Изучите представленные ниже схемы, сопоставьте их со схемами, полученными вами. Определите количественные характеристики информации, содержащейся в схемах.

Схема 3. Виды бетонов

Виды бетонов |

|

Species of concrete |

|

|

|

Силикатный бетон

Асфальтобетон

Горячий бетон

Холодный бетон

Аэрированный легкий бетон

Фибробетон

Полимербетон, пластобетон

Пемзобетон

Пенобетон

Газобетон

Газошлакобетон

Газозолобетон

Керамзитобетон

silicate concrete

asphalt(ic) concrete, asphaltic-cement concrete, bituminous

hot-lay asphalt concrete

cold-lay asphalt

aerated lightweight concrete

fibrous concrete

polymer concrete

pumice concrete, pumeconcrete

aerated concrete, foam(ed) concrete, gas concrete, foam

blown-out concrete, aerocrete, aerated concrete, foam(ed) concrete, gas

gas-ash cilicate

(gas-)ash concrete, breeze concrete, flyash concrete

ceramsite concrete, claydite-concrete, expanded-clay concrete

25

Схема 4. Бетонирование

Бетонирование

Бетоновоз (с перемешиванием в пути)

Бетономешалка

Concrete casting

agitator, concrete carrier, gondola, concrete hauler, dumpcrete truck

concrete mixer, mixer, batch plant

Бетононасос |

|

|

concrete pump |

|

|

|

|

|

|

|

|

Бетонировать |

|

|

incase, concrete |

|

|

|

|

|

Схема 5. Типы бетонов |

||

Типы бетонов

Строительный бетон

Ячеистый бетон

Тяжелый бетон (со средней плотностью 2200 – 2400 кг/м3)

Быстротвердеющий бетон

Армированный бетон

Неармированный бетон

Опилочный бетон

Types of concrete

structural concrete

cell concrete, cellular concrete, hollow concrete, porous concrete

heavy concrete

early-strength concrete, fast-hardening concrete, overnight concrete

armoured concrete

mass concrete, plain concrete

sawdust concrete

26

Схема 6. Железобетон

Железобетон |

|

Reinforced (steel) concrete, ferroconcrete |

|

|

|

Ячеистый железобетон

Легкий железобетон

Сборный железобетон

Тяжелый железобетон

wire-mesh reinforced concrete

light-weight reinforced concrete

precast concrete, precast structural concrete

heavy reinforced concrete

Задание 7. На основе всех сведений, полученных об обозначенном понятии, составьте учебный текст на английском языке.

Модуль 3. СТРОИТЕЛЬНЫЕ МАТЕРИАЛЫ ПО НАЗНАЧЕНИЮ Задание 1. Изучите схему. Постройте на ее основе учебный текст на

английском языке.

Схема 7. Строительные материалы. Классификация по назначению

Строительные материалы |

|

Building materials |

|

|

|

Классификация по назначению

Конструкционные

Теплоизоляционные

Акустические

Гидроизоляционные и кровельные

Герметизирующие

classification according purpose (function)

structural, constructional materials

heat-insulating materials (heatinsulators)

acoustic(al) materials

dampproofers, waterproofing and roofing materials

sealing materials

Отделочные |

|

finishing (trimming) agents |

|

|

|

|

|

|

Спец. назначения |

|

special-purpose products |

|

|

|

|

27 |

|

Задание 2. Определите место данных ниже терминов в предложенной выше классификации, дополните дефиниции терминов указанием на принадлежность материала к одной из групп в зависимости от его назначения.

Wood putty, also called plastic wood, is a substance used to fill imperfections, such as nail holes, in wood prior to finishing. It is often composed of wood dust combined with a binder that dries and a diluent (thinner), and, sometimes, pigment. Pore fillers used for large flat surfaces such as floors or table tops generally contain silica instead of or in addition to wood dust. Pores can also be filled using multiple coats of the final finish rather than a pore filler.

The main problem in using putty is matching the colour of the putty to that of the wood. Putties are usually sanded after they dry before applying the finish.

Many different brands, types, and colours are commercially available. Binders include lacquer, water-base, and linseed oil. Some woodworkers make their own putty using fine sanding dust (not sawdust, which is too coarse) with wood glue or a wood finish such as shellac.

Reed pressboard is a heat insulating slab building material moulded from reed stalks (or thatch) and connected with steel zinked wire.

Cut stone is a parallelepiped-shaped stone block used to blockworks and stone arching.

Tempera, also known as egg tempera, is a permanent, fast-drying painting medium consisting of colored pigment mixed with a water-soluble binder medium (usually a glutinous material such as egg yolk or some other size). Tempera also refers to the paintings done in this medium. Tempera paintings are very long lasting, and examples from the 1st centuries AD still exist. Egg tempera was a primary method of painting until after 1500 when it was superseded by the invention of oil painting. A paint consisting of pigment and glue size commonly used in the United States as poster paint is also often referred to as "tempera paint," although the binders and sizes in this paint are different from traditional tempera paint.

Fillers are particles added to material (plastics, composite material, concrete) to lower the consumption of more expensive binder material or to better some properties of the mixtured material. Worldwide more than 53 million tons of fillers are used every year in different application areas, such as paper, plastics, rubber, paints, coatings, adhesives and sealants.

A tile is a manufactured piece of hard-wearing material such as ceramic, stone, metal, or even glass. Tiles are generally used for covering roofs, floors, walls, showers, or other objects such as tabletops. Alternatively, tile can sometimes refer to similar units made from lightweight materials such as perlite, wood, and mineral

28

wool, typically used for wall and ceiling applications. In another sense, a tile is a construction tile or similar object, such as rectangular counters used in playing games (see tile-based game). Tiles are often used to form wall and floor coverings, and can range from simple square tiles to complex mosaics. Tiles are most often made from porcelain, fired clay or ceramic with a hard glaze, but other materials are also commonly used, such as glass, metal, cork, and stone. Tiling stone is typically marble, onyx, granite or slate. Thinner tiles can be used on walls than on floors, which require thicker, more durable surfaces.

Задание 3. Дайте дефиницию понятия грунтовка на английском языке. Дополните полученную дефиницию указанием на тип строительного материала (собственно материалы или изделия), происхождение и назначение. Используйте следующие выражения:

Наносимые первым слоем spreading as priming coat

подготовленную к окраске поверхность surface prepared for painting

уменьшение пористости decrement of porosity (sponginess) обеспечение требуемой адгезии adhesion requirements supporting лакокрасочное покрытие paint-and-lacquer coating окрашивающий состав coloring, dyeing compound

содержание пигмента pigmentation

Грунтовки – составы, наносимые первым слоем на подготовленную к окраске поверхность для уменьшения ее пористости и обеспечения требуемой адгезии лакокрасочного покрытия. От окрашивающих составов отличаются меньшим содержанием пигментов.

Задание 4. Изучите таблицу, выпишите транскрипцию терминов из словаря. Используйте полученную информацию при выполнении следующего задания.

Сочетаемость |

Толкование |

heavyweight aggregate |

Тяжелый заполнитель |

mineral filler |

Заполнитель дорожного покрытия |

gravel ballast |

Заполнитель из гравия |

mortar aggregate |

Заполнитель для раствора |

concrete aggregate |

Заполнитель для бетона |

fine aggregate |

Мелкий заполнитель |

coarse aggregate |

Крупный заполнитель |

multiple-size a. |

Многофункциональный заполнитель |

breeze aggregate |

Шлаковый заполнитель |

crushed-stone (crushed) aggregate |

Щебеночный заполнитель |

joint filler |

Заполнитель швов |

|

29 |

Задание 5. На основе информации, данной в переводе, и текста, представленного после таблицы, дайте развернутое толкование понятия.

Definition |

Translation |

Aggregate is a hard materials |

Заполнители – для бетонов и растворов – |

such as sand and crushed stone |

природные или искусственные материалы, |

used to make concrete |

составляющие основную (до 85 % по массе) |

|

часть бетонов |

Construction aggregate

Construction aggregate, or simply "aggregate", is a broad category of coarse particulate material used in construction, including sand, gravel, crushed stone, slag, recycled concrete and geosynthetic aggregates. Aggregates are the most mined materials in the world. Aggregates are a component of composite materials such as concrete and asphalt concrete; the aggregate serves as reinforcement to add strength to the overall composite material. Due to the relatively high hydraulic conductivity value as compared to most soils, aggregates are widely used in drainage applications such as foundation and French drains, septic drain fields, retaining wall drains, and road side edge drains. Aggregates are also used as base material under foundations, roads, and railroads. In other words, aggregates are used as a stable foundation or road/rail base with predictable, uniform properties (e.g. to help prevent differential settling under the road or building), or as a low-cost extender that binds with more expensive cement or asphalt to form concrete.

The American Society for Testing and Materials publishes an exhaustive listing of specifications for various construction aggregate products, which, by their individual design, are suitable for specific construction purposes. These products include specific types of coarse and fine aggregate designed for such uses as additives to asphalt and concrete mixes, as well as other construction uses. State transportation departments further refine aggregate material specifications in order to tailor aggregate use to the needs and available supply in their particular locations.

Sources for these basic materials can be grouped into three main areas: Mining of mineral aggregate deposits, including sand, gravel, and stone; use of waste slag from the manufacture of iron and steel; and recycling of concrete, which is itself chiefly manufactured from mineral aggregates. In addition, there are some (minor) materials that are used as specialty lightweight aggregates: clay, pumice, perlite, and vermiculite.

30

Задание 6. Используя полученную информацию о понятии и схему, данную ниже, составьте учебный текст на английском языке.

Схема 8. Заполнители

Заполнители

Тяжелый заполнитель

Мелкий заполнитель

Крупный заполнитель

Многофункциональный

Шлаковый заполнитель

Щебеночный заполнитель

Заполнитель из гравия

Минеральный заполнитель

Заполнитель для раствора

Заполнитель для бетона

Заполнитель швов

filling aggregate, bolus material

heavyweight aggregate

fine aggregate

coarse aggregate

multiple-size a.

breeze aggregate

crushed-stone aggregate, crushed aggregate

gravel ballast

mineral filler

mortar aggregate

concrete aggregate

joint filler

31