The above screen image is only for reference

At main screen press “Mold Selection” icon to open the “Mold Selection” screen.

MOLD SELECTION: Setting station 1 to last station product mode. Each station can only

setting one item. No. 1 station “OFF/Left mold” and the last station “Right mold/OFF” cannot setting.

The machine provide single injector can control left mold or right mold injection function. But No. 1 and the last station restrain the function selection.

When select “OFF/OFF”, at automatic mode execute the open/close mold action (heating press), the injector function doesn’t execute and the injector doesn’t move to this station

.10/28/2009

T

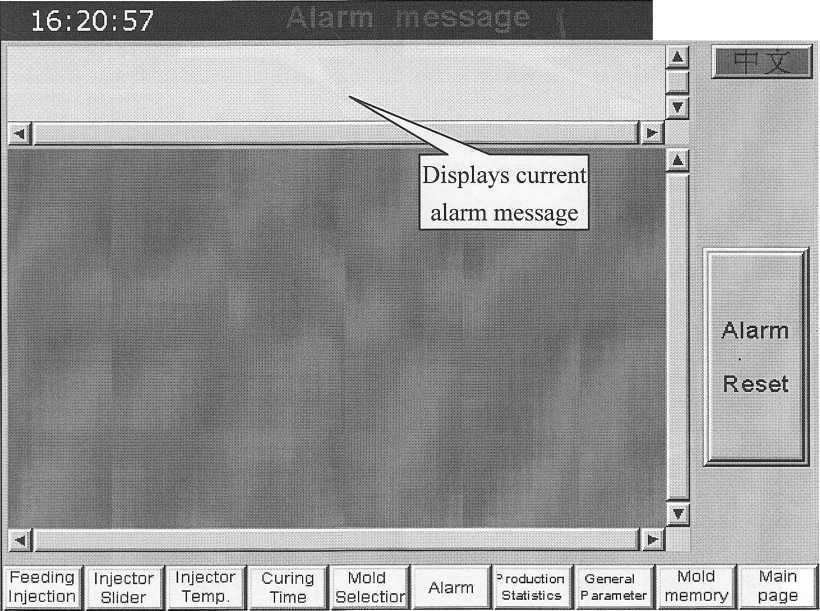

3 5-8 Alarm message

he above screen image is only for referenceWhen the machine appears alarm, open the screen and check the message for trouble shooting.

At main screen press “Alarm” to open the “Alarm” screen.

Displays alarm message record and current alarm message condition.

Press “Alarm Reset” to clear the alarm message.

The above screen is displayed alarm message and clear alarm message5-9 Production statistics

U Grand total resetl

timate uornpli

■■

Esti

Total

Total

i (

2 '

I

4

c

_>

6

0

0

0

0

0

Is

u

0

0

0

0

0

.0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

c

§j

0

0

Right iv 0

IjiSP

d'T ^ cr: o 0 0 0

10/28/2009

I UNLOCK

ipiai

Injection | |

| Injector 1 | Slider ;| |

[ InjectorT [ Temp. | |

Time j |

Selection |

j Alarm j |

13 roducti on f I Statistics j |

1 General | j.P arameter | |

1 Mold 1 | memory! |

Page

The above screen image is only for reference

At main screen press “Production Statistic” to open the “Product Statistic" screen.

Setting station 1 to last station product quantity.

“Estimate” set the planned production quantity value.

“Complete”:

After update the “Estimate” column data and reset.

Restart the counter.

“Grand total”: History records, add up product quantity (Auto mode, every close mold one time add up 1).

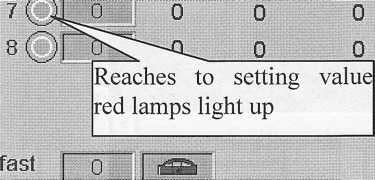

Fast: Replace all column value by key in value.4. 5-10 General parameter

|

|

|

|

|

|

|

||||||

1 bUZ-.hb |

|

|

1 |

10/28/2009 |

||||||||

T ime |

lnj.1 |

inj.2 |

. Pressure . Speed ;Setting |

lnj.1. |

/ lllpgj ■BWBgMijpSM |

|||||||

Feed. Delay |

c |

|

0 |

:;N Loading ■ B ack P ressure |

I o |

o |

;. injector pressure : |

|||||

Pre- i in, i —i 1. |

0.0 |

0.0 |

F • Loading Speed |

0 |

0 |

' 0: ^ V 0 |

||||||

el ay inj Bwd |

all |

0 |

" 0.0 |

Till Prs -Compression ;; ■ P ressure |

0 |

o |

Injector speed |

|||||

|

|

P re -Compression Speed illf |

BIB |

1 O' |

I ! :%!) |

|||||||

Max. Close Mold |

|

0 |

f Inj. Pressure |

0 |

mm |

OP/CL pressure |

||||||

Max.Feeding Time |

|

0 |

: Inj. Speed |

0 j |

ro” |

I |

||||||

:■ 'nj.Time |

|

iifcii |

Inj. F/E |

|

1 0 |

|

||||||

-"i Mold |

|

WM |

inj. F/B Speed |

r o |

MiT |

|

||||||

"open MGl&luzfer |

|

■ HI |

Inj F/a Press |

|

1 o |

|

||||||

|

|

|

|

inj F/B Speed |

r o |

1 o |

|

|||||

|

|

|

1 |

Y2 ■ 4- |

C J] |

6 7 |

.f"8 - )§- |

|||||

6 pressure Release Time |

[□.do r |

0,-00 J 0.00 Iq.OO raaa&k. -r—**—i |

|

.00 10.00 |

f 0,00 |

|||||||

Feeding

I Injector | Injection! Slider :

Curing

Time

Intput

Output