- •2. Steel

- •4. Properties of engineering materials and methods of testing them

- •1. Chipping metal and chipping tools

- •2. Metal-cutting and locksmith's cutting tools

- •3. Filing and filing tools

- •4. Mechanical tools

- •5. Measuring tools and devices

- •1, 2, 3, 8 -Jaws; 4 - adjusting screw; 5 - primary scale; 6 - depth rod;

- •6. Machine-cutting tools

- •7. Drills and drilling

- •8. Threading tools

- •9. Methods of holding tools between centres

- •10. Holding work in a chuck

- •II. Holding work in a vice

- •Chapter III machine parts

- •1. Welding

- •2. Induction brazing and soldering

- •3. Threads

- •4. Gears

- •5. Belt and chain drives

- •6. Bearings

- •7. Clutches

- •Chapter IV metal-cutting machines

- •1. Lathes

- •2. Drilling machines

- •3. Milling machines

- •4. Planers

- •5. Shapers and slotters

- •6. Grinding and grinding machines

- •Chapter V texts for home reading

- •1. The russian metallurgist d. K. Chernov

- •2. Oxygen in the bessemer converter

- •3. Oxygen enrichment in the blast furnace

- •4. Oxygen for direct reduction of iron ore

- •5. Crucible furnace

- •6. Portable hardness tester

- •7. High-speed precision ball bearing testing machines

- •Составные предлоги

- •Сокращения

- •Англо-русский словарь

5. Belt and chain drives

The belt drive is the most widely used kind of driving on metal-cutting lathes. The belt drive in lathes is used mainly for transmitting rotation of an electromotor from one pulley to another owing to the tension of the belt. For instance, in some lathes drive to the headstock is provided by belts from a motor, the mounting plate of which is allowed to pivot freely so that the belts are tensioned by the weight of the motor.

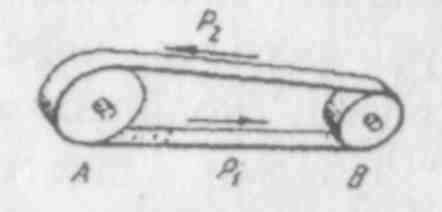

Fig. 43. Belt Drive

Pi, P3 - belt tension

The belt-and-pulley system of transmitting rotary motion is subject to belt slippage and is therefore not positive. Belts are still incorporated in the drive, because of the safety factor inherent in a friction drive and because of the silence, as compared with gearing run at high speeds. Fig. 43 shows a belt drive consisting of two | pulleys A and B, mounted on two parallel shafts which are connected by an endless belt. The pulley A which transmits rotation is called the "driving pulley"* while the pulley В receiving rotation from the pulley A and transmitting it to its shaft is known as "driven pulley."** The friction surface of a driving pulley should be of a

comparatively soft material, while that of the driven pulley is usually made of hard material. Such an arrangement ensures the maintenance of the friction surfaces. Otherwise, if the driven pulley were made of the softer material, its surface would be injured and ruined.

There are two main kinds of belts such as flat belts and V-belts. Flat belts are made of leather, cotton yarn or rubberized cloth. V-belts manufactured of rubberized cloth are of a trapezoidal shape. They are pulled over the pulleys into special grooves, which considerably reduces their slipping off the pulleys during operation. Therefore this kind of belt finds ever increasing application on metal-cutting tools and is tending to replace flat belts. When a chain is applied there is no rolling contact as with gears. It transmits its tension uniformly to every tooth of the chain gear coming into contact with it. In this case there is no one-tooth action as in gears, and no losses due to rolling friction and the shock of transferring the load from the tooth. The link-belt silent chain can be, and should be, run slack. Belts require a tension in excess of the effective working tension, and to that extent there is a loss of power on the pulley of the shaft. Belts run on1 by inertia and slip and lose power in that way and the less the belt tension is the more it slips, but the link-belt silent chain never slips.

1. Belts run on - ремни набегают

* American - driver

** American – follower

Exercises

I. Use the following words and phrases in sentences of your own:

metal-cutting tools, to pivot, to slip, to lose power, tension, of the belt, driven pulley, driving pulley, rubberized cloth, chain gear, slack, to tend, to incorporate, inertia, to ruin, to injure

II. Answer the following questions:

1. What is the belt drive used for and in what machines? 2. Because of what feature is the belt-and-pulley system of transmitting rotary motion not positive? 3. Owing to what features are belts still incorporated in the drive? 4. What are the main two types of belts? 5. What are different belts made of? 6. For what purpose are V-belts pulled over the pulleys into special grooves? 7. How does a chain transmit its tension to every tooth of the chain gear which comes into contact with it? 8. What are the advantages of a link-belt silent chain over a belt?

III. Underline the suffixes in the following words and state to what part of speech they belong:

tension, pulley, friction, widely, endless, manufacture, special, slipping, effective

IV. Connect the following sentences using participle constructions and gerundial constructions:

Example: 1. V-belts are of a trapezoidal shape. They are made of rubberized cloth. V-belts made of rubberized cloth are of a trapezoidal shape.

2. V-belts are pulled over the pulleys into special grooves. The special grooves reduce slipping of V-belts.

V-belts are pulled over the pulleys into special grooves for reducing slipping of V-belts.

1. The belt drive is used for driving lathes. The belt drive transmits rotation of an electromotor from one pulley to another. 2. The chain transmits tension to every tooth of the chain gear coming into contact with it. The chain is applied on the lathe. 3. The lathe is provided with an electromotor. The electromotor sets in motion the belt drive. 4. The two pulleys of the belt are mounted on two parallel shafts. The shafts are connected by an endless belt. 5. Flat belts are widely used on metal-cutting tools. Flat belts are made of leather or rubberized cloth. 6. The driving pulley is incorporated in the lathe drive. The driving pulley transmits rotation of an electromotor.

V. Translate into English:

1. Следует указать, что ремень тем больше проскальзывает, чем слабее его натяжение и чем меньшую часть шкива он охватывает по окружности. 2. Клиновидные ремни натягиваются по несколько в ряд и укладываются на шкивах в канавки. 3. В токарных станках передачи как клиновидными, так и плоскими ремнями применяются только с натяжным устройством. 4. Передача плоскими ремнями отличается от передачи клиновидными ремнями. 5. Ременная передача в токарных станках применяется главным образом для передачи вращения приводному шкиву от электромотора.

VI. (a) Read and translate the text without using a dictionary:

While a motor drive is standard equipment there are certain cases where pulley and belt drive meets the conditions of varied power requirements. It is possible to obtain belt connection with idle pulley and motor mounted in special way. In such a case the 6 inch 6 spindle machine when pulley drive is desired is equipped with 14 inch diameter pulley with 4Ѕ inch face which should run at 760 r.p.m., but the 8 inch 6 spindle machine is equipped with 14 inch diameter pulley with 4Ѕ inch face which should run at 600 r.p.m.

(b) On the bash- of this text make up questions and answer them:

VIII. Giving answers to the following questions describe the principle of operation of the belt drive shown in Fig. 48:

1. What is shown in Fig. 43? 2. How many pulleys does this drive consist of? 3. Where are these two pulleys mounted and how are they connected? 4. What are the functions of the pulleys used in belt drives? 5. How are pulleys classified depending upon the functions performed by them? 6. What pulley is called the "driving pulley"? 7. What pulley is called the "driven pulley'"?