- •2. Steel

- •4. Properties of engineering materials and methods of testing them

- •1. Chipping metal and chipping tools

- •2. Metal-cutting and locksmith's cutting tools

- •3. Filing and filing tools

- •4. Mechanical tools

- •5. Measuring tools and devices

- •1, 2, 3, 8 -Jaws; 4 - adjusting screw; 5 - primary scale; 6 - depth rod;

- •6. Machine-cutting tools

- •7. Drills and drilling

- •8. Threading tools

- •9. Methods of holding tools between centres

- •10. Holding work in a chuck

- •II. Holding work in a vice

- •Chapter III machine parts

- •1. Welding

- •2. Induction brazing and soldering

- •3. Threads

- •4. Gears

- •5. Belt and chain drives

- •6. Bearings

- •7. Clutches

- •Chapter IV metal-cutting machines

- •1. Lathes

- •2. Drilling machines

- •3. Milling machines

- •4. Planers

- •5. Shapers and slotters

- •6. Grinding and grinding machines

- •Chapter V texts for home reading

- •1. The russian metallurgist d. K. Chernov

- •2. Oxygen in the bessemer converter

- •3. Oxygen enrichment in the blast furnace

- •4. Oxygen for direct reduction of iron ore

- •5. Crucible furnace

- •6. Portable hardness tester

- •7. High-speed precision ball bearing testing machines

- •Составные предлоги

- •Сокращения

- •Англо-русский словарь

9. Methods of holding tools between centres

When machining a piece of work on a lathe the former is usually mounted between the lathe centres. Having been mounted on the lathe the work is supported by the conical points of the live and dead centres .The work must therefore have centre holes in each end drilled by using a combined drill and a countersink. The size of the centre hole has to be proportioned to the weight of the work and the size of cut to be taken. By virtue of the clearance holes the work does not rest on the extreme points of the centres. This is important because otherwise the position of the work will be indefinite. Owing to this method of holding work between centres, the work can be removed from the lathe as often as may be desired. If the work has to be mounted again between centres for further treatment, it will rotate about the same axis as before.

The two lathe centres are mounted in two spindles: one - the live centre is held in the headstock spindle and turns together with the spindle and the work, the other - the dead centre is held in the tailstock spindle and in most cases does not turn and rubs against the workpiece. The point of the dead centre should be hardened to prevent its wearing during the operations performed on the lathe. Both lathe centres should

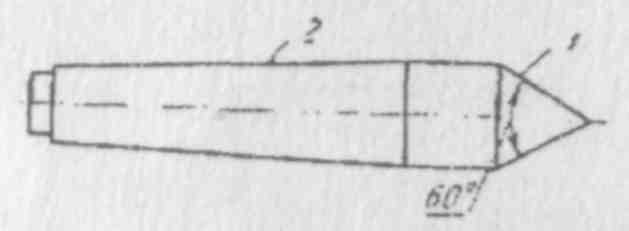

always be aligned, i. e. the points are to meet when the tailstock with its centre is moved up to the headstock centre. A turner tests the alignment of the centres by taking a cut and then measuring both ends of the cut by a micrometer. Having got the same measurements, the turner may be sure that the centres are aligned and he may proceed with the taming. The centre shown in Fig. 26 consists of a cone, on which the work to be treated is installed, and of a tapered shank, which fits corresponding taper holes in the headstock spindle and tailstock popper.

Fig. 26. Centre:

1 - cone; 2 - tapered shank

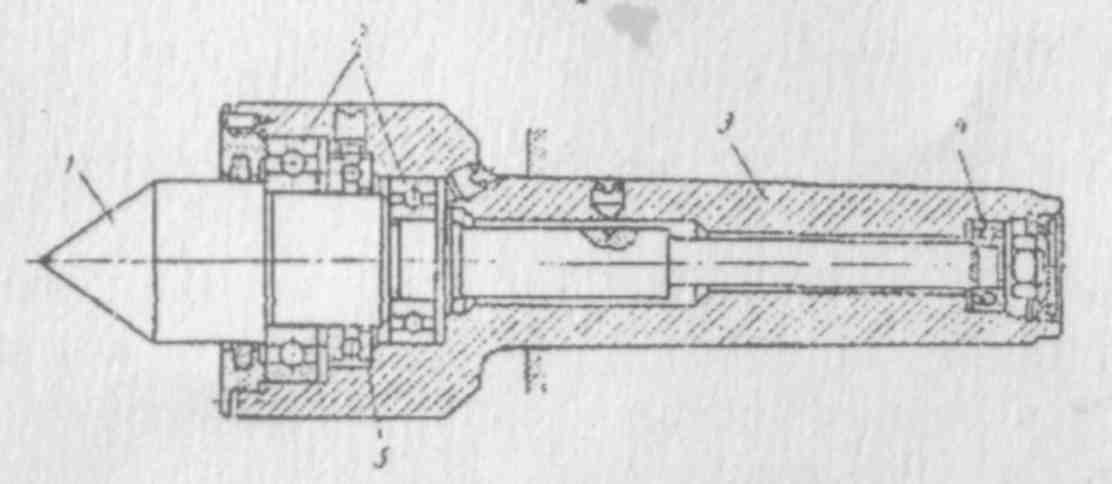

Fig. 27. Running Centre:

1 - centre; 2, 4 - ball bearings; 3 - tapered shank; 5 - ball thrust bearing

When works are machined at high speeds or when the former are too heavy a dead centre and the work will be heated up so as to cause excessive wear from friction. In such cases the so called "running centres" are used. Fig.27 shows a running centre inserted into the taper hole of the tailstock poppet. The centre rotates on ball bearings. The thrust exerted on the centre is taken by the available ball thrust bearing. The tapered shank fits the taper hole of the tailstock poppet.

Exercises

I. Use the following words and phrases in sentences of your own:

to countersink, to mount, live centre, dead centre, headstock, tailstock, to align, taper hole, to fit, tailstock poppet, running centre, to insert, speed, to exert

II. Retell the text giving answers to the following questions:

1. What is the most widely used method of holding work in the lathe? 2. By what parts of the centres is the work supported while being turned? 3. By what means are centre holes drilled in the work? 4. What would happen if the work rested on the extreme points of the centres? 5. Owing to what method of holding work in the lathe, can it be removed from the lathe as often as may be desired? 6. Where are the two lathe centres mounted on the lathe? 7. What kinds of centres are used

on Iathes? 8. Where is the live centre held and how does it operate? 9. Where is the dead centre held and does it turn or not?

III. Underline the suffixes and prefixes and translate into Russian the following groups of words of the same stem:

to combine, combined, combination, uncombined; to lubricate, lubrication, lubricant; to mount, to dismount, mounting, mountable, discountable

IV. Find in the text English equivalents for:

зенковка, предотвращать, шпиндель задней бабки, шпиндель передней бабки, вращающийся центр, хвостовик, неподвижный центр, подогревать, центрировать

V. Give derivatives from the following words and translate them into Russian:

to support, to live, to wear, point, to align, to insert, to fit

VI. Change the sentences using the predicates in the Past and Future tenses and translate them into Russian:

Example: Each end of the work must be countersunk.

Each end of the word had to be countersunk.

Each end of the work will have to be countersunk.

1. When being machined the work must be fastened between the lathe centres. 2. Countersinking must be done by means of a countersink. 3. The axial adjustment of the tailstock centre must be done carefully. 4. The poppet must be re-adjusted from time to time during the process of work. 5. The live centre of the lathe can turn together with the spindle and the work. 6. The dead centre of the lathe cannot turn. 7. Both centre points of the lathe must be aligned.

VII. Connect the following sentences using participle constructions and translate the sentences into Russian:

Example: A piece of work has been delivered to the shop.

The work was machined on the lathe.

Having been delivered to the shop, a work was machined on the lathe.

1 .The work has been countersunk with a combined drill and countersink. The work is ready to be machined. 2. The tailstock reduced wear of the dead centre. It has been lubricated. 3. The turner has got different measurements. The turner has to change the position of the dead centre. 4. The worker has turned a special screw in the tailstock. The worker removed the tailstock centre from the tailstock spindle. 5. The point of the dead centre has been hardened. The point of the dead centre increased its wear-resistance. 6. The work has been mounted in the lathe. The work is turned.

VIII. Giving answers to the following questions describe the construction and principle of operation of the centre shown in Fig. 26:

1. What parts does the centre consist of? 2. Where is the work to be machined installed? 3. Where does the tapered shank of the centre fit? 4. What causes excessive wear of the dead centre and the work?

IX. Describe the construction of the running centre shown in Fig. 27.