- •V.S. Martynjuk, I.I. Popovska

- •Study of the electromechanics energy converters design Aim of work

- •Theoretical positions

- •Design of direct current electromechanics converters

- •Design of synchronous electromechanic converters

- •Designs of asynchronous electromechanics converters

- •Order of work performance

- •Contents of a report

- •Control questions

- •Research of single-phase transformer Aim of work

- •Order of work implementation

- •Table of report contents

- •Control questions

- •Research of dc generator of parallel excitation Aim of work

- •Order of work implementation

- •Control questions

- •Research of direct current мотоrs Aim of work

- •Report content

- •Control questions

- •Research of three-phase asynchronous motor with squirrel-cage rotor Aim of work

- •Order of work performance

- •Table of report contents

- •Control questions

- •Calculation of electromagnets of direct-current а. Preliminary calculation of electromagnet. Calculation of key size of core

- •1.1. Electromagnets with external turning armature

- •B) Recursive short-time mode

- •C) Short-time duty

- •1.2. Electromagnets with external forward armature travel

- •B) Recursive short-time mode

- •C) Short-time duty

- •Design of asynchronous machines

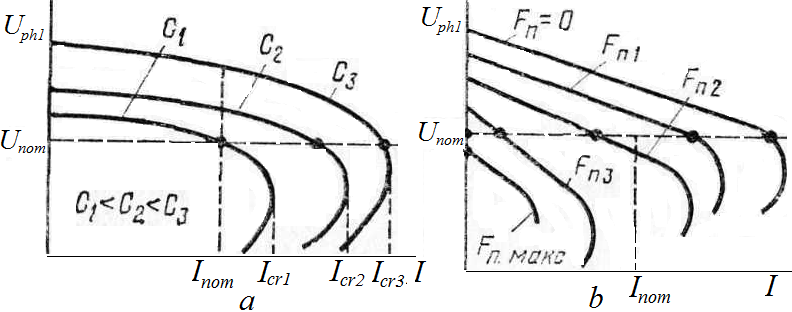

- •Features of asynchronous generators operation

- •2. Determination of main sizes and calculation of asynchronous machine

- •Choice of number of stator and rotor slots

- •4. Active and inductive resistances of stator and rotor winding

- •5. Choice of excitation capacitor

- •6. A calculation of magnetic circuit and determination of o.C. Current of asynchronous machine in traction mode

- •7. Calculation and plotting of magnetic characteristic (b-h curve) of asynchronous machine

- •8. Plotting of operating characteristics of asynchronous motor

- •9. Losses of energy and efficiency of asynchronous machine

- •Home work (by discipline “Aviation electric machines and devices”)

2. Determination of main sizes and calculation of asynchronous machine

The principal sizes of asynchronous machine (diameter and length of armature) are determined by operation mode and value of external load. If an asynchronous machine is designed for operation in motor and generator modes with commensurable powers, then a calculation must be conducted for these two modes and the sizes of machine get out those which turned out most. If load in the motor mode there is the far less load of the generator mode, then its sizes are determined by the generator mode. Therefore at the choice of parameters all requirements are taken into account on providing of normal motor mode. If an asynchronous machine operates only in the generator mode, then its sizes are determined by the generator mode.

Fig. 4

The principle sizes of asynchronous machine can be defined by means of the known calculation equation:

D2li = (6,1∙104Pel) / αi∙ksh∙kw1∙A∙Bδ∙n (6)

Here Рel − electromagnetic power, V∙A. Electromagnetic power is determined:

а) for the motor mode

Рel = P1Eph1 / Unom (7)

where Р1 − power, consumed from a network; η – efficiency of motor; соs φM − power-factor of motor; kE = Еph1/Unom − coefficient, taking into account a voltage drop across active and inductive resistances of motor; kE = 0,8÷0,9 − value, dependent on the number of pole pairs; large values behave to the two-poles motors; Р2 − power at the output (on a shaft).

The rated value of primary current can be preliminary defined by a formula

I1nom = P1 / (m1Unom)

b) for the generator mode

Рel = т1Еph1 /I1 = m1 Unom I1nom kЕ; (8)

it is preliminary possible to accept kE = 1.

Unlike synchronous machines an armature current value for the asynchronous generators is not known, because it depends on the values of currents: through an excitative capacitor and magnitizing current. The exact value of stator current can be defined from the plotting of vector diagram of voltage at a test calculation. Preliminary the value of stator current can be defined by means of expression (for nominal power)

I1nom = Inom cosφ / cos φG (9)

where Inom − current of load (nominal); соs φ – power factor of load; φG − phase shift angle between voltage and armature current I1.

For generators by power about 1 kV∙A

tg φG = 0,5÷ 0,7; cos φG = 0,86÷0,81.

The values of angles φG depend on generator load in a strong degree. The less load current, the anymore angle φG, and the armature current increases.

If in initial equation (6) to enter the relation λi = li/D, then

D = 3√(6,1∙104Pel) / (αi∙kph∙kw1∙A∙Bδ∙n∙λi) (10)

At the choice of the electromagnetic load A and Bδ as it applies to asynchronous machines it is necessary to take into account the following.

1.Choice of large values Bδ results in the increase of magnetizing current

Im = pF2 / 0,9m1kw1wph, (11)

Im ≡ Bδ2 (12)

because F∑ ≡ Bδ; wph1 ≡ 1/ Bδ; F∑ − total MMF of magnetic circuit.

2. With the increase of Bδ the power-factor соs φM goes down, dispersion diminishes, the short circuit current increases.

3. The value of excitant capacity increases with the increase of Bδ, because the magnetizing current Im increases. General mass of the system increases.

4. Not only the numerical value of product A∙Bδ, but also their correlation A / Bδ have influence on the value of inductive resistances of short circuit Хsc and magnetizing Хm, and also on the value of magnetizing current Im.

Increase of ratio A / Bδ increases a value Хsc, because

Xsc* = Xsc I1nom / Unom ≡ Λ А/Вδ, (13)

where Xsc = Хs1+ Х’s2 − total inductive resistance of dispersion; Λ − coefficient, characterizing dispersion.

The less value of Xsc, the more torque, the more overload of motor. Therefore, if it is need, for example, to improve Мmax, it is necessary to increase Bδ and to decrease A.

If to accept F∑ =1,6∙kδ1∙ kδ2∙Вδ∙δ∙kμ and to take into account that (m1∙wph1 / p) I1nom =Аτ, that

Im /I1nom = 1,78∙kμ(kδ1∙ kδ2) / (δ/τ)(Вδ/A)104 (14)

Xm = 0,56(kw1/kμ)( δ/τ’)(A/Вδ)(Unom/I1nom)10-4 (15)

i.е. at increase of Bδ and diminishing of A a relative value of Im /I1nom increases and, so, соsφM diminishes.

For asynchronous machines at the choice of values A and Bδ it is necessary to pay attention to the got values of magnetizing current Im, and so, соsφM, and also on the coefficient of overload kovl, determined by Хsc.

At A∙Bδ = const for the increase of power-factor соsφM it is necessary to diminish a value Bδ and to increase a value A, and for the increase of overload ability kovl it is necessary to increase a value Bδ and to diminish a value A.

This contradiction is solved by the choice of such ratio between A and Bδ, at which the most value of power-factor is provided at the given value of overload ability.

Recommended values of Bδ and A for asynchronous machines, operating in the continuous duty, driven accordingly in the table. 1 and 2 (f = 400 Hz, m1= 3, 2p = 4).

Tabl. 1

-

P2, kW

0,1

0,2

0,5

0,75

1,0

2,0

5,0

10

Вδ, T

0,36

0,48

0,55

0,57

0,6

0,62

0,64

0,66

Tabl. 2

-

P2, kW

0,1

0,2

0,5

0,75

1,0

2,0

5,0

10

A, A/cm

160

180

220

235

250

270

290

310

For asynchronous machines, operating in the individual systems of electrical equipment, it is rationally to choose frequency of rotation most. With the increase of frequency of rotation mass of machine diminishes. So, for example, mass of machine by power of 1 kW at n = 6000 r/m is approximately in two times more as compared to the same machine at n = 12 000 r/m. For individual turbine-generator sets at f = 400 Hz usually frequency of rotation is got out equal to 24 000 r/m (2р = 2). At the choice of frequency of rotation it is necessary to check a machine for mechanical durability. For asynchronous machines a permissible linear speed equals to 80m/s.

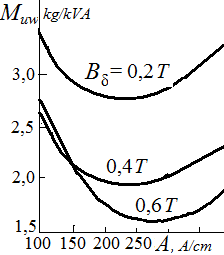

Data of tables. 1 and 2 for a choice of optimal electromagnetic load A and Bδ are correct also for bipolar asynchronous machines with n = 24 000 r/m, what the curves of specific mass are evidence in a fig. 5.

I f

the designed asynchronous machine in the traction mode operates on

flyweight with the great moment of inertia, then in order to avoid

its overheat during acceleration it is necessary considerably to

reduce the linear load (up to 80÷100 A/cm

at power about 1÷2 kW).

f

the designed asynchronous machine in the traction mode operates on

flyweight with the great moment of inertia, then in order to avoid

its overheat during acceleration it is necessary considerably to

reduce the linear load (up to 80÷100 A/cm

at power about 1÷2 kW).

With the increase of rotation frequency and power of asynchronous machine an efficiency η and power factor Fig. 5 соsφM are increased. Thus the less a power of machine, the stronger influence of rotation frequency on values of η and соsφM, that is explained by the known correlations for specific losses and magnetizing current:

ΔP =P/Pel ≡ Mam/Pel ≡ (Pel/n)3/4/Pel = 1/(Pel1/4n3/4), (16)

im = Im/I1nom = l/l2 = 4√(1/Pel) = 1/Pel1/4 (17)

where Мam − mass of active materials.

Specific losses on unit of power (at Bδ = const and jа = const) are proportional to 4-th root of power and 3-d root of frequency of rotation, i.e. with the increase of rotation frequency the specific losses fall and efficiency increases.

A magnetizing current is directly proportional to linear dimensions, and the load current is directly proportional to the second degree of linear dimensions.

So, relative value of magnetizing current im = Im/I1nom is inversely proportional to linear dimensions, i.е. a relative magnetizing current goes down with increasing power, that corresponds to growth of соsφM for asynchronous machines. The increase of rotation frequency acts just the same, if to take into account that with the increase of n at f = const a ratio δ'/τ diminishes.

If operation of asynchronous machine is provided for traction mode, then it have to set oneself preliminary by values of efficiency and power-factor соsφM. Recommended values η and соsφM for three-phase asynchronous motors by frequency of f = 400 Hz and number of poles 2p = 4 in the function of power driven to the table. 3.

Tabl. 3

-

P2,W

25

50

100

200

500

750

1000

η

0,40

0,53

0,63

0,70

0,76

0,77

0,78

соsφM

0,53

0,62

0,70

0,76

0,77

0,77

0,78

At р = 1 a value of η and соsφM more than in a table. So, for example, at Р2 = 1000 W: η = 0,79, соsφM = 0,86.

For asynchronous machines attitude of length of machine toward the diameter λ = l/D ≈ λi gets out greater, than for synchronous machines, i.е. asynchronous machines are executed relatively longer, than synchronous, at the same quantity of poles.

There is an area of optimal value of λi which gives the least value of mass and fabrication cost at given energy rates. On the basis of theoretical researches and their practical confirmation for asynchronous machines next optimal values are set for λi = f (р) at condition that surface speed and flywheel moment (GD2) does not limit the choice of diameter value:

λi = li / D = 1,6p-2/3 (18)

λ’i = li / τ = 3√p (19)

The optimal value of λi at given number of pole pairs depends also on the diameter (powers) of machine – is decreased at the increase of diameter. The optimum of ratio λi diminishes with increasing of power. The choice of ratio λi in defiance of geometric similarity is often determined by the terms of machine cooling.

As it applies to the asynchronous generators of small power dependence of specific mass of attitude of armature length toward its diameter illustrated by curves, brought around to a fig. 6.

A s

researches show, asynchronous generators must

to have less values λi,

then

asynchronous motors,

for providing of the small nominal sliding.

s

researches show, asynchronous generators must

to have less values λi,

then

asynchronous motors,

for providing of the small nominal sliding.

By the chosen value λi a calculation armature length is determined: li = λi D (20)

Checking of this value is thus conducted under the required value of E.M.F. in generator mode: li = (Eph1I1nom ∙p∙m1) / (ksh∙kw1∙f∙π2∙αi∙A∙Bδ∙D2) (21)

Length of active part of armature in the first approaching it is possible to assume by an Fig. 6 equal to calculation.