- •LIST OF ABBREVIATIONS

- •New Ignition Interlock Sidestand System

- •Current Ignition Interlock Sidestand System

- •Materials of Semi-Conductor and Emitting Color

- •Units of Mass:

- •Units of Volume:

- •Units of Force:

- •Units of Length:

- •Units of Torque:

- •Units of Pressure:

- •Units of Speed:

- •Units of Power:

- •Periodic Inspection:

- •Periodic Replacement Parts:

- •Basic Torque for General Fasteners

- •Throttle Grip Free Play

- •Idle Speed

- •Engine Vacuum

- •Water and Coolant Mixture Ratio (when shipping)

- •Valve Clearance

- •Clutch Lever Free Play

- •Engine Oil

- •Tread Depth

- •Air Pressure (when cold)

- •Chain Slack

- •Drive Chain 20-link Length

- •Standard Chain

- •Pad Lining Thickness

- •Sample Diagnosis Sheet

- •Poor Running at Low Speed

- •Poor Running or No Power at High Speed:

- •Wiring Connection

- •Idle Speed

- •Wiring Connection

- •Main Throttle Sensor Resistance

- •Inlet Air Pressure Sensor Output Voltage

- •Inlet Air Temperature Sensor Output Voltage

- •Water Temperature Sensor Output Voltage

- •Atmospheric Pressure Sensor Input Voltage

- •Output Voltage at Sensor

- •Wiring Connection

- •Wiring Connection

- •Throttle Sensor Resistance

- •Stick Coil Input Voltage at ECU

- •Input Voltage at ECU

- •Subthrottle Valve Actuator Resistance

- •Subthrottle Valve Actuator Input Voltage

- •Input Voltage at Actuator

- •FI Indicator LED Light Check

- •ECU Grounding Inspection

- •ECU Power Source Inspection

- •Testing Relay

- •Fuel Pressure

- •Fuel Pressure (idling)

- •Amount of Fuel Flow

- •Testing Relay

- •Injector Power Source Voltage at ECU

- •Output Voltage at Injector Connector

- •Injector Wiring Inspection

- •Choke Lever Free Play

- •Radiator Cap Relief Pressure

- •Thermostat Valve Opening Temperature

- •Camshaft Journal, Camshaft Cap Clearance

- •Camshaft Journal Diameter

- •Camshaft Runout

- •Cylinder Compression

- •Cylinder Head Warp

- •Valve/Valve Guide Clearance (Wobble Method)

- •Valve Seating Surface Outside Diameter

- •Valve Seating Surface Width

- •Cylinder Inside Diameter

- •Piston Diameter

- •Piston Ring/Groove Clearance

- •Piston Ring Groove Width

- •Piston Ring Thickness

- •Piston Ring End Gap

- •Clutch Plate Assembly

- •Friction Plate Thickness

- •Friction and Steel Plate Warp

- •Clutch Spring Free Length

- •Oil Pressure

- •Connecting Rod Bend

- •Connecting Rod Twist

- •Connecting Rod Big End Side Clearance

- •Crankpin Diameter

- •Crankpin Diameter Marks

- •Connecting Rod Big End Inside Diameter Marks

- •Crankshaft Side Clearance

- •Crankshaft Runout

- •Crankshaft Main Journal Diameter

- •Crankshaft Main Journal Diameter Marks

- •Crankcase Main Bearing Inside Diameter Marks

- •Shift Fork Ear Thickness

- •Gear Groove Width

- •Shift Fork Guide Pin Diameter

- •Shift Drum Groove Width

- •Rim Runout

- •Axle Runout/100 mm (3.94 in.)

- •Balance Weight

- •Link Pin Outside Diameter

- •Link Plates Outside Width

- •Rear Sprocket Warp

- •Pedal Position

- •Front Disc Thickness

- •Rear Disc Thickness

- •Disc Runout

- •Oil Level (fully compressed, without spring)

- •Fork Spring Free Length

- •Rebound Damping Adjustment

- •Spring Preload Setting

- •Spring Preload Adjustment

- •Table 1 Alternator Output Voltage

- •Table 2 Stator Coil Resistance

- •Rectifier Circuit Inspection

- •Charging Voltage

- •Crankshaft Sensor Peak Voltage

- •Connections:

- •Camshaft Position Sensor Peak Voltage

- •Ignition Coil Winding Resistance

- •Primary Lead Connection

- •Connection:

- •Condition:

- •Starter Motor Brush Length

- •Commutator Diameter

- •Testing Relay

- •Testing Turn Signal Relay

- •Water Temperature Sensor

- •Fuel Level Sensor Resistance

- •Connections:

- •Fuse Circuit Inspection

- •Relay Circuit Inspection (with the battery disconnected)

- •Relay Circuit Inspection (with the battery connected)

- •Diode Circuit Inspection

- •Foreword

- •General Information

- •Battery Ground

- •Edges of Parts

- •Solvent

- •Cleaning vehicle before disassembly

- •Arrangement and Cleaning of Removed Parts

- •Storage of Removed Parts

- •Inspection

- •Replacement Parts

- •Assembly Order

- •Tightening Sequence

- •Tightening Torque

- •Force

- •Gasket, O-ring

- •Liquid Gasket, Locking Agent

- •Press

- •Ball Bearing and Needle Bearing

- •Oil Seal, Grease Seal

- •Circlips, Cotter Pins

- •Lubrication

- •Direction of Engine Rotation

- •Electrical Wires

- •ZR750–J1 Left Side View:

- •ZR750–J1 Right Side View:

- •Subthrottle Control System

- •Outline

- •Outline

- •Due Position of LED Installation

- •Honeycomb Type Catalytic Converter

- •Prefixes for Units:

- •Units of Temperature:

- •Periodic Maintenance

- •Steering Stem Nut Wrench:

- •Fuel System (DFI)

- •Fuel Hose and Connection Inspection

- •Throttle Control System Inspection

- •Engine Vacuum Synchronization Inspection

- •Air Cleaner Element Cleaning

- •Cooling System

- •Radiator Hose and Connection Inspection

- •Coolant Change

- •Engine Top End

- •Valve Clearance Inspection

- •Clutch

- •Engine Lubrication System

- •Engine Oil Change

- •Wheels/Tires

- •Tire Wear Inspection

- •Air Pressure Inspection

- •Final Drive

- •Drive Chain Slack Inspection

- •Brakes

- •Rear Brake Light Switch Connections:

- •Caliper Fluid Seal Damage

- •Brake Line Bleeding

- •Suspension

- •Steering

- •Steering Adjustment

- •Electrical System

- •General Lubrication

- •Lubrication

- •Nut, Bolt, and Fastener Tightness

- •Fuel System (DFI)

- •Terminal Names

- •Part Name

- •Oil Pressure Gauge:

- •DFI Servicing Precautions

- •Outline

- •Outline

- •DFI Diagnosis Flow Chart

- •Inquiries to Rider

- •Inquiries to Rider

- •DFI System Troubleshooting Guide

- •Self-diagnosis Outline

- •Self-diagnosis Outline

- •Self-diagnosis Procedures

- •Self-diagnosis Procedures

- •Service Code Clearing Procedures

- •How to Read Service Codes

- •How to Read Service Codes

- •How to Erase Service Codes

- •How to Erase Service Codes

- •Service Code Table

- •Service Code Table

- •Notes:

- •Backups

- •Backups

- •Main Throttle Sensor Removal/Adjustment

- •Input Voltage Inspection

- •Resistance Inspection

- •CAUTION

- •Removal

- •Installation

- •Input Voltage Inspection

- •Output Voltage Inspection

- •Removal/Installation

- •Output Voltage Inspection

- •Removal/Installation

- •Output Voltage Inspection

- •CAUTION

- •Removal

- •Input Voltage Inspection

- •Crankshaft Sensor Inspection

- •Camshaft Position Sensor Removal/Installation

- •Camshaft Position Sensor Inspection

- •Input Voltage Inspection

- •Removal

- •Installation

- •Inspection

- •Subthrottle Sensor Removal/Adjustment

- •Input Voltage Inspection

- •Removal/Installation

- •Input Voltage Inspection

- •Subthrottle Valve Actuator Removal

- •Audible Inspection

- •Input Voltage Inspection

- •Inspection Flow Chart

- •CAUTION

- •ECU Power Source Circuit

- •ECU Fuse Installation

- •ECU Main Relay Removal

- •Fuel Pressure Inspection

- •Fuel Flow Rate Inspection

- •Fuel Pump Removal

- •Operation Inspection

- •Operating Voltage Inspection

- •Pressure Regulator Removal

- •Pump Screen, Fuel Filter Cleaning

- •Fuel Pump Relay Removal

- •Removal/Installation

- •Choke Lever Operation

- •Throttle Body Assy Removal

- •Throttle Body Assy Disassembly

- •Throttle Body Assy Assembly

- •Air Cleaner Oil Draining

- •Fuel Tank Removal

- •Fuel Tank Cleaning

- •Cooling System

- •Bearing Driver:

- •Coolant Level Inspection

- •Cooling System Flushing

- •Water Pump Housing Disassembly

- •Water Pump Housing Assembly

- •Radiator and Radiator Fan Removal

- •CAUTION

- •Engine Top End

- •Exhaust System

- •Compression Gauge:

- •Camshaft Chain Tensioner Removal

- •Cylinder Compression Measurement

- •Cylinder Head Installation

- •Valve Guide Installation

- •Seat Cutter Operation Care:

- •Cylinder Installation

- •WARNING

- •Clutch

- •Clutch Holder:

- •Clutch Lever Adjustment

- •Release Shaft Removal

- •Engine Lubrication System

- •WARNING

- •Oil Pressure Measurement

- •Engine Removal/Installation

- •Crankshaft/Transmission

- •Bearing Puller:

- •Crankcase Splitting

- •Crankcase Assembly

- •Crankshaft Installation

- •Connecting Rod Installation

- •Wheels/Tires

- •Bearing Driver Set:

- •Front Wheel Installation

- •Axle Inspection

- •Tire Installation

- •Tire Repair

- •Hub Bearing Inspection

- •Final Drive

- •Bearing Driver Set:

- •Coupling Bearing Inspection

- •Brakes

- •Jack:

- •Brake Lever Position Adjustment

- •Brake Pedal Position Adjustment

- •Caliper Holder Shaft Wear

- •Rear Master Cylinder Disassembly

- •Brake Hose Removal/Installation

- •Suspension

- •Fork Cylinder Holder Handle:

- •Swingarm Installation

- •Swingarm Bearing, Sleeve Inspection

- •Steering

- •Steering Stem Nut Wrench:

- •Frame

- •Electrical System

- •Rotor Puller, M16/M18/M20/M22 × 1.5 :

- •Battery Removal

- •Initial Charge

- •Precautions

- •Alternator Inspection

- •Charging System Circuit

- •WARNING

- •Special Tool -

- •Crankshaft Sensor Peak Voltage Inspection

- •Stick Coil (Ignition Coil together with Spark Plug Cap) Removal

- •Stick Coil Primary Peak Voltage

- •IC Igniter Inspection

- •Ignition System Circuit

- •Starter Motor Removal

- •Starter Motor Installation

- •Electric Starter Circuit

- •Headlight/Tail Light Circuit (CA, AS)

- •Headlight/Tail Light Circuit (Other than CA, AS)

- •Turn Signal Light Circuit

- •Turn Signal Light Bulb Replacement

- •Radiator Fan Circuit

- •Electronic Combination Meter Unit Inspection

- •Meter Circuit

- •Rear Brake Light Switch Connections

- •Side Stand Switch Connections

- •Neutral Switch Connections

- •Oil Pressure Switch Connections*

- •Special Tool -

- •Junction Box Internal Circuit

- •30 A Main Fuse Removal

- •15 A ECU Fuse Removal

- •Appendix

- •NOTE

- •Starter motor not rotating:

- •No fuel flow:

- •Engine flooded:

- •No spark; spark weak:

- •Fuel/air mixture incorrect:

- •Compression Low:

- •Poor Running at Low Speed:

- •Spark weak:

- •Fuel/air mixture incorrect:

- •Compression low:

- •Other:

- •Poor Running or No Power at High Speed:

- •Firing incorrect:

- •Fuel/air mixture incorrect:

- •Compression low:

- •Knocking:

- •Miscellaneous:

- •Overheating:

- •Firing incorrect:

- •Muffler overheating:

- •Fuel/air mixture incorrect:

- •Compression high:

- •Engine load faulty:

- •Lubrication inadequate:

- •Gauge incorrect:

- •Coolant incorrect:

- •Cooling system component incorrect:

- •Over Cooling:

- •Gauge incorrect:

- •Cooling system component incorrect:

- •Clutch Operation Faulty:

- •Clutch slipping:

- •Clutch not disengaging properly:

- •Gear Shifting Faulty:

- •Jumps out of gear:

- •Overshifts:

- •Abnormal Engine Noise:

- •Knocking:

- •Piston slap:

- •Valve noise:

- •Other noise:

- •Abnormal Drive Train Noise:

- •Clutch noise:

- •Transmission noise:

- •Drive line noise:

- •Abnormal Frame Noise:

- •Front fork noise:

- •Rear shock absorber noise:

- •Disc brake noise:

- •Other noise:

- •Oil Pressure Warning Light Goes On:

- •Exhaust Smokes Excessively:

- •White smoke:

- •Black smoke:

- •Brown smoke:

- •Handlebar hard to turn:

- •Handlebar shakes or excessively vibrates:

- •Handlebar pulls to one side:

- •Shock absorption unsatisfactory:

- •Battery Trouble:

- •Battery discharged:

- •Battery overcharged:

5-30 ENGINE TOP END

Cylinder, Pistons

NOTE

○If a new piston is used, use new piston ring.

•Install the piston with its marking hollow facing forward.

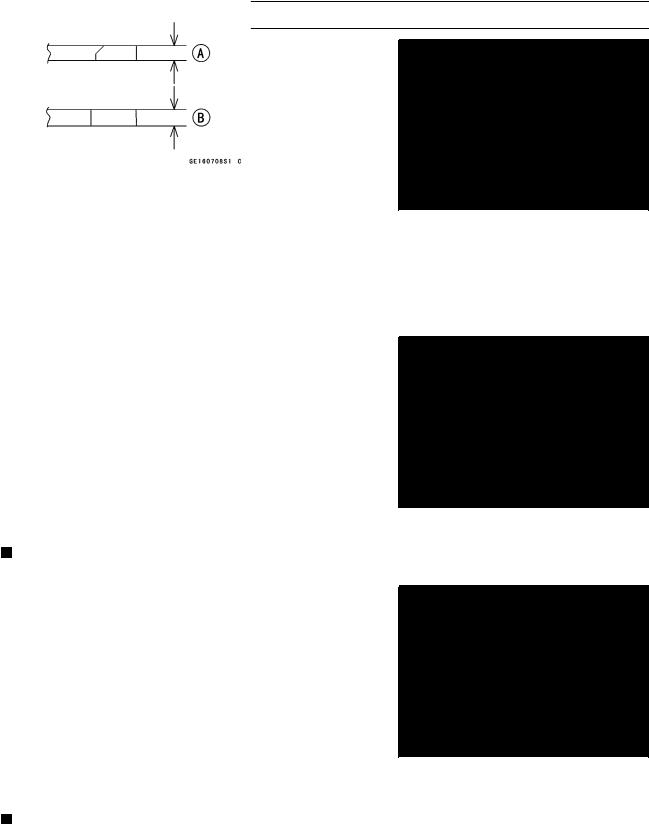

•Fit a new piston pin snap ring into the side of the piston so that the ring opening [A] does not coincide with the slit [B] of the piston pin hole.

○Apply molybdenum disulfide oil solution to the piston pins and piston journals.

○When installing the piston pin snap ring, compress it only enough to install it and no more.

CAUTION

Do not reuse snap rings, as removal weakens and deforms them. They could fall out and score the cylinder wall.

•Install the cylinder (see Cylinder Installation).

Cylinder• Wear

Since there is a difference in cylinder wear in different directions, take a side-to-side and a front-to-back measurement at each of the two locations (total of four measurements) shown in the figure.

If any of the cylinder inside diameter measurements exceeds the service limit, replace the cylinder.

10 mm (0.39 in.) [A]

60 mm (2.36 in.) [B]

Cylinder Inside Diameter

Standard: 68.400 68.412 mm (2.6929 2.6934 in.)

Service Limit: 68.50 mm (2.6969 in.)

Piston• Wear

Measure the outside diameter [A] of each piston 5 mm (0.20 in.) [B] up from the bottom of the piston at a right angle to the direction of the piston pin.

If the measurement is under service limit, replace the piston.

Piston Diameter

Standard: 68.345 68.360 mm (2.6907 2.6913 in.)

Service Limit: 68.21 mm (2.6854 in.)

ENGINE TOP END 5-31

Cylinder, Pistons

Piston• Ring, Piston Ring Groove Wear

Check for uneven groove wear by inspecting the ring seating.

The rings should fit perfectly parallel to groove surfaces.

•If not, replace the piston and all the piston rings.

With the piston rings in their grooves, make several measurements with a thickness gauge [A] to determine piston ring/groove clearance.

Piston Ring/Groove Clearance |

|

|

Top |

|

|

Standard: |

0.04 0.08 mm (0.0016 |

0.0031 in.) |

Service Limit: |

0.18 mm (0.0071 in.) |

|

Second |

|

|

Standard: |

0.02 0.06 mm (0.0008 |

0.0024 in.) |

Service Limit: |

0.16 mm (0.0063 in.) |

|

Piston• Ring Groove Width

Measure the piston ring groove width.

○Use a vernier caliper at several points around the piston.

Piston Ring Groove Width |

|

|

|

Top [A] |

|

|

|

Standard: |

0.83 |

0.85 mm (0.0327 |

0.0335 in.) |

Service Limit: |

0.93 mm (0.037 in.) |

|

|

Second [B] |

|

|

|

Standard: |

0.81 |

0.83 mm (0.0319 |

0.0327 in.) |

Service Limit: |

0.91 mm (0.036 in.) |

|

|

If the width of any of the two grooves is wider than the service limit at any point, replace the piston.

Piston• Ring Thickness

Measure the piston ring thickness.

○Use the micrometer to measure at several points around the ring.

Piston Ring Thickness |

|

|

|

Top [A] |

|

|

|

Standard: |

0.77 |

0.79 mm (0.0303 |

0.0311 in.) |

Service Limit: |

0.70 mm (0.028 in.) |

|

|

Second [B] |

|

|

|

Standard: |

0.77 |

0.79 mm (0.0303 |

0.0311 in.) |

Service Limit: |

0.70 mm (0.028 in.) |

|

|

If any of the measurements is less than the service limit on either of the rings, replace all the rings.

NOTE

○When using new rings in a used piston, check for uneven groove wear. The rings should fit perfectly parallel to the groove sides. If not, replace the piston.

5-32 ENGINE TOP END

Cylinder, Pistons

Piston• Ring End Gap

Place the piston ring [A] inside the cylinder, using the piston to locate the ring squarely in place. Set it close to the

•bottom of the cylinder, where cylinder wear is low. Measure the gap [B] between the ends of the ring with a thickness gauge.

Piston Ring End Gap |

|

|

Top |

|

|

Standard: |

0.30 0.40 mm (0.0118 |

0.0157 in.) |

Service Limit: |

0.7 mm (0.028 in.) |

|

Second |

|

|

Standard: |

0.45 0.55 mm (0.0177 |

0.0217 in.) |

Service Limit: |

0.8 mm (0.031 in.) |

|

If the end gap of either ring is greater than the service limit, replace all the rings.

ENGINE TOP END 5-33

Throttle Body Holder

Throttle• Body Holder Installation

•Be sure to install the O-rings [A].

Install the clamps [B] as shown and so that its hole fit on

•the projection [C] of the holder. Tighten:

Torque - Throttle Body Holder Bolts [D]: 13 N·m (1.3 kgf·m, 113 in·lb)

Throttle Body Assy Holder Clamp Bolts [E]: 2.0 N·m (0.20 kgf·m, 17 in·lb)