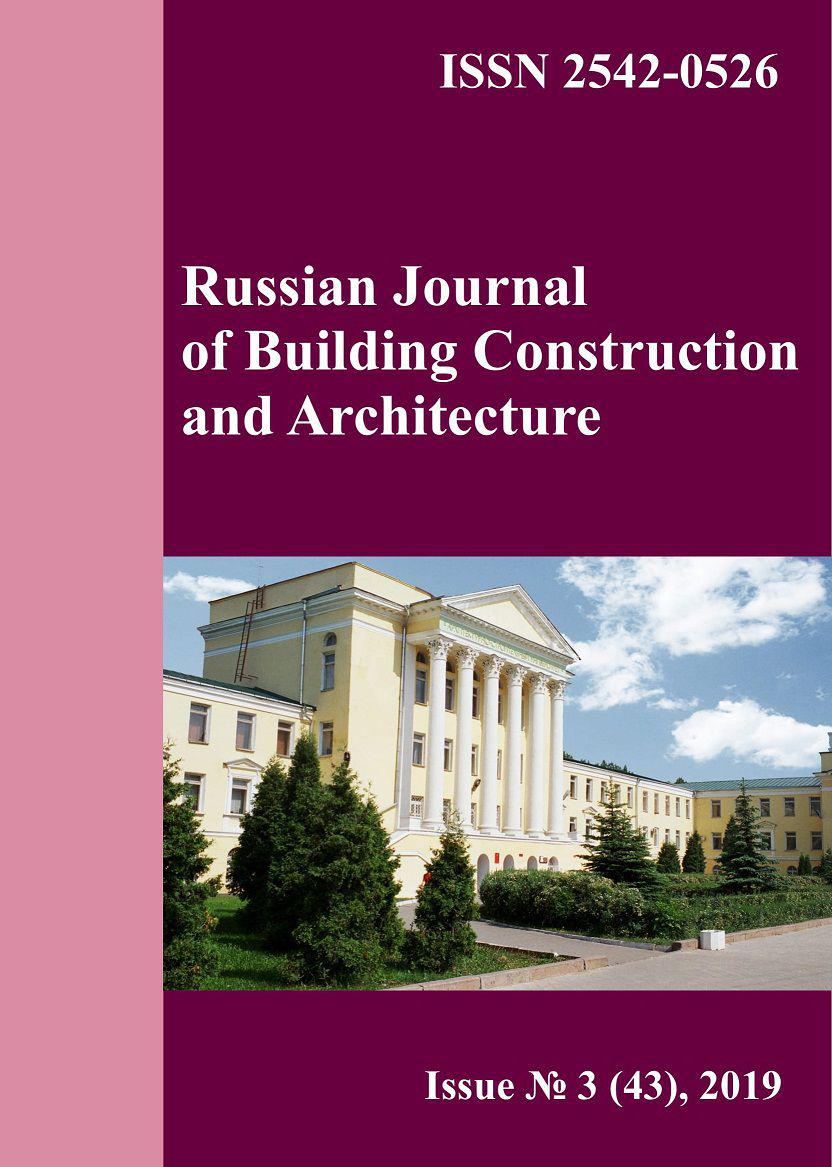

Russian Journal of Building Construction and Architecture

.pdf

RUSSIAN JOURNAL

OF BUILDING

CONSTRUCTION AND ARCHITECTURE

1

The journal is indexed/abstracted in:

Web of Science Core Collection

(Emerging Sources Citation

Index)

(Thomson Reuters), USA

Ulrich's Periodicals Directory

(Bowker), USA,

DOAJ

(Lund University), Sweden,

Academic Search Complete

(EBSCO), USA,

SOCOLAR

(China Educational Publications Import and Export Corporation –– CEPIEC), China,

Google Scholar

(Google), USA,

E-Library

(ООО «РУНЭБ»), Russia,

J-Gate

(Informatics Ltd), India

2

ISSN 2542-0526

RUSSIAN JOURNAL

OF BUILDING

CONSTRUCTION AND ARCHITECTURE

N 3 (43)

BUILDING STRUCTURES, BUILDINGS AND CONSTRUCTIONS

BASES AND FOUNDATIONS, UNDERGROUND STRUCTURES

HEAT AND GAS SUPPLY, VENTILATION, AIR CONDITIONING, GAS SUPPLY AND ILLUMINATION

BUILDING MATERIALS AND PRODUCTS

TECHNOLOGY AND ORGANIZATION OF CONSTRUCTION

DESIGNING AND CONSTRUCTION OF ROADS, SUBWAYS, AIRFIELDS, BRIDGES AND TRANSPORT TUNNELS

BUILDING MECHANICS

THEORY AND HISTORY OF ARCHITECTURE, RESTORATION AND RECONSTRUCTION OF HISTORICAL

AND ARCHITECTURAL HERITAGE

ARCHITECTURE OF BUILDINGS AND STRUCTURES. CREATIVE CONCEPTIONS OF ARCHITECTURAL ACTIVITY

CITY PLANNING, PLANNING OF VILLAGE SETTLEMENTS

Voronezh 2019

3

Russian Journal

of Building Construction and Architecture

Periodical scientific edition

Published since 2009 |

Comes out 4 times per annum |

Founder and publisher: Federal State Education Budget Institution of Higher Professional Education «Voronezh State Technical University».

The articles are reviewed and processed with the program ANTIPLAGIARISM. This publication cannot be reprinted without the prior permission of the publisher, references are obligatory.

Number of the certificate of registration of the media ПИ № ФС 77-67855

Issued by the Federal Service for Supervision of Communications, Information Technology, and Mass Media (Roskomnadzor)

Price is subject to change

EDITORIAL COUNCIL

The Head of the Council: Kolodyazhny S. A., D. Sc. in Engineering, rector (Voronezh State Technical University)

EDITORIAL BOARD

Editor-in-Chief: Melkumov V. N., D. Sc. in Engineering, Prof.

(Voronezh State Technical University)

Members:

Boldyrev А.М., Corresponding Member of the Russian Academy of Architecture and Engineering Science, D.Sc. in Engineering, Prof., Voronezh State Technical University, Russia

Bondarev B. А., D. Sc. in Engineering, Prof., Lipetsk State Technical University, Russia

Gagarin V. G., Corresponding Member of RAABS, Moscow State University of Civil Engineering, Russia

Gelfond А. L., Corresponding Member of the Russian Academy of Architecture and Construction Science, D. Sc. in Architecture, Nizhniy Novgorod State University of Architecture and Construction, Russia

Enin A. Ye., PhD in Architecture, Prof., Voronezh State Technical University, Russia

Karpenko N. I., Academician of RAABS, Research Institute of Building Physics (NIISF RAABS), Russia

Kirsanov М.N., D.Sc. in Physics and Mathemat-

ics, Professor (National Research University “Moscow Power Engineering Institute”)

Kobelev N. S., D. Sc. in Engineering, Prof., Southwest State University, Kursk, Russia

Kolchunov V. I., Academician of RAABS, Southwest State University, Kursk, Russia

Ledenyev V. I., D. Sc. in Engineering, Prof., Tambov State Technical University, Russia

Lyahovich L. S., Academician of RAABS, Tomsk State University of Architecture and Building, Russia

Mailyan L. R., D. Sc. in Engineering, Prof., Don State Technical University, Rostov, Russia

Panibratov Yu. P., Academician of RAABS, Saint Petersburg State University of Architecture and Civil Engineering, Russia Podolsky Vl.P.,D. Sc. in Engineering, Prof., Voronezh State Tech-

nical University, Russia (Dep. of the Editor-in-Chief)

SlavinskayaG.V.,D. Sc. in Chemistry, Prof, Voronezh State Technical University, Russia

SuleymanovА.М.,D. Sc. in Engineering, Prof.,Kazan State University of Architecture and Engineering, Russia

Fyedorov V. S., Academician of RAABS, Moscow State University of Railway Engineering, Russia

Fedosov S. V., Academician of RAABS, Ivanovo State Polytechnic University, Russia

Chernyshov Ye. M., Academician of RAABS, Voronezh State Technical University, Russia

Shapiro D. M., D. Sc. in Engineering, Prof., Voronezh State Technical University, Russia

Shubenkov М. V., Academician of the Russian Academy of Architecture and Construction Science, D. Sc. in Architecture, Prof., Моscow Institute of Architecture (State Academy), Russia Asanowicz Alexander, Prof., Dr. of Sn., Technical University of Bialystok, Poland

Figovsky Oleg L., Prof., Dr. of Sn., Member of EAS, Israel Korsun V. I., D. Sc. in Engineering, Prof., The Donbas National Academy of Civil Engineering and Architecture, Ukraine Nguyen Van Thinh, Prof., Dr. of Sn., Hanoi University of Architecture, Vietnam

Editor: Kotlyarova E. S. |

Translator: Litvinova O. A. |

THE ADDRESS of EDITORIAL AND THE PUBLISHER OFFICE:84 20-letiya Oktyabrya str., Voronezh, 394006, Russian Federation Tel./fax: (473)2-774-006; e-mail: vestnik_vgasu@mail.ru

Publication date 20.07.2019. Format 60×84 1/8. Conventional printed sheets 14,6. Circulation 500 copies. Order 153.

Published in Printing Office of Voronezh State Technical University 84 20-letiya Oktyabrya str., Voronezh, 394006, Russian Federation

ISSN 2542-0526 |

© Voronezh State Technical |

|

University, 2019 |

4

CONTENTS

BUILDING STRUCTURES,BUILDINGS AND CONSTRUCTIONS ................................................... |

6 |

Nikolyukin A. N., Yartsev V. P., Bondarev B. A., Korneev A. O.

Modeling the Coupling of Reinforcement in Concrete Based on an Artificial Neural Network.. 6

HEAT AND GAS SUPPLY,VENTILATION,AIR CONDITIONING, |

|

GAS SUPPLY AND ILLUMINATION............................................................................................ |

17 |

Levtzev A. P., Makeev A. N. |

|

Controllable Shock Unit of the Opposite Construction for Heat Supply Systems |

|

with Pulse Circulation of the Heat Carrier............................................................................... |

17 |

Kuschev L. А., Nikulin N. Yu., Feoktistov А. Yu. |

|

Highly Efficient Shell-and-Tube Heat Exchangers for Communal Household Systems ......... |

35 |

BUILDING MATERIALS AND PRODUCTS.................................................................................. |

46 |

Pimenov S. I. |

|

Features of the Structure Formation of a Cement Stone After Hydro-Mechanochemical |

|

Activation of Cement............................................................................................................... |

46 |

Khouadjia M. L. K., Belebchouche C., BensacI-Chibane L. |

|

Characterization of Recovery Filler from Hot-Mix Asphalt Plants and Its Effect |

|

on the Workability and Compressive Strength of Concrete ................................................... |

59 |

DESIGNING AND CONSTRUCTION OF ROADS,SUBWAYS,AIRFIELDS, |

|

BRIDGES AND TRANSPORT TUNNELS .................................................................................... |

72 |

Matua V. P., Isaev Ye. N. |

|

Studies of the Influence of the Moisture Content and Density of Subgrade Soil |

|

on the Accumulation of Residual Strain .................................................................................. |

72 |

Tiraturyan A. N. |

|

New Approach to Technical Monitoring of the Condition |

|

of Flexible Roadway Pavements.............................................................................................. |

81 |

ARCHITECTURE OF BUILDINGS AND STRUCTURES. |

|

CREATIVE CONCEPTIONS OF ARCHITECTURAL ACTIVITY ................................................... |

95 |

Eiraji Javad |

|

National Identity and Its Contrast with the Western Modernity in the Contemporary |

|

Architecture of Turkey............................................................................................................. |

95 |

Podolskaya L. V. |

|

Role and Place of Ornaments in the Composition of Facades and Interiors |

|

of Private Residences Using the Example of S. P. Ryabushinskiy’s Mansion...................... |

109 |

INSTRUCTIONS TO AUTHORS................................................................................................. |

125 |

5

BUILDING STRUCTURES,BUILDINGS AND CONSTRUCTIONS

DOI 10.25987/VSTU.2019.3.43.001

UDC 691.328.4

A. N. Nikolyukin1, V. P. Yartsev2, B. A. Bondarev3, A. O. Korneev4

MODELING THE COUPLING OF REINFORCEMENT IN CONCRETE

BASED ON AN ARTIFICIAL NEURAL NETWORK

Tambov State Technical University1, 2

Russia, Tambov

Lipetsk State Technical University3, 4

Russia, Lipetsk

1PhD student of the Dept. of Construction of Buildings and Structures, tel.: +7-953-717-16-44, e-mail: valax1@yandex.ru

2D. Sc. in Engineering, Prof. of the Dept. of Construction of Buildings and Structures, e-mail: kzis@nnn.tstu.ru 3D. Sc. in Engineering, Prof. of the Dept. of Construction Materials Science and Road Technologies

4PhD in Engineering, Assoc. Prof. of the Dept. of Construction Materials Science and Road Technologies

Statement of the problem. One of the major reasons for the loss of the bearing capacity of reinforced concrete structures is considered to be failure of coupling between the reinforcement and concrete. As a result, there is a need to study the change in the value of the coupling of the reinforcing bar and concrete under various influences. It should be noted that due to external and technological influences, the mechanical characteristics of concrete are subject to change, which directly affects the amount of adhesion.

Results and conclusions. Using artificial neural networks the analytical model was obtained that describes the final coupling strength by means of average tangential strains. Concrete of different strength types reinforced with metal and composite reinforcement is used for this study. Coupling was found to be associated with concrete characteristics and reinforcement type. A two-layer reverse neural network was also developed that describes coupling of reinforcement with concrete precisely.

Keywords: coupling, concrete, reinforcement, composite reinforcement, artificial neural networks, model.

Introduction. The major characteristics of evaluation of reinforcement coupling with concrete is tangential strain τсц. It is transformed in a conditional cylindrical surface at the reinforcement concrete interface. Conditional means that even if different types or reinforcement materials are used, their surfaces which are rough and protruding interact with each other. As

© Nikolyukin A. N., Yartsev V. P., Bondarev B. A., Korneev A. O., 2019

6

Issue № 3 (43), 2019 |

ISSN 2542-0526 |

a result, there are strains directed to the surface at some angle. According to R. G. Litvinova, P. P. Nazarenko and G. Rehm, this is a contact task [3, 16]. Conditional tangential strain is a simplified characteristics of the reinforcement concrete adhesion. It does not seem contradictory as generalized theories yielding practical results are allowed for.

V. I. Zhukov, P. P. Nazarenko, M. M. Kholmyanskiy, S. D. Santiago, etc. argued that strain that is normal to the longitudinal reinforcement axis is transverse reinforcement pressure on concrete or thrust that is associated with tangential coupling [6, 16].

As more experimental data were accumulated and new types of reinforcement were designed, a new idea of reinforcement concrete coupling came about. Tangential coupling for wire and smooth slab reinforcement is due to coupling of cement gel with reinforcement and shrinkage pressure friction. There has been a growing interest towards coupling due to the emergence of periodic reinforcement [7]. Besides, it was found that gripping forces generate significant friction on the contact surface. The emergence of twisted and spinned reinforcement causes a material and concrete to interact in particular ways [2]. Tangential adhesive strains and area lengths were obtained as a result of measuring normal strains in reinforcement.

As a result of the studies by A. A. Oatul it was found that coupling is characterized with mutual shift of reinforcement in relation to concrete [4]. Besides, T. I. Astrov identified the dependence of g on the axial strains σ-g on the reinforcement. In the meantime А. I. Semenov and G. Rehm were able to find the dependence of relative deformations of rope reinforcement and concrete on the contact surface on the section under discussion [16].

Using a microscope, G. N. Sudakov conducted an experiment in order to identify mutual shifts by observing shifts of special references fixed on concrete and reinforcement [5]. Throughout the loading the reinforcement was observed using special holes located at a certain step in the concrete along the reinforcement. However, later on G. N. Sudakov discovered the methods of optically sensitive pavings that allowed shifts and deformations to be identified only on the surface of the samples [5]. V. G. Diatovskiy, S. A. Madatyan, А. А. Оаtul, etc. excluded failure of reinforcement-concrete contacts [1, 4].

Currently a lot of authors are of the opinion that numerical modeling is the most efficient method of studying coupling of materials.

Along with a wide range of methods of studying adhesion, a phenomenological approach to mathematical analysis of experimental results based on a series of simplifying prerequisites proved to be popular. It has also become possible to conduct in-depth studies of con- crete-reinforcement interaction. Interaction of materials is presently viewed in the context of numerical methods [4, 5].

7

Russian Journal of Building Construction and Architecture

P. P. Nazarenko found [3] that the behavior of coupling of reinforcement with concrete under long-term dynamic and cyclic interactions as well as short-term loads can remain unchanged. However, no particular attention has been paid to coupling under significant loads. Besides, use of phenomenological laws of coupling is limited as they only apply to a certain reinforcement type. V. G. Kolbasin, S. A. Madatyan, T. D. Tuleev and N. N. Surikov believed that a change in the profile of a bar reinforcement has a significant influence on the coupling of bars with it as there are also changes in the character of the profile and surface on the reinforcement [1].

Up to date, there has been no comprehensive theory regarding coupling of reinforcement and concrete. Therefore it is of importance to develop relevant theories of interaction of materials to account for a whole range of factors.

Therefore this study looks at an analytical model designed using artificial neural networks NN for predicting a strength limit of the coupling τсц of ferroconcrete. For that purpose, experiments were conducted to test pulling of bars out of concrete prisms. The dataset obtained experimentally by means of independent variables employed for developing a predicting model NN included strength characteristics of concrete (stretching, compression, elasticity modulus), anchorage depth, diameter of the reinforcement, freezing and thawing cycles of the samples, profile and material of the reinforcement bar (metal and composite reinforcement was used). A statistical analysis of the efficiency of the model while predicting a maximum tangential strain was conducted.

1. Description of the experimental dataset. The data of the 20 obtained samples was used in the experiments [8]. The examples of the used data from each sample are presented in Table 1.

Number of

|

|

|

|

|

|

|

Таble 1 |

|

|

|

Example of the experimental data used for designing the model |

|

|||||

|

|

|

|

|

|

Profile |

|

|

section |

GPа |

МPа |

МPа |

depth, mm |

impacts |

Maximum |

||

and material of the |

tangential |

|||||||

|

Е, |

Rprism, |

Rstretching, |

Embedment |

External |

|||

the |

|

|

|

|

|

reinforcement bar |

strain, МPа |

|

|

|

|

|

|

|

|

||

1 |

25.1 |

14.3 |

0.9 |

5 |

0 |

1 |

|

|

12 |

||||||||

2 |

28.3 |

17.2 |

1.2 |

5 |

0 |

1 |

|

|

17.44 |

||||||||

3 |

29.6 |

19.7 |

1.5 |

5 |

0 |

1 |

|

|

20.8 |

||||||||

4 |

32.3 |

29.5 |

2.14 |

5 |

0 |

1 |

|

|

24 |

||||||||

5 |

25.1 |

14.3 |

0.9 |

5 |

0 |

2 |

|

|

9.5 |

||||||||

6 |

28.3 |

17.2 |

1.2 |

5 |

0 |

2 |

|

|

10.3 |

||||||||

7 |

29.6 |

19.7 |

1.5 |

5 |

0 |

2 |

|

|

15 |

||||||||

8 |

32.3 |

29.5 |

2.14 |

5 |

0 |

2 |

|

|

17.3 |

||||||||

|

|

|

|

|

|

|

|

|

8

Issue № 3 (43), 2019 |

ISSN 2542-0526 |

Number of

sectionthe

9

10

11

12

13

14

15

16

….

218

219

220

|

|

|

|

|

|

End of Table 1 |

|

|

|

|

|

Profile |

|

Е, |

Rprism, |

Rstretching, |

Embedment |

External |

Maximum |

|

and material of the |

tangential |

|||||

GPа |

МPа |

МPа |

depth, mm |

impacts |

reinforcement bar |

strain, МPа |

|

|

|

|

|

||

30.8 |

24.1 |

1.9 |

5 |

0 |

2 |

|

16.2 |

||||||

30.1 |

23.8 |

1.85 |

5 |

25 |

1 |

|

20.1 |

||||||

30.5 |

23 |

1.81 |

5 |

50 |

1 |

|

22.1 |

||||||

29.2 |

21.8 |

1.7 |

5 |

75 |

1 |

|

18.6 |

||||||

29.2 |

21.8 |

1.7 |

5 |

100 |

1 |

|

17.1 |

||||||

30.1 |

23.8 |

1.85 |

5 |

25 |

2 |

|

21.1 |

||||||

30.5 |

23 |

1.81 |

5 |

50 |

2 |

|

22.1 |

||||||

30.5 |

23 |

1.81 |

5 |

50 |

2 |

|

16.97 |

||||||

….. |

….. |

….. |

….. |

….. |

….. |

|

….. |

||||||

30.5 |

23 |

1.81 |

5 |

50 |

2 |

|

18.23 |

||||||

30.5 |

23 |

1.81 |

5 |

50 |

2 |

|

15.68 |

||||||

30.8 |

24.1 |

1.9 |

4 |

0 |

2 |

|

8.91 |

||||||

|

|

|

|

|

|

|

Note: E is the elasticity modulus of concrete, GPа; Rprism is the prismatic strength of concrete, МPа; Rstretching is the designed stretching resistance of concrete, МPа.

The pulling studies were conducted in accordance with the GOST (ГОСТ) 31938-2012 (Fig. 1).

Tested joint box

Supporting plate

Polyvinyl chloride pipe

Embedment depth |

|

|

|

|

|

Concrete sample |

|||

|

|

|

|

|

|

|

Reinforcement bar |

||

|

|

|

|

|

|

|

|

Sample size |

|

Fig. 1. Samples and scheme of the pulling tests

The prism samples reinforced in the centre with a square section 10 × 10 сm and a lengthdepth ratio of the anchorage l/d = 5 were employed. Bars with the diameter of 10 mm were

9