- •Content

- •Unit 1 Engineering

- •1. Read words and translate sentences with them into Ukrainian:

- •2. Find Ukrainian equivalents of the words:

- •3. Read and translate following word-combinations into Ukrainian:

- •What is Engineering. Realms of Engineering.

- •Vocabulary

- •Word study

- •Comprehension Check

- •People and their positions at the plant

- •Vocabulary

- •Answer the questions

- •Match the position with the description of their responsibilities

- •Say what position would you like to have at the plant and why?

- •Read and memorize the dialogue

- •Notes and commentary

- •Exercises.

- •1. Answer the following questions.

- •2. Write out from the text all the words naming the parts of the equipment you saw at the plant. Learn them.

- •3. Retell Pete’s part of the dialogue in the form of a narration in the first person. Additional vocabulary Склад підприємства

- •Fill in the diagram:

- •Text 2 Engineering Ethics

- •Vocabulary

- •Word Study

- •Comprehension Check

- •Unit 2 Machining. Metal cutting processes and tools.

- •Text 1a

- •Unit 3 General description of lathers.

- •Notes and commentary

- •149 Machine Tools I

- •150 Machine Tools II

- •Unit 4 Types of metal-cutting machines. Tools and materials.

- •Урок 10

- •Урок 11

- •Unit 5 Technology - Growing Fast! What Is Technology?

- •What Is Technology?

- •Technology - Growing Fast!

- •Text 2 Technology - Growing Fast!

- •Future Technology

- •Text 3 Future Technology

- •Grammar Exercises The Infinitive

- •The Participle

- •Контрольні завдання

- •Machinability of metals.

- •Бібліографія:

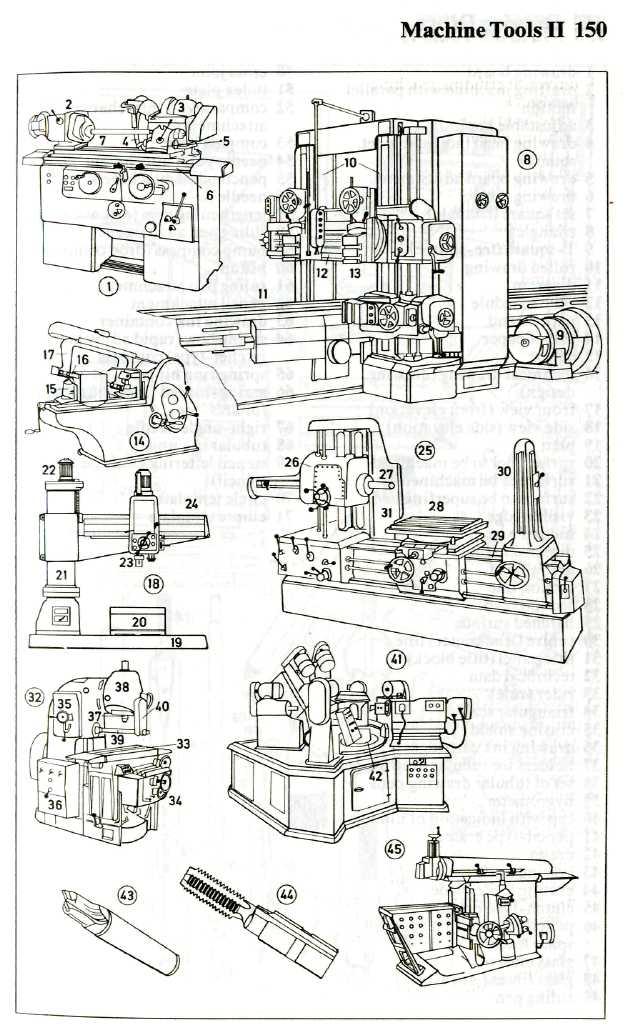

150 Machine Tools II

-

universal grinding machine

-

headstock

-

wheelhead slide

-

grinding wheel

-

tailstock

-

grinding machine bed

-

grinding machine table

-

two-column planing machine (two-column planer)

-

drive motor, a direct current motor

-

column

-

planer table

-

cross slide (rail)

-

tool box

-

hacksaw

-

clamping device

-

saw blade

-

saw frame

-

radial (radial-arm) drilling machine

-

bed (base plate)

-

block for workpiece

-

pillar

-

lifting motor

-

drill spindle

-

arm

-

horizontal boring and milling machine

-

movable headstock

-

spindle

-

auxiliary table

-

bed

-

fixed steady

-

boring mill column

-

universal milling machine

-

milling machine table

-

table feed drive

-

switch lever for spindle rotation speed

-

control box (control unit)

-

vertical milling spindle

-

vertical drive head

-

horizontal milling spindle

-

end support for steadying horizontal spindle

-

machining centre (v4m. center), a rotary-table machine

-

rotary (circular) indexing table

-

end mill

-

machine tap

-

shaping machine (shaper)

Unit 4 Types of metal-cutting machines. Tools and materials.

Завдання l. Уважно прочитайте подані нижче слова та їх переклад. Запам’ятайте їх переклад.

exclusively - виключно, тільки, лише

by means of – з допомогою

to drive (drove, driven) - правити (машиною)

provision - вживания заходів

as well as - так само як

once - раз

to assess – оцінювати

to fit .- пристосовувати

appropriate – відповідній, підхожий

according to –відповідно до

convenient- зручний

flat - плоский, рівний

axis - вісь

plane - площина

either – кожний, будь-який

either…… or – або…….або

to support – підтримувати

to align – вирівнювати

end - торець

hole - отвір

restriction – обмеження

to revolve – обертатися

Завдання 2. Прочитайте та перекладіть подані нижче групи слів. Не забувайте поповнювати таблицю словотворчих елементів.

to shear - shears;

to manufacture - manufacturer;

relative - to relate - to be related - relation - relationship;

line - linear;

accuracy - accurate;

to revolve - revolving – non-revolving- revolution.

Завдання 3. Дайте українські еквіваленти поданих нижче слів. Не забувайте доповнювати таблицю словотворчих елементів.

power-driven machines; to cut by abrasive action; machine tool manufacturer; operation of all machines; on the other hand; the key to understandings; in this light; to generate a surface of rotation; a flat surface; linear movement; cutting edge; axis of rotation; theoretically perfect machining; to move in a single plane; drilling, machine, milling machine, unidirectional machining.

Завдання 4. Уважно прочитайте текст 7А. Постарайтеся якомога точніше та повніше зрозуміти його зміст:

TEXT 7A

Conventional machining today is almost exclusively performed by means of machine tools, which are power-driven machines that have provisions to hold and move the workpiece as well as to hold and move a cutting tool. Once the machining requirements have been assessed, the Job is fitted to the most appropriate machine available*.

Traditionally, machine tools are grouped according to the Kinds of cutting they perform. All machines that cut by abrasive action, for example, are classified as grinding machines. Other familiar groups include lathes, milling machines and shears. Such classifications are usually convenient for the machinist and the machine tool manufacturer - the technology and operation of all machines in any one class are usually closely related.

On the other hand, the key to understanding what machine tools are and how they work is not in knowing that certain machines "grind" and others "make chips"*. Machine tools are best described by how the workpiece is held and what the relative movements are between the part and the tool.

In this light, mechanical machine tools can be grouped into two large families: those that generate surfaces of rotation and those that generate fiat or formed surfaces by linear movement.

To generate a surface of rotation, the workpiece must be rotated while one or more cutting edges generate their form on the surface of the part. This typical geometric relationship between the workpiece, axis of rotation, and centerline of the cutting edge is commonly found in most turning machines and cylindrical grinders. The centerline of the workpiece, the axis of rotation, and the cutting edge must all lie in the same plane for theoretically perfect (or 100% accurate) machining.

To generate a flat or formed surface by linear movement, either the table supporting the part moves or the cutting edge moves in a single plane*. Milling machines and surface grinders, for example, utilize their geometric relationship between the cutting edge and the workpiece.

Drilling is a special condition that fits either of the two groups of machine tools*. In lathes, for example, drills are aligned along the axis of rotation, and the nonrevolving drill feeds into the end of the rotating workpiece. So a drilled hole on a lathe is a surface of rotation. On the other hand, drilling in a drilling machine or milling machine is subject to the restrictions of flat, unidirectional machining. The drill rotates and technically generates a, "formed" unidirectional surface.

Завдання 5. Поясніть виходячи з тексту, значення термінів:

table (worktable), grinder.

Завдання 6. Визначте, які з поданих нижче речень відповідають змісту тексту:

1. Machine tools are usually discussed according to traditional family groupings, emphasizing the two major metal-removal methods grinding and cutting.

2. Machine tools were developed and refined to satisfy a specific manufacturing need.

3. Machines vary from small hand-held drilling or grinding

devices to large, automatic multioperation machine-tools.

4. How easily and how accurately a surface can be machined depends on how well the surface can be matched to ( відповідати) the movements of the machine and the cutting edge of the tool.

5. The machines which hold the cutting tools and in some cases

the workpieces, and furnish the power for cutting, vary greatly in size and configuration.

6.Then the machines are regrouped - not according to the type of tool used, but by how the workpiece is held and carried on the machine.

7. The drill usually produces a hole, while the boring machine finishes an existing one.

Завдання 7. Виберіть правильний варіант продовження поданих нижче речень у відповідності до змісту тексту:

1. All machines that cut by abrasive action are classified as:

a) lathes

б) milling machines;

в)grinding machines.

2. Classifications of machine tools according to the kind or

cutting they perform are usually convenient for:

а) the machine tool manufacturers;

б) the machinist;

в) explaining how machine tools work.

3. The key to understanding what machine tools are and how they work is in knowing:

а) how the workpiece is held;

б) that certain machines grind and others make chips;

в) what the relative movements are between the part and the tool.

Завдання 8. Поставте подані нижче речення в порядку розгортання теми тексту:

1. Traditionally machine tools are classified according to the kind of cutting they perform.

2. Machining is very important for our industry because 4/5

(four fifths) of all manufactured parts should be machined.

3. But this traditional classification does not help explain how machine tools work.

4.To obtain a good surface finish the workpiece should be geometrically oriented with the movements of the cutting edge.

5. Machine tools are best described by how the workpiece is held and what the relative movements are between the part and the tool.

6. Machining is performed by special power-driven devices called machine-tools.

Завдання 9. Розбийте текст на смислові частини та дайте назву кожній з них.

Завдання 10. Дайте заголовок до тексту.

Завдання 11. Напишіть стислу (5-6 речень) анотацію тексту 7А.

Завдання 12; Випишіть з тексту речення позначені (*).

Завдання 13. Перекладіть подані нижче фрагменти речень, звертаючи увагу на модальні дієслова та пасивну форму присудка:

Parts must be machined, before they are completed……; these parts should be designed so that they can be machined easily and economically...; how to design parts that can be machined easily...; how easily a surface can be machined....; how well the surface can be matched to the movements of the machine….; the workpiece must have locating surfaces... .

Завдання 14. Складіть схему класифікації металообробних верстатів. Зробіть усне повідомлення, користуючись цією схемою.

Завдання 15. Прочитайте та перекладіть текст 7Б, користуючись словником.

TEXT 7Б

Many machine tools generate shapes with simple linear movement. Basically, they use cutting tools to saw or slit; to machine flat, square, or parallel surfaces: or to generate long, linear forms such as keyways, splines, or channels.

Milling machines are the most common metal-cutting machine tools in the category. During milling a horizontally rotating hardened toothed cutter shears large amounts of metal from its path as the part passes by on a moving worktable.

Surface grinding machines are often used to generate flat or linear surfaces on closely toleranced parts and to cut hardened or hard-to-machine metals. In most machines, the workpiece reciprocates bасk and forth while the spinning grinding wheel slowly drops down on the workpiece surface.

Most precision-machined surfaces are surfaces of rotation. Bearings, shafts, pistons, and cylinders, for example, are all surfaces generated by rotating the workpiece about an axis and applying a grinding wheel or a cutting tool. Under these conditions, the generated surface is always concentric about the axis of rotation. Common machine tools of this type include the diverse lathe family (including the vertical boring mill), and cylindrical grinding machines.

In general, machines in this group can perform any of three operations. They can move a cutting tool parallel to the axis of rotation (as when single-point turning or grinding a diameter for example). They can move a cutting tool radially into the part . (as when forming a diameter or when removing metal from the end of a part-commonly called "facing"). Or they can move the cutting tool into the face of the part along the axis of rotation.

Any metal cutting machine that rotates the workpiece and applies a forming or single-point tool to the surface to be machined is a "turning machine". The basic turning machine - and probably the oldest precision metalworking machine tool - is the lathe. Until the advent of the cylindrical grinder, lathe turning was the most accurate metalworking process available. Production cylindrical grinding, however, is usually ten times more accurate and repeatable than most turning operations.

Завдання 16. Прочитайте та дайте українські еквіваленти поданих нижче слів та словосполучень:

а) Keyway, spline, channel, path, shaft, face, facing;

б) horizontally rotating; toothed cutter; a moving worktable; surface grinding machine; closely toleranced parts; to reciprocate back and forth; spinning grinding wheel; vertical boring mill; precision-machined surfaces; cylindrical grinding machine; forming tool; single-point tool; production cylindrical grinding; accurate metalworking process; axis of rotation.

Завдання 17. Перекладіть такі фрагменти речень, звертаючи увагу на не особові форми дієслова:

…..they use cutting tools to generate long linear forms;…..surfaces generated by rotating the workpiece about an axis and applying a grinding wheel or a cutting tool;. .....including the vertical boring mill;.....as when forming a diameter or when removing metal from the end of a part...; …... the surface to be machined.

Завдання 18.Дайте відповіді на такі запитання:

1. What are the two major types of surfaces?

2. What machines are used to generate linear surfaces?

3. What is the peculiarity of processing surfaces of rotation?

4. What are the common machine tools used to generate surfaces of rotation?

5. What are the three operations performed by these machines?

6. What is the oldest precision metalworking machine tool?

7. What can you say if you compare lathes and cylindrical grinders?

Завдання 19.Прочитайте зміст тексту схематично.

Завдання 20: Розділіть подані нижче речення в порядку розгортання їх теми:

1. Forming is a fast way to generate intricate shapes on a workpiece, but the forming tool may be costly.

2. Machine tools generate surfaces in two ways: either by "forming" or by feeding the cutting tool in and out along the length of the part.

3. A tool with a notch (паз) in its cutting edge for example, generates a raised rib on the workpiece.

4. Forming, then, transfers the exact shape of the tool to the workpiece in one tool movement.

5. Either concept can be applied to grinding, turning, milling, and other common machining processes.

6. Tools for forming are specially ground to reflect the shape of the finished part.

7. And as the forming cutter wears down unevenly, the shape generated on the part may change.

Завдання 21. Передайте зміст тексту рідною мовою.

Завдання 22. Зробіть переказ.

УРОК 8

Завдання 1. Уважно прочитайте подані нижче слова та їх переклад, запам'ятайте їх значення.

self - само-себе

to explain - пояснювати

honing – хонінгування

blade - лезо, клинок

to vary - різнитися, змінюватися

straight [streit] - прямий

bent - зігнутий

offset - зміщення

to reach - діставати, досягати

solid - твердий .

insert- вставка

to attach - прикріплювати

to sinter - спікати(ся)

to fasten - прикріпляти

shank - хвостовик

groove - жолобок, виїмка, паз

stock - запас, матеріал

to break (broke, broкen) - ламати (ся), .зламувати

curl - локон, звивина

to manage - управляти, справлятися

to dispose (of) - розпоряджатися

to secure - укріпляти

to contribute (to) - сприяти (чомусь), робити внесок

slab - плоска заготовка

helical - спіральний

whilst - поки, доки, тоді як

layer – шар

tapping - нарізка, різьблення мітчиком

thread - різь, нарізка

to cause - завдавати, спричиняти

Завдання 2. Прочитайте та перекладіть такі слова та словосполучення:

а) to adapt, to intend, series, term;

б) sharp - to sharpen; cutting tip = cutting edge;

в) multi-point tool; honing stone: cutting action; area of machining; high-quality steel; sintered carbide; self-explanatory term; chipbreaker; twist drill; slab milling cutter; complicated action; broaching tool; tool shank; helical broach; gradually increasing thickness; workpiece (worn) material; desired thread shape; relative motion.

Завдання 3. Уважно прочитайте текст 8А. Спробуйте: якомога точніше та повніше зрозуміти його зміст:

TEXT 8А

Practical cutting tools mаy be divided into two categories: (1) single-point tools; (2) multi-point tools. These terms are self-explanatory.

Single-or multiple-point cutting tools, including broaching tools, milling cutters, honing stones, abrasives, and saw blades, are common forms of cutting devices. Although varied in configuration, the basic cutting action performed by each is much the same.

Single-point tools vary, in design, each adapted to the operation for which it is intended. The tool may be straight, bent, offset, or have some other special form that will enable its cutting tip to reach the desired area of machining. The tool may be made from one solid piece of tool steel with the cutting edge round on the end, or it may have an insert or tip attached to it to provide a harder cutting surface. The insert may be a piece of high-quality tool steel or a special material such as sintered carbide and be brazed, welded, or fastened to the tool shank by mechanical means.

Tools may be sharpened or shaped by grinding, and inserts may be replaced or rotated when chipped or worn. Frequently a groove or irregularity is ground in the face of the tool behind the cutting edge. This groove, called a chipbreaker, causes removed stock to manage into chips or small curls, thus becoming easier manage or to dispose of.

Any multi-point cutting tool can be regarded as a series of two or more single-point cutting tools secured to a common body. The relative motion between workpiece and tool is such that each tool point contributes to the removal of workpiece material. For example, a twist drill mar be regarded as two single-point cutting tools fixed to а common shank which is rotated about its axis. As the drill is fed in a direction parallel to its axis each cutting edge should remove an equal share of the work material.

The slab milling cutter also has a rather complicated action. Here the cutter, which has a number of lone helical cutting edges, is rotated whilst the workpiece is fed past the cutter. Each cutting edge removes a layer of material of gradually increasing thickness.

A broach is a further example of a multipoint tool. In broaching the tool is forced past the workpiece at low speed and each broach tooth removes a small layer of the work material.

A process similar to that of broaching is the tapping process. Here the tap, which at its lower and may be likened to a helical broach, is fed and rotated into a prepared hole. Each cut tine edge removes a small layer of metal to form the desired thread shape.

Завдання 4. Визначте, які з поданих нижче речень містять додаткову до тексту 8А інформацію:

1. a multi-point cutting tool can always be regarded as several single-point tools Joined together and constrained to move in such a way that each individual tool contributes to the process of metal removal.

2. Single-point tools consist usually of a piece of material of rectangular section caned the shank on one edge of' which are ground the faces and flanks which, intersect to form the cutting edges.

3. The tool and the workpiece are held in the machine tool in such a way that when the appropriate motions are applied be the machine, the tool point (i.e. the end of the tool on which the cutting edges are formed) generates the desired shape of the workpiece.

4. A second type of cutting device commonly used on such power tool as milling machines, horizontal boring machines, etc. is the revolving multitoothed cutter.

5. Multipoint cutters are made in many destine, each to perform efficiently a certain operation.

Завдання 5. Користуючись текстом 8А та завданням 4, дайте відповіді ва запитання:

1. In what way are practical cutting tools classified?

2. What is the difference between a single-point tool and a multipoint tool?

3. What is the tool point?

4. Why are single-point tools of various forms?

5. What is the aim of us me inserts?

6. What is a chipbreaker?

Завдання 6. Випишіть з тексту ключові слова.

Завдання 7. Випишіть з тексту речення, позначені-зірочкою (*). Перекладіть, їх.

Завдання 8. Розбийте текст на частини та дайте назву кожній з них.

Завдання 9. Перекажіть текст за складеним планом, користуючись ключовими словами.

Завдання І0. Прочитайте та перекладіть текст 8Б користуючись словником.

TEXT 8Б

A variety of materials is used to meet the many requirements :of the metal-cutting industries, carbon steel tools having low initial cost are used to machine the light metals, or free cutting steels, with light cuts at low speeds. They retain their hardness up to temperatures of 400 F. High-speed steel tools of many types the work-horses of industry. Their cost is several times that carbon steel tools, but they permit, cut tine speeds about twice those of carbon steel and withstand temperatures up to 1000 F*. Tungsten-base and molybdenum-base high speed steels, each having chromium and vanadium and sometimes cobalt and other metals added, fill special requirements*.

Tools of sintered carbide are still more expensive than those of high-speed steel*. They have greater hardness with working -temperature limits up to 1800 F. Tools of this kind will machine steels of average hardness 4-8 times as those of high-speed steel*.They will machine very hard metals satisfactorily. Being less ductile than the tool steels, they must be carefully designed and supported to prevent chipping or fracture. Because of their high cost they are used as tips, small formed pieces which are brazed or clamped into rigid steel shanks. Present practice in high quantity production is to use small, thin, indexible tips of triangular, square, or circular profile, clamped to strong shanks. When the cutting points on both faces are worn, the tip is thrown away rather than resharpened. This reduces or eliminates the expensive diamond-wheel grinding.

Industrial diamonds are also used to machine metals at light cuts and high speeds up to 100 ft/min and produce high dimensional accuracy and superior surface finish. Ceramic materials, called cermets and cemented oxides, permit high cutting speeds (1000-15.000 ft/min) with light cuts, speeds of 1000-3000 ft/min are more practical for the thin indexing, throw-away types.

Завдання 11. Прочитайте та перекладіть рідною мовою такі слова та словосполучення:

a) to retain, to prevent, chipping, to clamp, trianguiar, cermet (ceramal), cemented, to resharpen;

6) initial cost; freecutting steel: work-horses of industry; to withstand temperatures up to 1000 F; rigid, steel shank; tungsten-base high-speed-steel; working temperature limits; circular profile; diamond wheel grinding industrial diamonds; cemented oxides; high dimensional accuracy; thin indexing throwaway types! to meet the requirements; high

quantity production.

Завдання 12. Розставте речення таким чином, щоб отримати переказ

тексту.

1. Tools of sintered carbide machine very hard metals satisfactorily, but because of their high cost they are usually used as tips.

2. A number of materials are used to meet the requirements of the metal cutting industries.

З. Though high-speed steel tools are much more expensive than carbon steel tools they are the work-horses of -industry as they permit high cutting speeds and withstand high temperatures.

4. Industrial diamonds provide superior surface finish and, high dimensional accuracy at light cuts and high speeds.

5. Besides all these materials there are some ceramic materials, called cermets, used to machine metals.

6. Carbon steel tools are very cheap and are used to machine the light metals at low speeds and comparatively low temperatures.

Завдання І3. Визначте, чи відповідають змісту тексту такі твердження:

1. Carbon steel tools retain their hardness up to temperatures of 1000 F.

2. High-speed steel tools permit cutting speeds al out twice those of carbon steels and are very cheap.

3. Tools of sintered carbide permit very high cutting speeds. Sintered carbide tips are usually resharpened when then cutting points are worn.

5. Industrial diamonds permit to produce high dimensional accuracy.

Завдання І4. Виправте хибні твердження із завдання І3

Завдання 15. Дайте заголовок до тексту 8Б.

Завдання 16. Перекладіть речення, позначені в тексті зірочкою звертаючи особливу увагу на виділені їх частини.

Завдання 17. Користуючись даною схемою, розкажіть про використання різних матеріалів для виготовлення металорізальних інструментів:

Cutting tool materials:

Metals: Non-ferrous – Satellites.

Ferrous: High steel – carbon – high speed steel.

Non-metals: Metallic carbides - Aluminium oxides - Diamond

Завдання 18. використовуючи тексти уроку, підготуйте письмове повідомлення на тему "Типи металорізальних інструментів та матеріали, які використовуються для їх виготовлення" (обсяг - 10 тис. знаків).

УРОК 9

«Взаємозв'язок між величиною основних кутів різання, строком служби інструменту та якістю обробки".

Завдання 1. Уважно прочитайте подані нижче олова та їх переклад. запам'ятайте їх значення:

steady - стійкий, постійний

state - стан

friction - тертя

presence - присутність, наявність

to lead (to) - призводити (до)

to build up - наварювати, наплавляти

pile - нагромадження

severe - суворий

to occur - траплятися, зустрічатися

tо carry away - відносити, захоплювати

Завдання 2. Прочитайте та перекладіть групи слів, доповніть таблицю словотворчих елементів:

continuous - discontinuous;

table - unstable;

side – underside;

to go – to undergo.

Завдання 3. Дайте-українські еквіваленти таких словосполучень. Прочитайте їх:

Cutting conditions; continuous chip: discontinuous chip formation; mild steel; under these conditions; a “steady state” process; under some conditions; welds itself to the tool face; layer upon layer; the resulting pile of material; a built-up edge; one of the principal factors; to undergo severe strain; primary deformation zone; high rates of feed.

Завдання4. Уважно прочитайте текст 9А. Постарайтеся якомога точніше та повніше зрозуміти його зміст:

TEXT 9А

The type of chip produced during metal cutting depends on the material being machined and the cutting conditions used. Continuous chip is common when machining most ductile materials such as wrought iron, mild steel, copper and aluminum. Cutting under these conditions is a "steady state" process.

Under some conditions the friction between the chip and tool is so treat that the chip material welds itself to the tool face. The presence of this welded material further increases the friction and this leads to the building up of layer upon layer of chip material. The resulting pile of material is referred to as a built-UP edge.

Often the built-up edge continues to grow and then breaks down when it becomes unstable, the broken pieces being carried away by the underside of the chip and the new workplace surface. A study of built-up edge formation in metal cutting is most important as it is one of the principal factors affecting surface, finish.

During the formation of a chip the material undergoes severe -strain and if the work material is brittle, fracture will occur in the primary deformation zone when the chip is only partly formed, under these conditions the chip is segmented and the condition is referred to as discontinuous chip formation. Discontinuous chips are always produced when machining such materials as cast iron or cast brass but mar also be produced when machining ductile materials at very low speeds and high rates of feed.

Завдання 5. Назвіть номери абзаців, які містять відповіді на такі запитання:

1. What does the chip type depend on?

2. What kind of chip is formed when ductile metals are being machined?

3, What happens when the chip material welds itself to the tool face?

4. Why is the built-up edge formation one of the principal factors affecting surface finish?

5. Under what conditions are discontinuous chips formed?

Завдання 6. Визначте в тексті ключові слова.

Завдання 7. Напишіть стислу (4-5 речень) анотацію тексту.

Завдання 8. Письмово перекладіть 2-й та 3-й абзаци тексту, звертаючи особливу увагу на переклад термінологічної лексики.

Завдання 9. Прочитайте текст. Чи містись він додаткову до тексту 9А інформацію? Яку? Розташуйте цю інформацію у тексті 9А.

The type of chip produced depends upon the properties of the metal being cut. Discontinuous chips are produced when a brittle material is cut. Continuous chip is produced when a ductile metal is cut.

When the cutting edge of the tool shaves the surface smooth, the thin slivers (стрічки) of metal that are removed are trapped between the chip and the tool face. The combination of pressure, heat and chemically clean, freshly cut surface results in the ideal conditions for pressure welding. This, in fact, occurs and the slivers of metal become welded to the tip of the tool forming a built-up edge.

Chip welding can be prevented by adopting one or more of the following precautions (застережні - заходи):

1. Preventing an intimate metal to metal contact by using a suitable lubricant (мастило);

2. Selecting a cutting tool/workplace material combination that does not have an affinity (потяг) for each other;

3. Reducing the pressure between the chip and the tool.

Завдання 10. Використовуючи текст 9А. текст із завдання 9 та запитання із завдання 5, зробіть усне повідомлення на тему уроку.

Завдання 11. Прочитайте текст 9Б та перекладіть його, користуючись словником.

TEXT 9Б

We are not completely certain what happens when metal is cut, despite an the research that has been and is being carried out. However, certain fundamental principles have emerged which. If adhered to will ensure reasonable success*.

One of the first cutting actions that we perform must be the sharpening of a pencil with a penknife. It is unlikely that any formal instruction is received before our first attempt, but by trial and error we soon find that the knife blade must be presented to the wood at a definite angle if success is to be achieved*. This anile is called the clearance angle. The clearance angle also reduces friction and, 'therefore, increases the life of the tool.

If in Place of the wooden pencil, a piece of soft metal such as brass is cut, it will be found that the cutting edge of the blade soon becomes blunt. If this edge is examined under a magnifying class, it will be seen that the edge has crumbled away. For the blade to cut brass successfully, the cutting edge must be sharpened at a less accurate angle to give it greater strength*. The angle to which the blade is round is caned the tool angle or wedge angle.

The greater the tool angle, the stronger will be the tool*. Unfortunately, the greater this angle is made, the greater will e the effort required to force the tool through the material being cut.

To complete the angles associated with cutting tools, reference must be made to the ankle which is called the rаkе angle. This is a very important angle for it alone controls the geometry of the chip formation for any given material, and therefore controls the mechanics of the cutting action of the tool.

Завдання 12. Прочитайте та перекладіть подані слова та словосполучення:

а) to happen, to emerge, to adhere to, angle, blunt, to crumble away;

б) to be certain: certain fundamental principles; to ensure reasonable success; by trial and error; life of the tool; in place of; to examine under a magnifying glass; reference must be made to.

Завдання І3. Дайте визначення таких понять:

clearance angle; tool angle (wedge angle); rake angle.

Перекладіть наведені терміни.

Завдання 14. Випишіть з тексту речення, позначені зірочкою. Письмово перекладіть їх, звертаючи увагу на значення особових та не особових форм дієслів, дайте пояснення.

Завдання І5. Підготуйте усне повідомлення на тему: «Взаємозв'язок між величиною основних кутів різання, строком служби інструменту та якістю обробки".

"Змащувально-охолоджуючі речовини та їх використання при механічній обробці металів"