- •Ministry of Education and Science of Ukraine

- •Methodical instructions for accomplishment of the course paper

- •1. Introduction

- •2. Structure of the course paper

- •3. Contents of the course paper parts

- •3.2.1. Choice of material and specimens type for pendulum-type impact machine testing, determination of impact toughness

- •3.2.2. Description and estimation of a fracture type

- •3.2.3. Estimation of influence of impact specimens notch radius on fracture character

- •3.2.4. Determination of cold brittleness temperature by means of serial dynamic bending tests

- •Appendix 1 task

- •Appendix 2 impact toughness data values after the test of impact specimens kcu (type ι)

- •Kcv (type IV)

- •Appendix 3 macrophotographs of fractures

- •Appendix 4 microphotographs of fractures

- •Appendix 5 design regulations of the course paper

- •Introduction

- •Introduction

- •Rules of the explanatory note execution

- •Illustrations

- •VOcabulary

- •1. Introduction 3

- •2. Structure of the course paper 5

- •3. Contents of the course paper parts 6

3.2.3. Estimation of influence of impact specimens notch radius on fracture character

Impact bending test of notched specimens is the sensible control method that reacts to the change of metal state. Usually, the impact tests are the addition to the static tests of smooth and notched specimens.

Notch is very an important factor that increases probability of metal transition into brittle state. The presence of notch causes the uniform volume tension, lowers the part of tangential stresses. As a result, the plastic deformation caused by these tensions diminishes. This effect promotes transition of metal into brittle state.

Impact bending test of prismatic specimens with a notch at 20С on pendulum-type impact testing machines is the most handy and simple method of the mass control. A specimen freely lying on two bearings is tested by applied falling pendulum-type impact testing machine at the middle load. A notch is disposed on a side that will be tensed.

As it was pointed earlier, the basic type is a specimen of type Ι with sizes 101055 mm. It has U-notch with a radius of 1 mm and depth of 2 mm. A specimen of type IV with a notch of radius 0,25 mm and depth 2 mm, can also be used as an additional one according to the GOST. Production method can influence the impact toughness. Shallow, but rather sharp feed marks are left after milling notch preparation. They are located perpendicular to tensile forces and as a result, minimal impact toughness appears. Feed marks that appear at drilling notch preparation and are parallel to specimen axis have the maximal impact toughness. Notch grinding leads to intermediate values of impact toughness.

Impact toughness аn consists of two constituents: work of formation аf and growth of crack аg or:

аn= аf + аg

This equation is the formula of impact toughness constituents. This is a methodical basis of determination of energy expenditure at separate stages of destruction at impact bending test.

At the division of impact toughness in constituents with notch radius of 1 mm, work ag is less than аf, and this difference increases with the test temperature decrease. When absolutely brittle failure takes place, the impact work аn is determined by the work of crack formation because fracture energy is close to zero. Determination of impact toughness in the case of soft notch mainly allows to get information about the work of failure formation.

The sharp notch noticeably decreases the work of crack formation аf while the work of crack growth ag does not change practically. Resistance of a metal to crack growth is the most important characteristic of toughness. This value limits an ability of ductile-brittle transition of metal. The tests of impact specimens with the sharpest notches allow to describe of metal resistance to the crack growth more completely. The tests of specimens with notches in the form of cracks give the most complete information about metal resistance to the crack growth.

3.2.4. Determination of cold brittleness temperature by means of serial dynamic bending tests

The serial dynamic bending (impact toughness) test of notched specimens is the most widespread determination method of temperature critical value (ТCR).

This method is widely used at estimation of steel liability to brittleness while working at low temperatures. Low temperatures increase resistance of metals to plastic deformation and rise metals liability to brittle failure. The main aim of impact bending tests at low temperature is to define the minimal temperature at which the metal can work reliably with a small probability of brittle failure formation.

The information received as a in result of conducting of series of impact bending tests at the gradual decrease of FATT is used at serial curves construction. There is a sudden lowering of impact toughness at a certain temperature (temperature interval) called the critical brittleness temperature. The critical brittleness temperature is a comparative characteristic of metal liability to brittle failure at low temperatures.

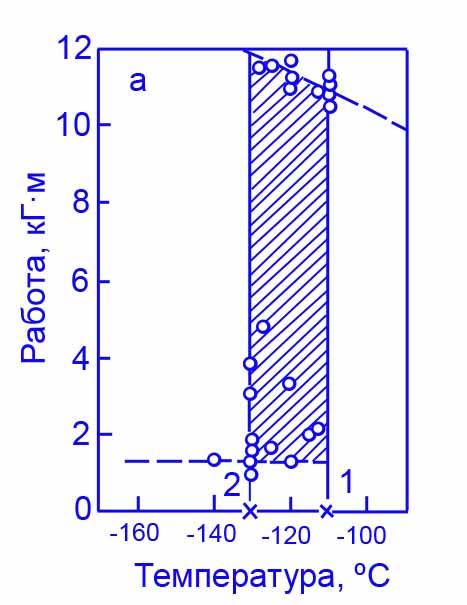

The ductile-brittle transition in a short critical temperature interval appears as a result of serial tests of round unnotched specimens (fig. 3.6 a).

The point 1

determines the beginning of transition, and a temperature

corresponding to this point is called the upper boundary of

cold-brittleness

threshold.

This temperature is taken as cold-brittleness

threshold

and is denoted as

![]() .

The

point 2 corresponds to the end of ductile-brittle transition. The

temperature at this point is called the lower boundary of

cold-brittleness

threshold.

.

The

point 2 corresponds to the end of ductile-brittle transition. The

temperature at this point is called the lower boundary of

cold-brittleness

threshold.

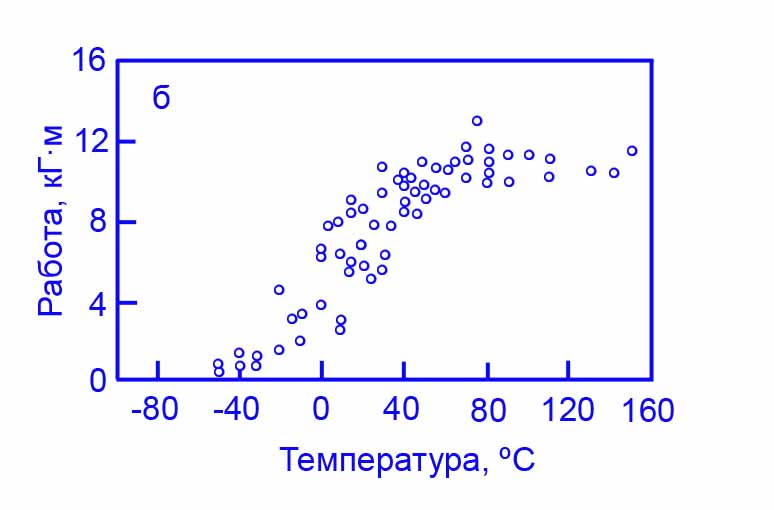

While testing of notched specimens, especially specimens made of ductile materials (for example, low-carbon steels), the ductile-brittle transition takes place gradually in a wide temperature interval (fig. 3.6 б). At determination of for such materials some values of impact toughness are used. On the basis of these values a critical temperature is estimated.

Fig. 3.6. Serial curves of smooth (а) and notched (б) specimens test.

The

following conditions are used in some cases: аn

= nаn

(where 0<n<1), usually n = 0,5 or n = 0,8. Critical

temperatures obtained

on

the basis of these criteria are marked as

![]() and

and

![]() .

The fixed values of impact toughness

(equal

to 2,5 kgmcm2)

are also used. These fixed values are mostly used in west-european

countries while testing specimens

with

the notch radius of 0,25 mm, its critical temperature is

denoted

as

.

The fixed values of impact toughness

(equal

to 2,5 kgmcm2)

are also used. These fixed values are mostly used in west-european

countries while testing specimens

with

the notch radius of 0,25 mm, its critical temperature is

denoted

as

![]() .

The critical value of

ан

= 3,0 kgmcm2

is used in the Soviet practice, its critical temperature is denoted

as

.

The critical value of

ан

= 3,0 kgmcm2

is used in the Soviet practice, its critical temperature is denoted

as

![]() .

.