Chemical Tankers / Day 3 / Day 3 Topic 6 Tank Cleaning Chemicals & Best Industry Practi

.pdf

6.3 Use of cleaning chemicals

Direct injection into tank cleaning system during washing process

This method is used extensively with saving in time and labor, as a number of machines can be operated and consequently a number of tanks wash simultaneously. It is important to calculate the drops of machines to avoid having large “blind” spots which are not cleaned.

6.3 Use of cleaning chemicals

Direct injection into tank cleaning system during washing process

The cleaning agent which is suitable for direct injection method:

• various emulsifying agents and degreasers;

6.3 Use of cleaning chemicals

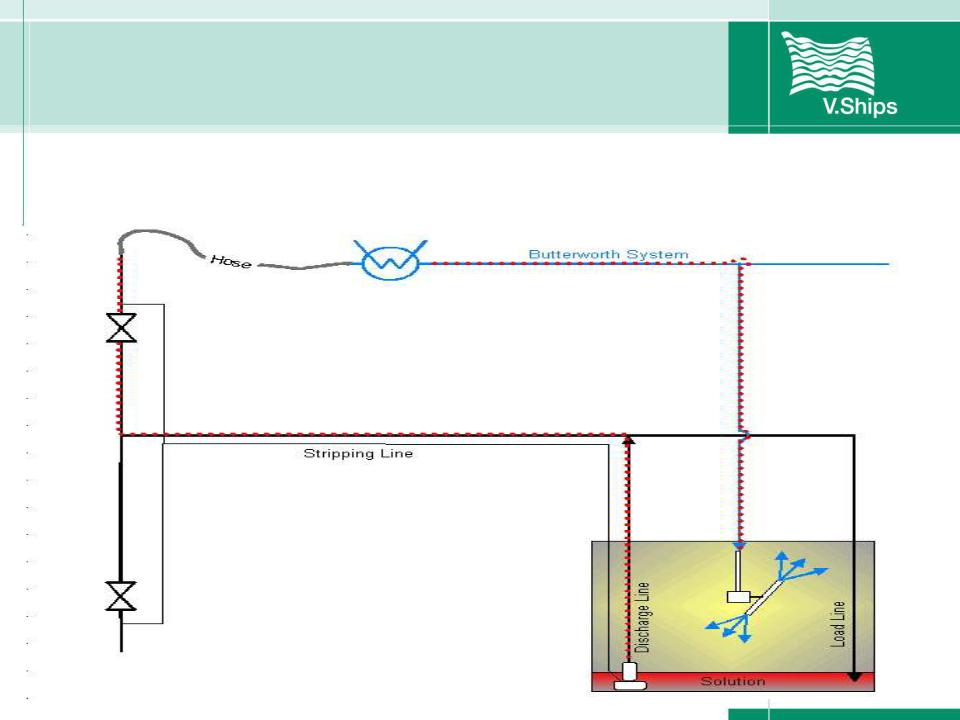

Re-circulation with tank cleaning machines

The re-circulation of a mixture of wash water with cleaning chemicals or with pure cleaning chemicals together with the use of tank cleaning machines is another widely used cleaning method.

6.3 Use of cleaning chemicals

Re-circulation with tank cleaning machines

The water/chemical or pure chemical mixture is circulated through the cargo line system to cleaning machines of the designated tank using the tank cargo pump. This solution can then be used to perform similar cleaning operations to several tanks before a solution to be disposed.

6.3 Use of cleaning chemicals

Re-circulation with tank cleaning machines

It is always advisable to prepare new cleaning solutions rather than add chemicals to an exhausted mixture of wash water and chemicals containing cargo residues. The number of times any one wash water/ chemical or pure chemical can be re-used depend on the condition of the tanks.

6.3 Use of cleaning chemicals

Re-circulation with tank cleaning machines

Usually a 5-10 m3 of water is using for mixture preparation depend on tank size. Heat will, in most cases, assist in the cleaning operations, and heating of the cleaning solution is achieved by the tank cleaning system heat exchanger or the tank heating coils. Re-circulation can also be made via service or storage tank.

6.3 Use of cleaning chemicals

Re-circulation with tank cleaning machines

6.3 Use of cleaning chemicals

Re-circulation with tank cleaning machines

The following cleaning agents are suitable for re-circulation

method:

•Various emulsifying agents and degreasers (Pure or water solution could be made. Water solution should be heated up to 60C);

•Alkaline cleaners (Heat up solution to 50C);

more>>>

6.3 Use of cleaning chemicals

Re-circulation with tank cleaning machines

•Chlorinated solvent (Pure only. No any water inside the tank);

•Butyl Cellosolve (Pure only);

•Acid based or Metal Bright agents (Water solution. Heat up to 50C);

6.3 Use of cleaning chemicals

Hand spraying

The hand spraying method requires that the tank is ready for entry. This method involves spraying undiluted cleaning chemical directly onto the bulkheads, tank bottom, under deck, frames and stringers. This method is very effective, but is very time and manpower consuming both in preparation, execution of the method.