Electronics_Projects_For_Dummies

.pdf

290 Part IV: Good Vibrations

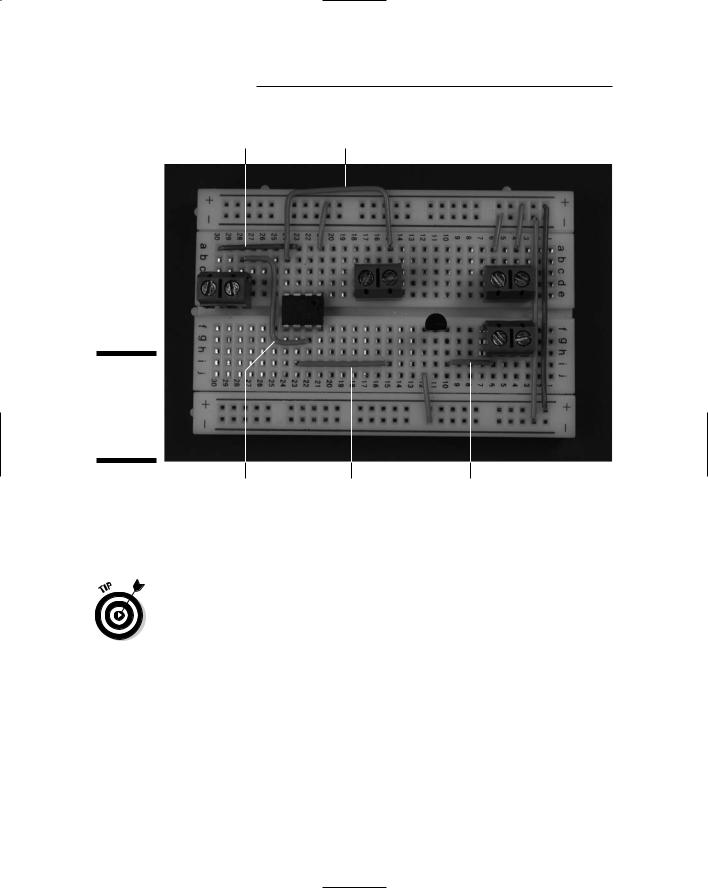

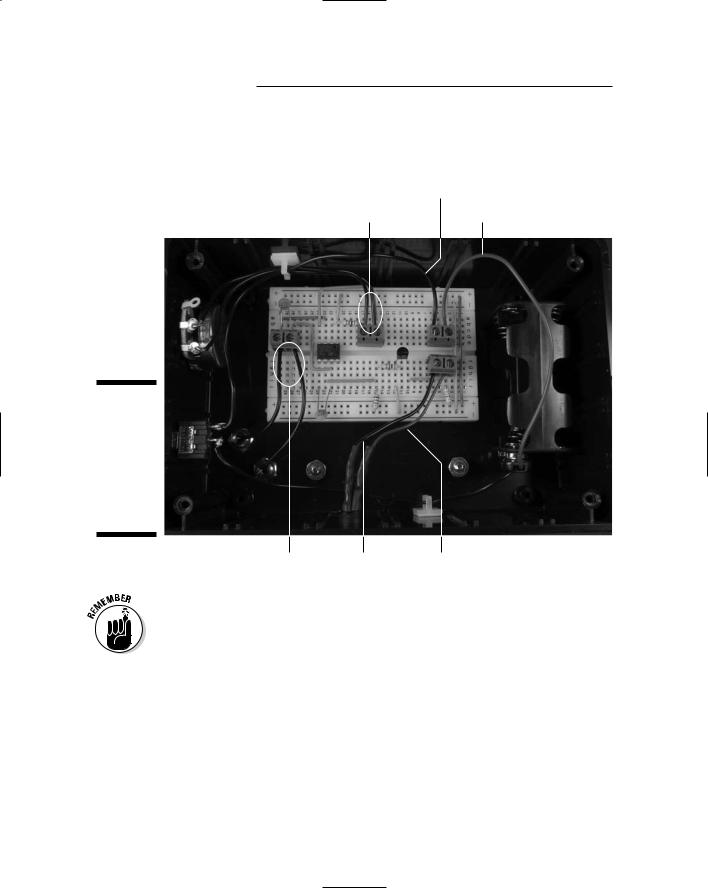

L1 TB |

R2 TB |

to Pin 3 of IC1 |

to Pin 4 of IC1 |

Figure 12-8:

Hook up the ICs, terminal blocks (TB), and discrete components.

L1 TB |

Pin 6 of IC1 |

LED TB |

to Pin 7 of IC1 |

to open region |

to collector pin of Q1 |

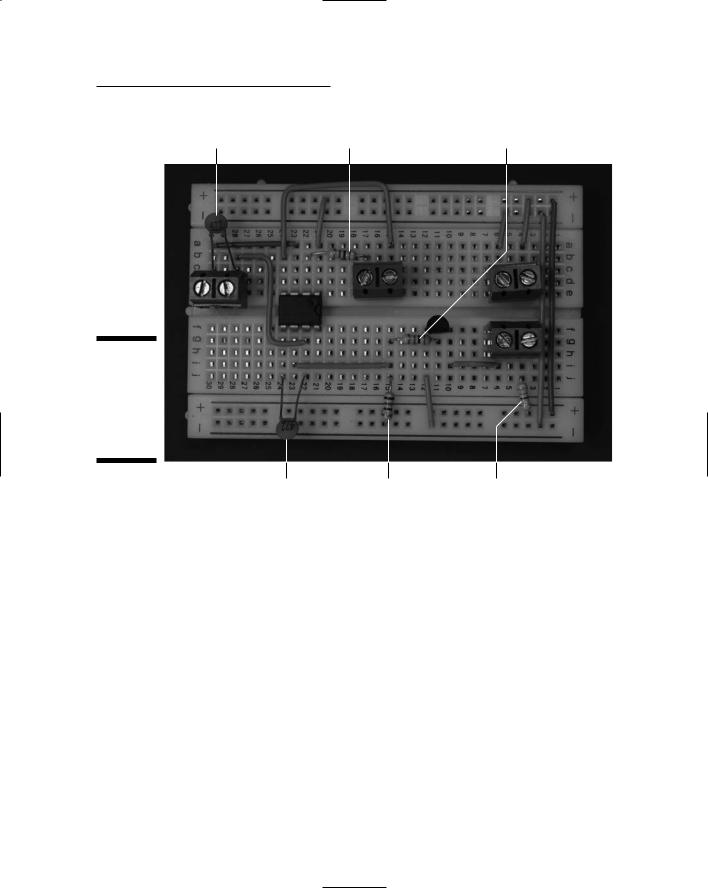

5.Insert two 0.0047 microfarad capacitors (C1 and C2), two 247 ohm resistors (R3 and R5), one 1 kohm resistor (R1), and one 120 ohm resistor (R5) on the breadboard, as shown in Figure 12-9.

We discuss in Chapter 4 how to determine how short to clip the leads of many of these components to make them fit neatly on the breadboard. Make sure you wear your safety glasses when clipping leads!

Chapter 12: A Handy-Dandy Metal Detector 291

C1 between pins |

R1 from Pin 2 |

R4 from base pin of Q1 |

of L1 TB |

of IC1 to R2 TB |

to Pin 6 of IC1 |

Figure 12-9:

Insert resistors and capacitors on the breadboard.

C2 from Pin 5 of IC1 |

R5 from R4 |

R3 from LED TB |

to Pin 7 of IC1 |

to ground |

to +V |

Building the box to house the circuit

The box that houses the circuit needs holes so that you can place the LED, the potentiometer dial you use to adjust resistance on the IC, and the on/off switch as well as various wire connections.

Follow these steps to get the metal detector circuit enclosure ready:

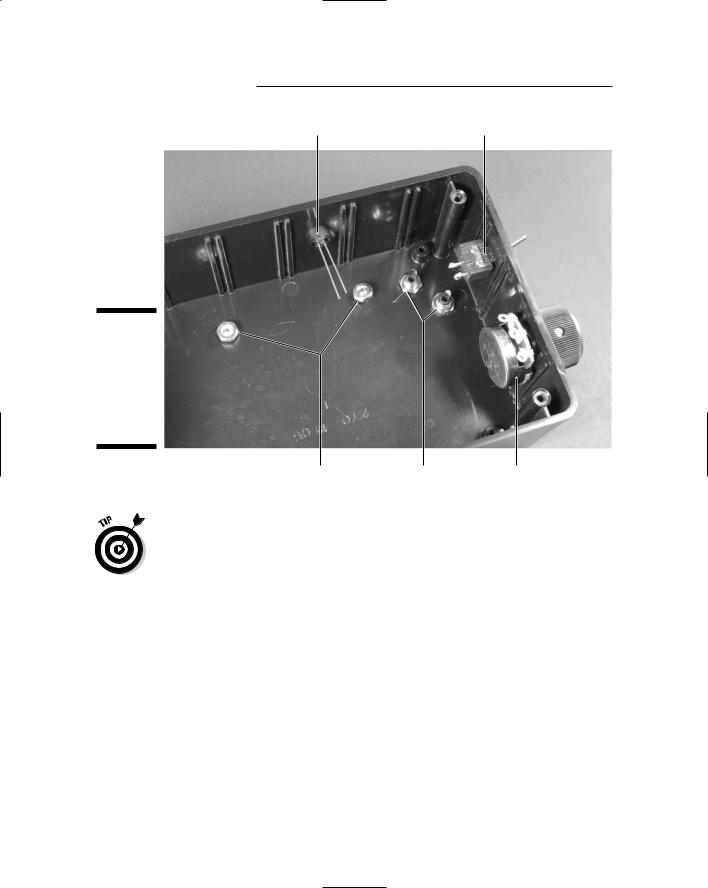

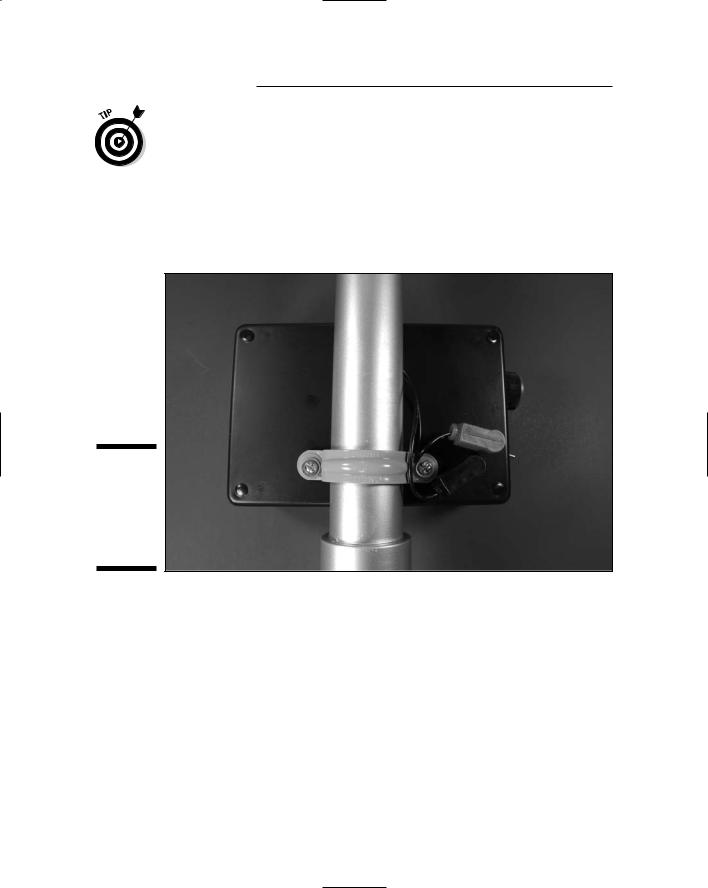

1.Drill holes in the box where you will mount the LED, potentiometer, audio jacks, on/off switch, and clamp.

We put the on/off switch and the potentiometer on one side of the box, the LED on one end, and the audio jacks on the bottom. However, the placement is really up to you. Figure 12-10 shows where we placed these components.

292 Part IV: Good Vibrations

LED |

On/off switch |

Figure 12-10:

Box with on/off switch, phono jacks, potentiometer, and LED in place.

Screws and nuts securing the clamp |

Phono jacks |

Potentiometer |

See Chapter 4 for more information about choosing drill bit sizes for particular components and other advice about how to customize a box for your projects. And guess what? We always advise that you use safety glasses when drilling.

2.Slip the threads of the phono jacks through the drilled holes and secure with the nuts provided.

3.Slip the shaft of the on/off switch through the drilled hole and secure with the nut provided.

4.Slip the shaft of the potentiometer through the drilled hole and secure with the nut provided.

5.Slip the knob on the potentiometer shaft and secure with the set screw.

6.Feed the top half of the LED socket through the drilled hole from outside the box and insert the LED into the top half of the socket from inside the box.

7.Slip the bottom half of the socket over the leads and snap onto the top half of the socket to secure the LED.

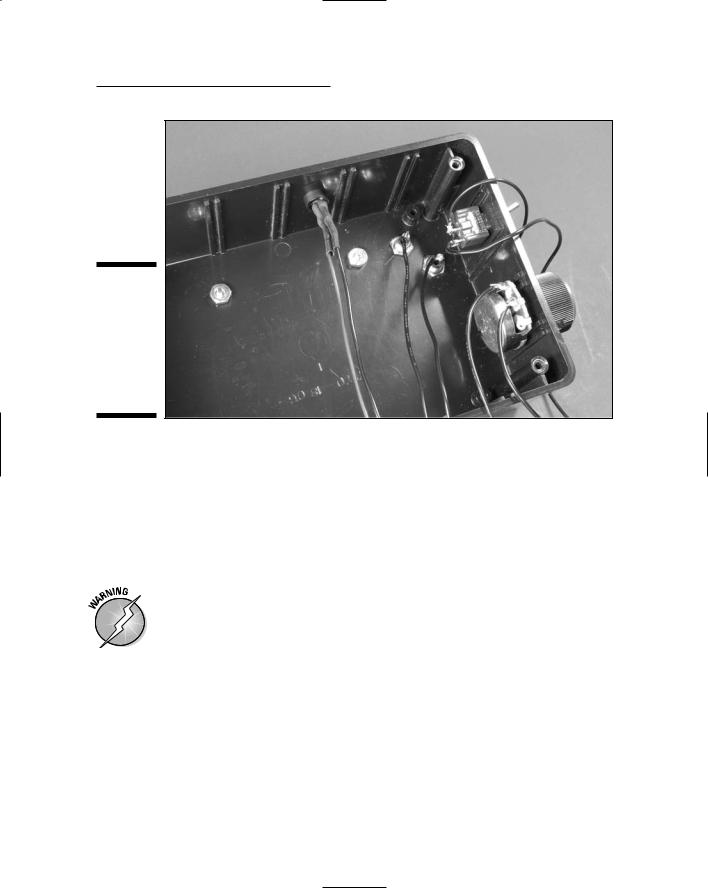

8.Solder the black wire from the battery pack to one lug of the on/off switch and solder an 8" black wire to the remaining lug of the on/off switch, as shown in Figure 12-11.

Chapter 12: A Handy-Dandy Metal Detector 293

Figure 12-11:

Wires soldered to the on/off switch, potentiometer, phone jacks, and LED.

9.Solder an 8" wire to the center potentiometer lug and another 8" wire to the left potentiometer lug, as shown in Figure 12-11.

10.Solder a red 8" wire to the long lead of the LED and a black 8" wire to the short lead of the LED, as shown in Figure 12-11.

11.Slip a 1" piece of heat shrink tubing over each solder joint and use a hair dryer to secure them in place.

12.Solder an 8" wire to the lug on each of the phono jacks, as shown in Figure 12-11.

See Chapter 2 for advice about safe soldering if you’re not very experienced in this art.

Putting it all together

After you have a box and a circuit, it’s time to introduce them to each other.

Follow these steps to do so:

1.Attach Velcro to the breadboard and the box and secure the breadboard in the box.

2.Attach Velcro to the battery pack and the box and secure the battery pack in the box.

294 Part IV: Good Vibrations

3.Insert the wires from the LED, potentiometer, on/off switch, and battery pack to the terminal blocks on the breadboard, as shown in Figure 12-12.

Black wire from on/off switch

Wires from Potentiometer Red wire from battery pack

Figure 12-12:

Connect

the LED, potentiometer, on/off switch, coil, and battery pack to the breadboard.

Wires from |

Black wire |

Red wire |

audio jacks |

from LED |

from LED |

As you insert the wires, cut each of them to a sufficient length to reach the assigned terminal block and strip the insulation from the end of the wires.

4. Secure the wires with wire clips where needed.

Handling the handle

To easily wander around pointing the metal detector at suspected deposits of metal, you need a handle. Here are the steps to do so:

Chapter 12: A Handy-Dandy Metal Detector 295

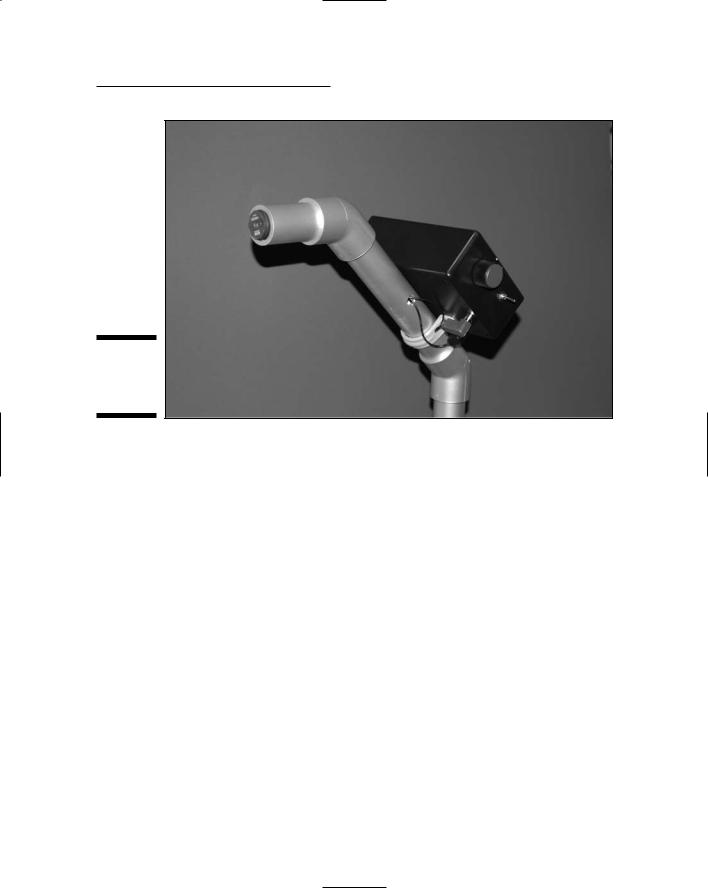

1.Glue an 8", 1"-diameter PVC pipe into one end of a 45°-angle PVC pipe fitting, facing up. (See the upcoming Figure 12-13.)

2.Glue the other 45° PVC pipe fitting onto the other end of the PVC pipe, facing down. (See the upcoming Figure 12-13.)

3.Glue a 3", 1"-diameter PVC pipe into the open end of one of the 45° pipe fittings to form the coil end of the metal detector.

4.Glue a 6", 1" PVC pipe into the open end of the other 45° fitting.

This becomes the handle end of the metal detector.

5.Glue the 1" PVC cap on the open end of the 6" PVC pipe.

6.Drill a 3⁄8" hole in the middle of the long section of PVC pipe on the side that will be to your left when you’re holding the metal detector.

You use this hole to feed the wires from the microphone cartridge to the box containing your circuit. Note: If you’re left handed, consider placing this hole on the side that will be to your right when you’re holding the detector so that you hold the handle in your left hand and operate the switches with your right hand.

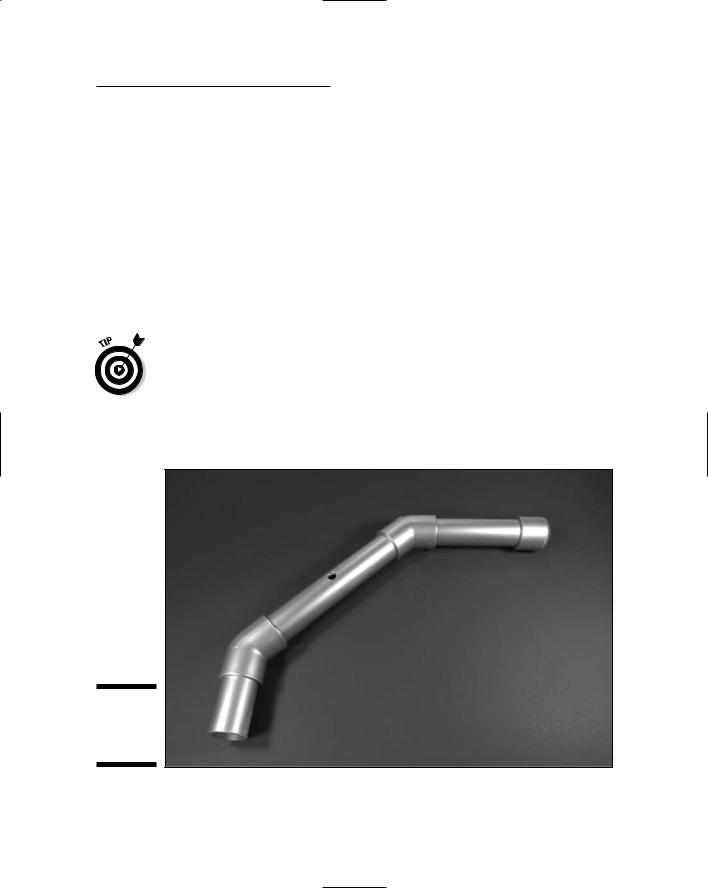

Figure 12-13 shows the PVC pipe and fittings made into a handle for the metal detector.

Figure 12-13:

Metal detector handle.

296 Part IV: Good Vibrations

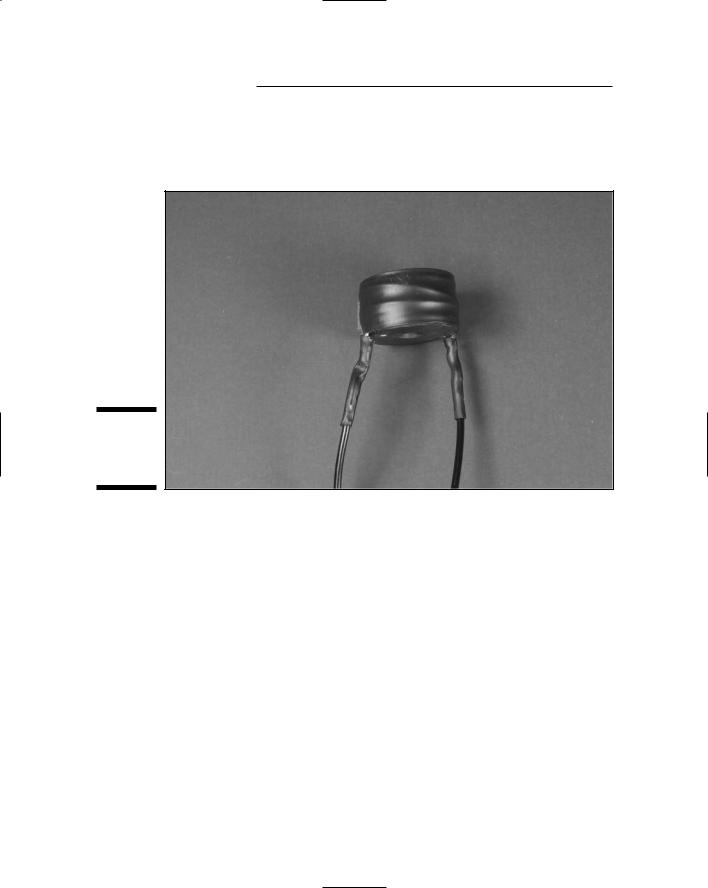

7.Solder 12" wires to each of the two inductor leads, as shown in Figure 12-14. Slip a 1" segment of heat shrink tubing over each solder joint and use a hair dryer to secure the tubing in place.

Figure 12-14:

Wires attached to inductor.

8.Twist together the free ends of the wires from the inductor and feed them through the PVC pipe from the coil end until the end of the wire strand reaches the 3⁄8" hole.

9.Form a hook shape with a piece of 20 or 22 gauge wire and pull the wires through the 3⁄8" hole.

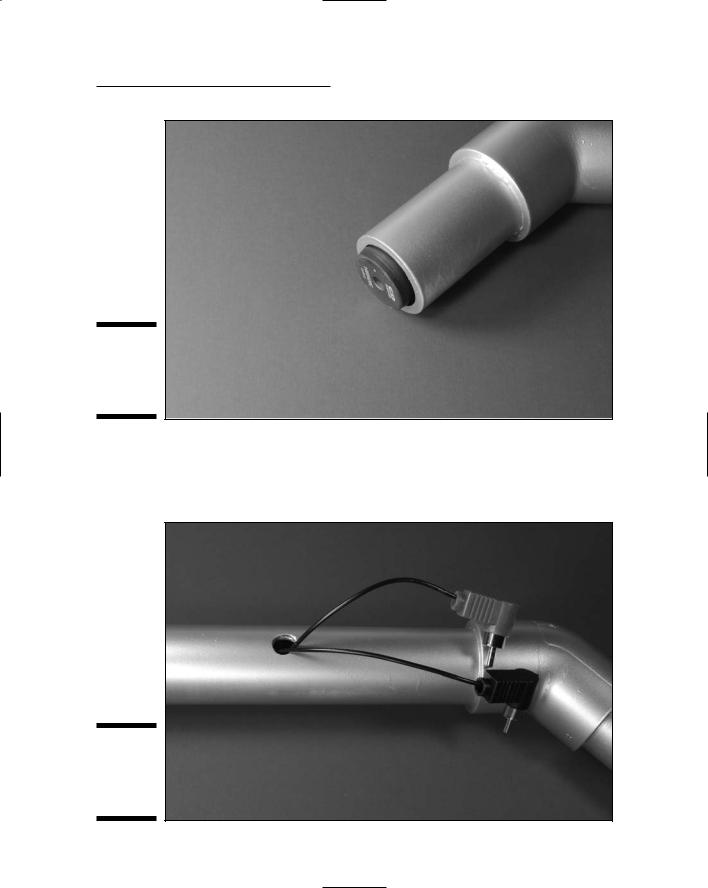

10.Insert the inductor in the end of the 1" PVC pipe, as shown in Figure 12-15, and use some glue to secure the inductor in the pipe.

Chapter 12: A Handy-Dandy Metal Detector 297

Figure 12-15:

Inductor in

the end of

the PVC

pipe.

11.Cut the wires to allow three inches to extend from the 3⁄8" hole in the pipe and attach each wire to a right-angle phono plug, as shown in Figure 12-16.

Figure 12-16:

Phono plugs attached to wires from inductors.

298 Part IV: Good Vibrations

You can use either a plug that requires soldering to the wire or one that uses a screw to secure the wire, as we have here.

12.Press the clamp onto the 1" PVC pipe and attach the box to the clamp with the 8-32 screws and nuts.

Figure 12-17 shows the box attached to the handle.

13.Plug the right-angle phono plugs into the phono jacks, as shown in Figure 12-17.

Figure 12-17:

Box attached to the handle and phono plugs in place.

The finished metal detector is shown in Figure 12-18.

Chapter 12: A Handy-Dandy Metal Detector 299

Figure 12-18:

The finished metal detector.

Trying It Out

You probably have a fortune in coins just waiting to be found at the bottom of your furniture cushions, so it’s time you got this metal detector thing on the trail of all those nickels and dimes! Here’s how to make this gadget work:

1.Insert the batteries.

2.Secure the lid on the box with the screws provided and flip the on/off switch to On.

3.Holding the coil away from any metal, turn the potentiometer knob so that the LED is on, and then turn the potentiometer knob slightly in the other direction till the LED turns off.

This calibrates the IC so that it is triggered by small changes in the oscillating signal that runs through the coil.

4.Try out your detector by holding it near different items containing metal.

We were able to detect coins and keys in pants pockets as well as various types of tools and nails at a distance of about 1⁄2". You should be able to detect larger metal objects (such as a space shuttle) at a distance of about an inch.