3649

.pdf

Russian Journal of Building Construction and Architecture

17.Karakus A. Investigating on possible use of Diyarbakir basalt waste in Stone Mastic Asphalt. Construction and Building Materials, 2011, no. 25, pp. 3502––3507.

18.Liu X., Zhang M., Shao L., Chen Z. Effect of volcanic ash filler on thermal viscoelastic property of SBS modified asphalt mastic. Construction and Building Materials, 2018, no. 190, pp. 495––507.

19.Nguyen H., Tran T. Effects of crumb rubber content and curing time on the properties of asphalt concrete and stone mastic asphalt using dry process. International Journal of Pavement Research and Technology, 2018, no. 11, pp. 236––244.

20.Schumacher G., Bullinger L., Lehdrich J. Splittmastixasphalt mint Zusats von synthetischen Fasern. Bitumen, 2002, no. 4, pp. 157––158.

50

Issue № 4 (44), 2019 |

ISSN 2542-0526 |

DOI 10.25987/VSTU.2019.44.4.004

UDC 691.168: 625.855

Nguyen Van Long 1, F. V. Matvienko 2, Nguyen Duc Sy 3

THE STUDY OF DEFORMATION STABILITY OF ASPHALT CONCRETE MODIFIED WITH AN ADDITIVE TAFPACK-PREMIUM

Ho Chi Minh City University of Transport 1

Vietnam, Hochiminh

Voronezh State Technical University 2

Russia, Voronezh

University of Technology and Education –– The University of Danang 3

Vietnam, Danang

1 PhD in Engineering, Head of the Dept. of Highways, e-mail: long_gtvt@mail.ru

2 PhD in Engineering, Associate Prof. at the Dept. of Construction and Operation of Highways, e-mail: fmatvienko@yandex.ru

3 PhD in Engineering, Head of Dept. of Technology and Education, e-mail: e-mail: ducnguyensy@yahoo com

Statement of the problem. The problem of increasing the rutting resistance of asphalt pavements is very urgent. One of the applied solution methods is the introduction of various modified additives in organic astringent.

Results. The paper presents a theoretical review of the results of studies the deformation stability of asphalt concrete modified with different additives. The results of experimental study related to the physical attributes and rutting resistance of the fine-grained asphalt concrete BTN C12.5 with a different amount of additive Tafpack-Premium.

Conclusions. A significant positive effect was identified from the use an additive TafpackPremium in number of 5 % in the bitumen mass to increase the rutting resistance of asphalt concrete. It is recommended to use improvement asphalt concrete BTN C12.5 modified by additive Tafpack-Premium additive of 5 % in the bitumen mass to construct the upper layer of high-class roadway pavements.

Keywords: asphalt concrete, additive Tafpack-Premium, deformation stability, rutting resistance, rutting.

Introduction. Improving rut resistance of roadway pavements is currently a hot topic [1, 2, 5–– 13, 17––20]. According to some studies [8, 17], a lot of Vietnamese highways are experiencing rutting as deep as 10 cm, which is above the admissible value. Rutting in roadway pavements leadstolowercomfortlevelsandtrafficsafetyandpresentsathreattonationaleconomy[8].

© Nguyen Van Long, Matvienko F. V., Nguyen Duc Sy, 2019

51

Russian Journal of Building Construction and Architecture

A number of studies [3, 6, 9, 12, 14––20] have indicated that rutting resistance of pavements can be improved by various modifying additives. Roadway bitumen is modified by a variety of additives and has been in use in the road industries of Russia, Vietnam, China, Japan, USA and Europe [3, 6, 9, 12, 14––16, 18]. According to [12], adhesive additives are employed in 44 U. S. states with liquid additives accounting for 56 % and lime hydrate for 44 %. According to the study by the American National Lime Association, use of limestone additives in the USA allows a 2––5 year increase in the life cycle of all types of highways [14].

The results of the research by the European Lime Association showed that introducing lime hydrate additives into asphalt concrete increases its life cycle by an average of 20––25 %. Liquid additives are also gaining momentum in European nations [140].

Depending on experience available, Asian countries are employing a variety of additives as well as a range of positive outcomes: liquid additives and lime hydrate additives in India, liquid additives in the Philippines, lime hydrates and Wetfix Be in Malaysia, lime hydrates and cement in China, lime hydrates and liquid additives Tough Fix, Tough Fix Hyper in Japan [20].

A number of studies have been conducted in Vietnam to investigate the use of different additives for improving strength characteristics and rutting resistance of asphalt concrete [6, 13, 15, 16, 18, 19]. The results of [6] showed that use of adhesive additive Wetfix BE contributes to better bitumen –– stone material cohesion as well as the Marshall stability and resistance to rutting of asphalt concrete.

In [18] it was shown that introduction of the additive Zycotherm into bitumen would allow its cohesion with stone materials as well as its softening temperature and the penetration PI index to increase and penetration to drop. The use of the additive Zycotherm enhances technical performance and deformation stability of asphalt concrete. The following studies [15] found that the use of 0.1 to 0.2 % of additive Toughfix in the bitumen mass enhances the overall performance, increases the softening temperature, causes no increase in penetration, raises the softening temperature and improves its cohesion with stone materials. The additive Toughfix enhances technical performance of asphalt concrete including the Marshall stability, plasticity, residual stability, rutting resistance and tensile strength. [19] indicates that there are 6 adhesive additives in Vietnam that are efficient for BTN C12.5 asphalt concrete. Their effects are shown in order of high to low: 1 is lime hydrate, 2 is cement, 3 is Wetfix Be, 4 is Zycotherm, 5 is Tough Fix, 6 is Tough Fix Hyper.

One of the additives employed in some countries for improving rutting resistance of asphalt concrete is Tafpack-Premium (TPP) which is a granulated white additive that is easily soluble

52

Issue № 4 (44), 2019 |

ISSN 2542-0526 |

in the asphalt concrete mix. In order to substantiate the use of TPP in the road construction in Vietnam, the authors investigated the main physical and mechanical operating properties of BTN C12.5 asphalt concrete modified by the additive.

1. Study of the effect of the TPP additive on the main properties of bitumen and asphalt concrete. The following original materials were used for the study:

––stone materials from the Tankang quary in Dong Nai province in compliance with the TCVN 8819-2011 requirements;

––bitumen Petrolimex 60/70 in compliance with the TCVN 7493-2005 requirements;

––mineral powder Hatien in compliance with the TCVN 8819-2011 requirements;

––0 % (control composition), 3, 4 and 5 % of Petrolimex bitumen mass 60/70 of the additive

Tafpack-Premium by the Taiyu Vietnam CO.

The main characteristics of Petrolimex bitumen 60/70 modified with additive ТРР were investigated. The results of the experiment are provided in Table 1. The data in Table 1 indicate that all the technical characteristics of Petrolimex bitumen 60/70 with a variety of additives ТРР meet the 27/2014/TT-BGTVT and TCVN 7493-2005 requirements.

Table

Results of determining the main characteristics of Petrolimex bitumen 60/70 with additive ТРР

Characteristics |

|

ТРР percentage, % |

|

In 27/2014/TT- |

||

|

|

|

|

BGTVT |

||

0 |

3 |

4 |

5 |

|||

|

||||||

|

|

53.5 |

|

|

|

|

Needle penetration depth at 25 оC –0.1 mm |

63.0 |

49.5 |

46.0 |

60–70 |

||

|

|

–0.67 |

|

|

|

|

Penetration index PI |

–0.83 |

–0.54 |

–0.36 |

–1.5–1 |

||

|

|

54.5 |

|

|

|

|

Softening temperature in the ring and the ball, oC |

48.6 |

57.0 |

60.0 |

≥ 46 |

||

|

|

278 |

|

|

|

|

Dynamic viscosity at 60 oC, Pa с |

256 |

290 |

315 |

≥ 180 |

||

|

|

>100 |

|

|

|

|

Stretchability at 25 °С, сm |

>100 |

>100 |

>100 |

≥ 100 |

||

|

|

1.57 |

|

|

|

|

Paraffin percentage, % |

1.58 |

1.56 |

1.56 |

≤ 2.2 |

||

|

|

340 |

|

|

|

|

Flashing temperature, oC |

336 |

345 |

349 |

≥ 232 |

||

|

|

99.69 |

|

|

|

|

Solubility in C2HCl3, % |

99.63 |

99.65 |

99.62 |

≥ 99 |

||

|

|

1.035 |

|

|

|

|

Specific weight at 25 oC, g/сm3 |

1.034 |

1.035 |

1.036 |

1.0–1.05 |

||

|

|

0.05 |

|

|

|

|

Mass loss, % |

0.06 |

0.03 |

0.03 |

≤ 0.8 |

||

|

|

72.30 |

|

|

|

|

Preserved penetrability, % |

70.53 |

77.50 |

80.30 |

≥ 54 |

||

|

|

4 |

|

|

|

|

Cohesion with stone materials, level |

3 |

4 |

4 |

≥ 3 |

||

|

|

|

|

|

|

|

Some indices of bitumen change dramatically: penetration at 25 °С drops by 15.08, 21.43 and 26.98 % respectively, softening temperature rises by 12.14, 17.28 and 23.46 %, cohesion with stone materials increases by 1 level and penetration index increases by 19.28, 34.94 and

53

Russian Journal of Building Construction and Architecture

56.63 % respectively. The higher is the penetration index, the lower is the effect that the temperature has on bitumen. Technical characteristics of Petrolimex bitumen 60/70 are at their best performance with 5 % of additive TPP.

Compositions of dense asphalt concrete BTN C12.5 were selected in compliance with the TCVN 8820-2011 and 858/QĐ-BGTVT requirements. The granulometric composition of BTN C12.5 asphalt concrete is provided in Fig. 1.

Mass percentage, %, finer grains,mm

Size of mineral material grains, mm

Fig. 1. Granulometric composition of dense fine-grained asphalt concrete BTN C12.5

The authors prepared asphalt concrete cylindrical samples and a series of experiments was performed using the Marshall method. The results of identifying volumetric characteristics of asphalt concrete BTN C12.5 in Petrolimex bitumen 60/70 with various contents of additive ТРР re given in Table 2.

The data in Table 2 show that the main volumetric characteristics of asphalt concrete BTN C12.5 with various contents of additive TPP do not change dramatically compared with the control sample andare incompliance withtheTCVN8819-2011and858/QĐ-BGTVT requirements.

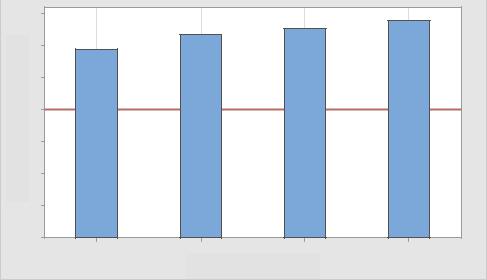

In Fig. 2––4 there are results of the tests of asphalt concrete BTN C12.5 with various contents of additive ТРР based on the Marshall method. All of the experiments meet the ASTM D6927––15 and AASHTO T 245––15 standards. The dispersion analysis ANOVA provides statistical significance with the coefficient p << 0.05 and corrected coefficient R2 which is 83 %.

54

Issue № 4 (44), 2019 |

ISSN 2542-0526 |

|

|

|

|

|

|

|

Таble 2 |

|

Volumetric characteristics of asphalt concrete BTN C12.5 with various contents of ТРР |

||||||||

|

|

|

|

|

|

|

|

|

|

|

Content of ТРР, % |

|

Values in |

||||

Characteristics |

|

|

|

|

|

|

TCVN 8819-2011 and |

|

0 |

|

3 |

4 |

|

5 |

|||

|

|

|

858/QĐ-BGTVT |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Optimal content of bitumen, % |

5.1 |

|

5.1 |

5.1 |

|

5.1 |

5.0––6.0 |

|

|

|

|

|

|

|

|

|

|

Absorption of bitumen by a filler, % |

0.50 |

|

0.48 |

0.46 |

|

0.44 |

–– |

|

|

|

|

|

|

|

|

|

|

Average density, g/сm3 |

2.42 |

|

2.43 |

2.43 |

|

2.43 |

–– |

|

Real density, g/сm3 |

2.54 |

|

2.53 |

2.53 |

|

2.53 |

–– |

|

|

|

|

|

|

|

|

|

|

Air void, % |

4.13 |

|

4.00 |

3.80 |

|

3.80 |

4––6 |

|

|

|

|

|

|

|

|

|

|

Void in the mineral filler, % |

14.96 |

|

14.86 |

14.75 |

|

14.73 |

≥ 13.5 |

|

|

|

|

|

|

|

|

|

|

Void filled with bitumen, % |

72.40 |

|

73.26 |

74.13 |

|

74.52 |

65––75 |

|

|

|

|

|

|

|

|

|

|

|

14 |

|

12.72 |

13.08 |

13.58 |

|

|

|

|

|

|||

|

|

11.82 |

|

|

||

УстойчивостьMarshall stability,МаршаллаkN, кН |

12 |

|

|

|

|

|

|

|

|

|

|

||

10 |

|

|

|

|

|

|

8 |

|

|

|

|

8 |

|

6 |

|

|

|

|

|

|

4 |

|

|

|

|

|

|

2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

0 |

3 |

|

4 |

5 |

|

|

|

||||

|

|

|

|

TPP content, % |

|

|

|

|

|

Содержание ТРР, % |

|

||

Fig. 2. Stability of asphalt concrete BTN C12.5 with various contents of additive ТРР

The data in Fig. 2––4 shows that as the ТРР content increases in the range of 0––5 % in the bitumen mass:

––as the samples are loaded at the temperature of 60 °С after 40 minutes and 24 hours, the Marshall stability of asphalt concrete BTN C12.5 increases and reaches the maximum value when the additive TPP content is 5 %;

––as 3, 4 and 5 % of additive ТРР in the mass bitumen is introduced into asphalt concrete BTN C12.5, its Marshall stability increases by 7.61, 10.68 and 14.89 % respectively, residual

55

Russian Journal of Building Construction and Architecture

Marshall stability increases by 5.31, 8.25 and 10.73 % and the plasticity drops by 2.7, 8.11 and 10.81 % respectively compared to the control sample.

% |

100 |

|

89.3 |

91.8 |

93.9 |

|

ОстаточнаяResidualустойчивостьMarshall stability,Маршалла% , |

|

84.8 |

|

|

||

|

|

|

|

|||

75 |

|

|

|

80 |

||

|

|

|

|

|||

50 |

|

|

|

|

||

25 |

|

|

|

|

||

0 |

0 |

3 |

4 |

5 |

||

|

||||||

|

|

|||||

|

|

|

TPP content, % |

|

||

|

|

|

Содержание ТРР, % |

|

||

Fig. 3. Residual stability of asphalt concrete BTN C12.5 with various contents of additive ТРР

|

4 |

3.7 |

3.6 |

|

4 |

|

|

|

3.4 |

|

|||

|

|

|

3.3 |

|||

|

|

|

|

|

||

|

|

|

|

|

|

|

, мм |

3 |

|

|

|

|

|

|

|

|

|

|

|

|

mm |

|

|

|

|

|

|

Пластичность |

2 |

|

|

|

|

2 |

|

|

|

|

|

|

|

Plasticity, |

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

0 |

3 |

|

4 |

5 |

|

|

|

||||

|

|

|

|

TPP content, % |

|

|

|

|

|

Содержание ТРР, % |

|

||

Fig. 4. Plasticity of asphalt concrete BTN C12.5 with various contents of additive ТРР

Therefore as the TPP additive content increases, technical characteristics of Petrolimex bitumen 60/70 and asphalt concrete BTN C12.5 degrade significantly and the best performance is observed as 5 % of additive TPP is added.

2. Experimental studies of the effect of the ТРР additive on the rutting resistance of asphalt concrete. An experimental study of the resistance of asphalt concrete to rutting was conducted using the Hamburg Wheel Tracking Device (HWTD) by means of the method of А

56

Issue № 4 (44), 2019 |

ISSN 2542-0526 |

order 1617/QĐ-BGTVT. The tests were run using the sample plates sized 320 × 260 × 50 mm at the temperature 50 оС. The sample plates were prepared according to the appendix С of the decree приказа 1617/QĐ-BGTVT. The rut depth in the tested plates was fixed after 15.000 loading cycles. The results of the experimental studies to identify the rut depth of asphalt concrete samples are provided in Fig. 5.

|

14 |

|

|

|

|

|

12 |

|

|

|

12.5 |

|

|

|

|

|

|

мм |

10 |

|

|

|

|

|

|

|

|

|

|

ГлубинаRut depth,колеиmm, |

8 |

7.39 |

|

|

|

6 |

|

4.68 |

|

|

|

|

|

|

|

||

4 |

|

|

2.94 |

|

|

|

|

|

|

||

|

|

|

|

2.03 |

|

|

2 |

|

|

|

|

|

|

|

|

|

|

|

0 |

0 |

3 |

4 |

5 |

|

|

||||

|

|

|

СодержаниеTPP content,ТРР% , % |

|

|

Fig. 5. Plasticity of asphalt concrete BTN C12.5 with various contents of additive ТРР

The data in Fig. 5 shows that

––the rut depth of asphalt concrete with various contents of additive ТРР is smaller than the admissible value of 12.5 mm identified in 1617/QĐ-BGTVT;

––the rut depth of asphalt concrete BTN C12.5 drops as the content of additive ТРР increases and reaches its minimum as 5 % of TPP in the bitumen mass is introduced. This indicates that introduction of additive ТРР allows the rutting resistance of asphalt concrete to be enhanced;

––the rut depth of asphalt concrete BTN С12.5 with 3, 4 and 5 % of additive ТРР in the bitumen mass for 15.000 loading cycles respectively is 4.68, 2.94 and 2.03 mm and drop by 36.67, 60.22 and 72.53 % compared to the control sample.

It was also found that during the test the mineral part of the filler was not bleached and the bitumen film was not exfoliated when additive ТРР was used.

Based on the research, it is recommended that asphalt concrete BTN C12.5 modified by 5 % of ТРР in the bitumen mass be utilized for the upper layer of high-class roadway pavements.

57

Russian Journal of Building Construction and Architecture

Conclusions

1.Use of modified asphalt concrete is one of the major ways of addressing the rutting resistance of roadway pavements particularly for multi-axial heavyweight vehicles and high temperatures of Vietnam.

2.It was found that as the TPP additive content increases, technical characteristics of Petrolimex bitumen 60/70 and asphalt concrete BTN C12.5 change dramatically and are at their best performance when 5 % of additive TPP is introduced.

3.As 5 % of additive TPP is introduced into Petrolimex bitumen 60/70, its penetration at

25°С drops by 26.98 %, softening temperature rises by 23.46 %, cohesion with stone materials increases by 1 level and penetration index rises by 56.63 %.

4. As 5 % of |

additive TPP in the mass bitumen is introduced into asphalt concrete |

BTN C12.5, its |

Marshall stability rises by 14.89 %, residual Marshall stability rises by |

10.73 %, plasticity drops by 10.81 % and the rut depth drops by 72.53 % after а 15.000 loading cycles compared to the control sample.

5. Based on the resulting data, it was recommended that asphalt concrete BTN C12.5 modified with 5 % of ТРР in the bitumen mass is used for the upper layer of high-class roadway pavements.

References

1.Vasil'ev A. P. Eshche raz o prichinakh koleinosti i metodakh ikh ustraneniya i neitralizatsii [Once again about the causes of rut and methods of their elimination and neutralization]. Avtomobil'nye dorogi, 2011, no. 2, pp. 75––79.

2.Dedyukhin A. Yu. Armirovanie asfal'tobetonnykh smesei kak sposob bor'by s koleei [Reinforcement of asphalt concrete mixtures as a way to combat ruts]. Vestnik VolgGASU. Seriya: Stroitel'stvo i arkhitektura, 2009, vol. 16 (35), pp. 88––92.

3.Kalgin Yu. I. Dorozhnye bitumomineral'nye materialy na osnove modifitsirovannykh bitumov [Road bitumen mineral materials based on modified bitumen]. Voronezh, Izd-vo VoronezhGASU, 2006. 272 p.

4.Mordvin S. S. Sovershenstvovanie metoda opredeleniya prochnosti nezhestkikh dorozhnykh odezhd dinamicheskim nagruzheniem. Avtoref. diss. kand. tekhn. nauk [Improvement of the method for determining the strength of non-rigid road surfaces by dynamic loading. Cand. eng. sci. diss.]. Moscow, MADI Publ., 2011. 22 p.

5.Nguen Van Long, Nguen Dyk Shi. Issledovanie vliyaniya struktury mineral'nogo sostava na ustoichivost' i plastichnost' asfal'tobetona [Research of influence of structure of mineral composition on stability and plasticity of asphalt concrete]. Inzhenerno-stroitel'nyi vestnik Prikaspiya: nauchno-tekhnicheskii zhurnal, 2017, no. 1 (19), pp. 25––30.

6.Podol'skii Vl. P., Nguen Van Long, Nguen Khak Khao, Nguen Dyk Shi. Issledovanie rabotosposobnosti asfal'tobetona, modifitsirovannogo dobavkoi Wetfix BE [Investigation of performance of asphalt concrete modified with wetfix BE additive]. Nauchnyi vestnik Voronezh. gos. arkh.-stroit. un-ta. Stroitel'stvo i arkhitektura, 2015, no. 3 (39), pp. 78––85.

58

Issue № 4 (44), 2019 |

ISSN 2542-0526 |

7.Podol'skii Vl. P., Nguen V. L., Nguen D. Sh. O neobkhodimosti vklyucheniya ispytanii asfal'tobetona pri temperature 60°S v normativnye dokumenty [About need of inclusion of tests of asphalt concrete at temperature of 60°C in normative documents]. Nauka i tekhnika v dorozhnoi otrasli, 2013, no. 4, pp. 22––25.

8.Podol'skii Vl. P., Long N. V., Chernousov D. I. Prichiny koleeobrazovaniya na asfal'tobetonnykh pokrytiyakh i metody povysheniya ikh deformativnoi ustoichivosti v usloviyakh Yuzhnogo V'etnama [Causes of rutting on asphalt concrete surfaces and methods to improve their deformative stability in South Vietnam]. Nauchnyi vestnik Voronezh. gos. arkh.-stroit. un-ta. Stroitel'stvo i arkhitektura, 2013, no. 1 (29), pp. 57––65.

9.Strokin A. S. Povyshenie sdvigoustoichivosti i sroka sluzhby dorozhnykh pokrytii putem primeneniya asfal'tobetona karkasnoi struktury na modifitsirovannom bitume. Diss. kand. tekhn. nauk [Increase of shear resistance and service life of road surfaces by application of asphalt concrete frame structure on modified bitumen. Cand. eng. sci. diss.]. Voronezh, VGASA Publ., 2009. 178 p.

10.Chan N. Kh. Asfal'tobeton s povyshennymi ekspluatatsionnymi svoistvami dlya uslovii zharkogo i vlazhnogo klimata V'etnama. Avtoref. diss. kand. tekhn. nauk [Asphalt concrete with improved performance for the hot and humid climate of Vietnam. Cand. eng. sci. diss.]. Rostov-on-don, RGSU Publ., 2011. 24 p.

11.Chernov S. A., Golyubin K. D. Puti povysheniya ustoichivosti k plasticheskomu koleeobrazovaniyu shchebenochno-mastichnykh asfal'tobetonov [Ways of increasing resistance to plastic rutting of crushed stonemastic asphalt concrete]. Dorogi i mosty, 2014, vol. 2, no. 32, pp. 264––272.

12.Aschenbrener T. B. Survey on moisture damage of hot mix asphalt pavements. Colorado Department of Transportation. Denver, Colorado, 2002.

13.Lã V. C. Nghiên cứu thực nghiệm bê tông nhựa liên quan đến vệt hằn lún vệt bánh xe trên một số tuyến quốc lộ. Kỷ yếu Hội thảo khoa học: Nguyên nhân và giải pháp khắc phục hằn lún vệt bánh xe trên mặt đường BTN. TP. HCM, 2014. Trang 35–41.

14.Lesueur D., Petit J., Ritter H. J. Increasing the durability of asphalt mixtures by hydrated lime addition. What evidence? The 5th Eurasphalt and Eurobitume Congress in Istanbul. Istanbul, June 2012. Paper 255. 10 p.

15.Nguyen Q. P., Vu N. P., Nakanishi Hiromitsu e. a. Experimental research on using Toughfix additive to increase water stability of hot mix asphalt. The transport journal, 2017, no. 6/2017, pp. 36––40.

16.Nguyễn T. B. T. Nghiên cứu phụ gia tăng bám dính đá nhựa trên cơ sở Oligoamid để tăng chất lượng mặt đường bê tông asphalt trong hệ thống đường bộ Hà Nội. Báo cáo tổng kết đề tài KHCN cấp Thành phố Hà Nội –– Chương trình: 01C – 04. Hà Nội, 2005. 127 trang.

17.Phạm H. K. Thực trạng hằn lún vệt bánh xe trên một số tuyến quốc lộ - nguyên nhân và biện pháp khắc phục. Kỷ yếu Hội thảo khoa học: Nguyên nhân và giải pháp khắc phục hằn lún vệt bánh xe trên mặt đường BTN. TP. HCM, 2014. Trang 5––13.

18.Tran N. H., Ta T. H. N., Vu T. T., Trong K. D. A number of experimental results using nano-organosilane (zycotherm) for asphalt concrete BTNC12.5 using acid-based aggregare in Vietnam. The transport journal, 2017, no. 12/2017, pp. 102––107.

19.Vũ N. P., Nguyễn T. L., Nguyễn V. C. Nghiên cứu đánh giá hiệu quả của một số loại phụ gia kháng bong tách đá nhựa cho bê tông nhựa sử dụng cốt liệu dính bám kém của khu vực Miền Trung. Tuyển tập báo cáo Hội nghị khoa học công nghệ năm 2018, Viện Khoa học và Công nghệ GTVT. Hà Nội, 2018. Trang 160––169.

20.Vũ N. P. Nghiên cứu sử dụng phụ gia tăng khả năng dính bám đá-nhựa cải thiện chất lượng bê tông nhựa ở Việt Nam. Luận án tiến sĩ kỹ thuật. Hà Nội, 2019. 140 trang.

59