Russian Journal of Building Construction and Architecture

.pdfRUSSIAN JOURNAL

OF BUILDING

CONSTRUCTION AND ARCHITECTURE

1

The journal is indexed/abstracted in:

Web of Science Core Collection

(Emerging Sources Citation

Index)

(Thomson Reuters), USA

Ulrich's Periodicals Directory

(Bowker), USA,

DOAJ

(Lund University), Sweden,

Academic Search Complete

(EBSCO), USA,

SOCOLAR

(China Educational Publications Import and Export Corporation –– CEPIEC), China,

Google Scholar

(Google), USA,

E-Library

(ООО «РУНЭБ), Russia.

2

ISSN 2542-0526

RUSSIAN JOURNAL

OF BUILDING

CONSTRUCTION AND ARCHITECTURE

N 2 (34)

BUILDING STRUCTURES, BUILDINGS AND CONSTRUCTIONS

BASES AND FOUNDATIONS, UNDERGROUND STRUCTURES

HEAT AND GAS SUPPLY, VENTILATION, AIR CONDITIONING, GAS SUPPLY AND ILLUMINATION

WATER SUPPLY, SEWERAGE, BUILDING CONSTRUCTION OF WATER RESOURCES PROTECTION

BUILDING MATERIALS AND PRODUCTS

TECHNOLOGY AND ORGANIZATION OF CONSTRUCTION

DESIGNING AND CONSTRUCTION OF ROADS, SUBWAYS, AIRFIELDS, BRIDGES AND TRANSPORT TUNNELS

BUILDING MECHANICS

ENVIRONMENTAL SAFETY OF CONSTRUCTION AND MUNICIPAL SERVICES

THEORY AND HISTORY OF ARCHITECTURE, RESTORATION AND RECONSTRUCTION OF HISTORICAL

AND ARCHITECTURAL HERITAGE

ARCHITECTURE OF BUILDINGS AND STRUCTURES. CREATIVE CONCEPTIONS OF ARCHITECTURAL ACTIVITY

CITY PLANNING, PLANNING OF VILLAGE SETTLEMENTS

FIRE AND INDUSTRIAL SAFETY (CIVIL ENGINEERING)

Voronezh 2017

3

Russian Journal

of Building Construction and Architecture

Periodical scientific edition

Published since 2009 |

Comes out 4 times per annum |

Founder and publisher: Federal State Education Budget Institution of Higher Professional Education «Voronezh State Technical University».

The articles are reviewed and processed with the program ANTIPLAGIARISM. This publication cannot be reprinted without the prior permission of the publisher, references are obligatory.

Number of the certificate of registration of the media ПИ № ФС 77-67855

EDITORIAL COUNCIL

The Head of the Council: Kolodyazhny S.A., rector (Voronezh State Technical University)

EDITORIAL BOARD

Editor-in-Chief: Melkumov V. N., D. Sc. in Engineering, Prof.

(Voronezh State Technical University)

Members:

Gagarin V. G., Corresponding Member of RAABS, Moscow State University of Civil Engineering, Russia

Barsukov Ye. М., PhD in Architecture, Prof., Voronezh State Technical University, Russia

Bondarev B. А., D. Sc. in Engineering, Prof., Lipetsk State Technical University, Russia

Enin A. Ye., PhD in Architecture, Prof., Voronezh State Technical University, Russia

Karpenko N. I., Academician of RAABS, Research Institute of Building Physics (NIISF RAABS), Russia

Kobelev N. S., D. Sc. in Engineering, Prof., Southwest State University, Kursk, Russia

Kolchunov V. I., Academician of RAABS, Southwest State University, Kursk, Russia

Ledenyev V. I., D. Sc. in Engineering, Prof., Tambov State Technical University, Russia

Lyahovich L. S., Academician of RAABS, Tomsk State University of Architecture and Building, Russia

Mailyan L. R., D. Sc. in Engineering, Prof., Don State Technical University, Rostov, Russia

Panibratov Yu. P., Academician of RAABS, Saint Petersburg State University of Architecture and Civil Engineering, Russia

PodolskyVl.P.,D. Sc. in Engineering, Prof., Voronezh State Technical University, Russia (Dep. of the Editor-in-Chief)

SlavinskayaG.V.,D. Sc. in Chemistry, Prof, Voronezh State Technical University, Russia

SuleymanovА.М.,D. Sc. in Engineering, Prof.,Kazan State University of Architecture and Engineering, Russia

Fyedorov V. S., Academician of RAABS, Moscow State University of Railway Engineering, Russia

Fedosov S. V., Academician of RAABS, Ivanovo State Polytechnic University, Russia

Chernyshov Ye. M., Academician of RAABS, Voronezh State Technical University, Russia

Shapiro D. M., D. Sc. in Engineering, Prof.,Voronezh State Technical University, Russia

Asanowicz Alexander, Prof., Dr. of Sn., Technical University of Bialystok, Poland

Figovsky Oleg L., Prof., Dr. of Sn., Member of EAS, Israel Korsun V. I., D. Sc. in Engineering, Prof., The Donbas National Academy of Civil Engineering and Architecture, Ukraine Nguyen Van Thinh, Prof., Dr. of Sn., Hanoi University of Architecture, Vietnam

Editor: Litvinova T. A. |

Translator: Litvinova O. A. |

THE ADDRESS of EDITORIAL OFFICE:84 20-letiya Oktyabrya str., Voronezh, 394006, Russian Federation

Tel./fax: (473)2-774-006; e-mail: vestnik_vgasu@mail.ru

Signed to print 28.04.2017. Format 60×84 1/8. Conventional printed sheets 9.1. Circulation 500 copies. Order 116.

Published in Printing Office of Voronezh State Technical University 84 20-letiya Oktyabrya str., Voronezh, 394006, Russian Federation

ISSN 2542-0526 |

© Voronezh State Technical |

|

University, 2017 |

4

CONTENTS |

|

BUILDING STRUCTURES,BUILDINGS AND CONSTRUCTIONS ................................................... |

6 |

Kositsyn S. B., Fedorov V. S., Tran Xuan Linh |

|

Analysis of Various Models of Foundation, Ambient Cylindrical Shell With |

|

a View of the Possibility of Detachment from a Shell ............................................. |

6 |

HEAT AND GAS SUPPLY,VENTILATION,AIR CONDITIONING, |

|

GAS SUPPLY AND ILLUMINATION........................................................................................... |

17 |

Mel'kumov V. N., Chuikin S. V., Kolosov A. I. |

|

District Heating from Nuclear Power Stations......................................................................... |

17 |

DESIGNING AND CONSTRUCTION OF ROADS,SUBWAYS,AIRFIELDS,BRIDGES |

|

AND TRANSPORT TUNNELS ..................................................................................................... |

26 |

Bondarev B. A., Prozorova L. A., Shtephan Yu. V. |

|

Stone Matrix Asphalt Based on a Cube-Shaped Slag Rubble.................................................. |

26 |

Nosov S. V. |

|

Generalized Dynamic Model of the Interaction of Compactors With Road |

|

Construction Materials ............................................................................................................ |

35 |

Nosov S. V. |

|

Determination of Rational Contact Pressure Under a Roller When |

|

Compacting Asphalt Concrete Mixes ...................................................................................... |

45 |

BUILDING MECHANICS............................................................................................................ |

54 |

Safronov V. S., Zazvonov V. V. |

|

Probable Method of Calculating the Effects of Temporary Static-Loads on |

|

Soil Bridge Construction.......................................................................................................... |

54 |

Shapiro D. M., Tyutin A. P., Rodionov V. A. |

|

Theory and Design Scheme of Road Engineering Structures From Pipe Groove .............. |

63 |

ARCHITECTURE OF BUILDINGS AND STRUCTURES.CREATIVE CONCEPTIONS |

|

OF ARCHITECTURAL ACTIVITY.............................................................................................. |

79 |

Maryam Ghorbanzadeh |

|

Green Roof, Yard Rehabilitating in Houses and a Way to Sustainable Architecture.............. |

79 |

Davud Saadat, Iraj Etesam, Seyyed Mostafa Mokhtabad Amrai |

|

Studying the Effect of the Evolution of Dome Chamber on the Process of Lighting and |

|

Transparency of Iranian Mosques Architecture .................................................................... |

98 |

INSTRUCTIONS TO AUTHORS................................................................................................. |

105 |

5

BUILDING STRUCTURES,BUILDINGS AND CONSTRUCTIONS

UDC 624.04

S. B. Kositsyn1, V. S. Fedorov2, Tran Xuan Linh3

ANALYSIS OF VARIOUS MODELS OF FOUNDATION, AMBIENT CYLINDRICAL

SHELL WITH A VIEW OFTHE POSSIBILITY

OF DETACHMENT FROM A SHELL

Moscow State University of Railway Engineering Nicolay II(MIIT) Russia, Moscow, tel.: (499) 978-16-73, e-mail: kositsyn-s@yandex.ru 1D. Sc. in Engineering, Prof., Head of the Dept. of Theoretical mechanics

2D. Sc. in Engineering, Prof., Head of the Dept. of building design, buildings and buildings Institute of Research and Development, Duy Tan University, Vietnam, Danang

3Tran Xuan Linh, PhD

Statement of the problem. The work is aimed at solving problems of contact interaction of cylindrical shells with surrounding arrays of soils in underground structures.

Results. Based on our previous study the authors developed methods that takes into account the unilateral contact interaction of shell and soil foundation, allowing to compare three models of the ground surrounding the shell: the foundation Fuss – Winkler, model of elastic layer and a volumetric array. An accurate formula for the elastic modulus of the elastic layer three-dementional array is provided.

Conclusions. The results of the shell in the system "shell – surrounding ground", obtained by the three considered models of soil are in good agreement with each other both qualitatively and quantitatively, which indicates the reliability of the constructed models and calculation. Displacements, stresses and strains of the shell, and areas of detachment of soil in all the calculated cases are almost identical. The model of the elastic layer should be applied in the absence of finite elements for modeling the elastic foundation, or by the irregularity of the shape of finite elements of the shell. When choosing a thickness of the elastic layer should not make it too thick. In practice one should primarily use three-dimensional models of the soil with a rigid unilateral contact elements to account for the detachment from the shell.

Keywords: cylindrical shell, soil array, elastic foundation, elastic layer, flat, three-dimensional and contact finite elements.

Introduction

One of the pressing issues of the development of technology is a wide application of easy and cost-effective wall-thinned structures. These systems are commonly used in construction of

© Kositsyn S. B., Fedorov V. S., Tran Xuan Linh, 2017

6

Issue № 2(34), 2017 |

ISSN 2542-0526 |

buildings and underground structures, pipelines, railway and highway tanks as well as ship and aircraft building, chemical and energy machine building, gas, oil and other industries. The major elements of these structures are cylindrical shells. For different types of laoding particularly in the intersection of shells there are significantly heterogeneous stress strains that typically have high levels of concentration of strains and thus there must be a special focus on accurate calculation methods that allow the resources of strength to be evaluated and a construction material to be highly reliable. Therefore this kind of research is essential these days.

Problems of contact of cylindrical shells and their intersections with surrounding soils in underground structures has not been sufficiently studied. Soils are not just a load but an environment where deformations occur. Therefore a lot of attention is given to contact of shells with soil. Presently in order to address this issue, flat calculation models are commonly used that are designed by cutting out of an actual spatial system by two longitudinal sections that are a length unit away from each other. In a flat model a shell is regarded as a rod system of a thickness unit and soil as a flat system or the Winkler-Fuss base. However, for underground objects with a complex geometry this problem cannot be formulated in such a way [1]. Note some studies dedicated to interactions of a cylindrical shell with soil (it is regarded as an elastic Winkler-Fuss base) [2, 3, 4, 5].

Analytical methods only use a non-complex geometry with simple boundary conditions and simplest behavior of materials. In [6] based on the use of operational calculation associated with the Laplace transform, analytical solutions for an isolated cylindrical shell with an elastic filler modelled using the Winkler-Fuss model with different boundary conditions for an axial symmetrical load are presented.

In [7] a method of calculating stress-strains of underground thin-walled melioration pipelines that considers a spatial nature of their operation and features of interactions of a pipeline and elastic soil under the impact of external loads.

One of the most effective and common numerical methods is the finite element method. Recently in order to analyze the stress-strain of the “shell-soil” system, latest finite element sets have been used to allow to consider a spatial nature of interactions of shells with surrounding soils. The results of calculating underground main pipelines using the finite element method are reported in publications in this country and abroad [8––16]. In these studies calculation schemes are complex, i.e. they include models of a pipe wall and in some cases contact layers between the pipe wall and soil as well.

7

Russian journal of building construction and architecture

However, it is still unclear how to connect the characteristics of different models of soil foundations considering the soil possibly sticking off the shell in order to get the results that could be compared while using the models.

The aim of this paper is to develop and improve calculation models of cylindrical shells interacting with the surrounding soil given it possibly sticking off and the methods that allow the characteristics of the resulting models to be connected.

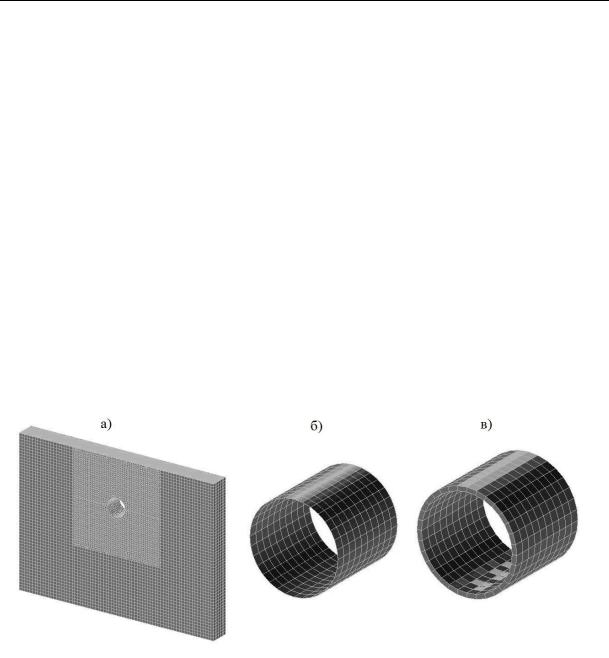

The study is performed using the example of a circle cylindrical shell with the radius of thickness of 0.02 m made of steel with the elasticity modulus Eоб = 2 · 1011 n/m2, the Poisson coefficient об = 0.3 and the density об = 7800 kg/m3. The shell is placed into the soil at the depth of 5 m (Fig. 1а). In order to approximate the soil considering that it might stick off the shell, let us design three spatial models of varying complexity, study its features and find a connection between the parameters of the models in order to obtain valid and consistent calculation results.

Fig. 1. Finite element model of the “shell-soil” system: а) a shell with a volumetric massive modelling soil;

b)a shell with GAP elements that replace an elastic foundation;

c)a shell with the approximated elastic layer

1.Cylindrical shell interacting with the surrounding volumetric soil massive

Soil is modelled using a homogeneous three-dimensional massive with the following characteristics: the deformation modulus Eгр = 1.634 · 109 n/m2, coefficient of longitudinal deformations гр = 0.3. The shell and soil materials were considered infinitely linearly elastic.

8

Issue № 2(34), 2017 |

ISSN 2542-0526 |

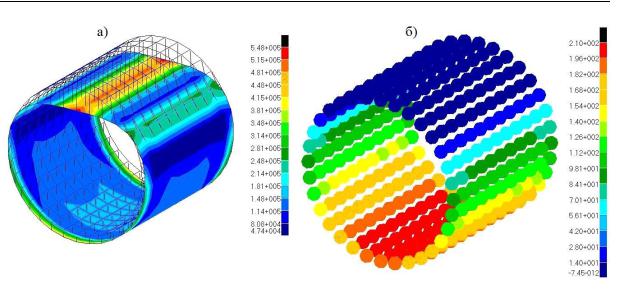

The sizes of the calculation region of the massive were accepted considering attenuation of the stress-strain of soil with 5 diameters of the shell to each side and down [17, 18]. A finite element complex MSC PATRAN –– NASTRAN was sued for the calculation. The shell is approximated with two-dimensional flat four-node elements based on the hypothesis of straight normal with six degress of freedom in each node. The sizes of the elements are 0.2 0.2 m. A volumetric massive modelling the soil is presented with three-dimensional finite elements in the shape of four-node tetrahedrons (a thick net next to the shell) and eight-node parallelepipeds (a rarer net next in the remaining parts of the massive) with three degrees of freedom in each node. The use of tetrahedrons is due to the fact that the geometry of the massive is rather complex at the place of a hole supported by the shell. The calculation region is supported from displacements normal to the surfaces of the massive, along the face, sides and down. The shell along its faces has identical supports to keep the calculation model geometrically stable. In order to be able to consider that the soil might stick off the soil, between the shell and massive there are special cotnanct elements [19] with the different tension and compression and tension stiffness (in the NASTRAN software they are called GAP elements). They have zero lengths and go to infinity and equalled (Sр = 10-7 n/m). Their compression stiffness went to infinity and were accepted to be Sсж = 107 n/m. The calculation was performed in a constructionally non-linear setting (using the method of sequential approximations these areas were investigated) to establish the impact of the shell’s own weight. The eigen weight of soil is not taken into account. The results of the calculations led to a model of the stress-strain. The maximum complete transformations wmax and maximum equivalent von Mises strain [20] in the internal вequiv and outside нequiv fibres of the shell are identified in Table (column “Variant 1”. Fig. 2a depicts a deformed shell and a field of equivalent strains in its external rings. Fig. 2b shows a field of effort in contact elements.

|

|

|

|

|

|

|

Table |

|

Maximum displacements and equivalent strains in the shell |

|

|

||||

|

|

|

|

|

|

|

|

Stress-strain parameter |

Variant 1 |

Variant 2 |

Variant 3 |

Variant 3 |

Variant 3 |

Variant 3 |

Variant 3 |

(tпр = 0.08 m) |

(tпр = 0.1 m) |

(tпр = 0.2 m) |

(tпр = 0.3 m) |

(tпр = 0.4 m) |

|||

|

|

|

|

|

|

|

|

wmax, 10-5m |

7.8164 |

7.6874 |

8.0483 |

8.0454 |

8.0316 |

8.0176 |

8.0628 |

|

|

|

|

|

|

|

|

вэкв, 105 n/m2 |

5.1381 |

5.0986 |

5.1358 |

5.1376 |

5.1366 |

5.1282 |

5.1389 |

|

|

|

|

|

|

|

|

нэкв, 105 n/m2 |

5.4799 |

5.5400 |

5.6483 |

5.6484 |

5.6440 |

5.6338 |

5.6443 |

|

|

|

|

|

|

|

|

9

Russian journal of building construction and architecture

Fig. 2. Stress-strain for the shell connecting the following with the volumetic massive: а) deformed type and intensity fields of von Mises in external Variant;

b)efforts and contanct elements

2.Cylindrical shell contacting an elastic foundation

The second calculation scheme is the following. The soil surrounding the shell is modelled using the elastic Winkler-Fuss base hat might stick off it (Fig. 1b). Since as well as in NASTRAN there is no model of such an elastic base, it is replaced with special contact elements (GAP elements) operating only during compression. The length of the GAP elements are accepted to be zero. The number of the GAP elements is determined with that of the nodes in the grid of the shell elements. The stiffness of the GAP elements during tension was accepted to strive for zero (Sр = 10-7 n/m) as well as in the previous model and the stiffness of the GAP elements during compression was calculated using the formula [19]:

Sсж Kab .

Here K is the coefficient of the subbase of the elastic base; a and b are linear sizes of the finite elements of the shell (in this case a b 0.2 m).

The stiffness of the GAP elements placed near the face of the shell is accepted to be twice as small as that of the remaining GAP elements as the face finite elements of the shell adjoin the corresponding GAP elements from two but not four sides.

In order to determine the coefficient of the subbase of the elastic base corresponding with the volumetric massive discussed above, the following extra calculation was performed. A threedimensional massive modelling the rod of the base (Eгр = 1.634·109 n/м2, гр = 0.3) in the plan

10