3456

.pdf

Issue № 4(32), 2016 |

ISSN 2075-0811 |

–– LNG is transported in the tank;

— LNG and cool carrier are supplied into the heat exchanger 7 where the products exchange the thermal energy through a separating wall. As a result of heat exchange, the cold carrier reduces its temperature roughly down to –130°С and LNG heats roughly up to –25°С and evaporates;

––gas is supplied into the reduction block under its own pressure of about 1,2 МPа where the pressure drops roughly to 0,2 МPа and supplied into a gas distribution network;

––after its operation the cold carrier after the heat exchanger 7 is pumped back into the cryogenic tank and then back to a liquefaction plant;

––at a liquefaction plant the cold carrier is supplied into the heat exchanger for preliminary cooling of network gas using heat exchange.

As a result of the above, energy for obtaining cold is saved due to the fact that the use of the same substance (cold carrier) for preliminary cooling of network gas, less energy is needed to further cool down and liquify natural gas in the liquefaction block.

Technical an economic justification of the use of the scheme with getting back the cold carrier. Let us identify the economic effect of using the developed method of transporting liquefied natural gas [8].

The sum of the fuel and energy costs in using a new method of delivery and a new structure of the tank, rouble/(kg LNG) is used as the objective function:

З 0, 01 L q2 МCOLD (1 0, 01 D) cT |

|

E cEL |

, |

|

|

1000 DG |

(3) |

||||

|

|

|

where cT is the cost of fuel, rouble; L is the length of the run of the tank from a plant to the

user and back, km; q2 |

is the consumption standard for transportation fuel; |

D is a correction |

||

coefficient; М COLD is |

the mass of the cold carrier, tonn; cEL is the |

energy cost, rou- |

||

ble/МWatt∙h; |

DG |

is the density of gas, kg/m3. |

|

|

|

|

|

|

|

The specific extra energy costs are accpeted to be minus as as a result of employing the new method of delivery energy costs drop.

The amount of the saved energy is determined by the difference between energy costs in the

compressor using the compared variants, .

The specific energy consumption is given by the following ratio:

E NG 0, 00272 |

LIS |

an |

|

, |

(4) |

||

is |

E |

|

|||||

|

|

|

|||||

|

|

|

TR |

|

|

||

41

Scientific Herald of the Voronezh State University of Architecture and Civil Engineering. Construction and Architecture

where LIS is the operation of isothermic compression, kgm; an is a correction coefficient for temperature and pressure; IS , E , TR is the isothermic coefficient of efficiency of the compressor, electrical engine and transfer respectively.

The amount of the saved specific energy is given by the formula:

|

23000 Р vINIT 0, 72 |

|

Р1 |

|

Р2 |

|

kWatt h |

|

|

||||

E 0, 00272 |

|

|

lg |

|

|

lg |

|

|

0, 001 |

|

|

. |

(5) |

IS |

E tr rE |

|

|

|

|

3 |

|||||||

|

|

Р |

|

Р |

|

m |

|

|

|

||||

where Р1 is the pressure on the inlet duct of the compressor, atm; Р2 is the pressure generated by the compressor, atm; vINIT is the initial volume of the sucked gas, m3; rE is the specific weight of gas, kg/m3.

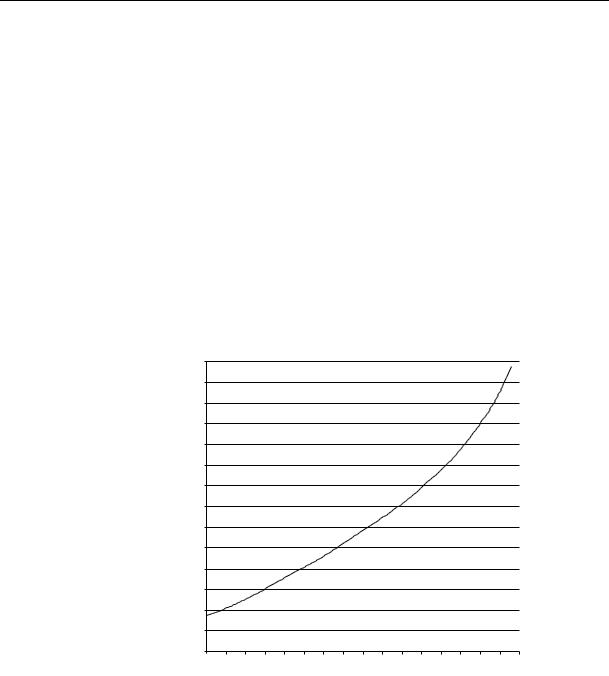

The results of the calculation are presented in Fig. 5.

, |

|

|

0,14 |

|

на электроэнергию |

|

|

|

|

|

|

0,13 |

|

|

|

|

0,12 |

|

|

|

|

0,11 |

|

|

|

|

0,10 |

|

|

|

|

0,09 |

|

|

дополнительные затраты |

extr |

0,08 |

|

|

|

|

|||

ч |

|

0,07 |

|

|

кВт |

3 |

0,06 |

|

|

м |

|

|||

|

|

|||

SpecificЭ, |

0,05 |

|

||

0,04 |

|

|||

0,03 |

|

|||

0,02 |

|

|||

Удельные |

|

|

|

|

|

|

0,01 |

|

|

|

|

0,00 |

|

|

|

|

0,5 0,6 0,7 0,8 0,9 1,0 1,1 1,2 1,3 1,4 1,5 1,6 1,7 1,8 1,9 |

2,0 2,1 |

|

|

|

|

кг |

|

|

|

|

Mass of the cold carrier in the calculation for 1 kg of LNG |

|

|

|

|

Масса хладоносителя в расчете на 1 кг СПГ, Мхлад , кг СПГ |

|

Fig. 5. Dependency graph E f М |

|

|

, |

kWatt h |

||

COLD |

m |

3 |

||||

|

|

|

||||

|

|

|

|

|

||

The boundary of the efficiency of the developed method of delivering LNG will be corresponded by the most remote from a support plant (liquifaction plant) gasification object:

L |

|

|

|

E cE |

|

||

|

|

|

|

|

. |

(6) |

|

0, 0068 q |

2 |

М |

COLD |

(1 0, 01 D) 2 c |

|||

|

|

|

T |

|

|||

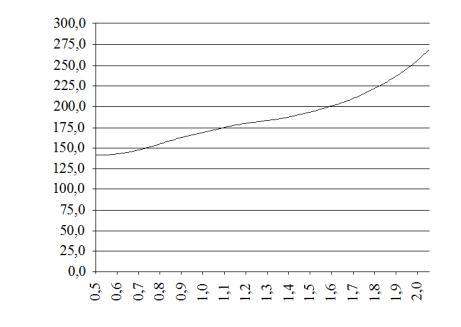

The results of the calculations are presented in Fig. 6.

42

Issue № 4(32), 2016 |

ISSN 2075-0811 |

Maximum remotedness of a gasified object, L, km

Fig. 6.

Boundaries of the efficiency of the method

Area of inefficient use

Area of efficient use

Mass of the cold carrier in the calculation of 1 kg of LNG Boundaries of the efficiency of the use of the suggested method of delivering LNG

The economic effect of using a new structure of the cryogenic tank is determined using the expression:

P |

n |

|

|

T |

E C1 C2 K1 p |

t |

mt |

И1 1 E t |

|

p 1 |

|

|

|

0 |

m 0 |

|

|

t 1 |

|

|

P |

|

K2 p |

|

p 1 |

n |

T |

|

t mt0 |

И2 1 E t , (7) |

|

m 0 |

t 1 |

|

where К1р, К2р are financial investments into the compared delivery options, rouble; m , n is the number and amount of continuous financial investments; t = mt0 is a year of continuous financial investments; t0 is the life cycle of the system, years; α is the efficiency coefficient of financial investments, 1/year; И1, И2 are operational costs for maintenance of the compared options, rouble/year; t is the number of the operation year; Т is the life cycle of the system, years; Е is the discount standard, 1/year. Integral costs of a LNG delivery option using the existing cryogenic tank over the entire operation are

C1 20116756 rouble .

In order to determine the energy costs in the compressor gэ for different ratios of the mass of the cold carrier and liquefied gas, the following expression was obtained:

gE 0,10837 МCOLD6 0, 67718 МCOLD5 1, 63245 МCOLD 4 1,87681 МCOLD3 (8)1, 03197 МCOLD 2 0,15399 МCOLD 0, 26925

Integral costs over the entire operation of the developed structure of the tank are

C2 17517235 rouble .

43

Scientific Herald of the Voronezh State University of Architecture and Civil Engineering. Construction and Architecture

The net discounted profit for the alternative delivery options is

T |

|

Z Z EL Z FUEL Z OPER 1 Е , |

(9) |

1

where τ is the number of an operation year; Z EL is the energy saved for the energy during the production of LNG, rouble; Z is the effect estimation of the costs for LNG transpor-

tation, rouble; |

Z OPER is the difference in the operation costs of the tank and the alternative |

|||||

|

|

|

|

|

|

|

delivery options, rouble. |

|

|

|

|

|

|

|

Z EL |

f (c ; g |

E |

; m |

; ) , |

(10) |

|

|

E |

LNG |

G |

|

|

where сэ is the cost of 1МWatt h of electrical energy; gэ is the amount of electrical energy consumed by the compressor in the compared options, kWatt h/(kg LNG); mLNG is the mass of the transported LNG, kg; г is the time of the operation of the compressor.

Z FUEL f (c ; g ; m |

; |

g |

;l) , |

(11) |

|

|

Т Т LNG |

|

|

|

|

where сТ is the cost of 1 l of extra costs of diesel fuel for transporting the cold carrier; l is the optimal run of the tank to a place of residence and back to a plant. The length of the route corresponds with one shift a day; gТ is the amount of extra fuel costs for transporting the cold carrier, l/km (kg of LNG).

Z OPER f ( ; K ) , |

(12) |

|

|

where K are financial costs of the tank, rouble; φ is the proportion of annual payments for operating the cryogenic tank.

As a result Z 3731721 rouble .

Conclusions

The calculation of economic efficiency of implementing the developed method of autonomous gas supply with the existing one showed that average savings of electrical energy re-

counted for |

1 kg |

of natural gas by reducing the capacity of the compressor is |

|

E 0,124 |

kWatt h |

and the economic effect of using the developed structure of the tank in |

|

kg |

|||

|

|

delivery scheme of 13% proves it to be effective.

The obtained guidelines are consistent with the results of the studies by other authors give a sufficient insight into functioning of gas distribution systems considering a variety of connections and factors contributing to the system.

44

Issue № 4(32), 2016 |

ISSN 2075-0811 |

The use of the current experience based om modern technologies in the operation of reserve supply systems of efficient energy is sure to cause them to become increasingly popular in this country.

References

1.STO 03321549-20-2012. Tekhniko-ekonomicheskoe obosnovanie parametrov sistem gazosnabzheniya [Standard 03321549-20-2012. Technical-economic justification of gas supply systems]. Saratov, OAO Giproniigaz, 2012. 18 p.

2.Medvedeva O. N., Frolov V. O. Sravnenie variantov sistem gazosnabzheniya potrebiteley [Comparing the options of gas supply systems of consumers]. Vestnik SGTU, 2010, no. 4 (51), iss. 3, pp. 128––133.

3.Medvedeva O. N., Frolov V. O. [Optimal centralization of supply systems on the basis of liquefied natural gas]. Trudy Mezhdunarodnoy nauchno-tekhnicheskoy konferentsii «Neft' i gaz Zapadnoy Sibiri» [Proc. of International scientific-technical conference "Oil and gas of West Siberia"]. Tyumen, TII-TyumGNGU, 2011, vol. 2, pp. 60––64.

4.Medvedeva O. N., Frolov V. O. Opredelenie optimal'nogo mestopolozheniya zavoda po szhizheniyu prirodnogo gaza [Determination of the optimal location of a plant for the liquefaction of natural gas]. Certificate No. 2013610839, 2013.

5.Medvedeva O. N. Tsisterna dlya transportirovki SPG [Tank for the transportation of liquid natural gas]. Salon L`Etudiant: Katalog ekspozitsii Ministerstva obrazovaniya i nauki Rossiyskoy federatsii, France, 2014, pp. 86––87.

6.Medvedeva O. N., Frolov V. O. Tsisterna dlya transportirovki szhizhennogo prirodnogo gaza [Tank for transportation of liquefied natural gas]. Patent RF, no. 2011130459, 2012.

7.Medvedeva O. N., Frolov V. O. Razrabotka konstruktsii avtomobil'noy tsisterny dlya dostavki szhizhennogo prirodnogo gaza [The design of road tankers to deliver liquefied natural gas]. Elektronnyy nauchnyy zhurnal "Neftegazovoe delo", 2012, no. 3, pp. 108––114.

8.Medvedeva O. N., Frolov V. O. [Autonomous gas supply system]. Materialy XIII mezhdunarodnogo foruma

«Novye idei novogo veka» [Proc. of the XIII international forum "New ideas of New century"]. Khabarovsk,

TGU, 2013, pp. 379––384.

45

Scientific Herald of the Voronezh State University of Architecture and Civil Engineering. Construction and Architecture

DESIGNING AND CONSTRUCTION OF ROADS, SUBWAYS,

AIRFIELDS, BRIDGES AND TRANSPORT TUNNELS

UDC 625.7

N. Ye. Kokodeeva1

PROBABILISTIC LIFE ASSESSMENT OF NON-RIGID

PAVEMENTS REINFORCED WITH GEOSYNTHETIC MATERIALS

Yuri Gagarin State Technical University of Saratov

Russia, Saratov, tel.: +7-937-245-80-89; e-mail: kokodeewa@mail.ru

1Dr. of Technical Science, Head of the Department of Transport Construction

Statement of the problem. In the Russian Federation in the conditions of intensive fleet growth and increasing traffic load on road surface and other related adverse factors, it is difficult to ensure the desired level of serviceability of roads throughout their life cycle. One way of solving this problem is the use of geosynthetics in road structures and it is therefore necessary to develop a probabilistic method of the calculation of life cycles of non-rigid pavement type reinforced by geosynthetic materials to provide the desired strength, durability and high transport and operational qualities of roads.

The Results. The developed methodology of assessing the condition of pavements on the basis of the prediction of the coefficient of variation of equivalent elastic modulus and the methodology of the probabilistic approach to assessing the impact of geosynthetic material on the service life of the road structure and the likelihood of its failure. Proposed recommendations to ensure the quality of state of pavements in the life cycle of a highway based choice of the optimal solution.

Conclusions. Probabilistic approach to life cycle assessment of road structures with geosynthetic materials on the basis of the theory of risk allows one to predict their state in the operation of the road and reduce damage caused by vehicles. The proposed approach meets the requirements of the Federal law No. 184-FZ "On the Technical Regulation".

Keywords: safety, risk, geosynthetics, reinforcement, road pavement, life cycle.

Introduction

According to the Russian Federation President’s Act from July 7, 2011 N 899, one of the prioritized directions in the development of science and technology in the Russian Federation is

© Kokodeeva N. Ye., 2016

46

Issue № 4(32), 2016 |

ISSN 2075-0811 |

transport systems and ways of ensuring their reliability and safety as stipulated by “Transport Strategy of the Russian Federation Until 2030” (in the edited version of the Russian Federation Government Act from June 11, 2014 № 1032-r). The qualitative characteristics of a transportation level are traffic speeds, timely services, consistency, safety and environmental performance of a transportation system. The major tasks of Transport Strategy in developing an effective transportation space of Russia based on a balanced development of an effective transportation infrastructure are to increase the capacities and speed parameters up to the world’s highest standards while creating the well-informed reserves as well the proportion of high-speed transportation networks and embracing new construction technologies, reconstruction and maintenance of a transportation infrastructure, e.g., by introducing geosynthetic materials for road structures.

Problems of scientific grounds behind designing roadways using geosynthetic materials.

In the Russian Federation as well as abroad there is a growing focus on geosynthetic materials for roadways including reinforcing road structures as well as slopes, constructing parking spaces, etc. The introduction of geosynthetic materials in road construction is guided by a number of domestic and foreign regulations which are unfortunately commonly contradictive when it comes to the terminology and lack the general classification of geosynthetic materials and thus define their applications differently [1].

The use of geosynthetic materials in road surfacings is known to increase their life cycles due to stopping cracks and pitholes from generating thus keeping a surface even and capable of distributing the transport load. However, the methodological approaches to calculating life cycles of road surfacing listed in the relevant guidelines are deterministic, i.e. they take into account only the parameters that are available and not expected to deviate. In this case the results of such calculations are commonly inconsistent with the actual data obtained in practice and this proves that changes in the parameters of road surfacings specified in calculations are probabilistic.

In addition, in accordance with the Federal Law № 184-FZ “On Technical Regulation” road surfaces in particular are to be evaluated (considering the construction quality, geosynthetic materials in road surface layers, etc.) based on accepted risks for the reasons of the safety of individuals, environment and property. This also explains that for a more accurate evaluation of road structures considering a stochastic nature of input parameters, it is necessary to employ a probabilistic approach to the life cycles of road surfaces using geosynthetic materials, e.g., using the ruin theory [3].

47

Scientific Herald of the Voronezh State University of Architecture and Civil Engineering. Construction and Architecture

System of technical regulation in the Russian Federation. The Russian Federation introduced the Federal Law №184-FZ “On Technical Regulation” in 2003 to get integrated into the global trade. Its major regulations rely on those of the Convention on technical barriers in the WTO trade as well as European Union regulations “On Providing Information for Technical Regulations and Standards”. This approach allows original innovative methods to be developed to cope with technical barriers for the global circulation of goods [9, 10].

As the Russian Federation became part of the World Trade Organization, the state took the lead in putting together legal documents specifying the rights and duties of the governments in the global trade of goods and services as well as transport construction.

A number of legal documents to comply with the Federal Law № 184-FZ “On Technical Regulation” (with changes coming into power from December 12, 2014) are being introduced which suggest that an accepted risk level is used as a measure of safety: 1) safety of production and manufacturing, operation, storage, transportation, selling and use (further on – safety) involves no life or health threats to individuals, private and corporate property, state and municipal property, environment, life and health of animals and plants; 2) risk is a probability of damage to life or health of individuals, private and corporate property, state and municipal property, environment, life and health of animals and plants depending on the level of damage.

The Federal Law № 184-FZ “On Technical Regulation” legally reinforced the reform of a long-standing system of technical standardization in order to make sure the three following regulative measures are effective: 1) introduction, application and administration of the necessary requirements in terms of technological processes, operation and services); 2) voluntary introduction and application of national standards, organization standards and set of rules to the quality of goods, design guidelines and characteristics; 3) evaluation (according to the Federal Law № 184-FZ “On Technical Regulation” its forms and schemes should be listed in the technical regulations and rely on risk assessment).

As part of the Federal Law № 184-FZ “On Technical Regulation”, there are presently 35 technical regulations of the Customs Union for different activities as well as road transport that is guided by the following technical regulations:

1) The Federal Law of the Russian Federation “Technical Safety Regulation for Buildings and

Structures” from December 30, 2009 № 384-FZ and the Russian Government Act from June 21, 2010 № 1047-r. “On The Revisited List of National Standards and Sets of Rules (parts of such standards and sets of rules) guarantees that the Federal Law “Technical Safety Regulation for Buildings and Structures” is adhered to;

48

Issue № 4(32), 2016 |

ISSN 2075-0811 |

2) Technical Regulation of the Customs Union “On Safety of Buildings and Structures, Construction Materials and Goods” that came into power on October 1, 2015. Extra requirements to construction structures for different purposes can be set forth as part of developing this technical regulation in corresponding technical regulations of the Customs Union. There is the List of Legal Guidelines that guarantee that the technical regulation of the Customs Union

“On Safety of Buildings and Structures, Construction Materials and Goods” is adhered to.

3)Project of the Technical Regulation of Eurasian Economic Community “On Safety of Buildings and Structures, Construction Materials and Goods”.

4)Technical Regulation ТS 014/2011 “Safety of Roads”. As decided by the Customs Union Committee № 187 from October 18, 2011 according to the Article 13 of the Convention of Common Principles and Rules of Technical Regualtion in the Republic of Belarus, Kazakhstan and Russian Federation from November 18, 2010, Technical Regulation TS “Safety of Roads” was enacted and came into power on February 15, 2015. As decided by the Counsil of Eurasian Economic Commission № 81 from June 13, 2012, “Program for Developing Interstate Standards” resulting in voluntary administration of the technical regulation of the Customs Union “Safety of Roads” (ТR ТS 014/2011) as well as the interstate standards containing the rules and methods of studying (testing) and measuring as well as selecting samples for the application and administration of ТR ТS 014/2011.

ТR ТS 014/2011 only manages general roads under construction, reconstruction and use and relating road structures including the construction elements (for road services only their location is regulated) as well as associated design, construction, reconstruction, high-scale maintenance and operation and roads and road structures and construction materials and goods.

Calculation of the life cycles of non-rigid road surfaces using geosynthetic materials.

There are a number of causes of a decline in the quality of roadways during their operation, e.g., error in calculation of the design characteristics of road surface layers, negligence of technical procedures, higher transport loads in spring, etc. Therefore the actual life cycle of a road surface is below the designed one. Thus such a technological solution should be proposed at the construction stage that would enable road structures to achieve the specified level of quality.

The design life cycle of road surfaces is a time period when the bearing capacity (strength coefficient) is in decline so that the designed reliability of a road surface and corresponding evenness of a surface is achieved.

49

Scientific Herald of the Voronezh State University of Architecture and Civil Engineering. Construction and Architecture

The efficiency of the use of geosynthetic materials in road construction is proved globally and domestically. In [1] there is the analysis of existing approaches to the use of geosynthetic materials in road structures and analysis of legal guidelines on geosynthetics of roads.

The use of geosynthetics and geocells in particular (volumetric geogrid) is one of the most simple ways of improving the transportational and operational performace of a road not involving the use of complex, costly technologies and equipment.

If the actual efficiency of the use of geosynthetic materials is beyond questioning, economical reasoning and calculations of road structures using these materials are more daunting. E.g., there are actually fewer failures of road surfaces reinforced with geocells and the life cycle is thus longer but it does not seem possible to calculate this increase using the existing (deterministic) methods.

In [3––8] there are methods of designing non-rigid road structures using geosynthetic materials, methods of calculating life cycles as well as evaluating their quality based on the accepted level of failure risks.

Conclusions

It is necessary that theoretical and experimental studies employing the ruin theory are used in road structures with geosynthetic materials.

The use of probabilistic evaluation of the life cycle of non-rigid road surfaces allows the strength of some reliable options for road surfaces to be selected and calculated (as well as using geosynthetic materials) and select an optimal one to increase the actual design life cycle of road surfaces and obtain the quality of road surfaces at the end of the actual life cycle as specified at the design stage.

The probabilistic approach suggested in [3, 6––8] to address this is in accordance with the requirements of the Federal Law №184-FZ “On Technical Regulation” and Technical Regulation of the Customs Union 014/2011 “Safety of Roads” and the results can thus be employed in developing the standards of organizations, road legislation, etc.

References

1. Moskalev O. Yu., Yankovskiy L. V., Kokodeeva N. E. Analiz sushchestvuyushchikh podkhodov i normativnoy dokumentatsii v oblasti primeneniya geosinteticheskikh materialov v dorozhnykh konstruktsiyakh [Analysis of existing approaches and normative documents in the field of application of geosynthetic materials in road constructions]. Nauchnyy vestnik Voronezhskogo GASU, iss. 1, no. 1 (37), 2015, pp. 80––88.

50