Careers in the mining indastry

..pdfWhere do you usually work?

Well, typically, this is an office-based job, where you spend your time either on the computer or in meetings/discussions with your colleagues. So far I have had quite a few different jobs, covering the whole spectrum of reservoir engineering, from calculating oil reserves, analysing well tests, building simulation models, risk and uncertainty studies, planning well locations, evaluating the value of new oil and gas projects, etc.

What kind of reserves do you work with?

The reservoirs I worked on were in all states in their life cycle – from fields not yet in production to fields in late life decline, included all different types of reservoirs (oil, gas, gas condensate, high pressure/high temperature gas, and tight gas) and covered a range from small well developments to super giant fields with hundreds of wells.

Does your job include other activities?

Lately, I have also been involved in recruitment of new engineers, training and software development.

What is your typical day?

On a typical day I start in the office at about 8am and check my emails for any news from the field and read the daily production and drilling reports to understand what has happened in the last 24 hours. Then I check the results of the simulation runs I submitted the day before. Sometimes those models run for many hours, so you have to plan in advance to make sure everything is finished on time. Then I usually have a meeting to discuss some of the latest problems, decide what changes I have to make to the simulation model and submit the next runs. Often I have to prepare presentations to management or to other companies who are partners in our project. I have to supply the commercial team with production forecasts and studies about the related uncertainties.

What personal qualities do you need to be a reservoir engineer?

To do this job, you need very good analytical skills, and you have to be able to deal with huge uncertainties; you can never really finish your work, there is

61

always more data coming in, so you need to refine your calculations constantly. Detailed technical understanding of your discipline is a must, but a broad understanding of related disciplines like drilling, geology, facilities or commercial is also very important for reservoir engineers. This of course means good interpersonal skills are required as well as you have to be able to communicate with so many different people.

10.Изучите текст интервью и выпишите из каждого абзаца слова и словосочетания, передающие основное содержание.

11.Прочитайте текст интервью и скажите, какие аргументы приводит Бен Стоун в подтверждение того, что специалисты в области разработки нефти и газа имеют большие перспективы в области трудоустройства в будущем.

12.Изучите текст интервью и найдите абзац, в котором ключевыми словами являются: link, drilling engineers, petroleum engineers, geologists, geophysicists, commercial analysts. Скажите, о чем сообщается в данном абзаце.

13.Используя слова и выражения сообщите, как проходит рабочий день Бена Стоуна: production and drilling, reports, meetings, the latest problems, simulation models, presentations, partners, commercial teams, production forecasts.

14. Изучите текст интервью и напишите статью о

профессиональных и личностных качествах Бена Стоуна.

62

UNIT 6

Drilling Engineering

and

Drilling Engineers

63

6.1. Drilling Engineering

Drilling engineering is a subset of petroleum engineering. It is primarily involved in the design and drilling of production and injection wells. The drilling engineer has the responsibility for the efficient penetration of the earth by a well bore, and for cementing of the steel casing from the surface to a depth usually just about the target reservoir.

The planning phases involved in drilling an oil well typically involve estimating the value of sought reserves, estimating the costs to access reserves, acquiring property by a mineral lease, a geological survey, a well bore plan, and a layout of the type of equipment required to reach the depth of the well. Drilling engineers are in charge of the process of planning and drilling oil wells. Their responsibilities include:

Designing casing strings in conjunction with drilling fluid plans to prevent blowouts (uncontrolled well-fluid release) and Formation evaluation.

Designing or contributing to the design of casing (drill string), cementing plans, directional drilling plans, and drill bit programs.

Specifying equipment, material and ratings and grades to be used in the drilling process.

Providing technical support and audit during the drilling process.

Performing cost estimates and analysis

Developing contracts with vendors

Drilling engineers are often degreed as petroleum engineers, although they may come from other technical disciplines (i.e., mechanical engineer or petroleum geologist) and subsequently be trained by an oil and gas company. They also may have practical experience as a rig hand or mudlogger or mud engineer.

Activities

1. Прочитайте текст и выпишите все возможные выражения со словом drilling. Какую информацию передают выписанные словосочетания?

64

2. Найдите в тексте английские эквиваленты следующих слов и выражений: бурение, нагнетательные скважины, ствол скважины, искомые ресурсы, технология бурения, договор аренды участков недр с целью добычи полезных ископаемых, крепление скважины, выброс их скважины, головка бура, инженер по буровым растворам, практический опыт.

3. Прочитайте текст и выпишите слова, характеризующие круг задач, выполняемых инженером-буровиком.

4. Используя лексику, выписанную в соответствии с заданием 3,

составьте краткое сообщение из 8–10 предложений, описывающих трудовую деятельность инженера-буровика.

5.Попросите партнера ответить на вопросы:

1.What is drilling engineering involved in?

2.What are drilling engineers responsible for?

3.What phases are involved in planning of drilling?

4.What do drilling engineers deal with in drilling wells?

5.What can drilling engineers specialize in?

6.Прочитайте текст и зафиксируйте в форме тезисов основные этапы бурения нефтяных и газовых скважин.

7. Изучите дополнительную информацию и скажите, где в тексте целесообразнее ее разместить.

The job of the drilling engineer is to design and implement a procedure to drill the well as economically as possible. The well will confirm the presence of oil or natural gas in the location selected by geologists and geophysicists. Drilling engineers work closely with the drilling contractor (the operator of the rig and its crews), service contractors, and compliance personnel, as well as the other members of his internal team. A drilling engineer must manage the complex drilling operation, including both the people and technology. Drilling a well can often cost several million dollars, and the drilling engineer has the responsibility for making certain that costs are minimized while getting all of the necessary

65

information to evaluate the reservoir, protecting the health and safety of workers and any nearby residents, and protecting the environment.

8. Прочитайте текст задания 7 и дополните список слов, выписанных в соответствии с заданием 3.

9. Напишите учебный перевод текста, представленного в задании 7.

6.2. History of Drilling Engineering

The earliest known oil wells were drilled in China in 347 CE. They had depths of up to about 800 feet (240 m) and were drilled using bits attached to bamboo poles. The oil was burned to evaporate brine and produce salt. By the 10th century, extensive bamboo pipelines connected oil wells with salt springs. The ancient records of China and Japan are said to contain many allusions to the use of natural gas for lighting and heating. Petroleum was known as burning water in Japan in the 7th century.

The earliest oil wells were drilled percussively by hammering a cable tool into the earth. Soon after, cable tools were replaced with rotary drilling, which could drill boreholes to much greater depths and in less time. Until the 1970s, most oil wells were vertical. However, modern directional drilling technologies allow for strongly deviated wells which can, given sufficient depth and with the proper tools, actually become horizontal. This is of great value as the reservoir rocks which contain hydrocarbons are usually horizontal, or sub-horizontal. A horizontal wellbore placed in a production zone has more surface area in the production zone than a vertical well, resulting in a higher production rate. The use of deviated and horizontal drilling has also made it possible to reach reservoirs several kilometers or miles away from the drilling location (extended reach drilling), allowing for the production of hydrocarbons located below locations that are either difficult to place a drilling rig on, environmentally sensitive, or populated.

66

Activities

1.Прочитайте текст и скажите, отражает ли заголовок тему

текста.

2.Прочитайте тест и выпишите информацию об истории происхождения и этапах развития технологии бурения нефтяных и газовых скважин.

3.Попросите партнера ответить на ваши вопросы:

1.Where did drilling start?

2.What tools were used in early drilling?

3.How did the Chinese make salt?

4.What was natural gas used for in Japan?

5.What did the Japanese call a burning water?

6.What methods were used to drill the early oil well?

7.What was the advantage of rotary drilling?

8.What type of oil wells are of great value and why?

9.What did the use of horizontal drilling make possible?

6.3. Drilling Equipment

Drilling engineers use special equipment - a drilling rig, a machine which creates holes usually called boreholes and shafts in the ground. Drilling rigs can be massive structures housing equipment used to drill water wells, oil wells, or natural gas. They sample sub-surface mineral deposits, test rock, soil and groundwater physical properties, and to install sub-surface fabrications, such as underground utilities, instrumentation, tunnels or wells. Drilling rigs can be mobile equipment mounted on trucks, tracks or trailers, or more permanent land or marine-based structures such as oil platforms, commonly called «offshore oil rigs». The term

«rig» therefore generally refers to the complex of equipment that is used to penetrate the surface of the earth's crust.

67

Oil and natural gas drilling rigs can be used not only to identify geologic reservoirs but also to create holes that allow the extraction of oil or natural gas from those reservoirs. Primarily in on shore oil and gas fields once a well has been drilled, the drilling rig will be moved off of the well and a service rig (a smaller rig) that is purpose built for completions will be moved on to the well to get the well on line. This frees up the drilling rig to drill another hole and streamlines the operation as well as allowing for specialization of certain services, i.e. completions vs. drilling.

Activities

1. Прочитайте текст и выпишите группу слов и словосочетаний,

отражающую тему «Drilling Equipment».

2.Прочитайте текст и скажите, какое оборудование используется для бурения нефтяных и газовых скважин.

3.Прочитайте текст и выделите все термины, характеризующие перечень работ, выполняемых с помощью бурильной установки.

4.Попросите партнера ответить на вопросы.

1.What equipment is used in drilling?

2.What do the drilling engineers use the machine for?

3.What structures are used to drill wells in sees?

4.What does the word «rig» refer to?

5.Why do the engineers move off the drilling rig after the completion of drilling?

6.What is a general function of a service rig?

5.Опираясь на лексику, выписанную в задании 3, сообщите, какие операции позволяет осуществлять бурильная установка.

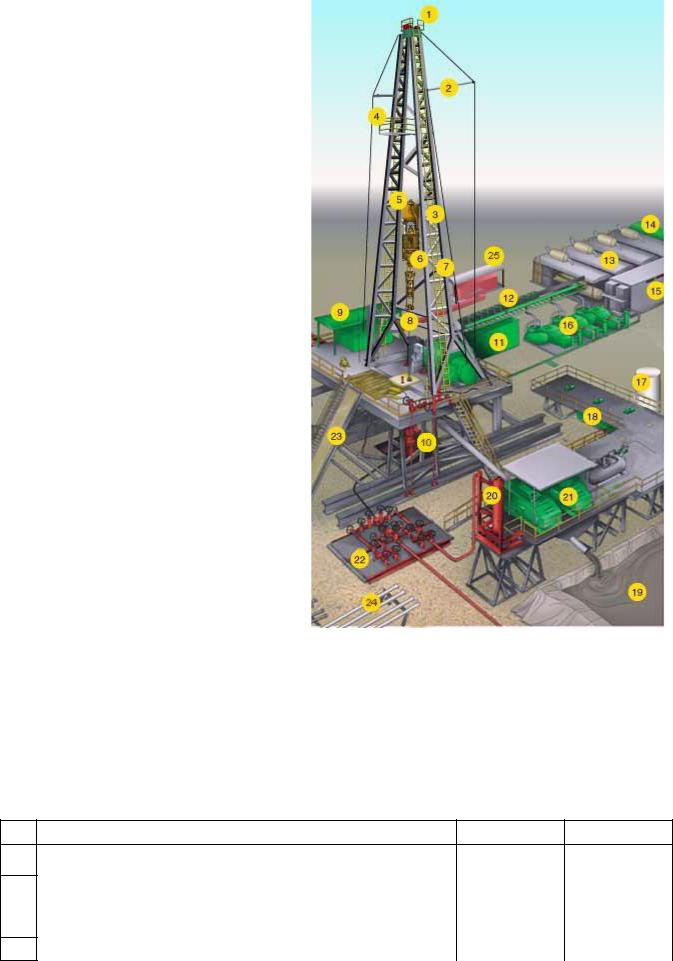

Structure of a Typical Drilling Rig

The equipment associated with a rig is to some extent dependent on the type of rig but typically includes at least some of the following items:

68

1.Crown Block and Water Table

2.Catline Boom and Hoist Line

3.Drilling Line

4.Monkeyboard

5.Traveling Block

6.Top Drive

7.Mast

8.Drill Pipe

9.Doghouse

10.Blowout Preventer

11.Water Tank

12.Electric Cable Tray

13.Engine Generator Sets

14.Fuel Tank

15.Electric House

16.Mud Pump

17.Bulk Mud Components in Storage

18.Mud Pits

19.Reserve Pits

20.Mud Gas Separator

21.Shale Shaker

22.Choke Manifold

23.Pipe Ramp

24.Pipe Racks

25.Accumulator

6.Прочитайте информацию в таблице и, опираясь на представленные выше элементы бурильной установки и схему их расположения,

распределите названия этих элементов на русском и английском языках в

соответствии с определениями.

1

2

3

Description |

English |

Russian |

A device that removes gas from the mud coming out of a well when a kick is being circulated out.

A diesel, Liquefied Petroleum Gas (LPG), natural gas, or gasoline engine, along with a mechanical transmission and generator for producing power for the drilling rig. Newer rigs use electric generators to power electric motors on the other parts of the rig.

A horizontal support for tubular goods.

69

4A large reciprocating pump used to circulate the mud (drilling fluid) on a drilling rig.

5A large valve, usually installed above the ram preventers, that forms a seal in the annular space between the pipe and well bore or, if no pipe is present, on the well bore itself

6A mud pit in which a supply of drilling fluid has been stored. Also, a waste pit, usually an excavated, earthen-walled pit. It may be lined with plastic to prevent soil contamination.

7A portable derrick capable of being erected as a unit, as distinguished from a standard derrick, which cannot be raised to a working position as a unit.

8A series of open tanks, usually made of steel plates, through which the drilling mud is cycled to allow sand and sediments to settle out. Additives are mixed with the mud in the pit, and the fluid is temporarily stored there before being pumped back into the well. Mud pit compartments are also called shaker pits, settling pits, and suction pits, depending on their main purpose.

9A series of trays with sieves or screens that vibrate to remove cuttings from circulating fluid in rotary drilling operations. The size of the openings in the sieve is selected to match the size of the solids in the drilling fluid and the anticipated size of cuttings. Also called a shaker.

10A small enclosure on the rig floor used as an office for the driller or as a storehouse for small objects. Also, any small building used as an office or for storage.

11A structural framework erected near the top of the derrick for lifting material

12An angled ramp for dragging drill pipe up to the drilling platform or bringing pipe down off the drill platform.

13An arrangement of pulleys or sheaves through which drilling cable is reeved, which moves up or down in the derrick or mast.

14An assembly of sheaves or pulleys mounted on beams at the top of the derrick. The drilling line is run over the sheaves down to the hoisting drum.

15Fuel storage tanks for the power generating system.

16Hopper type tanks for storage of drilling fluid components.

17Is used to store water that is used for mud mixing, cementing, and rig cleaning.

18On diesel electric rigs, powerful diesel engines drive large electric generators. The generators produce electricity that flows through cables to electric switches and control equipment enclosed in a control cabinet or panel. Electricity is fed to electric motors via the panel.

19Supports the heavy electrical cables that feed the power from the control panel to the rig motors.

20The arrangement of piping and special valves, called chokes, through which drilling mud is circulated when the blowout preventers are closed to control the pressures encountered during a kick.

21The derrickman's working platform. Double board, tribble board, fourable board; a monkey board located at a height in the derrick or mast equal to two, three, or four lengths of pipe respectively.

22The heavy seamless tubing used to rotate the bit and circulate the drilling fluid. Joints of pipe 30 feet long are coupled together with tool joints.

23The storage device for nitrogen pressurized hydraulic fluid, which is used in operating the blowout preventers.

24The top drive rotates the drill string end bit without the use of a kelly and rotary table. The top drive is operated from a control console on the rig floor.

25Thick, stranded metal cable threaded through the two blocks (traveling & crown) to raise and lower the drill sting.

70