- •UNIT II

- •PREPARATORY WORKS DURING ROAD RECONSRUCTION

- •1. Arrangement of bypass parallel to the road under reconstruction.

- •2. Arrangement of profile subgrade with prefabricated surface laying along the whole road under reconstruction.

- •3. Motor cars passing along the half of the road

- •Replacement of reconstruction by new construction

- •At significant traffic intensity it is reasonable to observe the problem of new road construction instead of reconstruction. In this case the existing road at the period of new road construction will play the role of bypass.

- •Fig. 3.3. Order of operations at subgrade widening

- •UNIT IV

- •CORRECTION OF VERTICAL ALIGNMENT OF ROAD

- •In some cases simultaneously with excavation deepening for slop stability or snowdrift extant slop steepness is increased (slop flattening).

- •In fig. 4.3 there is a diagram for determination of geometrical parameters of cut deepening.

- •UNIT V

- •RECONSTRUCTION OF HEAVING AREAS

- •Fig. 5.7. Shallow laying drainage construction

- •UNIT VI

- •ROAD PAVEMENT WIDENING AND EDGES STRENGTHENING

- •Carriage way widening value

- •Operations technology

- •Technology.

- •7.1. Variants of road pavement reconstruction.

- •а) detour parallel to reconstructed road;

- •аdhesion – адгезия

- •аggloporite – аглопорит

- •аsphaltenes – асфальтены

- •Berm – банкет

- •Cement activity

If synthetic material used as constant element there is arranged closer course from soil filler not less than 5cm over it. On cut slops with glue soil of higher moisture closed course are made of 10-30cm thickness.

Synthetic materials used as constant element are fixed on edge. Simultaneously with slops it is necessary to strength edges.

For total slops stability synthetic material is put into embankment body to make them cross designed surface of sliding.

Synthetic material is rolled on slop surface. Longitudinal rolling is used at gently sloping with slop steepness from 1:2 and less. It is also applied crossed roll

For total slops stability synthetic material is put into embankment body to make them cross designed surface of sliding.

At such a disposition of layers part of tensions provides the possibility to increase slop steepness. Number of layers is designed with account of needed safety factor and their length of deepening L into soil should not be more than maximally designed one.

For increasing local stability interlayers are put with withdrawal onto slop and if necessary to increase rigidity of lower part they can be united into shoulder. At withdrawal of interlayers onto slop there is constructed protection finished course.

Fig. 4.5. Combined method of slop pitching is presented

Combined method of slop pitching is presented in fig. 4.5.

UNIT V

RECONSTRUCTION OF HEAVING AREAS

5.1.Causes of heavens formation.

5.2.Classification of soils according to heaving.

5.3.Measures for elimination of causes of heaving formation applied during road construction:

26

a)regulation of soil properties;

b)regulation of water regime of roadbed;

c)regulation of thermal regime of roadbed.

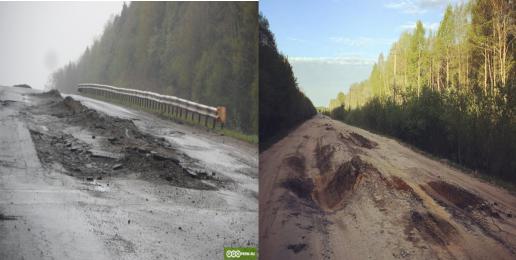

5.1. Heaving areas are places of deformation of road pavement and roadbed appeared in winter time as surface bumps, alligatoring and loss of evenness, and in the period of thaw in roadbed breaches at vehicle moving caused by degradation of waterlogged soil durability (fig. 5.1).

Fig. 5.1. Carriageway road section defects caused by of heavens formation

Heavens on roads are appeared at simultaneous combination of three factors:

a)presence of heaving soils;

b)intensive frost moisture accumulation;

c)slow and deep soil frost penetration under road pavement to depth more than 0,5m.

Heavens do not appear without any of these factors.

In order to escape heavens formation working course of roadbed in embankments and cuts on 1,2m from surface of cement concrete and 1m from asphalt concrete surface in II road climatic zone and on depth of1 and 8m consequently in III road climatic zone should consist of nonfrost-susceptible and weakly heaving soils

All soils are divided into 5 groups according to the degree of evening:

I – nonfrost-susceptible soils, relative frost evening of which less than 1%

(Кпуч≤1). This sand is gravelly, coarse and fine with particles content smaller than 0,05 до 2 %.

II – weakly heaving, relative frost heaving is from 1% до 4% (Кпуч = 1- 4).This sand is gravelly, coarse and fine with particles content smaller than 0.05 до 15%, sandy loam is light and coarse.

27

III – heaving Кпуч = 4 % - 7 %. This sandy loam is light, loamy soil (light and heavy), clays.

IV – strong heaving Кпуч = 7-10. This sand and sandy loam is pulverescent and loam (heavy, light), clay.

V – excessively heaving Кпуч > 10. This sandy loam is heavy pulverescent and loamy soil is heavy, pulverescent.

5.2. Measures directing for elimination of possibility to heaves formation can be divided into three groups:

I group Regulation of soil properties.

Change of heaving soil of roadbed in embankments starts with removal of vegetation layer from edges and slops. Road pavement is destructed and transported into piles or onto the places of recycling. After that top layer is loosened by bulldozers or excavators. Soil is removed and transported into deposit or to the place of stacking.

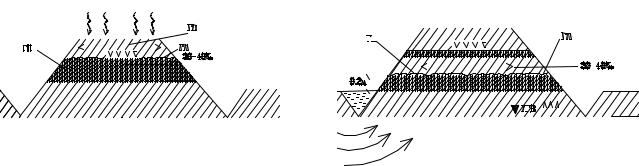

Drained soil is delivered from borrow and poured out in layers with compaction up to the working mix (fig. 5.2).

Independently on properties of soil which changes the previous one from lower side of reconstructed section along longitudinal slop it is necessary to arrange cross slit in subgrade full width. It should be of depth up to old soil of subgrade and there should be put the pipe of d = 80-100мм in it. If pipe walls are water proofing as for example asbestos cement pipe has then it is perforated up to the half of diameter or there are made silts in every 30-40cm (fig. 5.3).

Sometimes instead of heaving soil there are applied different methods of improvement of its properties.

Change of soil properties by the way of their reinforcement by cement or cement concrete mortar. For that on the road surface there are drilled net of apertures in the whole depth of working layer from heaving soil into which mortar is pumped under pressure.

conjunction |

is done as |

wedge |

Fig. 5.2. Diagram of conjunction of heaving section with not reconstructed one l – length of heaving section; h – thickness of replaceable soil layer

1 – road pavement on the neighboring not reconstructed sections; 2 – new road pavement; 3 – replaced soil.

28

a) |

b) |

Fig. 5.3. Diagram of structure of cross cuts of shallow slots with filters from artificial fibre materials: a) pipes with silts; b) perforated pipes

1 – pipe; 2 – thick felt or mats from basalt or glass fibres.

II group. Regulation of roadbed water regime.

Presence of soils with high water capillary raising, surface ground and nearby waters, water infiltration through slops, edges or surface promote intensive frost moisture accumulation.

Roadbed water proving is applied for protection of moisture penetration in to the body of roadbed: atmospheric precipitation through edges, not reinforced with water permeable material, waters from ditches at constant state of surface waters.

Rubber bitumen (izol, brizol, borumen) polymeric without base roll materials (polyethylene polyvinylchloride and polyamide film, film armador -2; roll materials (hydro izole, ruberoid) are used as water proving interlayers.

Woven and nonwoven synthetic materials treated with bitumen up to their complete water proving can be also applied.

Water proving interlayer placement is chosen in dependence of the moisture penetration sources

Technology of operations on arrangement of water proving interlayer depends on road pavement structure and placement of water proving interlayer. In fig. 5.4 there is shown roadbed water proving.

If during the process of reconstruction water proving interlayer is placed only on the edge width, soil is removed from edges up to the sandy layer surface which is leveled and compacted; water proving interlayer is put on and then soil is dumped and compacted on edge.

Water proving rolls are expanded by two workers along roadbed beginning with its borders.

They are laid with overlapping of 8-12cm. After the fist and then second roll 15-20cm overlapping mutual rolls are joined with each other. Then the laying are made simultaneously.

The rolls are joined by portable device equipped with gas burner. You can find the sequence and indexes of works while placing water proving interlayer into lower part of roadbed in table 5.1.

29

a),b) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

c),d) |

|

|

|||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fig. 5.4. Roadbed water proofing:

а) edges water proving; b) water proving of covers and edges; c) water proving of embankment lower part at continuous state of surface waters;

d) the same at near level of ground waters

|

Technological order of operations |

|

Table 5.1 |

|||

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

on |

|

|

|

№ devision |

Technological process |

Unit of measures |

Number of operation volumefor |

Productivi ty |

Necessity machineshift |

|

|

||||||

I |

Levelling of embankment top by motor |

m2 |

|

|

|

|

grader for 9 circular passes at 200m length |

≈7000 |

620 |

11,1 |

|||

|

|

|

|

|

|

|

II |

Laying onto roadbed surface (11rolls of |

|

|

|

|

|

1,5m width each) by hand |

m |

1000 |

270 |

(3,7) |

||

|

||||||

|

|

|

|

|

|

|

II |

Joining of rolls with the help of plant |

m |

1000 |

260 |

(3,85) |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

III |

Delivering of sand by rucks 4,5 t per L=5 |

m3 |

|

|

|

|

km |

2880 |

29,3 |

96,3 |

|||

|

|

|

|

|

|

|

III |

Flattering of sand by bulldozers h=0,2 m |

m3 |

2880 |

1460 |

1,97 |

|

|

|

|

|

|

||

IV |

Delivering of water L=5km and its |

|

|

|

|

|

dispensing (4l/m2) onto surface |

l |

55200 |

42600 |

1,02 |

||

|

|

|

|

|

|

|

IV |

Compaction mix h=0,2m by rolling press |

m3 |

|

|

|

|

on pneumatic tires along one rack at pass |

2880 |

720 |

4,0 |

|||

|

length of 200m |

|

|

|

|

|

For water regime regulation of roadbed there is arranged deep drainages (trenches).

Trench drainage is used in the case when ground water level influences on soil moisture of roadbed working course. Usually it is the III type of terrain according to its moisture with ground water location not deeper than 1-1,5m from

30

surface on low embankment sections. Trench drainage can be done under ditch or near edge, from one side or from both sides. It is often used textile fabrics or water proving roll materials while constructing trench drainage (fig. 5.5).

Operations are done by following order:

–cutting out of ground from tranches by single –bucket excavator with back

digger;

–preparation, rolling and placing of synthetic nonwolen material into trench;

–laying of crushed stone and gravel courses, ceramic drainage pipe and filling with crushed stone and gravel materials;

–filling of trench with soil by bulldozer with layerwise compaction.

a)

b)

c)

Fig. 5.5. Construction of roadbed with trench drainage:

а) and b) – under ditch, from one and both sides drainages; c) – near edges drainage, Н – value of ground water level lowering

31