ENG 7B removal

.pdf

|

CFM56-7B |

TRAINING MANUAL |

|

||

|

|

|

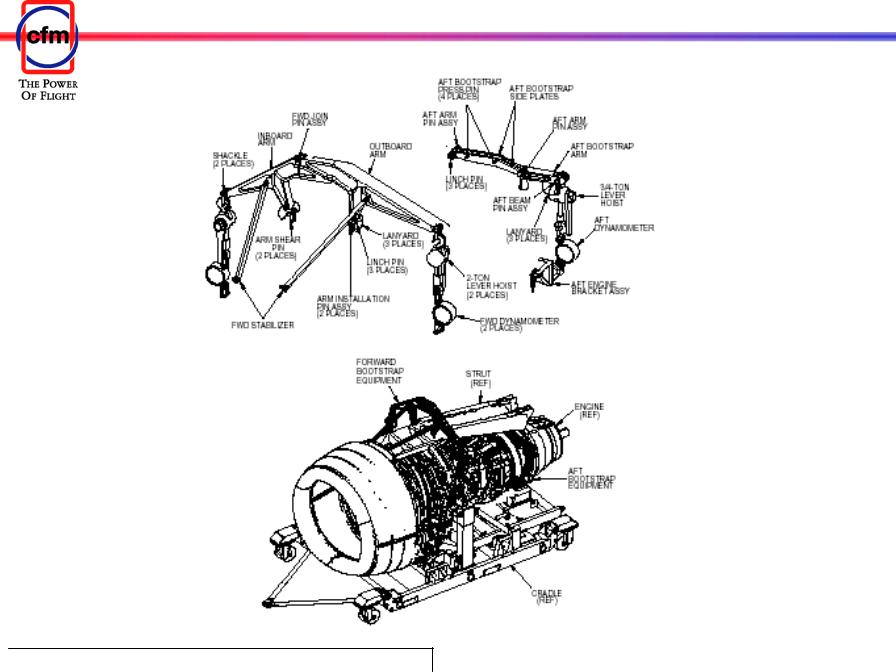

BOOTSTRAP TOOLING

Purpose (2.B.b)

The purpose of the bootstrap system is for installation/removal of the engine. The bootstrap equipment is used for removal and installation of the CFM56-7 engine and is used with the cradle. This system is a particular asset where an engine is changed at a remote site. The system includes a forward and an aft arm with lever hoists, dynamometers and engine attach brackets as integral components.

EFFECTIVITY 737-600/700/800/900/BBJ/C40A/B/C/P8A/MMA/AWAC |

|

CFM PROPRIETARY INFORMATION |

71-00-00 |

101 |

|

||||

|

|

|

Sept. 2006 |

|

|

CFM56-7B |

TRAINING MANUAL |

|

||

|

|

|

BOOTSTRAP TOOLING

EFFECTIVITY 737-600/700/800/900/BBJ/C40A/B/C/P8A/MMA/AWAC |

CFM PROPRIETARY INFORMATION |

71-00-00 |

102 |

|

|

Sept. 2006 |

|

|

CFM56-7B |

TRAINING MANUAL |

|

||

|

|

|

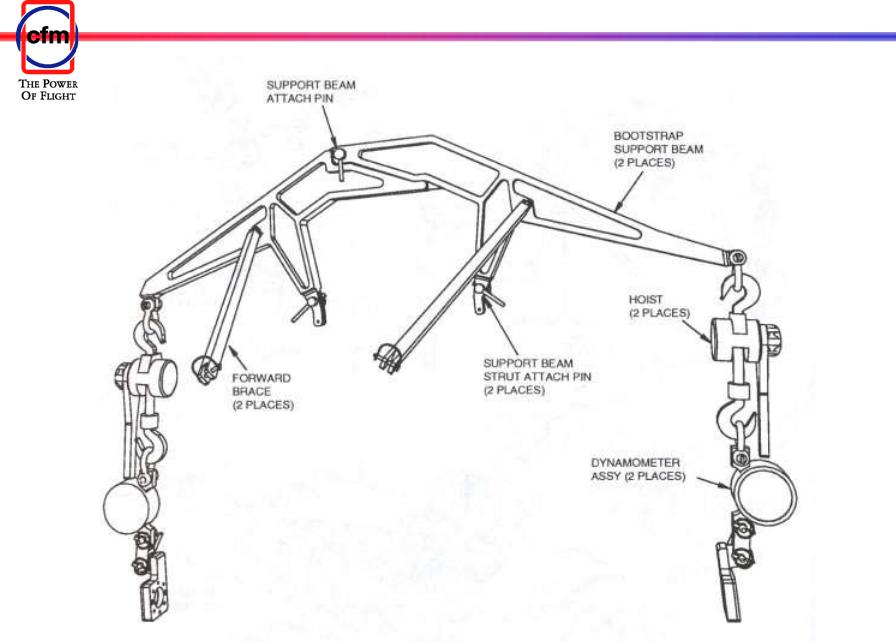

FORWARD BOOTSTRAP TOOLING

Identification (1.A.a)

The forward boot strap tooling consists of the following pieces:

-inboard dynamometer -outboard dynamometer

-2 chain hoists

-Support beam 2 pieces -2 braces

-7 Attachment Pins -2 shackles

-Dynamometer attachment adapters and pins

EFFECTIVITY 737-600/700/800/900/BBJ/C40A/B/C/P8A/MMA/AWAC |

|

CFM PROPRIETARY INFORMATION |

71-00-00 |

103 |

|

||||

|

|

|

Sept. 2006 |

|

|

CFM56-7B |

TRAINING MANUAL |

|

||

|

|

|

FORWARD BOOTSTRAP TOOLING

EFFECTIVITY 737-600/700/800/900/BBJ/C40A/B/C/P8A/MMA/AWAC |

|

CFM PROPRIETARY INFORMATION |

71-00-00 |

104 |

|

||||

|

|

|

Sept. 2006 |

|

|

CFM56-7B |

TRAINING MANUAL |

|

||

|

|

|

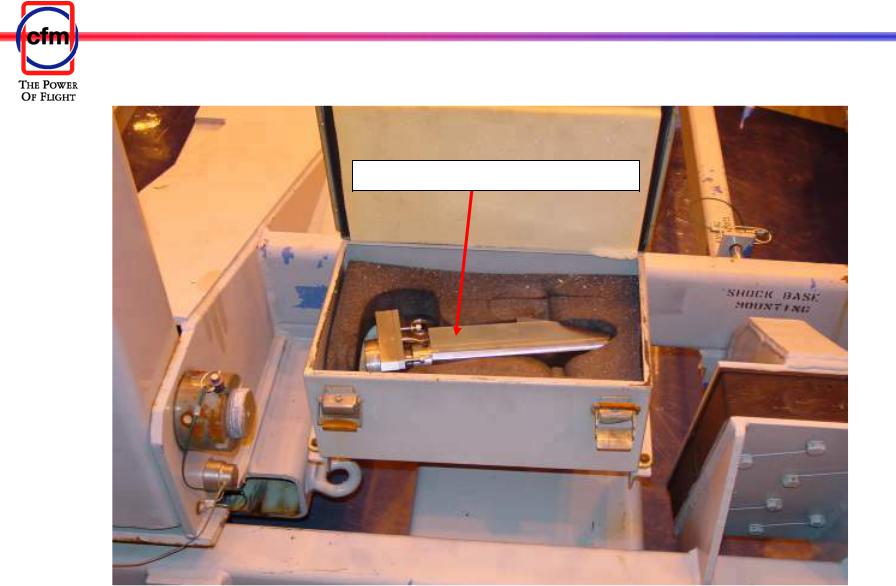

LH FAN FRAME ENGINE SUPPORT

Identification (1.A.a)

The engine stand supports tools are found on the engine stand in boxes. This is the LH engine support for the fan frame.

Purpose (2.B.b)

The purpose of the engine supports are to maintain the stand to the engine fan frame and the aft engine turbine rear frame during transportation.

MAINTENANCE TIP 737-MT-71-003 R1

SUBJECT: ENGINE REMOVAL AND INSTALLATION USING BOOTSTRAP EQUIPMENT

APPLICABILITY All 737-600/700/800/900 airplanes when using engine bootstrap equipment P/N C71020-80

(banana fitting at forward engine locations) with revised multi-purpose fitting. CONDITION: The fuel flow meter connector can be damaged when using the revised bootstrap equipment P/N C71020-80 and multi-purpose fitting.

RECOMMENDED ACTION

Disconnect the fuel flow meter (T435) connector DP0502 prior to attaching the bootstrap to the engine multipurpose fitting on the left hand side of the fan case.

EFFECTIVITY 737-600/700/800/900/BBJ/C40A/B/C/P8A/MMA/AWAC

BACKGROUND

During an engine change, the engine was dropped due to failed bolts that attach the multi-purpose fitting to the left hand side of the fan case. Upon inspection of these bolts in other engine change kits, several stretched and necked bolts were found. The bolts were over stressed while the multi-purpose fitting was being engaged in the engine cradle. To prevent over stressing the bolts, the multi-purpose

fitting, engine cradle and the bootstrap equipment were modified to move the bootstrap interface point toward the engine centerline approximately 2 inches. The straight fitting between the dynamometer and the multi-purpose fitting was replaced by a longer “banana” fitting. The “banana” shaped fitting is required to avoid contact with the inline fuel filter

(nozzle filter). The top of the “banana” fitting can come in contact with the fuel flow meter connector.

MAINTENANCE MANUAL ACTION

A step will be added in the 10 June 2003 revision of AMM 71-

00-02, Power Plant – Removal/Installation procedure, to disconnect the Fuel Flow Meter connector DP0502 before the bootstrap is connected to the engine multi-purpose fitting.

CFM PROPRIETARY INFORMATION |

71-00-00 |

105 |

|

Sept. 2006 |

|

|

CFM56-7B |

TRAINING MANUAL |

|

||

|

|

|

LH FAN FRAME ENGINE SUPPORT

LH FAN FRAME ENGINE SUPPORT

EFFECTIVITY 737-600/700/800/900/BBJ/C40A/B/C/P8A/MMA/AWAC |

|

CFM PROPRIETARY INFORMATION |

71-00-00 |

106 |

|

||||

|

|

|

Sept. 2006 |

|

|

CFM56-7B |

TRAINING MANUAL |

|

||

|

|

|

RH FAN FRAME ENGINE SUPPORT

Identification (1.A.a)

The engine stand supports tools are found on the engine stand in boxes. This is the RH engine support for the fan frame.

Before turning jam nut be sure to loosen set screw or damage to the threads of the RH trunnion may occure.

EFFECTIVITY 737-600/700/800/900/BBJ/C40A/B/C/P8A/MMA/AWAC |

|

CFM PROPRIETARY INFORMATION |

71-00-00 |

107 |

|

||||

|

|

|

Sept. 2006 |

|

|

CFM56-7B |

TRAINING MANUAL |

|

||

|

|

|

RH FAN FRAME ENGINE SUPPORT

RH Trunnion set screw

RH FAN FRAME ENGINE SUPPORT

EFFECTIVITY 737-600/700/800/900/BBJ/C40A/B/C/P8A/MMA/AWAC |

|

CFM PROPRIETARY INFORMATION |

71-00-00 |

108 |

|

||||

|

|

|

Sept. 2006 |

|

CFM56-7B

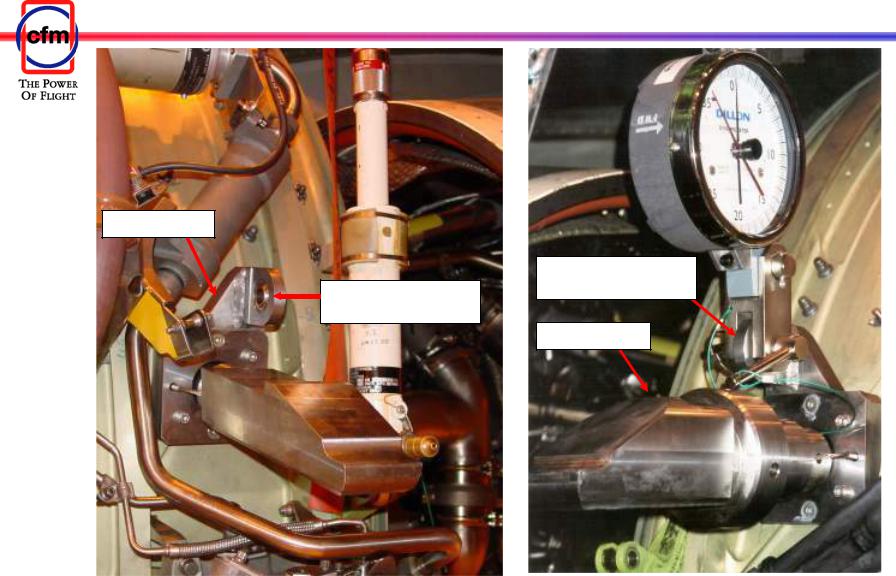

BOOTSTRAP CONNECTIONS

Training Information Points (3.E.c)

Zero the dynamometers once fully installed with no load.

- The forward inboard dynamometer reads 3700±100 pounds (1682±45 kilograms).

DO NOT APPLY MORE THAN 3850 POUNDS (1750 KG) TO THE FORWARD INBOARD DYNAMOMETER

-The forward outboard dynamometer should read 3200±100 pounds (1454±45 kilograms).

DO NOT APPLY MORE THAN 3350 POUNDS (1520 KG)

TO THE FORWARD OUTBOARD DYNAMOMETER

- The aft dynamometer reads 1100±100 pounds (500±45 kilograms). DO NOT APPLY MORE THAN 1300 POUNDS (590 KG) TO THE AFT DYNAMOMETER.

WARNING:

TRAINING MANUAL

Note: During installation of the engine, a total preload of 200 pounds (91 kilograms) is required to compress the seal on the engine to the strut.

IF YOU APPLY MORE THAN THE LIMITS, DAMAGE TO

THE POWER PLANT, WING AND STRUT CAN OCCUR.

MAKE SURE THERE ARE NO SPIRAL TWISTS IN THE

LEVER HOIST CHAIN BETWEEN THE LEVER HOIST.

HOUSING AND ITS LOWER BLOCK (THE ATTACH

POINT FOR THE DYNAMOMETER). IF YOU SEE A TWIST

IN THE CHAIN, YOU MUST REMOVE IT. IF YOU DO NOT

REMOVE IT, INJURIES TO PERSONS AND DAMAGE TO

EQUIPMENT CAN OCCUR.

EFFECTIVITY 737-600/700/800/900/BBJ/C40A/B/C/P8A/MMA/AWAC |

|

CFM PROPRIETARY INFORMATION |

71-00-00 |

109 |

|

||||

|

|

|

Sept. 2006 |

|

|

CFM56-7B |

TRAINING MANUAL |

|

||

|

|

|

LH TRUNNION

RH DYNAMOMETER

LH DYNAMOMETER CONNECTION

CONNECTION

RH TRUNNION

LH DYNAMOMETER CONNECTION RH DYNAMOMETER CONNECTION

BOOTSTRAP CONNECTIONS

EFFECTIVITY 737-600/700/800/900/BBJ/C40A/B/C/P8A/MMA/AWAC |

|

CFM PROPRIETARY INFORMATION |

71-00-00 |

110 |

|

||||

|

|

|

Sept. 2006 |

|