- •ANSYS Fluent Tutorial Guide

- •Table of Contents

- •Using This Manual

- •1. What’s In This Manual

- •2. How To Use This Manual

- •2.1. For the Beginner

- •2.2. For the Experienced User

- •3. Typographical Conventions Used In This Manual

- •Chapter 1: Fluid Flow in an Exhaust Manifold

- •1.1. Introduction

- •1.2. Prerequisites

- •1.3. Problem Description

- •1.4. Setup and Solution

- •1.4.1. Preparation

- •1.4.2. Meshing Workflow

- •1.4.3. General Settings

- •1.4.4. Solver Settings

- •1.4.5. Models

- •1.4.6. Materials

- •1.4.7. Cell Zone Conditions

- •1.4.8. Boundary Conditions

- •1.4.9. Solution

- •1.4.10. Postprocessing

- •1.5. Summary

- •Chapter 2: Fluid Flow and Heat Transfer in a Mixing Elbow

- •2.1. Introduction

- •2.2. Prerequisites

- •2.3. Problem Description

- •2.4. Setup and Solution

- •2.4.1. Preparation

- •2.4.2. Launching ANSYS Fluent

- •2.4.3. Reading the Mesh

- •2.4.4. Setting Up Domain

- •2.4.5. Setting Up Physics

- •2.4.6. Solving

- •2.4.7. Displaying the Preliminary Solution

- •2.4.8. Adapting the Mesh

- •2.5. Summary

- •Chapter 3: Postprocessing

- •3.1. Introduction

- •3.2. Prerequisites

- •3.3. Problem Description

- •3.4. Setup and Solution

- •3.4.1. Preparation

- •3.4.2. Reading the Mesh

- •3.4.3. Manipulating the Mesh in the Viewer

- •3.4.4. Adding Lights

- •3.4.5. Creating Isosurfaces

- •3.4.6. Generating Contours

- •3.4.7. Generating Velocity Vectors

- •3.4.8. Creating an Animation

- •3.4.9. Displaying Pathlines

- •3.4.10. Creating a Scene With Vectors and Contours

- •3.4.11. Advanced Overlay of Pathlines on a Scene

- •3.4.12. Creating Exploded Views

- •3.4.13. Animating the Display of Results in Successive Streamwise Planes

- •3.4.14. Generating XY Plots

- •3.4.15. Creating Annotation

- •3.4.16. Saving Picture Files

- •3.4.17. Generating Volume Integral Reports

- •3.5. Summary

- •Chapter 4: Modeling Periodic Flow and Heat Transfer

- •4.1. Introduction

- •4.2. Prerequisites

- •4.3. Problem Description

- •4.4. Setup and Solution

- •4.4.1. Preparation

- •4.4.2. Mesh

- •4.4.3. General Settings

- •4.4.4. Models

- •4.4.5. Materials

- •4.4.6. Cell Zone Conditions

- •4.4.7. Periodic Conditions

- •4.4.8. Boundary Conditions

- •4.4.9. Solution

- •4.4.10. Postprocessing

- •4.5. Summary

- •4.6. Further Improvements

- •Chapter 5: Modeling External Compressible Flow

- •5.1. Introduction

- •5.2. Prerequisites

- •5.3. Problem Description

- •5.4. Setup and Solution

- •5.4.1. Preparation

- •5.4.2. Mesh

- •5.4.3. Solver

- •5.4.4. Models

- •5.4.5. Materials

- •5.4.6. Boundary Conditions

- •5.4.7. Operating Conditions

- •5.4.8. Solution

- •5.4.9. Postprocessing

- •5.5. Summary

- •5.6. Further Improvements

- •Chapter 6: Modeling Transient Compressible Flow

- •6.1. Introduction

- •6.2. Prerequisites

- •6.3. Problem Description

- •6.4. Setup and Solution

- •6.4.1. Preparation

- •6.4.2. Reading and Checking the Mesh

- •6.4.3. Solver and Analysis Type

- •6.4.4. Models

- •6.4.5. Materials

- •6.4.6. Operating Conditions

- •6.4.7. Boundary Conditions

- •6.4.8. Solution: Steady Flow

- •6.4.9. Enabling Time Dependence and Setting Transient Conditions

- •6.4.10. Specifying Solution Parameters for Transient Flow and Solving

- •6.4.11. Saving and Postprocessing Time-Dependent Data Sets

- •6.5. Summary

- •6.6. Further Improvements

- •Chapter 7: Modeling Flow Through Porous Media

- •7.1. Introduction

- •7.2. Prerequisites

- •7.3. Problem Description

- •7.4. Setup and Solution

- •7.4.1. Preparation

- •7.4.2. Mesh

- •7.4.3. General Settings

- •7.4.4. Models

- •7.4.5. Materials

- •7.4.6. Cell Zone Conditions

- •7.4.7. Boundary Conditions

- •7.4.8. Solution

- •7.4.9. Postprocessing

- •7.5. Summary

- •7.6. Further Improvements

- •Chapter 8: Modeling Radiation and Natural Convection

- •8.1. Introduction

- •8.2. Prerequisites

- •8.3. Problem Description

- •8.4. Setup and Solution

- •8.4.1. Preparation

- •8.4.2. Reading and Checking the Mesh

- •8.4.3. Solver and Analysis Type

- •8.4.4. Models

- •8.4.5. Defining the Materials

- •8.4.6. Operating Conditions

- •8.4.7. Boundary Conditions

- •8.4.8. Obtaining the Solution

- •8.4.9. Postprocessing

- •8.4.10. Comparing the Contour Plots after Varying Radiating Surfaces

- •8.4.11. S2S Definition, Solution, and Postprocessing with Partial Enclosure

- •8.5. Summary

- •8.6. Further Improvements

- •Chapter 9: Using a Single Rotating Reference Frame

- •9.1. Introduction

- •9.2. Prerequisites

- •9.3. Problem Description

- •9.4. Setup and Solution

- •9.4.1. Preparation

- •9.4.2. Mesh

- •9.4.3. General Settings

- •9.4.4. Models

- •9.4.5. Materials

- •9.4.6. Cell Zone Conditions

- •9.4.7. Boundary Conditions

- •9.4.8. Solution Using the Standard k- ε Model

- •9.4.9. Postprocessing for the Standard k- ε Solution

- •9.4.10. Solution Using the RNG k- ε Model

- •9.4.11. Postprocessing for the RNG k- ε Solution

- •9.5. Summary

- •9.6. Further Improvements

- •9.7. References

- •Chapter 10: Using Multiple Reference Frames

- •10.1. Introduction

- •10.2. Prerequisites

- •10.3. Problem Description

- •10.4. Setup and Solution

- •10.4.1. Preparation

- •10.4.2. Mesh

- •10.4.3. Models

- •10.4.4. Materials

- •10.4.5. Cell Zone Conditions

- •10.4.6. Boundary Conditions

- •10.4.7. Solution

- •10.4.8. Postprocessing

- •10.5. Summary

- •10.6. Further Improvements

- •Chapter 11: Using Sliding Meshes

- •11.1. Introduction

- •11.2. Prerequisites

- •11.3. Problem Description

- •11.4. Setup and Solution

- •11.4.1. Preparation

- •11.4.2. Mesh

- •11.4.3. General Settings

- •11.4.4. Models

- •11.4.5. Materials

- •11.4.6. Cell Zone Conditions

- •11.4.7. Boundary Conditions

- •11.4.8. Operating Conditions

- •11.4.9. Mesh Interfaces

- •11.4.10. Solution

- •11.4.11. Postprocessing

- •11.5. Summary

- •11.6. Further Improvements

- •Chapter 12: Using Overset and Dynamic Meshes

- •12.1. Prerequisites

- •12.2. Problem Description

- •12.3. Preparation

- •12.4. Mesh

- •12.5. Overset Interface Creation

- •12.6. Steady-State Case Setup

- •12.6.1. General Settings

- •12.6.2. Models

- •12.6.3. Materials

- •12.6.4. Operating Conditions

- •12.6.5. Boundary Conditions

- •12.6.6. Reference Values

- •12.6.7. Solution

- •12.7. Unsteady Setup

- •12.7.1. General Settings

- •12.7.2. Compile the UDF

- •12.7.3. Dynamic Mesh Settings

- •12.7.4. Report Generation for Unsteady Case

- •12.7.5. Run Calculations for Unsteady Case

- •12.7.6. Overset Solution Checking

- •12.7.7. Postprocessing

- •12.7.8. Diagnosing an Overset Case

- •12.8. Summary

- •Chapter 13: Modeling Species Transport and Gaseous Combustion

- •13.1. Introduction

- •13.2. Prerequisites

- •13.3. Problem Description

- •13.4. Background

- •13.5. Setup and Solution

- •13.5.1. Preparation

- •13.5.2. Mesh

- •13.5.3. General Settings

- •13.5.4. Models

- •13.5.5. Materials

- •13.5.6. Boundary Conditions

- •13.5.7. Initial Reaction Solution

- •13.5.8. Postprocessing

- •13.5.9. NOx Prediction

- •13.6. Summary

- •13.7. Further Improvements

- •Chapter 14: Using the Eddy Dissipation and Steady Diffusion Flamelet Combustion Models

- •14.1. Introduction

- •14.2. Prerequisites

- •14.3. Problem Description

- •14.4. Setup and Solution

- •14.4.1. Preparation

- •14.4.2. Mesh

- •14.4.3. Solver Settings

- •14.4.4. Models

- •14.4.5. Boundary Conditions

- •14.4.6. Solution

- •14.4.7. Postprocessing for the Eddy-Dissipation Solution

- •14.5. Steady Diffusion Flamelet Model Setup and Solution

- •14.5.1. Models

- •14.5.2. Boundary Conditions

- •14.5.3. Solution

- •14.5.4. Postprocessing for the Steady Diffusion Flamelet Solution

- •14.6. Summary

- •Chapter 15: Modeling Surface Chemistry

- •15.1. Introduction

- •15.2. Prerequisites

- •15.3. Problem Description

- •15.4. Setup and Solution

- •15.4.1. Preparation

- •15.4.2. Reading and Checking the Mesh

- •15.4.3. Solver and Analysis Type

- •15.4.4. Specifying the Models

- •15.4.5. Defining Materials and Properties

- •15.4.6. Specifying Boundary Conditions

- •15.4.7. Setting the Operating Conditions

- •15.4.8. Simulating Non-Reacting Flow

- •15.4.9. Simulating Reacting Flow

- •15.4.10. Postprocessing the Solution Results

- •15.5. Summary

- •15.6. Further Improvements

- •Chapter 16: Modeling Evaporating Liquid Spray

- •16.1. Introduction

- •16.2. Prerequisites

- •16.3. Problem Description

- •16.4. Setup and Solution

- •16.4.1. Preparation

- •16.4.2. Mesh

- •16.4.3. Solver

- •16.4.4. Models

- •16.4.5. Materials

- •16.4.6. Boundary Conditions

- •16.4.7. Initial Solution Without Droplets

- •16.4.8. Creating a Spray Injection

- •16.4.9. Solution

- •16.4.10. Postprocessing

- •16.5. Summary

- •16.6. Further Improvements

- •Chapter 17: Using the VOF Model

- •17.1. Introduction

- •17.2. Prerequisites

- •17.3. Problem Description

- •17.4. Setup and Solution

- •17.4.1. Preparation

- •17.4.2. Reading and Manipulating the Mesh

- •17.4.3. General Settings

- •17.4.4. Models

- •17.4.5. Materials

- •17.4.6. Phases

- •17.4.7. Operating Conditions

- •17.4.8. User-Defined Function (UDF)

- •17.4.9. Boundary Conditions

- •17.4.10. Solution

- •17.4.11. Postprocessing

- •17.5. Summary

- •17.6. Further Improvements

- •Chapter 18: Modeling Cavitation

- •18.1. Introduction

- •18.2. Prerequisites

- •18.3. Problem Description

- •18.4. Setup and Solution

- •18.4.1. Preparation

- •18.4.2. Reading and Checking the Mesh

- •18.4.3. Solver Settings

- •18.4.4. Models

- •18.4.5. Materials

- •18.4.6. Phases

- •18.4.7. Boundary Conditions

- •18.4.8. Operating Conditions

- •18.4.9. Solution

- •18.4.10. Postprocessing

- •18.5. Summary

- •18.6. Further Improvements

- •Chapter 19: Using the Multiphase Models

- •19.1. Introduction

- •19.2. Prerequisites

- •19.3. Problem Description

- •19.4. Setup and Solution

- •19.4.1. Preparation

- •19.4.2. Mesh

- •19.4.3. Solver Settings

- •19.4.4. Models

- •19.4.5. Materials

- •19.4.6. Phases

- •19.4.7. Cell Zone Conditions

- •19.4.8. Boundary Conditions

- •19.4.9. Solution

- •19.4.10. Postprocessing

- •19.5. Summary

- •Chapter 20: Modeling Solidification

- •20.1. Introduction

- •20.2. Prerequisites

- •20.3. Problem Description

- •20.4. Setup and Solution

- •20.4.1. Preparation

- •20.4.2. Reading and Checking the Mesh

- •20.4.3. Specifying Solver and Analysis Type

- •20.4.4. Specifying the Models

- •20.4.5. Defining Materials

- •20.4.6. Setting the Cell Zone Conditions

- •20.4.7. Setting the Boundary Conditions

- •20.4.8. Solution: Steady Conduction

- •20.5. Summary

- •20.6. Further Improvements

- •Chapter 21: Using the Eulerian Granular Multiphase Model with Heat Transfer

- •21.1. Introduction

- •21.2. Prerequisites

- •21.3. Problem Description

- •21.4. Setup and Solution

- •21.4.1. Preparation

- •21.4.2. Mesh

- •21.4.3. Solver Settings

- •21.4.4. Models

- •21.4.6. Materials

- •21.4.7. Phases

- •21.4.8. Boundary Conditions

- •21.4.9. Solution

- •21.4.10. Postprocessing

- •21.5. Summary

- •21.6. Further Improvements

- •21.7. References

- •22.1. Introduction

- •22.2. Prerequisites

- •22.3. Problem Description

- •22.4. Setup and Solution

- •22.4.1. Preparation

- •22.4.2. Structural Model

- •22.4.3. Materials

- •22.4.4. Cell Zone Conditions

- •22.4.5. Boundary Conditions

- •22.4.6. Solution

- •22.4.7. Postprocessing

- •22.5. Summary

- •23.1. Introduction

- •23.2. Prerequisites

- •23.3. Problem Description

- •23.4. Setup and Solution

- •23.4.1. Preparation

- •23.4.2. Solver and Analysis Type

- •23.4.3. Structural Model

- •23.4.4. Materials

- •23.4.5. Cell Zone Conditions

- •23.4.6. Boundary Conditions

- •23.4.7. Dynamic Mesh Zones

- •23.4.8. Solution Animations

- •23.4.9. Solution

- •23.4.10. Postprocessing

- •23.5. Summary

- •Chapter 24: Using the Adjoint Solver – 2D Laminar Flow Past a Cylinder

- •24.1. Introduction

- •24.2. Prerequisites

- •24.3. Problem Description

- •24.4. Setup and Solution

- •24.4.1. Step 1: Preparation

- •24.4.2. Step 2: Define Observables

- •24.4.3. Step 3: Compute the Drag Sensitivity

- •24.4.4. Step 4: Postprocess and Export Drag Sensitivity

- •24.4.4.1. Boundary Condition Sensitivity

- •24.4.4.2. Momentum Source Sensitivity

- •24.4.4.3. Shape Sensitivity

- •24.4.4.4. Exporting Drag Sensitivity Data

- •24.4.5. Step 5: Compute Lift Sensitivity

- •24.4.6. Step 6: Modify the Shape

- •24.5. Summary

- •25.1. Introduction

- •25.2. Prerequisites

- •25.3. Problem Description

- •25.4. Setup and Solution

- •25.4.1. Preparation

- •25.4.2. Reading and Scaling the Mesh

- •25.4.3. Loading the MSMD battery Add-on

- •25.4.4. NTGK Battery Model Setup

- •25.4.4.1. Specifying Solver and Models

- •25.4.4.2. Defining New Materials for Cell and Tabs

- •25.4.4.3. Defining Cell Zone Conditions

- •25.4.4.4. Defining Boundary Conditions

- •25.4.4.5. Specifying Solution Settings

- •25.4.4.6. Obtaining Solution

- •25.4.5. Postprocessing

- •25.4.6. Simulating the Battery Pulse Discharge Using the ECM Model

- •25.4.7. Using the Reduced Order Method (ROM)

- •25.4.8. External and Internal Short-Circuit Treatment

- •25.4.8.1. Setting up and Solving a Short-Circuit Problem

- •25.4.8.2. Postprocessing

- •25.5. Summary

- •25.6. Appendix

- •25.7. References

- •26.1. Introduction

- •26.2. Prerequisites

- •26.3. Problem Description

- •26.4. Setup and Solution

- •26.4.1. Preparation

- •26.4.2. Reading and Scaling the Mesh

- •26.4.3. Loading the MSMD battery Add-on

- •26.4.4. Battery Model Setup

- •26.4.4.1. Specifying Solver and Models

- •26.4.4.2. Defining New Materials

- •26.4.4.3. Defining Cell Zone Conditions

- •26.4.4.4. Defining Boundary Conditions

- •26.4.4.5. Specifying Solution Settings

- •26.4.4.6. Obtaining Solution

- •26.4.5. Postprocessing

- •26.5. Summary

- •Chapter 27: In-Flight Icing Tutorial Using Fluent Icing

- •27.1. Fluent Airflow on the NACA0012 Airfoil

- •27.2. Flow Solution on the Rough NACA0012 Airfoil

- •27.3. Droplet Impingement on the NACA0012

- •27.3.1. Monodispersed Calculation

- •27.3.2. Langmuir-D Distribution

- •27.3.3. Post-Processing Using Quick-View

- •27.4. Fluent Icing Ice Accretion on the NACA0012

- •27.5. Postprocessing an Ice Accretion Solution Using CFD-Post Macros

- •27.6. Multi-Shot Ice Accretion with Automatic Mesh Displacement

- •27.7. Multi-Shot Ice Accretion with Automatic Mesh Displacement – Postprocessing Using CFD-Post

vk.com/club152685050Fluid Flow in an Exhaust|Manifoldvk.com/id446425943

1.2. Prerequisites

This tutorial is written with the assumption that you have completed one or more of the introductory tutorials (Fluid Flow and Heat Transfer in a Mixing Elbow (p. 35), for example) found in this manual and that you are familiar with the ANSYS Fluent outline view and ribbon structure. Some steps in the setup and solution procedure will not be shown explicitly.

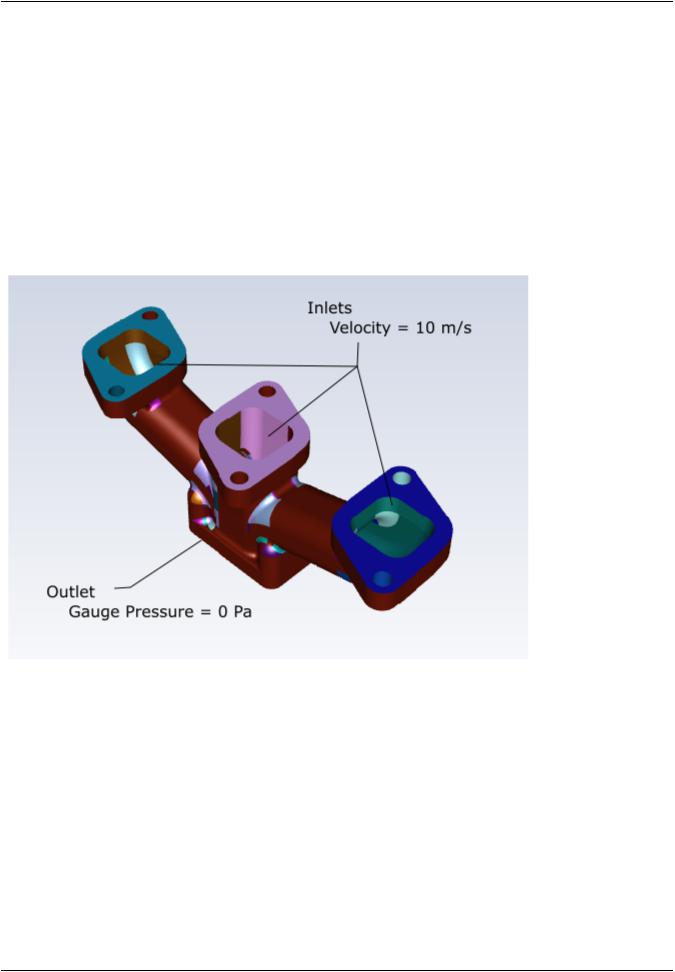

1.3. Problem Description

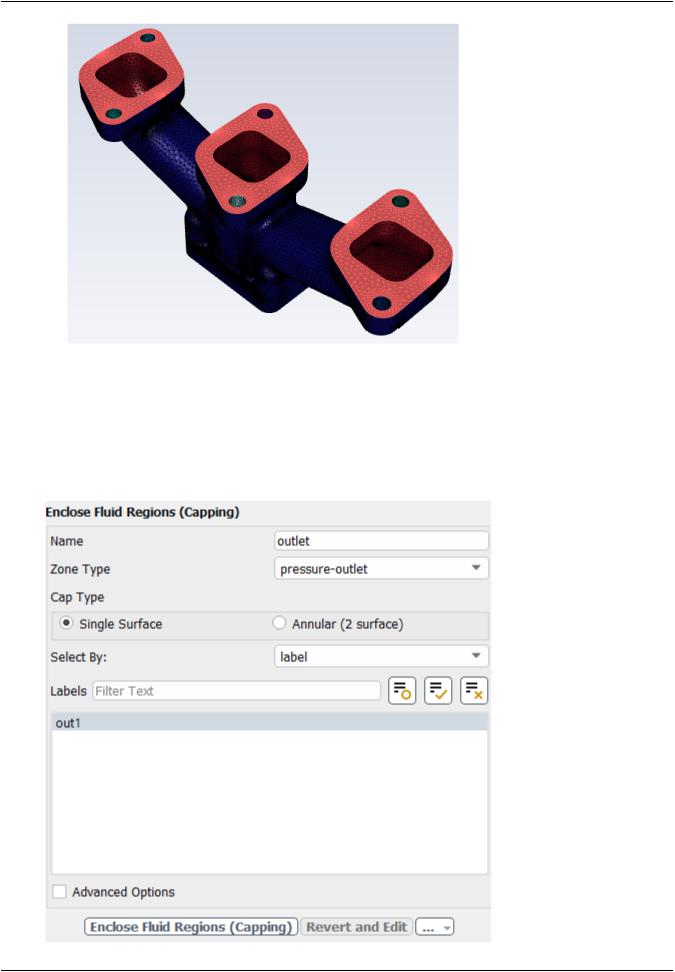

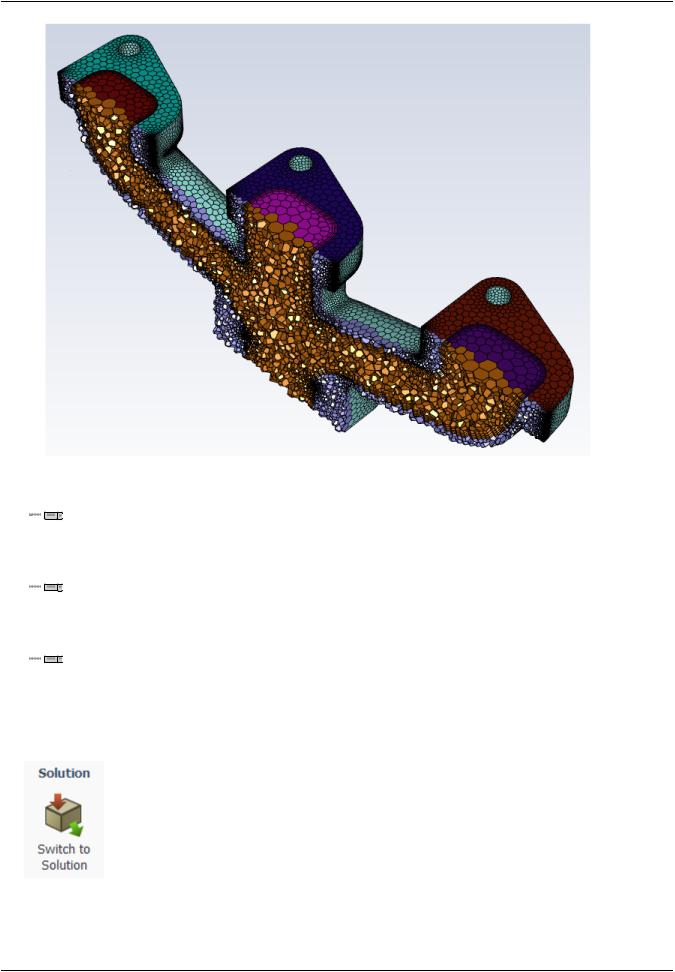

The manifold modeled here is shown in Figure 1.1: Manifold Geometry for Flow Modeling (p. 2). Air flows through the three inlets with a uniform velocity of 10 m/s, and then exits through the outlet.

Figure 1.1: Manifold Geometry for Flow Modeling

1.4. Setup and Solution

The following sections describe the setup and solution steps for this tutorial:

1.4.1.Preparation

1.4.2.Meshing Workflow

1.4.3.General Settings

1.4.4.Solver Settings

1.4.5.Models

1.4.6.Materials

1.4.7.Cell Zone Conditions

1.4.8.Boundary Conditions

1.4.9.Solution

1.4.10.Postprocessing

|

Release 2019 R1 - © ANSYS,Inc.All rights reserved.- Contains proprietary and confidential information |

2 |

of ANSYS, Inc. and its subsidiaries and affiliates. |

vk.com/club152685050 | vk.com/id446425943 |

Setup and Solution |

1.4.1. Preparation

To prepare for running this tutorial:

1.Download the exhaust_manifold.zip file here.

2.Unzip manifold.zip to your working directory.

The SpaceClaim CAD file manifold.scdoc can be found in the folder. In addition, the manifold.pmdb file is available for use on the Linux platform.

3.Use Fluent Launcher to start the 3D version of ANSYS Fluent.

4.Ensure that the Display Mesh After Reading option is enabled.

5.Enable Double Precision.

6.Enable Meshing Mode.

7.Ensure Parallel is selected under Processing Options.

8.Set Processes to 4.

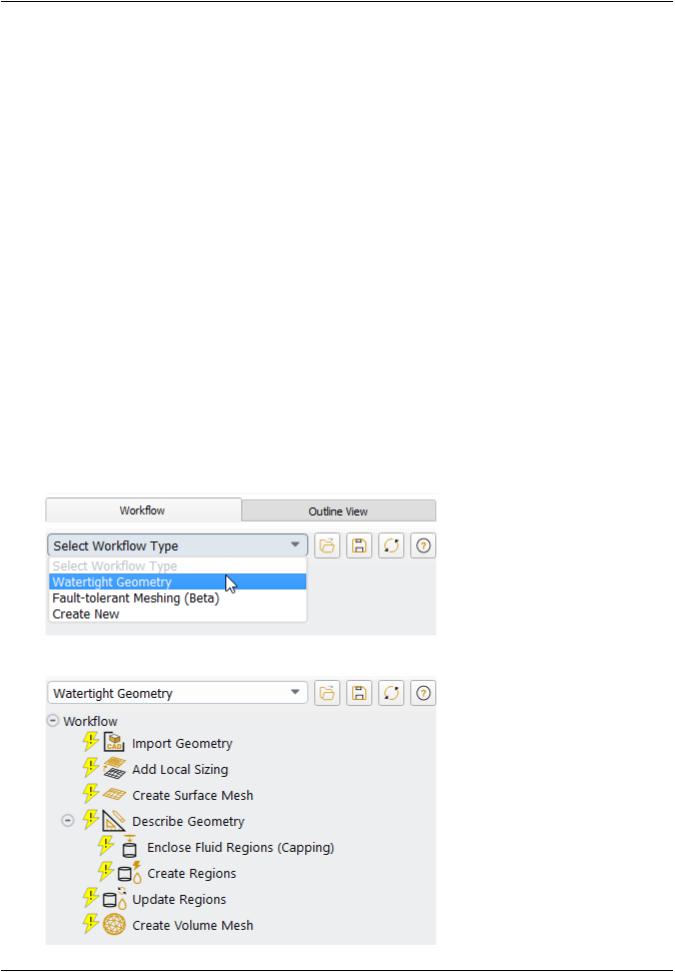

1.4.2. Meshing Workflow

1.Start the meshing workflow.

a. In the Workflow tab, select the Watertight Geometry workflow.

b. Review the tasks of the workflow.

Release 2019 R1 - © ANSYS,Inc.All rights reserved.- Contains proprietary and confidential information |

|

of ANSYS, Inc. and its subsidiaries and affiliates. |

3 |

vk.com/club152685050Fluid Flow in an Exhaust|Manifoldvk.com/id446425943

Each task is designated with an icon indicating its state (for example, as complete, incomplete, etc. For more information, see Understanding Task States in the Fluent User's Guide). All tasks are initially incomplete and you proceed through the workflow completing all tasks. Additional tasks are also available for the workflow. For more information, see Customizing Workflows in the

Fluent User's Guide.

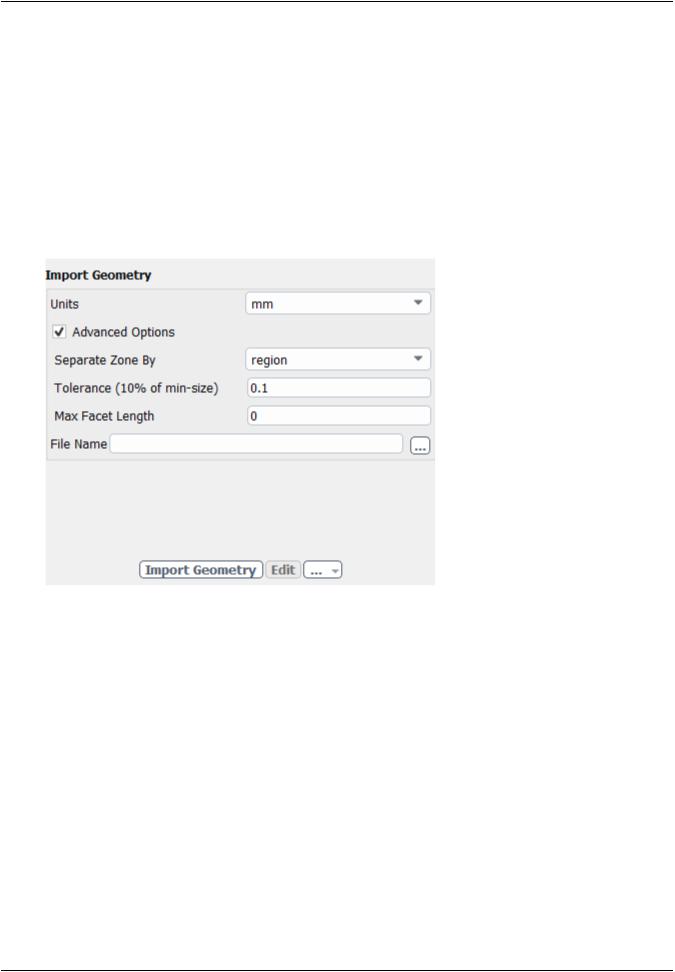

2.Import the CAD geometry (manifold.scdoc).

a.Select the Import Geometry task.

b.For Units, keep the default setting as mm.

c.(optional) Enable Advanced Options to expose additional options that may be required when importing a CAD geometry.

In this tutorial, we are keeping the default settings, so you can deselect the Advanced Options.

Many workflow tasks have advanced options that you may want to inspect before updating a task.

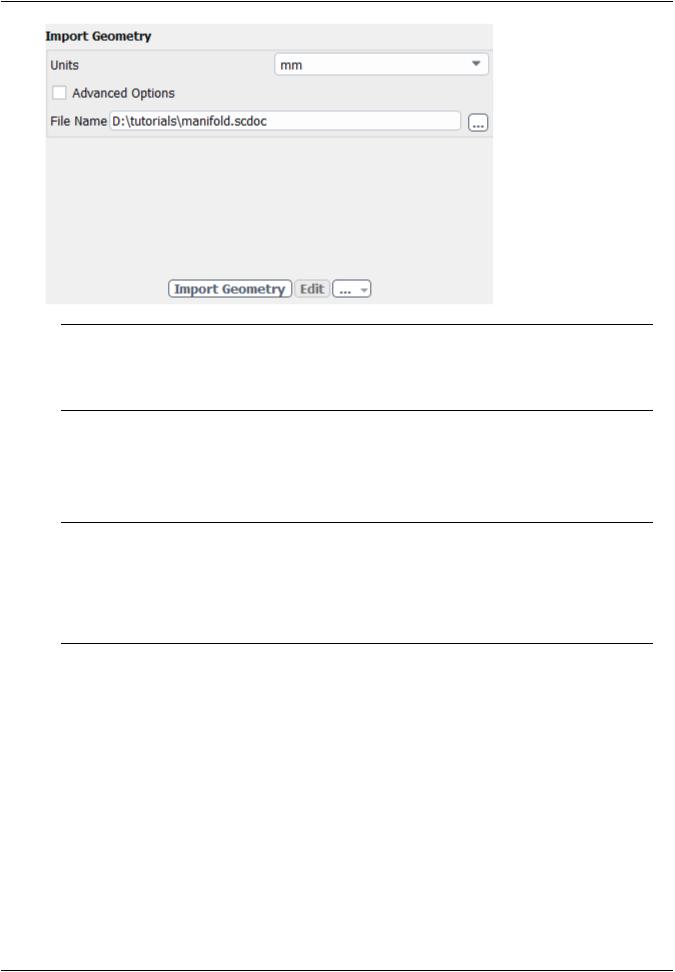

d.For File Name, enter the path and file name for the CAD geometry that you want to import (manifold.scdoc).

|

Release 2019 R1 - © ANSYS,Inc.All rights reserved.- Contains proprietary and confidential information |

4 |

of ANSYS, Inc. and its subsidiaries and affiliates. |

vk.com/club152685050 | vk.com/id446425943 |

Setup and Solution |

Note

The workflow only supports *.scdoc (SpaceClaim) and the intermediary *.pmdb file formats.

e.Select Import Geometry.

This will update the task, display the geometry in the graphics window, and allow you to proceed onto the next task in the workflow.

Note

Alternatively, you can use the … button next to File Name to locate the CAD geometry file, after which, the Import Geometry task automatically updates, displaying the geometry in the graphics window, and the workflow automatically progresses to the next task.

Throughout the workflow, you are able to return to a task and change its settings using either the Edit button, or the Revert and Edit button. For more information, see Editing Tasks in the Fluent User's Guide

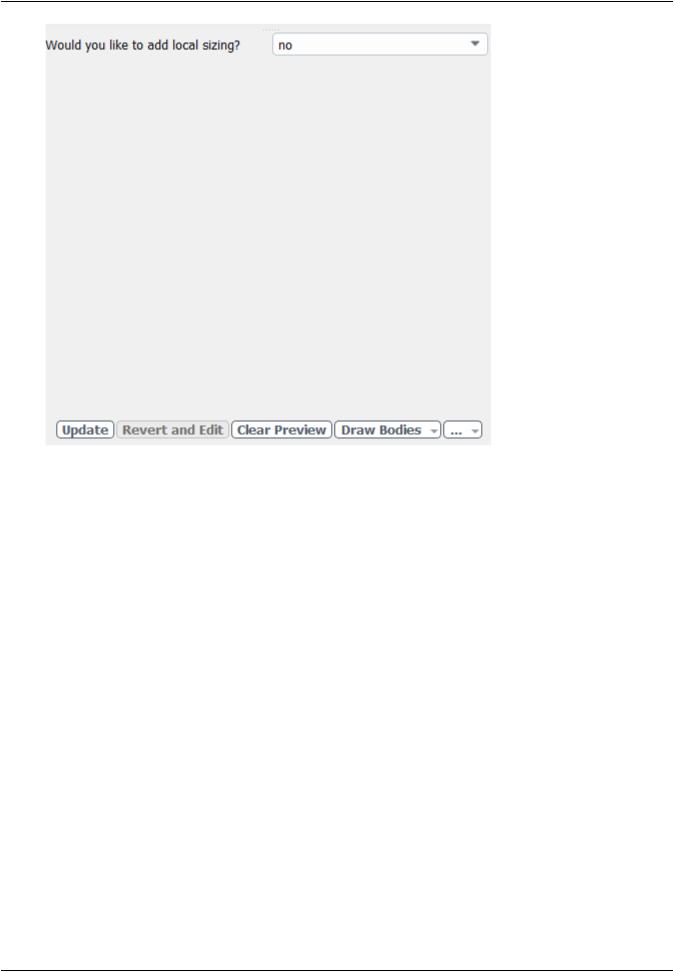

3.Add local sizing.

a.In the Add Local Sizing task, you are prompted as to whether or not you would like to add local sizing controls to the faceted geometry.

Release 2019 R1 - © ANSYS,Inc.All rights reserved.- Contains proprietary and confidential information |

|

of ANSYS, Inc. and its subsidiaries and affiliates. |

5 |

vk.com/club152685050Fluid Flow in an Exhaust|Manifoldvk.com/id446425943

b.For the purposes of this tutorial, you can keep the default setting of no.

c.Click Update to complete this task and proceed to the next task in the workflow.

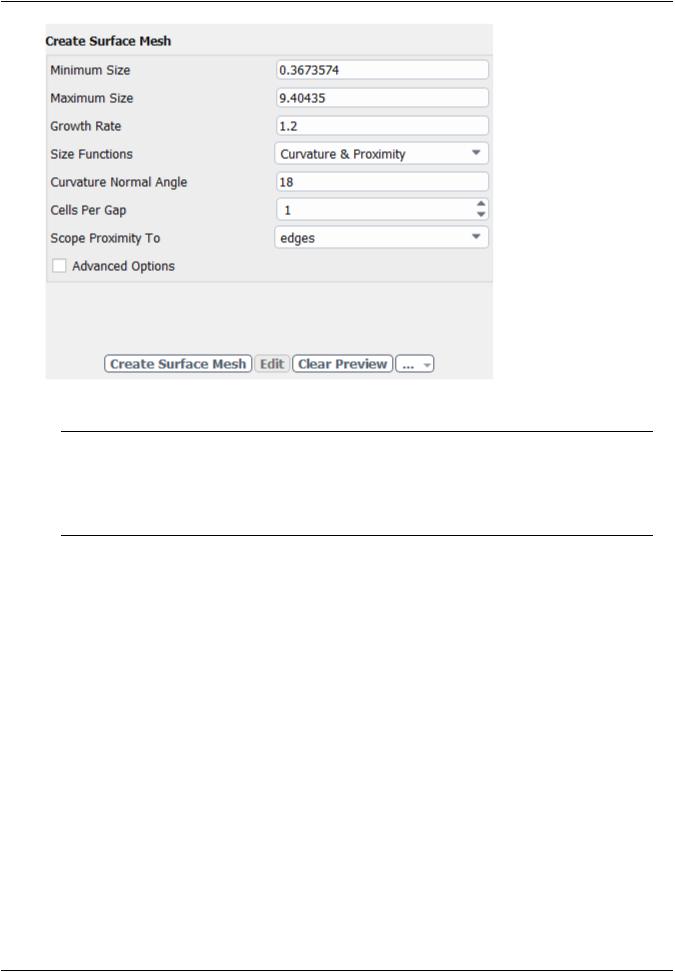

4.Create the surface mesh.

a.In the Create Surface Mesh task, you can set various properties of the surface mesh. for the faceted geometry.

|

Release 2019 R1 - © ANSYS,Inc.All rights reserved.- Contains proprietary and confidential information |

6 |

of ANSYS, Inc. and its subsidiaries and affiliates. |

vk.com/club152685050 | vk.com/id446425943 |

Setup and Solution |

b. For the purposes of this tutorial, you can keep the default settings.

Note

The red boxes displayed on the geometry in the graphics window are a graphical representation of size settings. These boxes change size as the values change, and they can be hidden by using the Clear Preview button.

c. Click Create Surface Mesh to complete this task and proceed to the next task in the workflow.

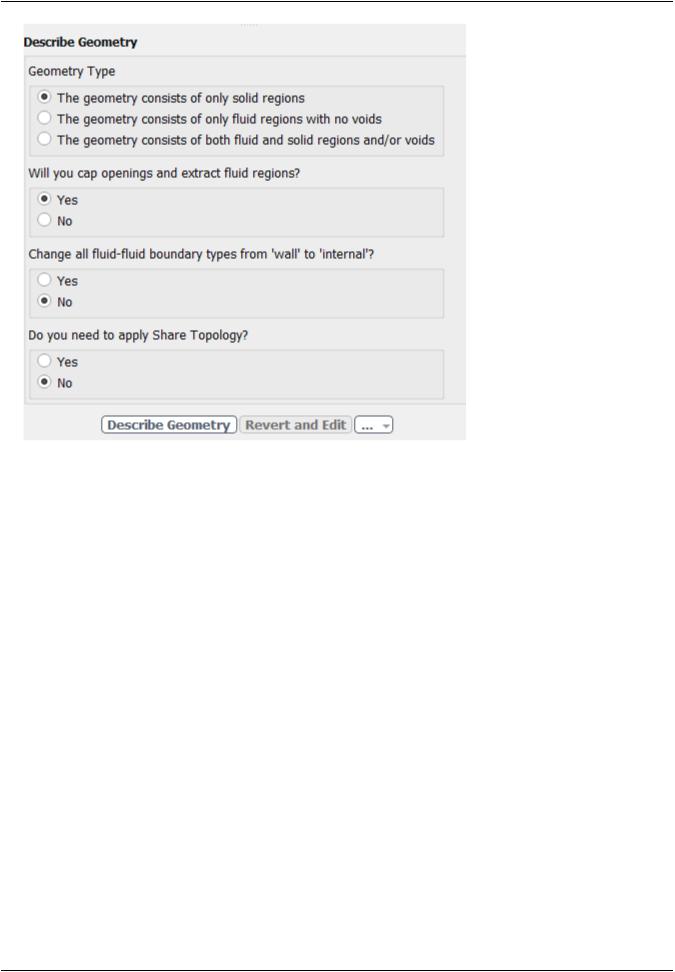

5.Describe the geometry.

When you select the Describe Geometry task, you are prompted with questions relating to the nature of the imported geometry.

Release 2019 R1 - © ANSYS,Inc.All rights reserved.- Contains proprietary and confidential information |

|

of ANSYS, Inc. and its subsidiaries and affiliates. |

7 |

vk.com/club152685050Fluid Flow in an Exhaust|Manifoldvk.com/id446425943

a.Since we plan on extracting a fluid region from this solid model, and adding capping surfaces, for the purposes of this tutorial, you can keep the default settings.

b.Click Describe Geometry to complete this task and proceed to the next task in the workflow.

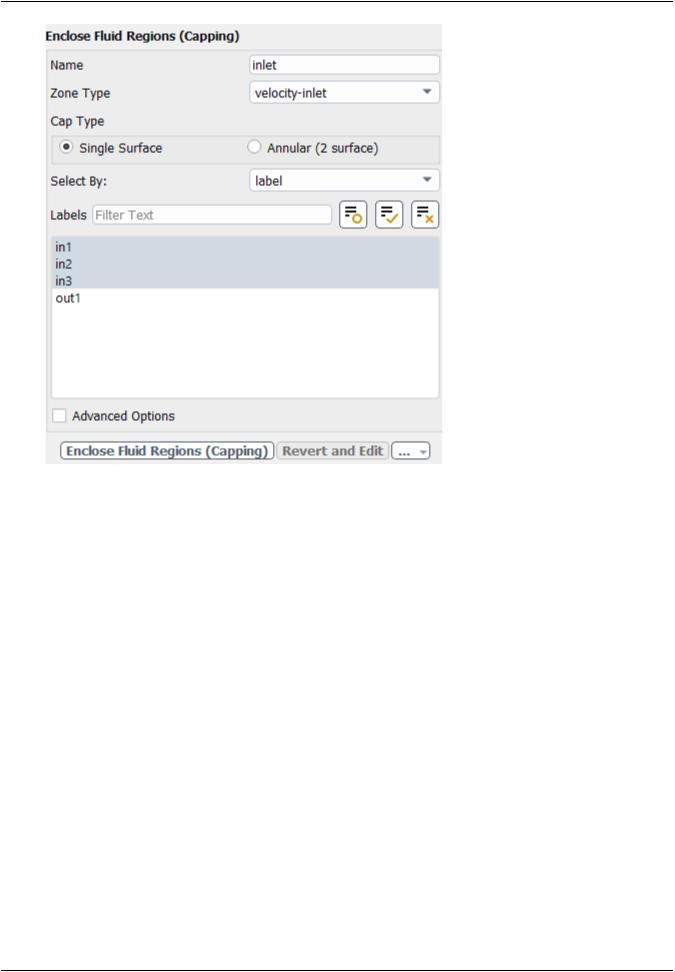

6.Cover any openings in your geometry.

Select the Enclose Fluid Regions (Capping) task, where you can cover, or cap, any openings in your geometry in order to later extract the enclosed fluid region.

a.Create a cap for the inlets.

|

Release 2019 R1 - © ANSYS,Inc.All rights reserved.- Contains proprietary and confidential information |

8 |

of ANSYS, Inc. and its subsidiaries and affiliates. |

vk.com/club152685050 | vk.com/id446425943 |

Setup and Solution |

i.In the Name field, assign a name for the capping surface (for example, inlet) to be assigned to all of the manifold's inlets.

ii.For the Zone Type, keep the default setting of velocity-inlet.

iii.For the Select By field, keep the default setting of label.

iv.In the Labels list, select in1, in2, and in3 for the openings that you want to cover.

The graphics window indicates the selected items.

Release 2019 R1 - © ANSYS,Inc.All rights reserved.- Contains proprietary and confidential information |

|

of ANSYS, Inc. and its subsidiaries and affiliates. |

9 |

vk.com/club152685050Fluid Flow in an Exhaust|Manifoldvk.com/id446425943

v.Click Enclose Fluid Regions (Capping) to complete this task and proceed to the next task in the workflow.

Once completed, this particular task will return you to a fresh task in order to assign additional capping surfaces, if necessary. We will proceed to assign a cap for the remaining opening

and assign it to be an outlet.

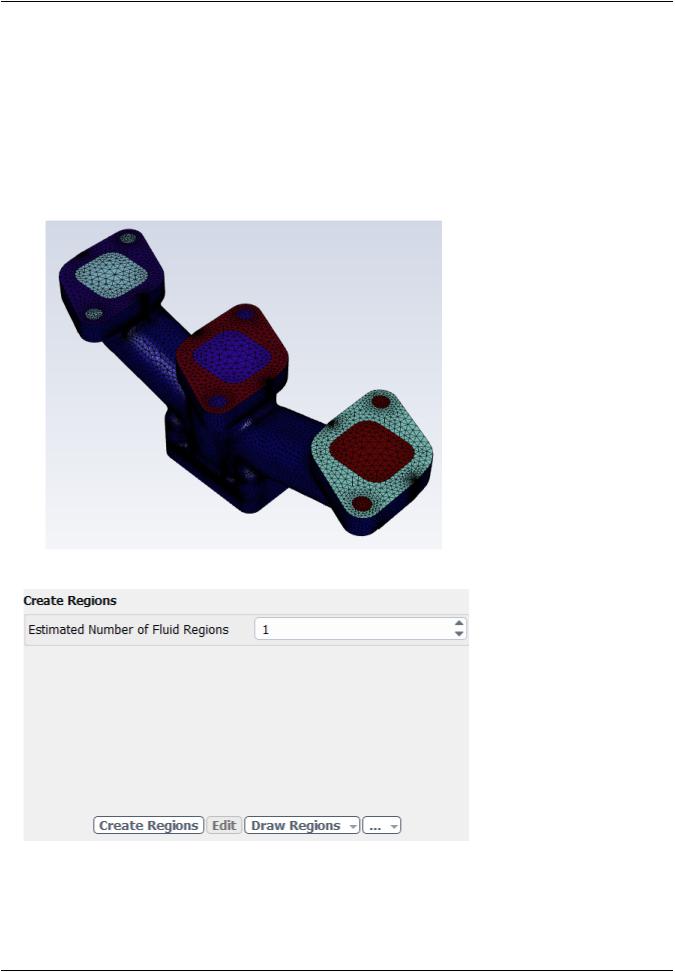

b.Create a cap for the outlet.

|

Release 2019 R1 - © ANSYS,Inc.All rights reserved.- Contains proprietary and confidential information |

10 |

of ANSYS, Inc. and its subsidiaries and affiliates. |

vk.com/club152685050 | vk.com/id446425943 |

Setup and Solution |

i.In the Name field, assign a name for the capping surface (for example, outlet) to be assigned to the manifold's outlet.

ii.For the Zone Type, change the setting to pressure-outlet.

iii.For the Select By field, keep the default setting of label.

iv.In the Labels list, select out1 for the outlet that you want to cover.

v.Click Enclose Fluid Regions (Capping) to complete this task.

Now, all of the openings in the geometry are covered.

7. Create the fluid region.

a.Select the Create Regions task, where you can determine the number of fluid regions that need to be extracted. ANSYS Fluent attempts to determine the number of fluid regions to extract automatically.

b.For the Estimated Number of Fluid Regions, keep the default selection of 1.

Release 2019 R1 - © ANSYS,Inc.All rights reserved.- Contains proprietary and confidential information |

|

of ANSYS, Inc. and its subsidiaries and affiliates. |

11 |

vk.com/club152685050Fluid Flow in an Exhaust|Manifoldvk.com/id446425943

c. Click Create Regions.

8.Update your regions.

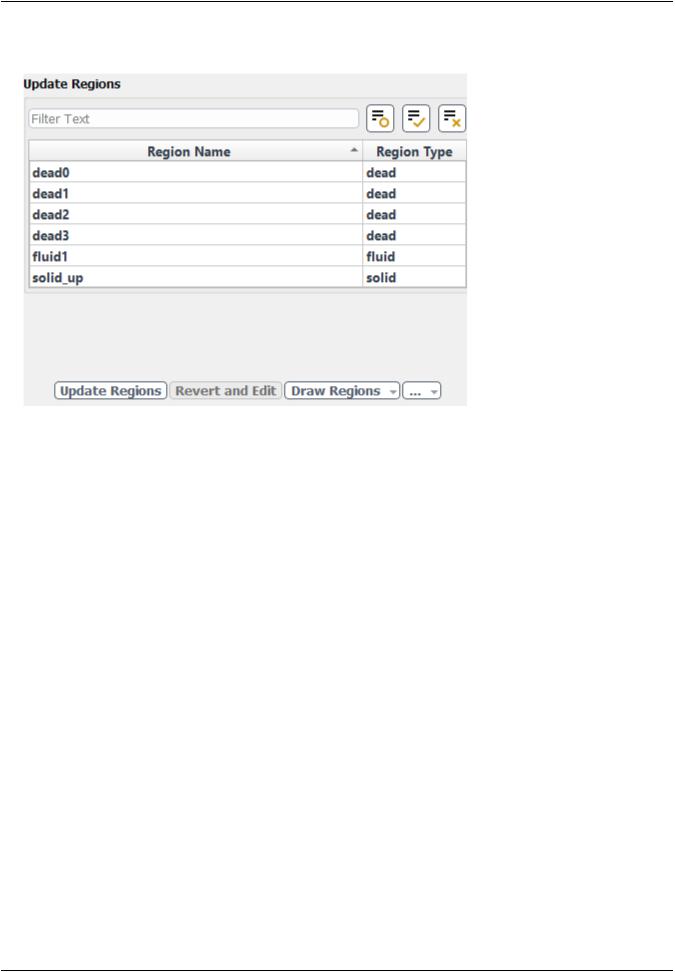

a.Select the Update Regions task, where you can review the names and types of the various regions that have been generated from your imported geometry, and change them as needed.

b.Keep the default settings, and click Update Regions.

Aside from fluid regions, and solid regions, you can also have voids within your geometry that are designated as dead regions. As you can see, there are four dead regions (corresponding to the four bolt holes near the outlet that were covered when the outlet was covered), a solid region, and a fluid region.

Once the regions have been updated, the fluid region is displayed by default in the graphics window. You can use the Draw Regions button to display other options, such as drawing just the solid region, just the dead regions, or all regions.

9.Create the volume mesh.

|

Release 2019 R1 - © ANSYS,Inc.All rights reserved.- Contains proprietary and confidential information |

12 |

of ANSYS, Inc. and its subsidiaries and affiliates. |

vk.com/club152685050 | vk.com/id446425943 |

Setup and Solution |

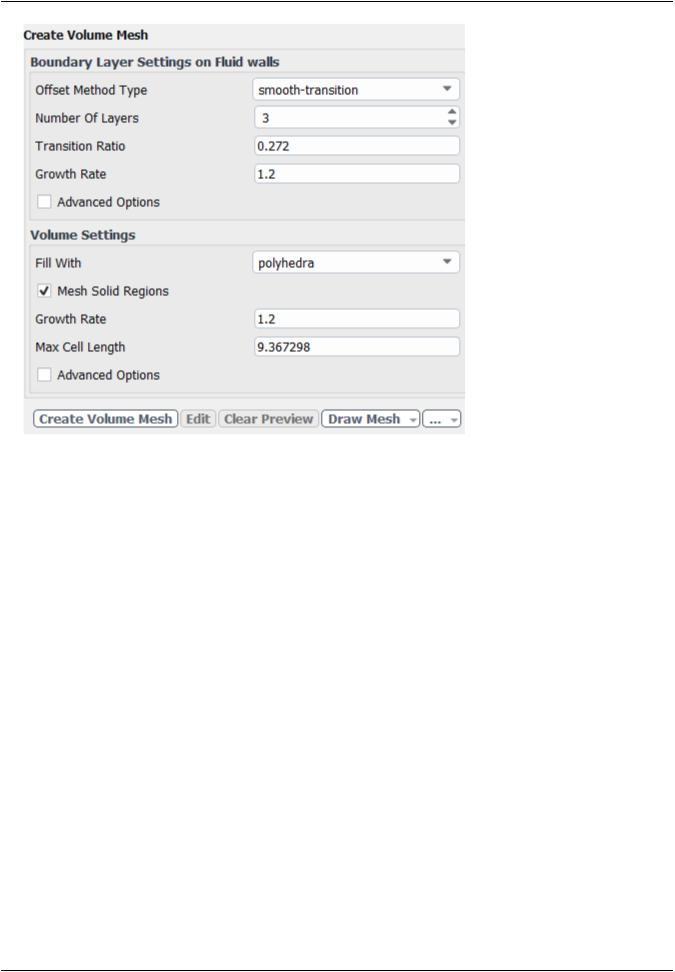

a.Select the Create Volume Mesh task, where you can set properties of the boundary layer mesh, as well as properties of the volume mesh itself.

b.Keep the default settings, and click Create Volume Mesh.

ANSYS Fluent will apply your settings and proceed to generate a volume mesh for the manifold geometry. Once complete, the mesh is displayed in the graphics window and a clipping plane is automatically inserted with a layer of cells drawn so that you can quickly see the details of the volume mesh.

Release 2019 R1 - © ANSYS,Inc.All rights reserved.- Contains proprietary and confidential information |

|

of ANSYS, Inc. and its subsidiaries and affiliates. |

13 |

vk.com/club152685050Fluid Flow in an Exhaust|Manifoldvk.com/id446425943

10.Check the mesh.

Mesh → Check

Mesh → Check

11.Save the mesh file (manifold.msh.gz).

File → Write → Mesh...

File → Write → Mesh...

12.Save the case file (manifold.cas.gz).

File → Write → Case...

File → Write → Case...

13.Switch to Solution mode.

Now that a high-quality mesh has been generated using ANSYS Fluent in meshing mode, you can now switch to solver mode to complete the set up of the simulation.

We have just checked the mesh, so select Yes when prompted to switch to solution mode.

|

Release 2019 R1 - © ANSYS,Inc.All rights reserved.- Contains proprietary and confidential information |

14 |

of ANSYS, Inc. and its subsidiaries and affiliates. |