- •ANSYS Fluent Tutorial Guide

- •Table of Contents

- •Using This Manual

- •1. What’s In This Manual

- •2. How To Use This Manual

- •2.1. For the Beginner

- •2.2. For the Experienced User

- •3. Typographical Conventions Used In This Manual

- •Chapter 1: Fluid Flow in an Exhaust Manifold

- •1.1. Introduction

- •1.2. Prerequisites

- •1.3. Problem Description

- •1.4. Setup and Solution

- •1.4.1. Preparation

- •1.4.2. Meshing Workflow

- •1.4.3. General Settings

- •1.4.4. Solver Settings

- •1.4.5. Models

- •1.4.6. Materials

- •1.4.7. Cell Zone Conditions

- •1.4.8. Boundary Conditions

- •1.4.9. Solution

- •1.4.10. Postprocessing

- •1.5. Summary

- •Chapter 2: Fluid Flow and Heat Transfer in a Mixing Elbow

- •2.1. Introduction

- •2.2. Prerequisites

- •2.3. Problem Description

- •2.4. Setup and Solution

- •2.4.1. Preparation

- •2.4.2. Launching ANSYS Fluent

- •2.4.3. Reading the Mesh

- •2.4.4. Setting Up Domain

- •2.4.5. Setting Up Physics

- •2.4.6. Solving

- •2.4.7. Displaying the Preliminary Solution

- •2.4.8. Adapting the Mesh

- •2.5. Summary

- •Chapter 3: Postprocessing

- •3.1. Introduction

- •3.2. Prerequisites

- •3.3. Problem Description

- •3.4. Setup and Solution

- •3.4.1. Preparation

- •3.4.2. Reading the Mesh

- •3.4.3. Manipulating the Mesh in the Viewer

- •3.4.4. Adding Lights

- •3.4.5. Creating Isosurfaces

- •3.4.6. Generating Contours

- •3.4.7. Generating Velocity Vectors

- •3.4.8. Creating an Animation

- •3.4.9. Displaying Pathlines

- •3.4.10. Creating a Scene With Vectors and Contours

- •3.4.11. Advanced Overlay of Pathlines on a Scene

- •3.4.12. Creating Exploded Views

- •3.4.13. Animating the Display of Results in Successive Streamwise Planes

- •3.4.14. Generating XY Plots

- •3.4.15. Creating Annotation

- •3.4.16. Saving Picture Files

- •3.4.17. Generating Volume Integral Reports

- •3.5. Summary

- •Chapter 4: Modeling Periodic Flow and Heat Transfer

- •4.1. Introduction

- •4.2. Prerequisites

- •4.3. Problem Description

- •4.4. Setup and Solution

- •4.4.1. Preparation

- •4.4.2. Mesh

- •4.4.3. General Settings

- •4.4.4. Models

- •4.4.5. Materials

- •4.4.6. Cell Zone Conditions

- •4.4.7. Periodic Conditions

- •4.4.8. Boundary Conditions

- •4.4.9. Solution

- •4.4.10. Postprocessing

- •4.5. Summary

- •4.6. Further Improvements

- •Chapter 5: Modeling External Compressible Flow

- •5.1. Introduction

- •5.2. Prerequisites

- •5.3. Problem Description

- •5.4. Setup and Solution

- •5.4.1. Preparation

- •5.4.2. Mesh

- •5.4.3. Solver

- •5.4.4. Models

- •5.4.5. Materials

- •5.4.6. Boundary Conditions

- •5.4.7. Operating Conditions

- •5.4.8. Solution

- •5.4.9. Postprocessing

- •5.5. Summary

- •5.6. Further Improvements

- •Chapter 6: Modeling Transient Compressible Flow

- •6.1. Introduction

- •6.2. Prerequisites

- •6.3. Problem Description

- •6.4. Setup and Solution

- •6.4.1. Preparation

- •6.4.2. Reading and Checking the Mesh

- •6.4.3. Solver and Analysis Type

- •6.4.4. Models

- •6.4.5. Materials

- •6.4.6. Operating Conditions

- •6.4.7. Boundary Conditions

- •6.4.8. Solution: Steady Flow

- •6.4.9. Enabling Time Dependence and Setting Transient Conditions

- •6.4.10. Specifying Solution Parameters for Transient Flow and Solving

- •6.4.11. Saving and Postprocessing Time-Dependent Data Sets

- •6.5. Summary

- •6.6. Further Improvements

- •Chapter 7: Modeling Flow Through Porous Media

- •7.1. Introduction

- •7.2. Prerequisites

- •7.3. Problem Description

- •7.4. Setup and Solution

- •7.4.1. Preparation

- •7.4.2. Mesh

- •7.4.3. General Settings

- •7.4.4. Models

- •7.4.5. Materials

- •7.4.6. Cell Zone Conditions

- •7.4.7. Boundary Conditions

- •7.4.8. Solution

- •7.4.9. Postprocessing

- •7.5. Summary

- •7.6. Further Improvements

- •Chapter 8: Modeling Radiation and Natural Convection

- •8.1. Introduction

- •8.2. Prerequisites

- •8.3. Problem Description

- •8.4. Setup and Solution

- •8.4.1. Preparation

- •8.4.2. Reading and Checking the Mesh

- •8.4.3. Solver and Analysis Type

- •8.4.4. Models

- •8.4.5. Defining the Materials

- •8.4.6. Operating Conditions

- •8.4.7. Boundary Conditions

- •8.4.8. Obtaining the Solution

- •8.4.9. Postprocessing

- •8.4.10. Comparing the Contour Plots after Varying Radiating Surfaces

- •8.4.11. S2S Definition, Solution, and Postprocessing with Partial Enclosure

- •8.5. Summary

- •8.6. Further Improvements

- •Chapter 9: Using a Single Rotating Reference Frame

- •9.1. Introduction

- •9.2. Prerequisites

- •9.3. Problem Description

- •9.4. Setup and Solution

- •9.4.1. Preparation

- •9.4.2. Mesh

- •9.4.3. General Settings

- •9.4.4. Models

- •9.4.5. Materials

- •9.4.6. Cell Zone Conditions

- •9.4.7. Boundary Conditions

- •9.4.8. Solution Using the Standard k- ε Model

- •9.4.9. Postprocessing for the Standard k- ε Solution

- •9.4.10. Solution Using the RNG k- ε Model

- •9.4.11. Postprocessing for the RNG k- ε Solution

- •9.5. Summary

- •9.6. Further Improvements

- •9.7. References

- •Chapter 10: Using Multiple Reference Frames

- •10.1. Introduction

- •10.2. Prerequisites

- •10.3. Problem Description

- •10.4. Setup and Solution

- •10.4.1. Preparation

- •10.4.2. Mesh

- •10.4.3. Models

- •10.4.4. Materials

- •10.4.5. Cell Zone Conditions

- •10.4.6. Boundary Conditions

- •10.4.7. Solution

- •10.4.8. Postprocessing

- •10.5. Summary

- •10.6. Further Improvements

- •Chapter 11: Using Sliding Meshes

- •11.1. Introduction

- •11.2. Prerequisites

- •11.3. Problem Description

- •11.4. Setup and Solution

- •11.4.1. Preparation

- •11.4.2. Mesh

- •11.4.3. General Settings

- •11.4.4. Models

- •11.4.5. Materials

- •11.4.6. Cell Zone Conditions

- •11.4.7. Boundary Conditions

- •11.4.8. Operating Conditions

- •11.4.9. Mesh Interfaces

- •11.4.10. Solution

- •11.4.11. Postprocessing

- •11.5. Summary

- •11.6. Further Improvements

- •Chapter 12: Using Overset and Dynamic Meshes

- •12.1. Prerequisites

- •12.2. Problem Description

- •12.3. Preparation

- •12.4. Mesh

- •12.5. Overset Interface Creation

- •12.6. Steady-State Case Setup

- •12.6.1. General Settings

- •12.6.2. Models

- •12.6.3. Materials

- •12.6.4. Operating Conditions

- •12.6.5. Boundary Conditions

- •12.6.6. Reference Values

- •12.6.7. Solution

- •12.7. Unsteady Setup

- •12.7.1. General Settings

- •12.7.2. Compile the UDF

- •12.7.3. Dynamic Mesh Settings

- •12.7.4. Report Generation for Unsteady Case

- •12.7.5. Run Calculations for Unsteady Case

- •12.7.6. Overset Solution Checking

- •12.7.7. Postprocessing

- •12.7.8. Diagnosing an Overset Case

- •12.8. Summary

- •Chapter 13: Modeling Species Transport and Gaseous Combustion

- •13.1. Introduction

- •13.2. Prerequisites

- •13.3. Problem Description

- •13.4. Background

- •13.5. Setup and Solution

- •13.5.1. Preparation

- •13.5.2. Mesh

- •13.5.3. General Settings

- •13.5.4. Models

- •13.5.5. Materials

- •13.5.6. Boundary Conditions

- •13.5.7. Initial Reaction Solution

- •13.5.8. Postprocessing

- •13.5.9. NOx Prediction

- •13.6. Summary

- •13.7. Further Improvements

- •Chapter 14: Using the Eddy Dissipation and Steady Diffusion Flamelet Combustion Models

- •14.1. Introduction

- •14.2. Prerequisites

- •14.3. Problem Description

- •14.4. Setup and Solution

- •14.4.1. Preparation

- •14.4.2. Mesh

- •14.4.3. Solver Settings

- •14.4.4. Models

- •14.4.5. Boundary Conditions

- •14.4.6. Solution

- •14.4.7. Postprocessing for the Eddy-Dissipation Solution

- •14.5. Steady Diffusion Flamelet Model Setup and Solution

- •14.5.1. Models

- •14.5.2. Boundary Conditions

- •14.5.3. Solution

- •14.5.4. Postprocessing for the Steady Diffusion Flamelet Solution

- •14.6. Summary

- •Chapter 15: Modeling Surface Chemistry

- •15.1. Introduction

- •15.2. Prerequisites

- •15.3. Problem Description

- •15.4. Setup and Solution

- •15.4.1. Preparation

- •15.4.2. Reading and Checking the Mesh

- •15.4.3. Solver and Analysis Type

- •15.4.4. Specifying the Models

- •15.4.5. Defining Materials and Properties

- •15.4.6. Specifying Boundary Conditions

- •15.4.7. Setting the Operating Conditions

- •15.4.8. Simulating Non-Reacting Flow

- •15.4.9. Simulating Reacting Flow

- •15.4.10. Postprocessing the Solution Results

- •15.5. Summary

- •15.6. Further Improvements

- •Chapter 16: Modeling Evaporating Liquid Spray

- •16.1. Introduction

- •16.2. Prerequisites

- •16.3. Problem Description

- •16.4. Setup and Solution

- •16.4.1. Preparation

- •16.4.2. Mesh

- •16.4.3. Solver

- •16.4.4. Models

- •16.4.5. Materials

- •16.4.6. Boundary Conditions

- •16.4.7. Initial Solution Without Droplets

- •16.4.8. Creating a Spray Injection

- •16.4.9. Solution

- •16.4.10. Postprocessing

- •16.5. Summary

- •16.6. Further Improvements

- •Chapter 17: Using the VOF Model

- •17.1. Introduction

- •17.2. Prerequisites

- •17.3. Problem Description

- •17.4. Setup and Solution

- •17.4.1. Preparation

- •17.4.2. Reading and Manipulating the Mesh

- •17.4.3. General Settings

- •17.4.4. Models

- •17.4.5. Materials

- •17.4.6. Phases

- •17.4.7. Operating Conditions

- •17.4.8. User-Defined Function (UDF)

- •17.4.9. Boundary Conditions

- •17.4.10. Solution

- •17.4.11. Postprocessing

- •17.5. Summary

- •17.6. Further Improvements

- •Chapter 18: Modeling Cavitation

- •18.1. Introduction

- •18.2. Prerequisites

- •18.3. Problem Description

- •18.4. Setup and Solution

- •18.4.1. Preparation

- •18.4.2. Reading and Checking the Mesh

- •18.4.3. Solver Settings

- •18.4.4. Models

- •18.4.5. Materials

- •18.4.6. Phases

- •18.4.7. Boundary Conditions

- •18.4.8. Operating Conditions

- •18.4.9. Solution

- •18.4.10. Postprocessing

- •18.5. Summary

- •18.6. Further Improvements

- •Chapter 19: Using the Multiphase Models

- •19.1. Introduction

- •19.2. Prerequisites

- •19.3. Problem Description

- •19.4. Setup and Solution

- •19.4.1. Preparation

- •19.4.2. Mesh

- •19.4.3. Solver Settings

- •19.4.4. Models

- •19.4.5. Materials

- •19.4.6. Phases

- •19.4.7. Cell Zone Conditions

- •19.4.8. Boundary Conditions

- •19.4.9. Solution

- •19.4.10. Postprocessing

- •19.5. Summary

- •Chapter 20: Modeling Solidification

- •20.1. Introduction

- •20.2. Prerequisites

- •20.3. Problem Description

- •20.4. Setup and Solution

- •20.4.1. Preparation

- •20.4.2. Reading and Checking the Mesh

- •20.4.3. Specifying Solver and Analysis Type

- •20.4.4. Specifying the Models

- •20.4.5. Defining Materials

- •20.4.6. Setting the Cell Zone Conditions

- •20.4.7. Setting the Boundary Conditions

- •20.4.8. Solution: Steady Conduction

- •20.5. Summary

- •20.6. Further Improvements

- •Chapter 21: Using the Eulerian Granular Multiphase Model with Heat Transfer

- •21.1. Introduction

- •21.2. Prerequisites

- •21.3. Problem Description

- •21.4. Setup and Solution

- •21.4.1. Preparation

- •21.4.2. Mesh

- •21.4.3. Solver Settings

- •21.4.4. Models

- •21.4.6. Materials

- •21.4.7. Phases

- •21.4.8. Boundary Conditions

- •21.4.9. Solution

- •21.4.10. Postprocessing

- •21.5. Summary

- •21.6. Further Improvements

- •21.7. References

- •22.1. Introduction

- •22.2. Prerequisites

- •22.3. Problem Description

- •22.4. Setup and Solution

- •22.4.1. Preparation

- •22.4.2. Structural Model

- •22.4.3. Materials

- •22.4.4. Cell Zone Conditions

- •22.4.5. Boundary Conditions

- •22.4.6. Solution

- •22.4.7. Postprocessing

- •22.5. Summary

- •23.1. Introduction

- •23.2. Prerequisites

- •23.3. Problem Description

- •23.4. Setup and Solution

- •23.4.1. Preparation

- •23.4.2. Solver and Analysis Type

- •23.4.3. Structural Model

- •23.4.4. Materials

- •23.4.5. Cell Zone Conditions

- •23.4.6. Boundary Conditions

- •23.4.7. Dynamic Mesh Zones

- •23.4.8. Solution Animations

- •23.4.9. Solution

- •23.4.10. Postprocessing

- •23.5. Summary

- •Chapter 24: Using the Adjoint Solver – 2D Laminar Flow Past a Cylinder

- •24.1. Introduction

- •24.2. Prerequisites

- •24.3. Problem Description

- •24.4. Setup and Solution

- •24.4.1. Step 1: Preparation

- •24.4.2. Step 2: Define Observables

- •24.4.3. Step 3: Compute the Drag Sensitivity

- •24.4.4. Step 4: Postprocess and Export Drag Sensitivity

- •24.4.4.1. Boundary Condition Sensitivity

- •24.4.4.2. Momentum Source Sensitivity

- •24.4.4.3. Shape Sensitivity

- •24.4.4.4. Exporting Drag Sensitivity Data

- •24.4.5. Step 5: Compute Lift Sensitivity

- •24.4.6. Step 6: Modify the Shape

- •24.5. Summary

- •25.1. Introduction

- •25.2. Prerequisites

- •25.3. Problem Description

- •25.4. Setup and Solution

- •25.4.1. Preparation

- •25.4.2. Reading and Scaling the Mesh

- •25.4.3. Loading the MSMD battery Add-on

- •25.4.4. NTGK Battery Model Setup

- •25.4.4.1. Specifying Solver and Models

- •25.4.4.2. Defining New Materials for Cell and Tabs

- •25.4.4.3. Defining Cell Zone Conditions

- •25.4.4.4. Defining Boundary Conditions

- •25.4.4.5. Specifying Solution Settings

- •25.4.4.6. Obtaining Solution

- •25.4.5. Postprocessing

- •25.4.6. Simulating the Battery Pulse Discharge Using the ECM Model

- •25.4.7. Using the Reduced Order Method (ROM)

- •25.4.8. External and Internal Short-Circuit Treatment

- •25.4.8.1. Setting up and Solving a Short-Circuit Problem

- •25.4.8.2. Postprocessing

- •25.5. Summary

- •25.6. Appendix

- •25.7. References

- •26.1. Introduction

- •26.2. Prerequisites

- •26.3. Problem Description

- •26.4. Setup and Solution

- •26.4.1. Preparation

- •26.4.2. Reading and Scaling the Mesh

- •26.4.3. Loading the MSMD battery Add-on

- •26.4.4. Battery Model Setup

- •26.4.4.1. Specifying Solver and Models

- •26.4.4.2. Defining New Materials

- •26.4.4.3. Defining Cell Zone Conditions

- •26.4.4.4. Defining Boundary Conditions

- •26.4.4.5. Specifying Solution Settings

- •26.4.4.6. Obtaining Solution

- •26.4.5. Postprocessing

- •26.5. Summary

- •Chapter 27: In-Flight Icing Tutorial Using Fluent Icing

- •27.1. Fluent Airflow on the NACA0012 Airfoil

- •27.2. Flow Solution on the Rough NACA0012 Airfoil

- •27.3. Droplet Impingement on the NACA0012

- •27.3.1. Monodispersed Calculation

- •27.3.2. Langmuir-D Distribution

- •27.3.3. Post-Processing Using Quick-View

- •27.4. Fluent Icing Ice Accretion on the NACA0012

- •27.5. Postprocessing an Ice Accretion Solution Using CFD-Post Macros

- •27.6. Multi-Shot Ice Accretion with Automatic Mesh Displacement

- •27.7. Multi-Shot Ice Accretion with Automatic Mesh Displacement – Postprocessing Using CFD-Post

vk.com/club152685050 | vk.com/id446425943

Chapter 27: In-Flight Icing Tutorial Using Fluent Icing

27.1. Fluent Airflow on the NACA0012 Airfoil

The objective of this tutorial is to obtain an airflow solution around a rough NACA0012 airfoil using Fluent, within the Fluent Icing framework, and to use this solution for water catch and ice accretion simulations. The NACA0012 grid corresponds to the case file produced at the end of Flow Solution on the Clean NACA0012 Airfoil within the FENSAP-ICE Tutorial Guide. The computational grid consists of 114,700 nodes and 56,810 hexahedral cells. Symmetry conditions are imposed on each spanwise boundary of the grid. The airfoil chord length is 0.5334 meters (21 inches) and the depth of elements along the span (Z-direction) is 0.1 meters. A no-slip wall boundary is imposed on the airfoil surface. Since the flow is viscous and turbulent, grid points have been clustered around the airfoil to better capture the boundary layer and wake. The initial cell height is 2.5e-6 chords, set up such that the maximum Y+ is below 1 in the first layer, and the expansion ratio is 1.14 in the normal direction which is a fine-grid setting that is required for capturing boundary layers. Far-field conditions are imposed on the outer surface of the grid. The mesh density can be considered medium.

Note

This tutorial uses the same in-flight conditions as In-Flight Icing using FLUENT within FENSAPICE within the FENSAP-ICE Tutorial Guide.

FENSAP-ICE modules used in Fluent Icing solve 2-D problems using a volume mesh of a single layer of 3-D elements instead of surfaces, for generalized implementation of the governing equations. This requires Fluent to be executed in 3-D mode even if the computational domain is in fact 2-D.

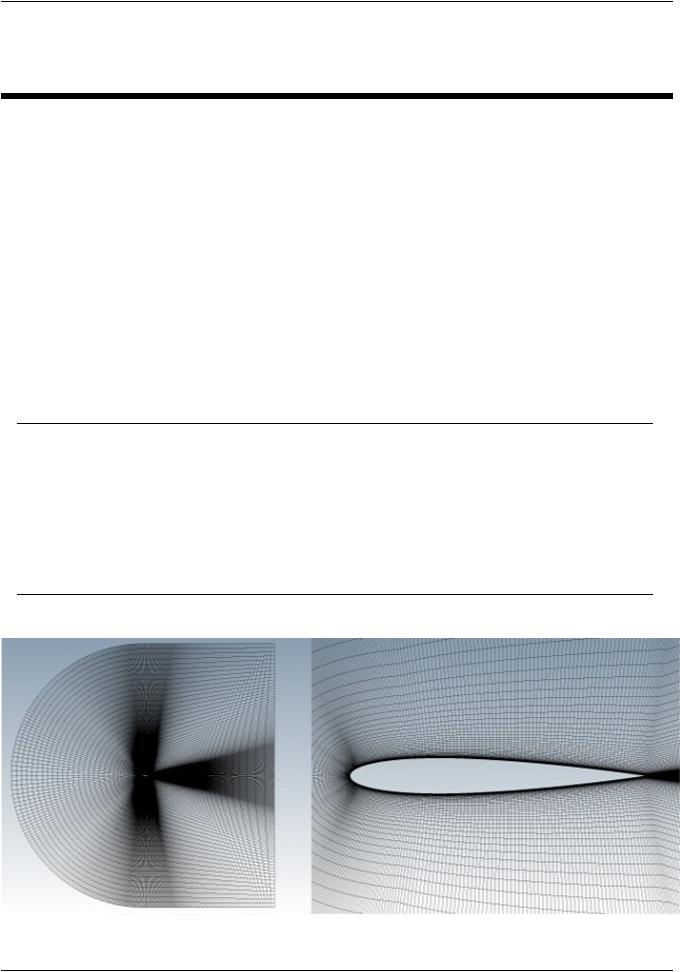

Figure 27.1: NACA0012 Structured C-Mesh Overview and Close-Up

Release 2019 R1 - © ANSYS,Inc.All rights reserved.- Contains proprietary and confidential information |

|

of ANSYS, Inc. and its subsidiaries and affiliates. |

891 |

vk.com/club152685050In-F ight Icing Tutorial Using| vk.Fluentcom/id446425943Icing

For more information on how to set up the input parameters of Fluent for in-flight icing simulations, you are invited to read Recommendations to Set up a Fluent Calculation within the FENSAP-ICE User Manual or the Recommended settings section under Fluent Icing within the Fluent User's Guide.

27.2. Flow Solution on the Rough NACA0012 Airfoil

Ice forms surface roughness where it accretes. This roughness increases the momentum deficit and skin friction, which in turn thickens the boundary layer and increases drag. Convective heat flux is also increased through additional turbulent conductivity within the boundary layer. It is therefore essential

to properly model the roughness produced naturally by the ice accretion process to obtain realistic ice shapes. Fluent Icing can model sand-grain roughness by means of modifying the wall turbulence model boundary conditions and eventually increasing the intensity of the eddy (turbulent) viscosity in

the boundary layer. The micro scale roughness is usually in the range of 0.1 ~ 3.0 mm. It can be specified on each wall as a constant value, or as a distribution via empirical or analytical methods. Roughness value greatly influences the final ice shape; therefore, it must be chosen appropriately. See Surface Roughness within the FENSAP-ICE User Manual or Set-up → Boundary Conditions → Wall and Set-up → Ice under Fluent Icing within the Fluent User's Guide for more details on surface roughness.

Download the FLUENT_ICING.zip file here.

1.Create a working directory folder and name it FLUENT_ICING_NACA0012.

2.Go to file ../workshop_input_files/Input_Grid/Naca0012/naca0012.clean.cas. Copy this case file along with its data file (naca0012.clean.dat) into your working directory FLUENT_ICING_NACA0012.

This case contains all the proper airflow settings required to conduct in-flight icing simulations using the following flight condition. See Flow Solution on the Clean NACA0012 Airfoil within the FENSAPICE Tutorial Guide for more detail.

3.Table 27.1: Flight Condition Table

Characteristic Length |

0.5334 m |

Speed |

102.8 m/s |

AoA |

4 deg |

Pressure |

101325 Pa |

Temperature |

265.67 K (7.48 °C) |

In this tutorial, only the wall boundaries require set-up as the original .CAS file corresponds to a clean surface.

4.Launch Fluent Icing from your working directory.

5.Go to File → Preferences…. Select Icing on the left hand-side of the Preferences window. Assign a number of CPUs, 2 to 4 CPUs, next to Default Fluent CPU, check Define working directory and set Working directory to the location of your working directory. Click Ok. A message box that asks you to confirm your changes appears. Press Yes.

6.Go to File → Open Case, and browse to and select the file naca0012.clean.cas located in your working directory.

|

Release 2019 R1 - © ANSYS,Inc.All rights reserved.- Contains proprietary and confidential information |

892 |

of ANSYS, Inc. and its subsidiaries and affiliates. |

vk.com/club152685050 | vk.com/id446425943 |

Flow Solution on the Rough NACA0012 Airfoil |

7.A message window will ask you to import the data file and then to launch Fluent, click Yes in both cases. In your Fluent Icing window, a new simulation tree appears under naca0012_clean.cas (loaded) in the

Outline View window.

8.Select Set-up under naca0012_clean.cas (loaded) and, in its Properties window, uncheck Particles and Ice.

9.Inside the Outline View window, right on the Airflow icon located under Set-up and select Update with Fluent Case settings to make sure that the Fluent simulation settings are properly transferred to Fluent Icing.

10.Under Set-up → Airflow, check Sync. with Fluent ref. conditions to synchronize the Properties of Airflow panel with the Reference Values panel of Fluent.

11.Under Set-up → Boundary Conditions, update the following wall surfaces:

•Select the wall-5 boundary. In the Wall roughness section of the Airflow panel, select High roughness for icing and set its Roughness Height (m) to 0.0005 m.

•Repeat this process for wall boundaries wall-6, wall-7, and wall-8.

12.Under Solve, right-click Airflow from the side menu. Select Initialize. A Hybrid initialization is executed using the settings of the original case file.

13.Under Solve → Airflow, increase the Number of iterations to 1000. A steady state simulation will be executed since the original case file contains steady state settings.

Note

Transient calculations are not yet supported. Therefore, the original case file must contain

asteady state set-up.

14.Right-click the Airflow icon under Solve and select Calculate to launch this simulation.

15.Once the simulation is complete, go to File → Save Case as… and save this calculation in the project directory FLUENT_ICING_NACA0012. Name this simulation naca0012_rough.

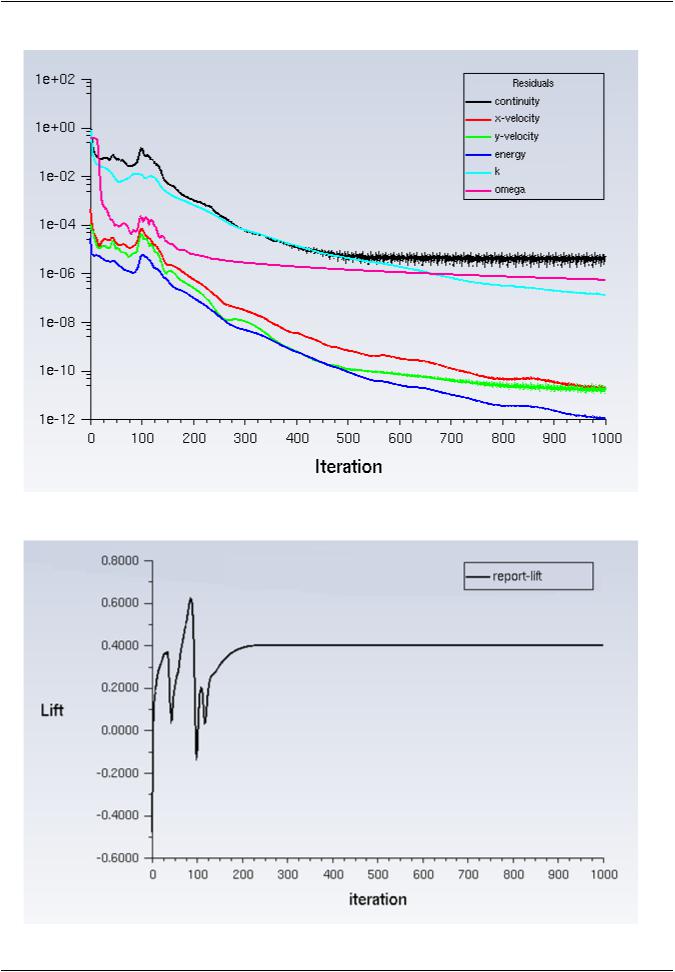

16.Take a look at the convergence history of this simulation in the Graphics window located at the right of your screen. The following two figures show the convergence of residuals and lift and drag coefficients. You can enlarge and move the legend box in the Graphics windows by dragging one side of or whole the box.

In the console, the residuals and coefficients are provided at each iteration. As it is not possible to zoom in on the graphs, the printed values in the log can be referred to if needed. Examine the convergence of lift and drag coefficients listed as “report-lif” and “report-dra”. Lift and drag coefficients have converged to 0.40367 and 0.019842 respectively.

Release 2019 R1 - © ANSYS,Inc.All rights reserved.- Contains proprietary and confidential information |

|

of ANSYS, Inc. and its subsidiaries and affiliates. |

893 |

vk.com/club152685050In-F ight Icing Tutorial Using| vk.Fluentcom/id446425943Icing

Figure 27.2: Scaled Residuals

Figure 27.3: Convergence of Lift and Drag Coefficients of the Rough Airfoil

|

Release 2019 R1 - © ANSYS,Inc.All rights reserved.- Contains proprietary and confidential information |

894 |

of ANSYS, Inc. and its subsidiaries and affiliates. |