- •Basic Models of Spin Coating s. L. Hellstrom October 28, 2007 (Submitted as coursework for Physics 210, Stanford University, Autumn 2007)

- •Physical Description and Common Approximations

- •Approximation of No Evaporation

- •Approximation of Constant Evaporation After a Set Point

- •Summary and Conclusion

- •References

Basic Models of Spin Coating s. L. Hellstrom October 28, 2007 (Submitted as coursework for Physics 210, Stanford University, Autumn 2007)

|

|

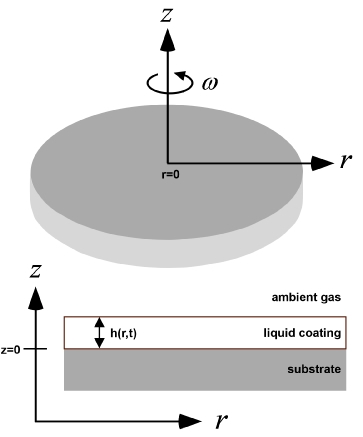

Figure 1: Schematic illustrating the spin coating problem, with relevant variables. |

Spin coating is a widespread practice in modern science and engineering, where it is used to deposit uniform coatings of organic materials and/or to uniformly distribute particulate matter on a flat surface. [1,2] In particular, spin coating is used in the microelectronics industry, to coat silicon wafers with a photoresist at the start of the lithographic patterning process. [3] In order to achieve high-fidelity lithography, a smooth, uniform photoresist film of predictable and reproducible thickness is required.

A great deal of effort has been invested in cataloguing the dependence of film thickness and uniformity on these experimental parameters, especially for coatings of standard photoresists. [4-7] Theoretical analyses of spin coating based on the principles of hydrodynamics have been hindered in part due to the physical and mathematical complexity of the system compared with the relative ease of acquiring process data. Nevertheless even partial analysis can provide some insight into the effectiveness and the limitations of the process.

Physical Description and Common Approximations

At the most fundamental level the physical system under consideration is that of a viscous fluid on a rotating disk. (Fig. 1) The following approximations are often made: that the rotating plane is horizontal so there is no radial gravitational component; that the liquid layer is so thin that differences in gravitational potential normal to the surface have negligible effect; and that that the radial velocity everywhere is small enough that Coriolis forces can be neglected.

To further simplify the problem, one or more of the following additional approximations may be made: that the rotating plane is infinite; that the liquid layer is radially symmetric; that the liquid is Newtonian; that the shear resistance is only appreciable in horizontal planes; and that the surface is already completely wet. These assumptions are certainly not always justified, however their inclusion provides an effective starting point for a quantitative treatment of the system. While a complete consideration of solvent evaporation in spin coating is complex, it cannot be ignored. It will be introduced to varying degrees of approximation in the following analysis.

Approximation of No Evaporation

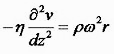

Ignoring evaporation completely, the basic physics were first worked out by Emslie et. al. [8] By making all of the assumptions described in the previous section, and equating the viscous and centrifugal forces per unit volume, you get

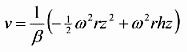

where η is the viscosity, ρ the liquid density, ω the spin speed, and v the radial velocity at any point (r, θ, z). For convenience, β=η/ρ defines the kinematic viscosity. Integrating with the boundary conditions that v=0 at the disk surface of z=0, and that dv/dz=0 at the free surface where there cannot be a shearing force, gives

From v, radial flow q is easily obtained by integration over z. h is the film thickness. Combining this with continuity equation

![]()

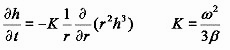

gives the differential equation which governs the thickness of the liquid film on the surface as a function of time:

As a check, for a uniform initial liquid distribution (h independent of r), the final liquid distribution is also uniform, and a thick layer thins significantly faster than a thin one so there will be a tendency towards uniformity for nonuniform initial films.

Using this last equation and the total derivative expression

![]()

one may write

![]()

with solutions

![]()

These solutions give the coordinates (r, h) of any point on the surface of the disk, in terms of original coordinates (r0, h0). Emslie et. al. analyze the problem further by considering the time and radius dependence of several different initial fluid distributions, and find increasing uniformity with increasing centrifugation time, within the range of validity of the initial set of assumptions. Of course, since there is an infinite disk and no solution evaporation to thicken and solidify the liquid, it will continue to flow radially outwards and thin for ever.

|

|

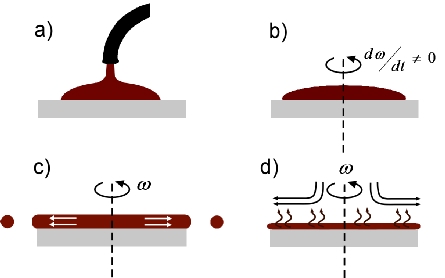

Figure 2: The different "stages" of spin coating. a) Dispensation (not modeled). b) Acceleration (not modeled). c) Flow dominated. d) Evaporation dominated. |