- •Методичні рекомендації

- •6.050503 Машинобудування

- •Вступ до методичних рекомендацій

- •Unit 6 Threads

- •Language

- •Threads

- •V. Oral Practice

- •VI. Reading and comprehension.

- •History of standardization

- •Text c Joseph Whitworth

- •Inventions

- •VII. Oral Practice.

- •Supplementary reading Texts for written translation.

- •Screw thread

- •Iso standard threads

- •Generating screw threads

- •Thread cutting

- •Thread rolling

- •Thread forming

- •Thread casting

- •Thread grinding

- •Thread lapping

- •Unit 7 Gears

- •Language

- •IV. Comprehension

- •V. Oral Practice

- •VI. Reading and comprehension

- •Fixed-gear bicycle

- •VII. Oral Practice.

- •Advantages and disadvantages of Fixed Gear bicycles.

- •Supplementary Reading Texts for written translation with a dictionary

- •Unit 8 Bearings.

- •Bearings

- •IV. Comprehension.

- •V. Reading and comprehension

- •History and development

- •Supplementary reading. Texts for written translation with a dictionary

- •Bearing (mechanical)

- •Bearing friction

- •Principles of operation

- •Motions

- •Maintenance

- •How to measure a bearing

- •Bearing Sizes

- •Bearing Example

- •Unit 9 Clutches

- •Clutches

- •Internal clutches

- •VI. Reading and comprehension

- •Operation in automobiles

- •Operation in motorcycles

- •Centrifugal

- •Supplementary reading. Texts for written translation with a dictionary

- •Single plate friction clutch

- •Multiple plate friction clutch

- •Vehicular

- •Cone clutch

- •Dog clutch

- •Electromagnetic clutch

- •Friction-plate clutch

- •Engagement

- •Mechanics

- •Benefits

- •Plan of rendering articles

- •Unit 10 Metal – cutting machines. Lathes.

- •I. Language.

- •II. Reading

- •Text a. Lathes

- •III. Language

- •IV. Comprehension.

- •V. Oral practice.

- •VI. Reading and comprehension.

- •Lathe related operations:

- •VII Oral practice

- •VIII. Reading and comprehension.

- •Text c types of lathes

- •IX. Oral practice.

- •Text e Metalworking lathes

- •Text f Glassworking lathes

- •Text g Metal spinning lathes

- •Text h Ornamental turning lathes

- •Text I Reducing Lathe

- •Unit 11 Drilling machines

- •I. Language.

- •II. Reading

- •Text a Drilling machines

- •III. Language.

- •IV. Comprehension.

- •V. Oral practice.

- •VI. Reading and comprehension.

- •Text b Cordless drills

- •VII. Oral practice.

- •VIII Reading and comprehension:

- •IX Oral practice.

- •Supplementary reading

- •Text d Pistol-grip (corded) drill

- •Text e Hammer drill

- •Text f Rotary hammer drill

- •Unit 12 Milling machines

- •I. Language.

- •II. Reading.

- •Text a Milling machines

- •III. Language.

- •IV. Comprehension.

- •V. Oral practice.

- •Text b Computer numerical control

- •Supplementary reading.

- •Text c Milling machine tooling

- •History Text d 1810s-1830s

- •Text e. 1840s-1860

- •Text f. 1860s

- •Text g. 1870s-1930s

- •Text h. 1940s-1970s

- •1980S-present

VII. Oral Practice.

Ex. 21. Prove that Sir Joseph Whitworth is a famous inventor.

Supplementary reading Texts for written translation.

Read the texts and translate them in writing. Use a dictionary.

Screw thread

A screw thread is a helical or tapered structure used to convert between rotational and linear movement or force.

A screw thread may be thought of as an inclined plane wrapped around a cylinder or cone. The tightening of a fastener's screw thread is comparable to driving a wedge into a gap until it sticks fast through friction and slight plastic deformation.

In most applications, the thread pitch of a screw is chosen so that friction is sufficient to prevent linear motion being converted to rotary, that is so the screw does not slip even when linear force is applied so long as no external rotational force is present. This characteristic is essential to the vast majority of its uses.

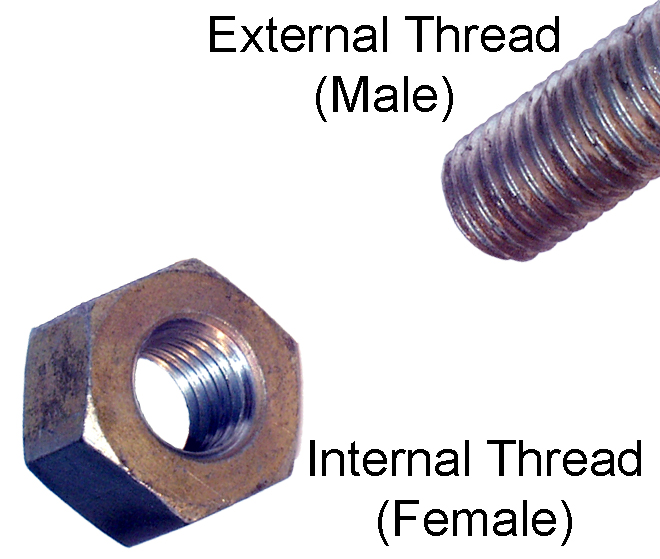

Internal and external threads illustrated using a common nut and bolt. The screw and nut pair can be used to convert torque into linear force. As the screw (or bolt) is rotated, the screw moves along its axis through the fixed nut, or the non-rotating nut moves along the lead-screw.

Screw thread, used to convert torque into the linear force in the flood gate. The operator rotates the two long vertical bolts (via bevel gear).

Screw threads have several applications:

Fastening

Fasteners such as wood screws, machine screws, nuts and bolts.

Connecting threaded pipes and hoses to each other and to caps and fixtures.

Gear reduction via worm drives

Moving objects linearly by converting rotary motion to linear motion, as in a screw jack.

Measuring by correlating linear motion to rotary motion (and simultaneously amplifying it), as in a micrometer.

Both moving objects linearly and simultaneously measuring the movement, combining the two aforementioned functions, as in a leadscrew.

In all of these applications, the screw thread has two main functions:

It converts rotary motion into linear motion.

It prevents linear motion without the corresponding rotation.

Standard threads

Standards for machine screw threads have evolved since the early nineteenth century to facilitate compatibility between different manufacturers and users. Many of these standards also specified corresponding bolt head and nut sizes, to facilitate compatibility between spanners and other driving tools.

Nearly all threads are oriented so that a bolt or nut, seen from above, is tightened (the item turned moves away from the viewer) by turning it in a clockwise direction, and loosened (the item moves towards the viewer) by turning anticlockwise. This is known as a right-handed thread, since the natural screwing motion for a right-handed person is clockwise, and is the default because most people are right-handed. Threads oriented in the opposite direction are known as left-handed. There are also self-tapping screw threads where no nut is required.

Left-handed threads are used:

Where the rotation of a shaft would cause a conventional right-handed nut to loosen rather than to tighten due to fretting induced precession, e.g. on a left-hand bicycle pedal.

In combination with right-handed threads in turnbuckles.

In some gas supply connections to prevent dangerous misconnections, for example in gas welding the flammable gas supply uses left-handed threads.

In some instances, for example early ballpoint pens, to provide a "secret" method of disassembly.

In some applications of a leadscrew, for example the cross slide of a lathe, where it is desirable for the cross slide to move away from the operator when the leadscrew is turned clockwise.

Unless stated otherwise, all standards below specify right-handed threads.