- •Методичні рекомендації

- •6.050503 Машинобудування

- •Вступ до методичних рекомендацій

- •Unit 6 Threads

- •Language

- •Threads

- •V. Oral Practice

- •VI. Reading and comprehension.

- •History of standardization

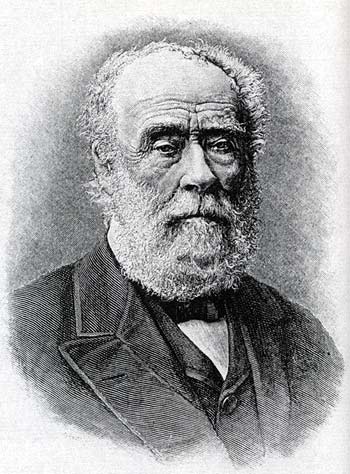

- •Text c Joseph Whitworth

- •Inventions

- •VII. Oral Practice.

- •Supplementary reading Texts for written translation.

- •Screw thread

- •Iso standard threads

- •Generating screw threads

- •Thread cutting

- •Thread rolling

- •Thread forming

- •Thread casting

- •Thread grinding

- •Thread lapping

- •Unit 7 Gears

- •Language

- •IV. Comprehension

- •V. Oral Practice

- •VI. Reading and comprehension

- •Fixed-gear bicycle

- •VII. Oral Practice.

- •Advantages and disadvantages of Fixed Gear bicycles.

- •Supplementary Reading Texts for written translation with a dictionary

- •Unit 8 Bearings.

- •Bearings

- •IV. Comprehension.

- •V. Reading and comprehension

- •History and development

- •Supplementary reading. Texts for written translation with a dictionary

- •Bearing (mechanical)

- •Bearing friction

- •Principles of operation

- •Motions

- •Maintenance

- •How to measure a bearing

- •Bearing Sizes

- •Bearing Example

- •Unit 9 Clutches

- •Clutches

- •Internal clutches

- •VI. Reading and comprehension

- •Operation in automobiles

- •Operation in motorcycles

- •Centrifugal

- •Supplementary reading. Texts for written translation with a dictionary

- •Single plate friction clutch

- •Multiple plate friction clutch

- •Vehicular

- •Cone clutch

- •Dog clutch

- •Electromagnetic clutch

- •Friction-plate clutch

- •Engagement

- •Mechanics

- •Benefits

- •Plan of rendering articles

- •Unit 10 Metal – cutting machines. Lathes.

- •I. Language.

- •II. Reading

- •Text a. Lathes

- •III. Language

- •IV. Comprehension.

- •V. Oral practice.

- •VI. Reading and comprehension.

- •Lathe related operations:

- •VII Oral practice

- •VIII. Reading and comprehension.

- •Text c types of lathes

- •IX. Oral practice.

- •Text e Metalworking lathes

- •Text f Glassworking lathes

- •Text g Metal spinning lathes

- •Text h Ornamental turning lathes

- •Text I Reducing Lathe

- •Unit 11 Drilling machines

- •I. Language.

- •II. Reading

- •Text a Drilling machines

- •III. Language.

- •IV. Comprehension.

- •V. Oral practice.

- •VI. Reading and comprehension.

- •Text b Cordless drills

- •VII. Oral practice.

- •VIII Reading and comprehension:

- •IX Oral practice.

- •Supplementary reading

- •Text d Pistol-grip (corded) drill

- •Text e Hammer drill

- •Text f Rotary hammer drill

- •Unit 12 Milling machines

- •I. Language.

- •II. Reading.

- •Text a Milling machines

- •III. Language.

- •IV. Comprehension.

- •V. Oral practice.

- •Text b Computer numerical control

- •Supplementary reading.

- •Text c Milling machine tooling

- •History Text d 1810s-1830s

- •Text e. 1840s-1860

- •Text f. 1860s

- •Text g. 1870s-1930s

- •Text h. 1940s-1970s

- •1980S-present

Text c Joseph Whitworth

|

|

|

|

Personal information |

|

Name |

Sir Joseph Whitworth |

Nationality |

British |

Birth date |

December 21, 1803 |

Birth place |

Stockport |

Date of death |

January 22, 1887 |

Place of death |

Monte Carlo |

Spouse |

Francis Anker (m. 1825) Mary Louisa Orrell (m. 1871) |

Work |

|

Institution memberships |

Royal Society Institution of Mechanical Engineers |

Significant advance |

Whitworth standardised screw threads |

Whitworth was born in Stockport, the son of Charles Whitworth, a teacher (some sources say that he was a Congregational minister), and at a young age developed an interest in machinery.

Career

After leaving school Whitworth became an indentured apprentice to an uncle who was a cotton spinner in Derbyshire. This was for a four year term after which he worked for another four years as a mechanic in a factory in Manchester. He then moved to London where he found employment working for Henry Maudslay, the inventor of the screw-cutting lathe, alongside such people has James Nasmyth (inventor of the steam hammer) and Richard Roberts.

Whitworth developed great skill as a mechanic while working for Maudslay, developing various precision machine tools and also introducing a box casting scheme for the iron frames of machine tools that simultaneously increased their rigidity and reduced their weight.

Whitworth also worked for Holtzapffel & Co (makers of ornamental lathes) and Joseph Clement. While at Clement's workshop he helped with the manufacture of Charles Babbage's calculating machine, the Difference engine. He returned to Openshaw, Manchester, in 1833 to start his own business manufacturing lathes and other machine tools, which became renowned for their high standard of workmanship. In 1850, architect Edward Walters was commissioned to build The Firs for Whitworth. This was a grand mansion at Fallowfield Manchester, which still stands today, functioning as Chancellors Hotel & Conference Centre.

Inventions

Whitworth popularized a method of producing accurate flat surfaces during the 1830s, using engineer's blue and scraping techniques on three trial surfaces. Up until his introduction of the scraping technique, the same three plate method was employed using polishing techniques, giving less accurate results. This led to an explosion of development of precision instruments using these flat surface generation techniques as a basis for further construction of precise shapes.

His next innovation, in 1840, was a measuring technique called "end measurements" that used a precision flat plane and measuring screw, both of his own invention. The system, with a precision of one millionth of an inch, was demonstrated at the Great Exhibition of 1851.

In 1841 Whitworth devised a standard for screw threads with a fixed thread angle of 55° and having a standard pitch for a given diameter. This soon became the first nationally standardized system; its adoption by the railway companies, who until then had all used different screw threads, leading to its widespread acceptance. It later became a British Standard, "British Standard Whitworth", abbreviated to BSW and governed by BS 84:1956.

Whitworth rifle

Whitworth was commissioned by the War Department of the British government to design a replacement for the calibre .577-inch Pattern 1853 Enfield, whose shortcomings had been revealed during the recent Crimean War. The Whitworth rifle had a smaller bore of 0.451 inch (11 mm) which was hexagonal, fired an elongated hexagonal bullet and had a faster rate of twist rifling [one turn in twenty inches] than the Enfield, and its performance during tests in 1859 was superior to the Enfield's in every way. The test was reported in The Times on April 23 as a great success. However, the new bore design was found to be prone to fouling and it was four times as expensive to manufacture than the Enfield, so it was rejected by the British government, only to be adopted by the French Army. An unspecified number of Whitworth rifles found their way to the Confederate states in the American Civil War, where they were called "Whitworth Sharpshooters".

The Enfield rifle was converted to Snider-Enfield Rifle by Jacob Snider, a Dutch-American wine merchant from Philadelphia. By converting existing Enfield rifles this way, the cost of a "new" breech-loading Snider-Enfield rifle was only 12 shillings.

Queen Victoria opened the first meeting of the British Rifle Association at Wimbledon, in 1860 by firing a Whitworth rifle from a fixed mechanical rest. The rifle scored a bull's eye at a range of 400 yards (366 m).

Breech-loading artillery

Whitworth also designed a large Rifled Breech Loading gun with a 2.75 inch (70 mm) bore, a 12 pound 11 ounce (5.75 kg) projectile and a range of about six miles (10 km). The spirally-grooved projectile was patented in 1855. This was also rejected by the British army, who preferred the guns from Armstrong, but was also used in the American Civil War.

While trying to increase the bursting strength of his gun barrels, Whitworth patented a process called "fluid-compressed steel" for casting steel under pressure, and built a new steel works near Manchester. Some of his castings were shown at the Great Exhibition in Paris ca. 1883.

Notes:

Flat surface – плоска поверхня To scrap – здавати на брухт

Explosion- вибух Techniques - техніка

Rifle – гвинтівк

Ex. 19 Answer the questions:

When and where was Sir Joseph Whitworth born?

What can you say about Sir Joseph Whitworth’s education?

What do you know about Sir Joseph Whitworth’s inventions?

Why was Queen Victoria proud of Sir Joseph Whitworth?

What did Sir Joseph Whitworth design for army?

Ex. 20 Speak on the following problems:

Sir Joseph Whitworth’s career.

Sir Joseph Whitworth’s inventions.

Whitworth rifle.