- •Методичні рекомендації

- •6.050503 Машинобудування

- •Вступ до методичних рекомендацій

- •Unit 6 Threads

- •Language

- •Threads

- •V. Oral Practice

- •VI. Reading and comprehension.

- •History of standardization

- •Text c Joseph Whitworth

- •Inventions

- •VII. Oral Practice.

- •Supplementary reading Texts for written translation.

- •Screw thread

- •Iso standard threads

- •Generating screw threads

- •Thread cutting

- •Thread rolling

- •Thread forming

- •Thread casting

- •Thread grinding

- •Thread lapping

- •Unit 7 Gears

- •Language

- •IV. Comprehension

- •V. Oral Practice

- •VI. Reading and comprehension

- •Fixed-gear bicycle

- •VII. Oral Practice.

- •Advantages and disadvantages of Fixed Gear bicycles.

- •Supplementary Reading Texts for written translation with a dictionary

- •Unit 8 Bearings.

- •Bearings

- •IV. Comprehension.

- •V. Reading and comprehension

- •History and development

- •Supplementary reading. Texts for written translation with a dictionary

- •Bearing (mechanical)

- •Bearing friction

- •Principles of operation

- •Motions

- •Maintenance

- •How to measure a bearing

- •Bearing Sizes

- •Bearing Example

- •Unit 9 Clutches

- •Clutches

- •Internal clutches

- •VI. Reading and comprehension

- •Operation in automobiles

- •Operation in motorcycles

- •Centrifugal

- •Supplementary reading. Texts for written translation with a dictionary

- •Single plate friction clutch

- •Multiple plate friction clutch

- •Vehicular

- •Cone clutch

- •Dog clutch

- •Electromagnetic clutch

- •Friction-plate clutch

- •Engagement

- •Mechanics

- •Benefits

- •Plan of rendering articles

- •Unit 10 Metal – cutting machines. Lathes.

- •I. Language.

- •II. Reading

- •Text a. Lathes

- •III. Language

- •IV. Comprehension.

- •V. Oral practice.

- •VI. Reading and comprehension.

- •Lathe related operations:

- •VII Oral practice

- •VIII. Reading and comprehension.

- •Text c types of lathes

- •IX. Oral practice.

- •Text e Metalworking lathes

- •Text f Glassworking lathes

- •Text g Metal spinning lathes

- •Text h Ornamental turning lathes

- •Text I Reducing Lathe

- •Unit 11 Drilling machines

- •I. Language.

- •II. Reading

- •Text a Drilling machines

- •III. Language.

- •IV. Comprehension.

- •V. Oral practice.

- •VI. Reading and comprehension.

- •Text b Cordless drills

- •VII. Oral practice.

- •VIII Reading and comprehension:

- •IX Oral practice.

- •Supplementary reading

- •Text d Pistol-grip (corded) drill

- •Text e Hammer drill

- •Text f Rotary hammer drill

- •Unit 12 Milling machines

- •I. Language.

- •II. Reading.

- •Text a Milling machines

- •III. Language.

- •IV. Comprehension.

- •V. Oral practice.

- •Text b Computer numerical control

- •Supplementary reading.

- •Text c Milling machine tooling

- •History Text d 1810s-1830s

- •Text e. 1840s-1860

- •Text f. 1860s

- •Text g. 1870s-1930s

- •Text h. 1940s-1970s

- •1980S-present

V. Oral Practice

Ex13. Speak about Threads. Use the questions of ex.12 as a plan.

VI. Reading and comprehension.

Ex. 14. Read the text B without a dictionary for 7 minutes and say what problems are mentioned in the text:

Text B

History of standardization

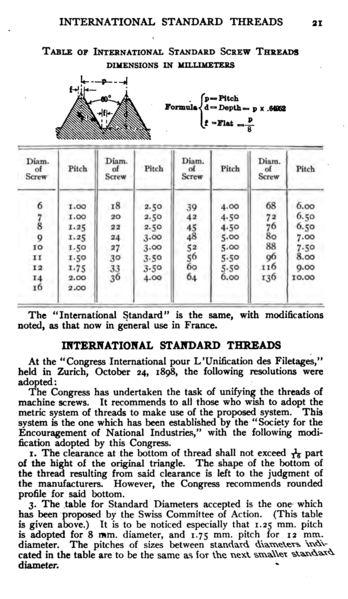

Graphic representation of formulas for the pitches

of threads of screw bolts

Graphic representation of formulas for the pitches

of threads of screw bolts

The first historically important intra-company standardization of screw threads began with Henry Maudslay around 1800, when the modern screw-cutting lathe made interchangeable screws a practical commodity. During the next 40 years, standardization continued to occur on the intra-company and inter-company level. In 1841, Joseph Whitworth created a design that, through its adoption by many British railroad companies, became a national standard for the United Kingdom called British Standard Whitworth. During the 1840s through 1860s, this standard was often used in the United States and Canada as well, in addition to myriad intra- and inter-company standards. In April 1864, William Sellers presented a paper to the Franklin Institute in Philadelphia, proposing a new standard to replace the U.S.'s poorly standardized screw thread practice. Sellers simplified the Whitworth design by adopting a thread profile of 60° and a flattened tip (in contrast to Whitworth's 55° angle and rounded tip). The 60° angle was already in common use in America, but Sellers's system promised to make it and all other details of threadform consistent.

The Sellers thread, easier for ordinary machinists to produce, became an important standard in the U.S. during the late 1860s and early 1870s, when it was chosen as a standard for work done under U.S. government contracts, and it was also adopted as a standard by highly influential railroad industry corporations such as the Baldwin Locomotive Works and the Pennsylvania Railroad. Other corporations adopted it, and it soon became a national standard for the U.S., later becoming generally known as the United States Standard. Over the next 30 years the standard was further defined and extended and evolved into a set of standards including National Coarse (NC), National Fine (NF), and National Pipe Taper (NPT).

For a good summary of screw thread standards

in curre

nt use in 1914, see Colvin FH,

Stanley FA (eds) (1914):

American Machinists' Handbook, 2nd ed.

New York and London: McGraw-Hill, pp. 16-22.

During this era, in continental Europe, the British and American threadforms were well known, but also various metric thread standards were evolving, which usually employed 60° profiles. Some of these evolved into national or quasi-national standards. They were mostly unified in 1898 by the International Congress for the standardization of screw threads at Zurich, which defined the new international metric thread standards as having the same profile as the Sellers thread, but with metric sizes. Efforts were made in the early 20th century to convince the governments of the U.S., UK, and Canada to adopt these international thread standards and the metric system in general, but they were defeated with arguments that the capital cost of the necessary retooling would damage corporations and hamper the economy. (The mixed use of dualling inch and metric standards has since cost much, much more, but the bearing of these costs has been more distributed across national and global economies rather than being borne up front by particular governments or corporations, which helps explain the lobbying efforts.)

Notes:

To defeat – завдавати поразки

To damage – руйнувати

To hamper –перешкоджати

To inspect –провіряти

Ex.15. Agree or disagree with the following statements:

The first historically important intra-company standardization of screw threads began with Robert Boil.

Sellers simplified the Whitworth design by adopting a thread profile of 50.

The Ukrainian threadforms were well known.

Engineers found that ensuring the reliable interchangeability of screw threads was a multi-faceted.

Small addition of carbon reduces the melting point.

Ex. 16. Answer the following questions:

What was the first intra-company standardization of screw threads?

What were the Sellers threads?

What threadforms were well known?

Ex. 17. Render the text B using the plan for rendering on page 67.

Ex. 18. Read the text C without a dictionary for 10 minutes and tell what Joseph Whitworth was famous for: