- •2007 Р.

- •3) Match a word in column

- •Rock Excavation in civil Engineering

- •Introduction to Remote Control Technology

- •Supplementary reading:

- •Introduction

- •Versatile Drillrig

- •Multiple Tasking in Western Australia

- •Improving Productivity

- •Exercises:

- •4) Give answers to the following questions:

- •Exercises:

- •1)Give Ukrainian equivalents of the following words and word combinations:

- •2) Give English equivalents of the following words and word combinations:

- •3)Fill the blanks with the necessary words and word combinations:

- •4) Quote the sentences in which these words and word combinations are used. Translate these sentences into Ukrainian:

- •5.Give answers to the following questions:

- •6. Tell what you know about:

- •Importance of Geology

- •Igneous Rocks

- •Investigation and Exploration

- •Exercises:

- •1) Give Ukrainian equivalents of the following words and word combinations:

- •4) Quote the sentences in which these words and word combinations are used:

- •5) Give answers to the following questions:

- •Exercises:

- •2) Give English equivalents of the following words and word combinations:

- •4) Quote the sentences in which these words and word combinations are used:

- •5) Answer the following questions:

- •6) Tell what you know about:

- •Vertical Crater Retreat

- •Exercises:

- •1) Give Ukrainian equivalents of the following words and word combinations:

- •2) Give English equivalents of the following words and word combinations:

- •3) Fill the blanks with the necessary words:

- •4) Quote the sentences in which these words and word combinations are used:

- •5) Answer the fallowing questions:

- •6) Tell what you know about:

- •Supplementary reading

- •Список використаної літератури:

- •«Наукова англійська мова»

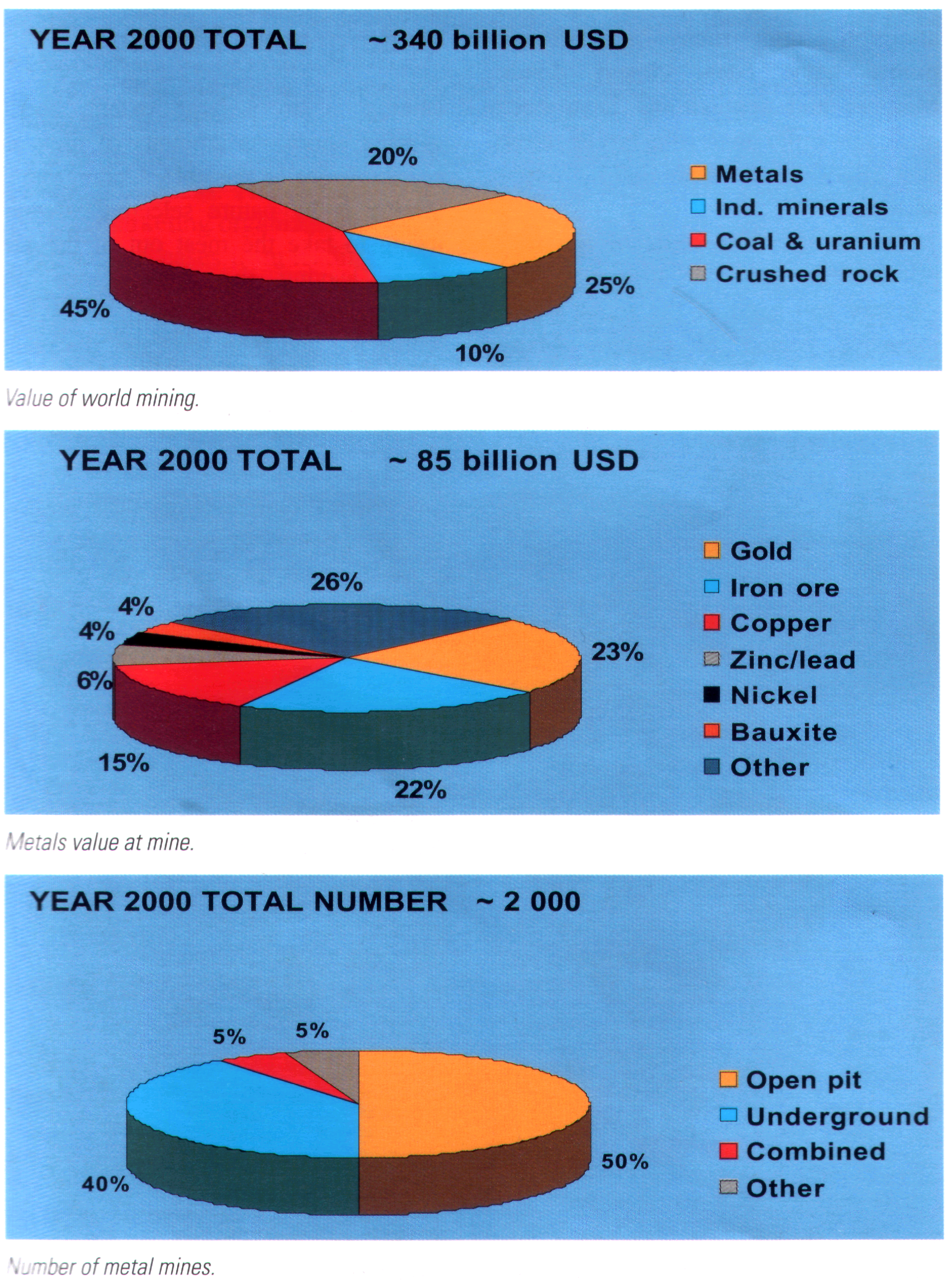

Improving Productivity

New, more effective, technology makes it possible to extract more metal out of lower grade material, and at a lower cost than earlier generations of miners could achieve. External pressures have also had an impact on the operations of the mining industry, causing it to move in many ways.

Intensive cost-cutting is now standard in all companies, while, at the same time, they have been investing in new and more productive equipment. Non-core businesses have been sold off, in order to focus management attention, and many unprofitable mines have been closed down. Mergers and acquisitions have been made, in order to create larger, more cost-effective, and financially stronger entities.

During the first years of the new millennium, the international mining industry has been in the midst of an intensive period of change. Many long-established, well-respected mining companies have disappeared, and new giants are emerging.

Undergroun Mining

Table 1. Total world underground ore production.

|

Region |

Mt |

|

North America 80 |

Europe 160 |

|

Latin America 105 |

Asia 60 |

|

Africa 160 |

SUM 6 |

|

Oceania 50 |

|

E ach

year, around 4,100 Mt of ore containing the most important metals

copper, gold, iron ore, lead/zinc, nickel, platinum group metals and

diamonds is produced globally. Of this, some 615 Mt is mined

underground, for which Table 1 gives the regional split. To support

this level of activity, a considerable amount of development work

has to be carried out.

ach

year, around 4,100 Mt of ore containing the most important metals

copper, gold, iron ore, lead/zinc, nickel, platinum group metals and

diamonds is produced globally. Of this, some 615 Mt is mined

underground, for which Table 1 gives the regional split. To support

this level of activity, a considerable amount of development work

has to be carried out.

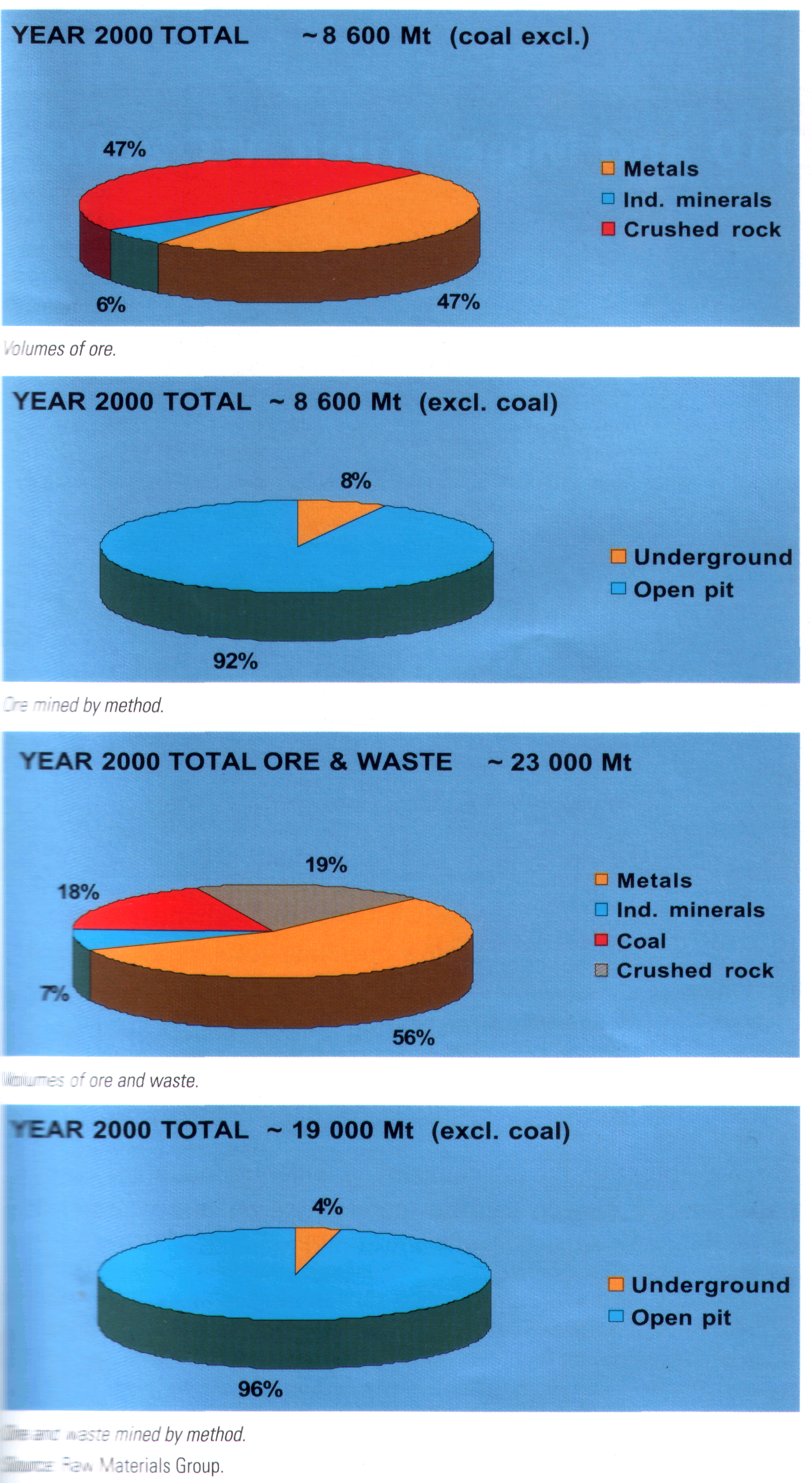

The proportion mined underground equates with some 16% of the total volume of ores extracted. In the centrally planned economies of the eastern bloc, underground mining accounts for 32% of the total activity in the sector, while the figure is 15% in the Western world.

There are 365 underground mines in the Western world, many of which are fairly small, but efficient, operations, hoisting an average of 400,000 t annually. Notwithstanding, many underground mines are huge, with very sophisticated equipment and a high level of automation.

Production Distribution

S pecial

skills are necessary to operate a profitable underground mine, and

these skills have been developed in a few key countries where

underground mining is more important than elsewhere.

pecial

skills are necessary to operate a profitable underground mine, and

these skills have been developed in a few key countries where

underground mining is more important than elsewhere.

South Africa is the most important country in underground ore production, with 141 Mt produced annually. In a second group are found Canada, Australia and the formerly centrally planned economies of Russia, Ukraine, and Kazakstan with 40-55 Mt of underground production. The USA, Brazil, Peru, Poland and Sweden follow in a third group, with production between 26 and 41 Mt of ore annually. Zambia, Mexico, Indonesia, India and Bulgaria are also all producing around 10 Mt/year. Together, the first two groups comprising South Africa, Canada, Australia, Russia, Ukraine and Kazakstan, represent some 70% of total underground production.

The most important mineral sector is zinc/lead, where over 80% of all ores are excavated in underground mines. A total of 115 Mt ore is needed to produce the Western world output of zinc; and over 90 Mt of this is mined underground. The corresponding figures for nickel are 80 Mt total for all ores, of which some 30 Mt from underground mines. Iron ore is at the other extreme, with a total of over 1,000 Mt ore produced, of which 675 Mt in the Western world. Less than 10% comes from underground mines located in Sweden, Norway, Slovakia and Colombia. The distribution of underground ore production around the world is shown on the map.

Future Growth

The grades of the ores from which metals are extracted vary greatly. Rich iron ores may contain up to 65% (650,000 g/t) of iron, while a gold ore in an average open pit mine might only be one part per million (0.0001 per cent, or 1 g/t). Hence, the volume of ore needed to obtain a tonne, or a kilogramme, of product varies considerably. The volume of ore production depends on the amount of metals consumed, and the grades of the ore deposits mined.

Over time, the orebodies have become depleted, and less rich deposits have started to be exploited. The graph in Figure 1 illustrates this point clearly, with an example from the world of copper. The average grade of copper ore has sunk continuously over the last 70 years. Roughly 5 times more ore needs to be extracted to get a tonne of copper in 2003 than was the case in 1950. Technical developments, resulting in more deeply penetrating exploration methods, increase the probability of finding new, richer, deeper ore deposits. This counterbalances the trend towards lower quality to some extent, but obviously not to the full.

I

The

six largest companies in underground ore production:

Anglo

American group 80 Mt/y (in AngloGold, Anglo Platinum, Base

Metals, etc)

Codelco

45

KGHM

Polish Copper 32

LKAB

30

Harmony

17

Norilsk

14

List of words

underground mining – підземнa розробкa,розробка підземним методом

to close down – закривати

open pit mining – відкрита розробка корисних копалин

selective mining – селективна розробка

crust – кора

development work – підготовчі роботи

to extract ores – видобувати ,вилучати руди

to hoist – піднімати на поверхню

(sophisticated) equipment – (складне) обладнання,

to operate a mine – експлуатувати шахту

rich iron ore – багата залізна руда

ore grade – сорт, тип руди

ore deposit – поклад руди