- •2007 Р.

- •3) Match a word in column

- •Rock Excavation in civil Engineering

- •Introduction to Remote Control Technology

- •Supplementary reading:

- •Introduction

- •Versatile Drillrig

- •Multiple Tasking in Western Australia

- •Improving Productivity

- •Exercises:

- •4) Give answers to the following questions:

- •Exercises:

- •1)Give Ukrainian equivalents of the following words and word combinations:

- •2) Give English equivalents of the following words and word combinations:

- •3)Fill the blanks with the necessary words and word combinations:

- •4) Quote the sentences in which these words and word combinations are used. Translate these sentences into Ukrainian:

- •5.Give answers to the following questions:

- •6. Tell what you know about:

- •Importance of Geology

- •Igneous Rocks

- •Investigation and Exploration

- •Exercises:

- •1) Give Ukrainian equivalents of the following words and word combinations:

- •4) Quote the sentences in which these words and word combinations are used:

- •5) Give answers to the following questions:

- •Exercises:

- •2) Give English equivalents of the following words and word combinations:

- •4) Quote the sentences in which these words and word combinations are used:

- •5) Answer the following questions:

- •6) Tell what you know about:

- •Vertical Crater Retreat

- •Exercises:

- •1) Give Ukrainian equivalents of the following words and word combinations:

- •2) Give English equivalents of the following words and word combinations:

- •3) Fill the blanks with the necessary words:

- •4) Quote the sentences in which these words and word combinations are used:

- •5) Answer the fallowing questions:

- •6) Tell what you know about:

- •Supplementary reading

- •Список використаної літератури:

- •«Наукова англійська мова»

Investigation and Exploration

It is clear that rock structures, and the minerals they contain, can result in a wide variety of possible mining strategies. Obviously, the more information that is gained, the better should be the chances of mining success. There are plenty of potential risks in underground mining, and it is best to minimize these. Using modern mining equipment, there is the potential to turn the mine into a mineral factory. However, if uncertainties manifest themselves in unforeseen ground conditions, disappearing orebodies, and factors such as excessive water infiltration, then the advantage of productive mining equipment will be lost, as it is forced to stand idle.

The only way to avoid these situations is to carry out as much exploration work as possible, not only to investigate the existence and location of worthwhile minerals, but also to check on rock qualities in and around the deposit. In underground mining, information from surface borehole and geophysical methods of investigation can be supplemented by probe or core drilling underground. The resulting vast amount of data may be too much to be assessed manually, but computer software programs are available to deduce the best strategies for mineral deposit exploitation. In addition, the mining expertise of the Atlas Copco group is available to help mining engineers decide, not only on the best equipment to use for investigation, development and production, but also how these can be used to best effect.

The value of the mineral to be mined will obviously be a determinant on how much investigation work is desirable, but there will be a minimum level for each type of mine, in order to give some assurance of success. For example, low-value stratified deposits, which are known to be fairly uniform in thickness and have regular dips, may not necessitate many boreholes, although there could still be surprises from sedimentary washouts or faults. On the other hand, gold deposits in contorted rock formations will require frequent boreholes from underground, as well as from the surface, to give assurance of the location of the deposit, and to sample the minerals it contains.

Rock Classification for Drilling

Having determined the value and shape of a mineral deposit, the nature and structure of the rocks that surround it, and the likely strategy for the mine development, it should be possible to determine the suitability of various excavation methods for the rocks likely to be encountered. It will also be necessary to determine which ancillary equipment may be required, and how best to fit this into the excavation cycle.

With drill-and-blast development drivages, for example, the rock types and structure may determine that substantial support is required. This, in turn, may require a rockbolting facility on the drillrig, perhaps with an access basket suitable for erecting arch crowns and charging blastholes. It may be decided that an additional rockbolting rig is required, for secondary support.

In order to systematically determine the likely excavation and support requirements, the amount of consumables required, and whether a particular method is suitable, a number of rock classification systems have been developed. These are generally oriented to a particular purpose, such as the level of support required, or the rock's drillability.

The methods developed to assess drillability are aimed at predicting productivity and tool wear. Factors of drillability include the likely tool penetration rate commensurate with tool wear, the stand-up qualities of the hole, its straightness, and any tendency to tool jamming. Tool wear is often proportional to drillability, although the rock's abrasiveness is important.

Rock drillability is determined by several factors, led by mineral composition, grain size and brittleness. In crude terms, rock compressive strength or hardness can be related to drillability for rough calculations, but the matter is usually more complicated.

The Norwegian Technical University has determined more sophisticated methods: the Drilling Rate Index (DRI) and the Bit Wear Index (BWI).

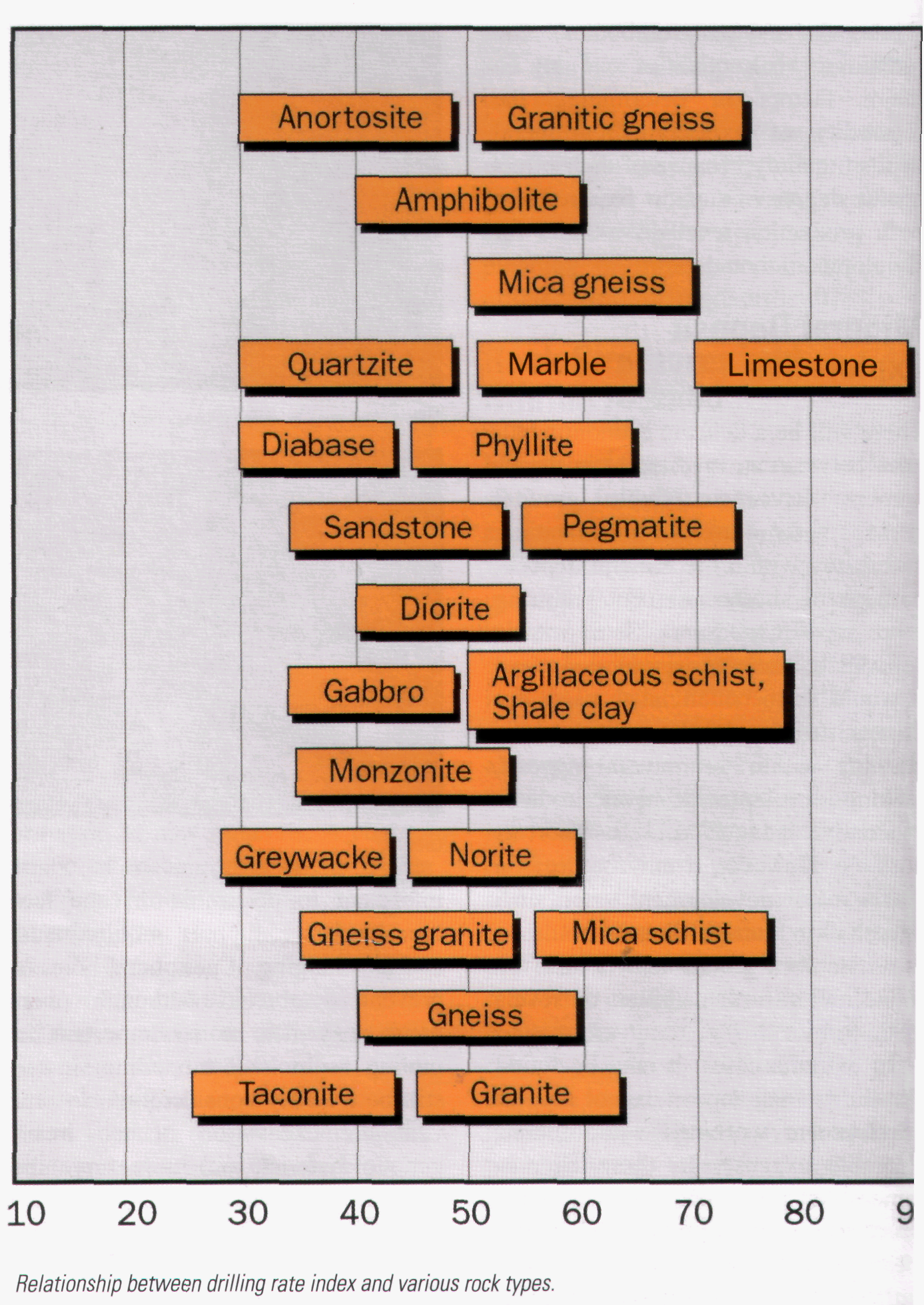

The DRI describes how fast a particular drill steel can penetrate. It also includes measurements of brittleness and drilling with a small, standard rotating bit into a sample of the rock. The higher the DRI, the higher the penetration rate, and this can vary greatly from one rock type to another (see bar chart right).

It should be noted that modern drillbits greatly improve the possible penetration rates in the same rock types. Also, there are different types of bits available to suit certain types of rock. For example. Secoroc special bits for soft formations, bits with larger gauge buttons for abrasive formations, and guide bits or retrac bits for formations where hole deviation is a problem.

The BWI gives an indication of how fast the bit wears down, as determined by an abrasion test. The higher the BWI, the faster will be the wear.

In most cases, the DRI and BWI are inversely proportional to one another. However, the presence of hard minerals may produce heavy wear on the bit, despite relatively good drillability. This is particularly the case with quartz, which has been shown to increase wear rates greatly. Certain sulphides in orebodies are also comparatively hard, impairing drillability. Other means of commonly used rock classification include: the Q-system (Barton et al, through the Norwegian Geotechnical Institute); Rock Mass Rating RMR (Bieniawski); and the Geological Strength Index GSI (Hoek et al). Bieniawski's RMR incor-porates the earlier Rock Quality Designation (RQD - Deere et al), with some important improvements, taking into account additional rock proper ties. All give valuable guidance on the rock's ease of excavation, and its self-supporting properties. In most case, engineers will employ more than one means of rock classification to give a better understanding of its behaviour and to compare results.

List of words:

crust – земна кора;

occur – залягання;залягати

homogeneous – однорідний, гомогенний;

streak – риска мінералу

luster – блиск мінералу;

cleavage – шаруватість;

fracture – тріщина, розрив;

discontinuity – відсутність неперервності

fault – розрив, зсув, склад

unconformity – незгодне нашарування

weathering – вивітрювання;звітрювання

microscopic and macroscopic properties – мікроскопічні та макроскопічні властивості

abrasiveness – абразивність

loose – рихлий, сипучий

compressive strength – границя міцності на стиск

precipitation – осадження

slatiness – шаруватість, пластинчастість

fissuring – розтріскування, тріщино-утворення

wear – спрацювання; зношування;

drillability – буримість (бурильність);

density – щільність;