Allen and Holberg - CMOS Analog Circuit Design

.pdf

Allen and Holberg - CMOS Analog Circuit Design |

II.5-1 |

II.5 - PASSIVE COMPONENTS CAPACITORS

εoxA C = tox

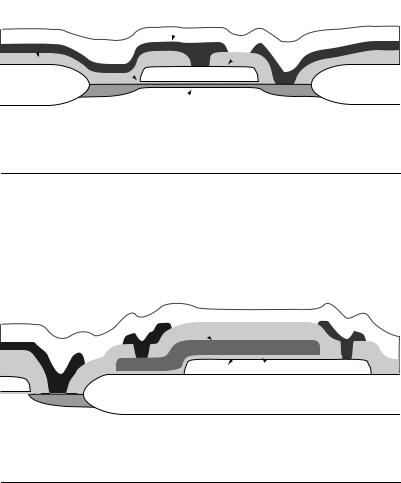

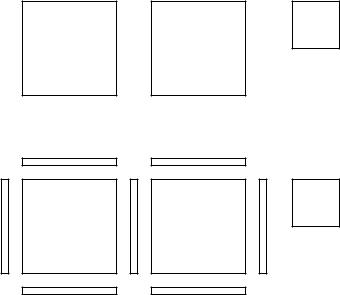

Polysilicon-Oxide-Channel Capacitor and Polysilicon-Oxide-Polysilicon

Capacitor

|

Metal |

|

SiO2 |

Polysilicon top plate |

|

Gate SiO2 |

||

|

FOX |

FOX |

p+ bottom-plate implant

p- substrate

(a)

Polysilicon top plate

Polysilicon bottom plate

FOX

Inter-poly SiO2

p- substrate

(b)

Figure 2.4-1 MOS capacitors. (a) Polysilicon-oxide-channel. (b) Polysilicon-oxide-polysilicon.

Allen and Holberg - CMOS Analog Circuit Design |

II.5-2 |

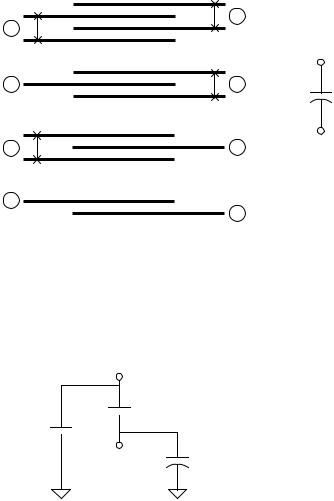

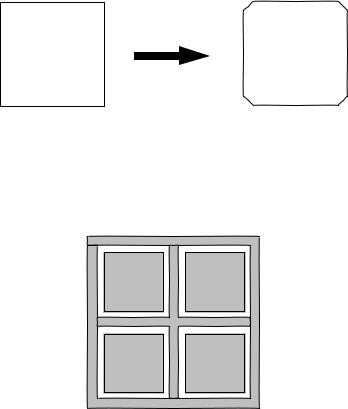

Metal-Metal and Metal-Metal-Poly Capacitors

|

|

M3 |

|

|

M2 |

|

T |

|

|

M1 |

|

B |

|

|

|

Poly |

|

|

|

|

|

|

|

|

|

M3 |

T |

|

|

|

|

T |

M2 |

|

B |

|

M1 |

||

|

|

|

|

|

M2 |

M1 |

B |

B |

|

T |

|

Poly |

|

||

|

|

|

M2

T

M1

B

Figure 2.4-2 Various ways to implement capacitors using available interconnect layers.

M1, M2, and M3 represent the first, second, and third metal layers respectively.

Top plate  Cdesired parasitic

Cdesired parasitic

Bottom plate parasitic

Figure 2.4-3 A model for the integrated capacitors showing top and bottom plate parasitics.

Allen and Holberg - CMOS Analog Circuit Design |

II.5-3 |

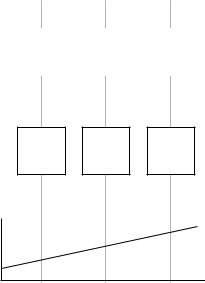

PROPER LAYOUT OF CAPACITORS

•Use “unit” capacitors

•Use “common centroid” Want A=2*B

Case (a) fails Case (b) succeeds!

(a) |

A1 |

|

A2 |

|

B |

|

|

|

|

|

|

(b) |

A1 |

B |

A2 |

|

y

x1 |

x2 |

x3 |

Figure 2.6-2 Components placed in the presence of a gradient, (a) without commoncentroid layout and (b) with common-centroid layout.

Allen and Holberg - CMOS Analog Circuit Design |

II.5-4 |

||

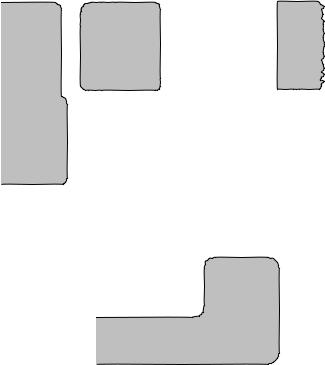

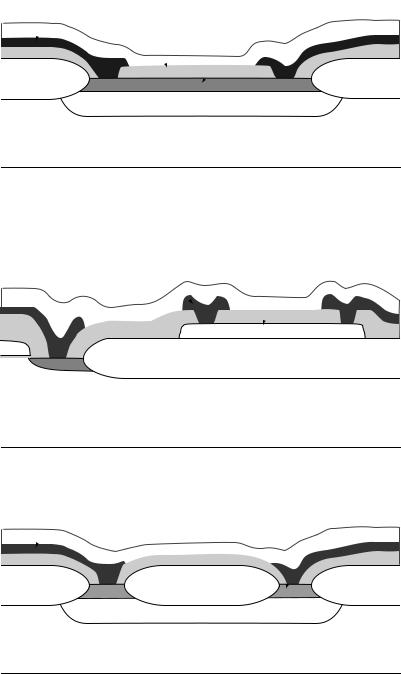

NON-UNIFORM UNDERCUTTING EFFECTS |

|

||

|

|

|

|

|

|

|

|

Random edge distortion

Large-scale distortion

Corner-rounding distortion

Allen and Holberg - CMOS Analog Circuit Design |

II.5-5 |

VICINITY EFFECT

C

A B

C

A B

Figure 2.6-1 (a)Illustration of how matching of A and B is disturbed by

the presence of C. (b) Improved matching achieved by matching surroundings of A and B

Allen and Holberg - CMOS Analog Circuit Design |

II.5-6 |

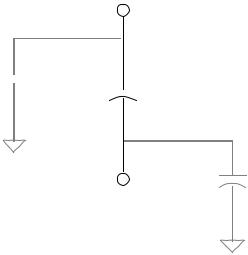

IMPROVED LAYOUT METHODS FOR CAPACITORS

Corner clipping:

Clip corners

Street-effect compensation:

Allen and Holberg - CMOS Analog Circuit Design |

II.5-7 |

ERRORS IN CAPACITOR RATIOS

Let C1 be defined as

C1 = C1A + C1P

and C2 be defined as

C2 = C2A + C2P

CXA is the bottom-plate capacitance

CXP is the fringe (peripheral) capacitance

CXA >> CXP

The ratio of C2 to C1 can be expressed as

C C + C |

|

C |

|

1 + CC2P |

|

||||

|

2 |

2A |

|

2P |

|

2A |

|

|

|

|

|

|

|

2A |

|||||

C1 |

= C1A + C1P |

= C1A |

C1P |

|

|||||

|

|

|

|

|

|

|

1 + C |

|

|

|

|

|

|

|

|

|

|

1A |

|

|

C2A 1 + |

C2P - |

C1P - |

(C1P)(C2P) |

|||||

|

C1A |

C2A |

C1A |

C1AC2A |

|

||||

|

C2A 1 + |

C2P - |

C1P |

|

|

|

|||

|

C1A |

C2A |

C1A |

|

|

|

|||

Thus best matching is achieved when the area to periphery ratio remains constant.

Allen and Holberg - CMOS Analog Circuit Design |

II.5-8 |

CAPACITOR PARASITICS

Top Plate

Top plate

parasitic

Desired

Desired

Capacitor

|

Bottom plate |

Bottom Plate |

parasitic |

|

Parasitic is dependent upon how the capacitor is constructed.

Typical capacitor performance

(0.8 m Technology)

Capacitor |

Range of Values |

Relative |

Temperature |

Voltage |

Absolute |

Type |

|

Accuracy |

Coefficient |

Coefficient |

Accuracy |

Poly/poly |

0.8-1.0 fF/ m2 |

0.05% |

50 ppm/°C |

50 ppm/V |

±10% |

capacitor |

|

|

|

|

|

MOS |

2.2-2.5 fF/ m2 |

0.05% |

50 ppm/°C |

50 ppm/V |

±10% |

capacitor |

|

|

|

|

|

MOM |

0.02-0.03 fF/ m2 |

1.5% |

|

|

±10% |

capacitor |

|

|

|

|

|

Allen and Holberg - CMOS Analog Circuit Design |

II.5-9 |

RESISTORS IN CMOS TECHNOLOGY |

|

Metal |

|

p+ |

|

SiO2 |

|

FOX |

FOX |

n- well |

|

p- substrate

(a)

Metal

Polysilicon resistor

FOX

p- substrate

(b)

Metal

n+

FOX |

FOX |

FOX |

n- well

p- substrate

(c)

Figure 2.4-4 Resistors. (a) Diffused (b) Polysilicon (c) N-well

Allen and Holberg - CMOS Analog Circuit Design |

II.5-10 |

PASSIVE COMPONENT SUMMARY

(0.8 m Technology)

Component |

Range of Values |

Matching |

Temperature |

Voltage |

Absolute |

Type |

|

Accuracy |

Coefficient |

Coefficient |

Accuracy |

Poly/poly |

0.8-1.0 fF/ m2 |

0.05% |

50 ppm/°C |

50ppm/V |

±10% |

capacitor |

|

|

|

|

|

MOS |

2.2-2.5 fF/ m2 |

0.05% |

50 ppm/°C |

50ppm/V |

±10% |

capacitor |

|

|

|

|

|

MOM |

0.02-0.03 fF/ m2 |

1.5% |

|

|

±10% |

capacitor |

|

|

|

|

|

Diffused |

20-150 Ω/sq. |

0.4% |

1500 ppm/°C |

200ppm/V |

±35% |

resistor |

|

|

|

|

|

Polysilicide R |

2-15 Ω/sq. |

|

|

|

|

Poly resistor |

20-40 Ω/sq. |

0.4% |

1500 ppm/°C |

100ppm/V |

±30% |

N-well |

1-2k Ω/sq. |

0.4% |

8000 ppm/°C |

10k ppm/V |

±40% |

resistor |

|

|

|

|

|