Allen and Holberg - CMOS Analog Circuit Design

.pdf

Allen and Holberg - CMOS Analog Circuit Design |

Page II.1-3 |

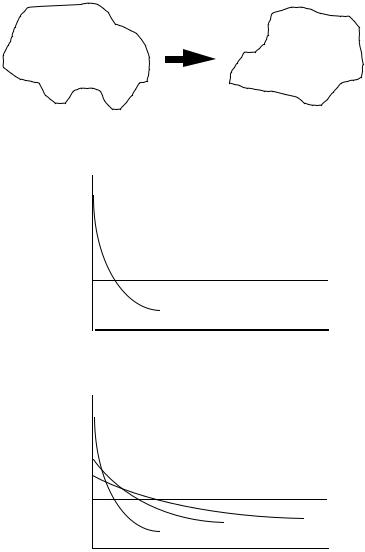

Diffusion

Movement of impurity atoms at the surface of the silicon into the bulk of the silicon - from higher concentration to lower concentration.

High |

Low |

|

Concentration |

||

Concentration |

||

|

Diffusion typically done at high temperatures: 800 to 1400 °C. Infinite-source diffusion:

N 0

ERFC

t1<t2<t3

N(x)

N B

t1 |

t2 |

t3 |

Depth (x)

Finite-source diffusion:

N 0

N(x)

N B

Gaussian

t1<t2<t3

t1 |

t2 |

t3 |

Depth (x)

Allen and Holberg - CMOS Analog Circuit Design |

Page II.1-4 |

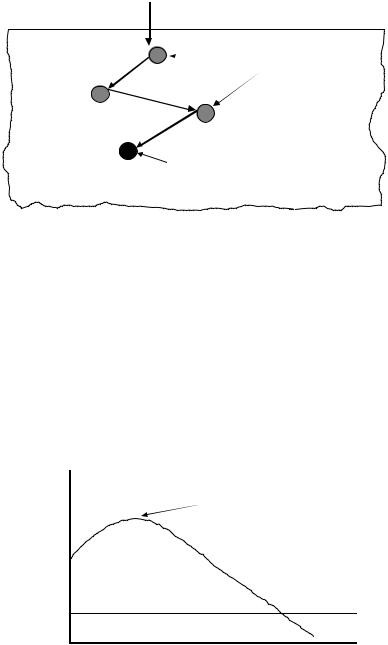

Ion Implantation

Ion implantation is the process by which impurity ions are accelerated to a high velocity and physically lodged into the target.

Path of impurity atom

Fixed atoms

Impurity final resting place

•Anneal required to activate the impurity atoms and repair physical damage to the crystal lattice. This step is done at 500 to 800 °C.

•Lower temperature process compared to diffusion.

•Can implant through surface layers, thus it is useful for field-threshold adjustment.

•Unique doping provile available with buried concentration peak.

Concentration peak

N(x)

NB

0

Depth (x)

Allen and Holberg - CMOS Analog Circuit Design Page II.1-5

Deposition

Deposition is the means by which various materials are deposited on the silicon wafer.

Examples:

•Silicon nitride (Si3N4)

•Silicon dioxide (SiO2)

•Aluminum

•Polysilicon

There are various ways to deposit a meterial on a substrate:

•Chemical-vapor deposition (CVD)

•Low-pressure chemical-vapor deposition (LPCVD)

•Plasma-assisted chemical-vapor deposition (PECVD)

•Sputter deposition

Materials deposited using these techniques cover the entire wafer.

Allen and Holberg - CMOS Analog Circuit Design |

Page II.1-6 |

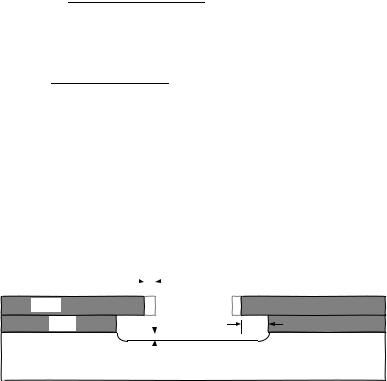

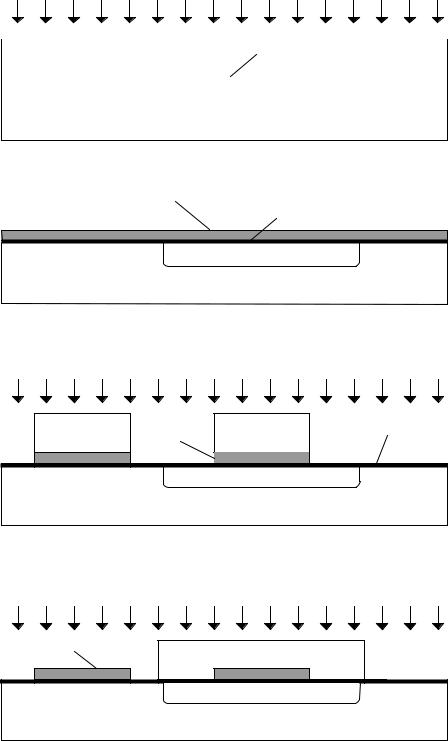

Etching

Etching is the process of selectively removing a layer of material.

When etching is performed, the etchant may remove portions or all of:

•the desired material

•the underlying layer

•the masking layer Important considerations:

•Anisotropy of the etch

lateral etch rate A = 1 - vertical etch rate

• Selectivity of the etch (film toomask, and film to substrate) film etch rate

Sfilm-mask = mask etch rate

Desire perfect anisotropy (A=1) and invinite selectivity.

There are basically two types of etches:

• Wet etch, uses chemicals

• Dry etch, uses chemically active ionized gasses.

a

Mask

Film |

c |

b

Underlying layer

Allen and Holberg - CMOS Analog Circuit Design |

Page II.1-7 |

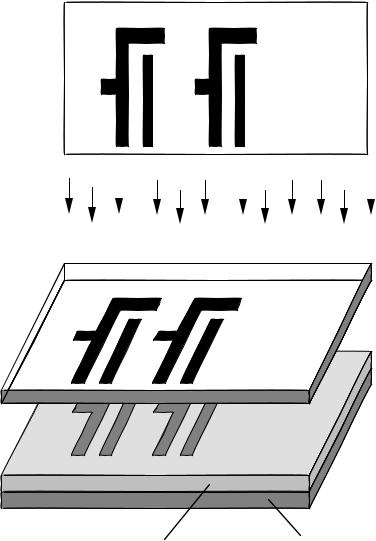

Photolithography

Components

•Photoresist material

•Photomask

•Material to be patterned (e.g., SiO2)

Positive photoresist-

Areas exposed to UV light are soluble in the developer

Negative photoresist-

Areas not exposed to UV light are soluble in the developer

Steps:

1.Apply photoresist

2.Soft bake

3.Expose the photoresist to UV light through photomask

4.Develop (remove unwanted photoresist)

5.Hard bake

6.Etch the exposed layer

7.Remove photoresist

Allen and Holberg - CMOS Analog Circuit Design |

Page II.1-8 |

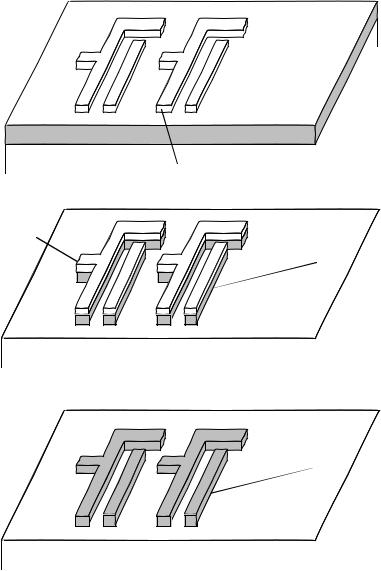

Photomask

UV

Light

Photomask

Photoresist |

Polysilicon |

Allen and Holberg - CMOS Analog Circuit Design |

Page II.1-9 |

||

|

|

|

|

|

|

|

|

Polysilicon

Polysilicon

Photoresist

Photoresist

Polysilicon

Polysilicon

Positive Photoresist

Allen and Holberg - CMOS Analog Circuit Design |

Page II.2-1 |

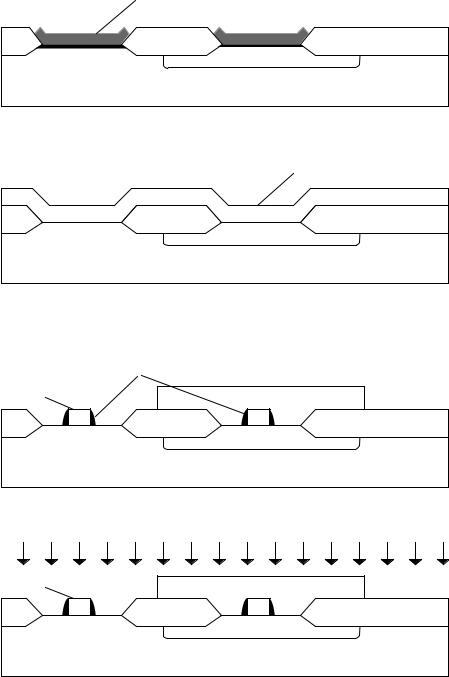

II.2 - CMOS TECHNOLOGY

TWIN-WELL CMOS TECHNOLOGY

Features

•Two layers of metal connections, both of them of high quality due to a planarization step.

•Optimal threshold voltages of both p-channel and n-channel transistors

•Lightly doped drain (LDD) transistors prevent hot-electron effects.

•Good latchup protection

Allen and Holberg - CMOS Analog Circuit Design |

Page II.2-2 |

n-well implant

Photoresist |

SiO2 |

Photoresist |

|

|

|

p- substrate

(a)

Si3N4

SiO2

n-well

p- substrate

|

(b) |

|

n- field implant |

Photoresist |

Pad oxide (SiO2) |

Photoresist |

|

|

Si3N4 |

n-well

p- substrate

|

(c) |

|

p- field implant |

Si3N4 |

Photoresist |

n-well

p- substrate

(d)

Figure 2.1-5 The major CMOS process steps.

Allen and Holberg - CMOS Analog Circuit Design |

Page II.2-3 |

Si3N4

FOX |

FOX |

|

n-well |

p- substrate |

|

|

(e) |

Polysilicon

FOX |

n-well |

p- substrate |

(f) |

SiO2 spacer

Polysilicon |

Photoresist |

|

FOX |

|

n-well |

p- substrate |

|

|

(g) |

|

n+ S/D implant |

Polysilicon |

Photoresist |

|

FOX |

|

n-well |

p- substrate |

|

|

(h) |

Figure 2.1-5 The major CMOS process steps (cont'd).