- •1. INTRODUCTION

- •1.1 BASIC TERMINOLOGY

- •1.2 EXAMPLE SYSTEM

- •1.3 SUMMARY

- •1.4 PRACTICE PROBLEMS

- •2. TRANSLATION

- •2.1 INTRODUCTION

- •2.2 MODELING

- •2.2.1 Free Body Diagrams

- •2.2.2 Mass and Inertia

- •2.2.3 Gravity and Other Fields

- •2.2.4 Springs

- •2.2.5 Damping and Drag

- •2.2.6 Cables And Pulleys

- •2.2.7 Friction

- •2.2.8 Contact Points And Joints

- •2.3 SYSTEM EXAMPLES

- •2.4 OTHER TOPICS

- •2.5 SUMMARY

- •2.6 PRACTICE PROBLEMS

- •2.7 PRACTICE PROBLEM SOLUTIONS

- •2.8 ASSIGNMENT PROBLEMS

- •3. ANALYSIS OF DIFFERENTIAL EQUATIONS

- •3.1 INTRODUCTION

- •3.2 EXPLICIT SOLUTIONS

- •3.3 RESPONSES

- •3.3.1 First-order

- •3.3.2 Second-order

- •3.3.3 Other Responses

- •3.4 RESPONSE ANALYSIS

- •3.5 NON-LINEAR SYSTEMS

- •3.5.1 Non-Linear Differential Equations

- •3.5.2 Non-Linear Equation Terms

- •3.5.3 Changing Systems

- •3.6 CASE STUDY

- •3.7 SUMMARY

- •3.8 PRACTICE PROBLEMS

- •3.9 PRACTICE PROBLEM SOLUTIONS

- •3.10 ASSIGNMENT PROBLEMS

- •4. NUMERICAL ANALYSIS

- •4.1 INTRODUCTION

- •4.2 THE GENERAL METHOD

- •4.2.1 State Variable Form

- •4.3 NUMERICAL INTEGRATION

- •4.3.1 Numerical Integration With Tools

- •4.3.2 Numerical Integration

- •4.3.3 Taylor Series

- •4.3.4 Runge-Kutta Integration

- •4.4 SYSTEM RESPONSE

- •4.4.1 Steady-State Response

- •4.5 DIFFERENTIATION AND INTEGRATION OF EXPERIMENTAL DATA

- •4.6 ADVANCED TOPICS

- •4.6.1 Switching Functions

- •4.6.2 Interpolating Tabular Data

- •4.6.3 Modeling Functions with Splines

- •4.6.4 Non-Linear Elements

- •4.7 CASE STUDY

- •4.8 SUMMARY

- •4.9 PRACTICE PROBLEMS

- •4.10 PRACTICE PROBLEM SOLUTIONS

- •4.11 ASSIGNMENT PROBLEMS

- •5. ROTATION

- •5.1 INTRODUCTION

- •5.2 MODELING

- •5.2.1 Inertia

- •5.2.2 Springs

- •5.2.3 Damping

- •5.2.4 Levers

- •5.2.5 Gears and Belts

- •5.2.6 Friction

- •5.2.7 Permanent Magnet Electric Motors

- •5.3 OTHER TOPICS

- •5.4 DESIGN CASE

- •5.5 SUMMARY

- •5.6 PRACTICE PROBLEMS

- •5.7 PRACTICE PROBLEM SOLUTIONS

- •5.8 ASSIGNMENT PROBLEMS

- •6. INPUT-OUTPUT EQUATIONS

- •6.1 INTRODUCTION

- •6.2 THE DIFFERENTIAL OPERATOR

- •6.3 INPUT-OUTPUT EQUATIONS

- •6.3.1 Converting Input-Output Equations to State Equations

- •6.3.2 Integrating Input-Output Equations

- •6.4 DESIGN CASE

- •6.5 SUMMARY

- •6.6 PRACTICE PROBLEMS

- •6.7 PRACTICE PROBLEM SOLUTIONS

- •6.8 ASSGINMENT PROBLEMS

- •6.9 REFERENCES

- •7. ELECTRICAL SYSTEMS

- •7.1 INTRODUCTION

- •7.2 MODELING

- •7.2.1 Resistors

- •7.2.2 Voltage and Current Sources

- •7.2.3 Capacitors

- •7.2.4 Inductors

- •7.2.5 Op-Amps

- •7.3 IMPEDANCE

- •7.4 EXAMPLE SYSTEMS

- •7.5 ELECTROMECHANICAL SYSTEMS - MOTORS

- •7.5.1 Permanent Magnet DC Motors

- •7.5.2 Induction Motors

- •7.5.3 Brushless Servo Motors

- •7.6 FILTERS

- •7.7 OTHER TOPICS

- •7.8 SUMMARY

- •7.9 PRACTICE PROBLEMS

- •7.10 PRACTICE PROBLEM SOLUTIONS

- •7.11 ASSIGNMENT PROBLEMS

- •8. FEEDBACK CONTROL SYSTEMS

- •8.1 INTRODUCTION

- •8.2 TRANSFER FUNCTIONS

- •8.3 CONTROL SYSTEMS

- •8.3.1 PID Control Systems

- •8.3.2 Manipulating Block Diagrams

- •8.3.3 A Motor Control System Example

- •8.3.4 System Error

- •8.3.5 Controller Transfer Functions

- •8.3.6 Feedforward Controllers

- •8.3.7 State Equation Based Systems

- •8.3.8 Cascade Controllers

- •8.4 SUMMARY

- •8.5 PRACTICE PROBLEMS

- •8.6 PRACTICE PROBLEM SOLUTIONS

- •8.7 ASSIGNMENT PROBLEMS

- •9. PHASOR ANALYSIS

- •9.1 INTRODUCTION

- •9.2 PHASORS FOR STEADY-STATE ANALYSIS

- •9.3 VIBRATIONS

- •9.4 SUMMARY

- •9.5 PRACTICE PROBLEMS

- •9.6 PRACTICE PROBLEM SOLUTIONS

- •9.7 ASSIGNMENT PROBLEMS

- •10. BODE PLOTS

- •10.1 INTRODUCTION

- •10.2 BODE PLOTS

- •10.3 SIGNAL SPECTRUMS

- •10.4 SUMMARY

- •10.5 PRACTICE PROBLEMS

- •10.6 PRACTICE PROBLEM SOLUTIONS

- •10.7 ASSIGNMENT PROBLEMS

- •10.8 LOG SCALE GRAPH PAPER

- •11. ROOT LOCUS ANALYSIS

- •11.1 INTRODUCTION

- •11.2 ROOT-LOCUS ANALYSIS

- •11.3 SUMMARY

- •11.4 PRACTICE PROBLEMS

- •11.5 PRACTICE PROBLEM SOLUTIONS

- •11.6 ASSIGNMENT PROBLEMS

- •12. NONLINEAR SYSTEMS

- •12.1 INTRODUCTION

- •12.2 SOURCES OF NONLINEARITY

- •12.3.1 Time Variant

- •12.3.2 Switching

- •12.3.3 Deadband

- •12.3.4 Saturation and Clipping

- •12.3.5 Hysteresis and Slip

- •12.3.6 Delays and Lags

- •12.4 SUMMARY

- •12.5 PRACTICE PROBLEMS

- •12.6 PRACTICE PROBLEM SOLUTIONS

- •12.7 ASIGNMENT PROBLEMS

- •13. ANALOG INPUTS AND OUTPUTS

- •13.1 INTRODUCTION

- •13.2 ANALOG INPUTS

- •13.3 ANALOG OUTPUTS

- •13.4 NOISE REDUCTION

- •13.4.1 Shielding

- •13.4.2 Grounding

- •13.5 CASE STUDY

- •13.6 SUMMARY

- •13.7 PRACTICE PROBLEMS

- •13.8 PRACTICE PROBLEM SOLUTIONS

- •13.9 ASSIGNMENT PROBLEMS

- •14. CONTINUOUS SENSORS

- •14.1 INTRODUCTION

- •14.2 INDUSTRIAL SENSORS

- •14.2.1 Angular Displacement

- •14.2.1.1 - Potentiometers

- •14.2.2 Encoders

- •14.2.2.1 - Tachometers

- •14.2.3 Linear Position

- •14.2.3.1 - Potentiometers

- •14.2.3.2 - Linear Variable Differential Transformers (LVDT)

- •14.2.3.3 - Moire Fringes

- •14.2.3.4 - Accelerometers

- •14.2.4 Forces and Moments

- •14.2.4.1 - Strain Gages

- •14.2.4.2 - Piezoelectric

- •14.2.5 Liquids and Gases

- •14.2.5.1 - Pressure

- •14.2.5.2 - Venturi Valves

- •14.2.5.3 - Coriolis Flow Meter

- •14.2.5.4 - Magnetic Flow Meter

- •14.2.5.5 - Ultrasonic Flow Meter

- •14.2.5.6 - Vortex Flow Meter

- •14.2.5.7 - Positive Displacement Meters

- •14.2.5.8 - Pitot Tubes

- •14.2.6 Temperature

- •14.2.6.1 - Resistive Temperature Detectors (RTDs)

- •14.2.6.2 - Thermocouples

- •14.2.6.3 - Thermistors

- •14.2.6.4 - Other Sensors

- •14.2.7 Light

- •14.2.7.1 - Light Dependant Resistors (LDR)

- •14.2.8 Chemical

- •14.2.8.2 - Conductivity

- •14.2.9 Others

- •14.3 INPUT ISSUES

- •14.4 SENSOR GLOSSARY

- •14.5 SUMMARY

- •14.6 REFERENCES

- •14.7 PRACTICE PROBLEMS

- •14.8 PRACTICE PROBLEM SOLUTIONS

- •14.9 ASSIGNMENT PROBLEMS

- •15. CONTINUOUS ACTUATORS

- •15.1 INTRODUCTION

- •15.2 ELECTRIC MOTORS

- •15.2.1 Basic Brushed DC Motors

- •15.2.2 AC Motors

- •15.2.3 Brushless DC Motors

- •15.2.4 Stepper Motors

- •15.2.5 Wound Field Motors

- •15.3 HYDRAULICS

- •15.4 OTHER SYSTEMS

- •15.5 SUMMARY

- •15.6 PRACTICE PROBLEMS

- •15.7 PRACTICE PROBLEM SOLUTIONS

- •15.8 ASSIGNMENT PROBLEMS

- •16. MOTION CONTROL

- •16.1 INTRODUCTION

- •16.2 MOTION PROFILES

- •16.2.1 Velocity Profiles

- •16.2.2 Position Profiles

- •16.3 MULTI AXIS MOTION

- •16.3.1 Slew Motion

- •16.3.1.1 - Interpolated Motion

- •16.3.2 Motion Scheduling

- •16.4 PATH PLANNING

- •16.5 CASE STUDIES

- •16.6 SUMMARY

- •16.7 PRACTICE PROBLEMS

- •16.8 PRACTICE PROBLEM SOLUTIONS

- •16.9 ASSIGNMENT PROBLEMS

- •17. LAPLACE TRANSFORMS

- •17.1 INTRODUCTION

- •17.2 APPLYING LAPLACE TRANSFORMS

- •17.2.1 A Few Transform Tables

- •17.3 MODELING TRANSFER FUNCTIONS IN THE s-DOMAIN

- •17.4 FINDING OUTPUT EQUATIONS

- •17.5 INVERSE TRANSFORMS AND PARTIAL FRACTIONS

- •17.6 EXAMPLES

- •17.6.2 Circuits

- •17.7 ADVANCED TOPICS

- •17.7.1 Input Functions

- •17.7.2 Initial and Final Value Theorems

- •17.8 A MAP OF TECHNIQUES FOR LAPLACE ANALYSIS

- •17.9 SUMMARY

- •17.10 PRACTICE PROBLEMS

- •17.11 PRACTICE PROBLEM SOLUTIONS

- •17.12 ASSIGNMENT PROBLEMS

- •17.13 REFERENCES

- •18. CONTROL SYSTEM ANALYSIS

- •18.1 INTRODUCTION

- •18.2 CONTROL SYSTEMS

- •18.2.1 PID Control Systems

- •18.2.2 Analysis of PID Controlled Systems With Laplace Transforms

- •18.2.3 Finding The System Response To An Input

- •18.2.4 Controller Transfer Functions

- •18.3.1 Approximate Plotting Techniques

- •18.4 DESIGN OF CONTINUOUS CONTROLLERS

- •18.5 SUMMARY

- •18.6 PRACTICE PROBLEMS

- •18.7 PRACTICE PROBLEM SOLUTIONS

- •18.8 ASSIGNMENT PROBLEMS

- •19. CONVOLUTION

- •19.1 INTRODUCTION

- •19.2 UNIT IMPULSE FUNCTIONS

- •19.3 IMPULSE RESPONSE

- •19.4 CONVOLUTION

- •19.5 NUMERICAL CONVOLUTION

- •19.6 LAPLACE IMPULSE FUNCTIONS

- •19.7 SUMMARY

- •19.8 PRACTICE PROBLEMS

- •19.9 PRACTICE PROBLEM SOLUTIONS

- •19.10 ASSIGNMENT PROBLEMS

- •20. STATE SPACE ANALYSIS

- •20.1 INTRODUCTION

- •20.2 OBSERVABILITY

- •20.3 CONTROLLABILITY

- •20.4 OBSERVERS

- •20.5 SUMMARY

- •20.6 PRACTICE PROBLEMS

- •20.7 PRACTICE PROBLEM SOLUTIONS

- •20.8 ASSIGNMENT PROBLEMS

- •20.9 BIBLIOGRAPHY

- •21. STATE SPACE CONTROLLERS

- •21.1 INTRODUCTION

- •21.2 FULL STATE FEEDBACK

- •21.3 OBSERVERS

- •21.4 SUPPLEMENTAL OBSERVERS

- •21.5 REGULATED CONTROL WITH OBSERVERS

- •21.7 LINEAR QUADRATIC GAUSSIAN (LQG) COMPENSATORS

- •21.8 VERIFYING CONTROL SYSTEM STABILITY

- •21.8.1 Stability

- •21.8.2 Bounded Gain

- •21.9 ADAPTIVE CONTROLLERS

- •21.10 OTHER METHODS

- •21.10.1 Kalman Filtering

- •21.11 SUMMARY

- •21.12 PRACTICE PROBLEMS

- •21.13 PRACTICE PROBLEM SOLUTIONS

- •21.14 ASSIGNMENT PROBLEMS

- •22. SYSTEM IDENTIFICATION

- •22.1 INTRODUCTION

- •22.2 SUMMARY

- •22.3 PRACTICE PROBLEMS

- •22.4 PRACTICE PROBLEM SOLUTIONS

- •22.5 ASSIGNMENT PROBLEMS

- •23. ELECTROMECHANICAL SYSTEMS

- •23.1 INTRODUCTION

- •23.2 MATHEMATICAL PROPERTIES

- •23.2.1 Induction

- •23.3 EXAMPLE SYSTEMS

- •23.4 SUMMARY

- •23.5 PRACTICE PROBLEMS

- •23.6 PRACTICE PROBLEM SOLUTIONS

- •23.7 ASSIGNMENT PROBLEMS

- •24. FLUID SYSTEMS

- •24.1 SUMMARY

- •24.2 MATHEMATICAL PROPERTIES

- •24.2.1 Resistance

- •24.2.2 Capacitance

- •24.2.3 Power Sources

- •24.3 EXAMPLE SYSTEMS

- •24.4 SUMMARY

- •24.5 PRACTICE PROBLEMS

- •24.6 PRACTICE PROBLEMS SOLUTIONS

- •24.7 ASSIGNMENT PROBLEMS

- •25. THERMAL SYSTEMS

- •25.1 INTRODUCTION

- •25.2 MATHEMATICAL PROPERTIES

- •25.2.1 Resistance

- •25.2.2 Capacitance

- •25.2.3 Sources

- •25.3 EXAMPLE SYSTEMS

- •25.4 SUMMARY

- •25.5 PRACTICE PROBLEMS

- •25.6 PRACTICE PROBLEM SOLUTIONS

- •25.7 ASSIGNMENT PROBLEMS

- •26. OPTIMIZATION

- •26.1 INTRODUCTION

- •26.2 OBJECTIVES AND CONSTRAINTS

- •26.3 SEARCHING FOR THE OPTIMUM

- •26.4 OPTIMIZATION ALGORITHMS

- •26.4.1 Random Walk

- •26.4.2 Gradient Decent

- •26.4.3 Simplex

- •26.5 SUMMARY

- •26.6 PRACTICE PROBLEMS

- •26.7 PRACTICE PROBLEM SOLUTIONS

- •26.8 ASSIGNMENT PROBLEMS

- •27. FINITE ELEMENT ANALYSIS (FEA)

- •27.1 INTRODUCTION

- •27.2 FINITE ELEMENT MODELS

- •27.3 FINITE ELEMENT MODELS

- •27.4 SUMMARY

- •27.5 PRACTICE PROBLEMS

- •27.6 PRACTICE PROBLEM SOLUTIONS

- •27.7 ASSIGNMENT PROBLEMS

- •27.8 BIBLIOGRAPHY

- •28. FUZZY LOGIC

- •28.1 INTRODUCTION

- •28.2 COMMERCIAL CONTROLLERS

- •28.3 REFERENCES

- •28.4 SUMMARY

- •28.5 PRACTICE PROBLEMS

- •28.6 PRACTICE PROBLEM SOLUTIONS

- •28.7 ASSIGNMENT PROBLEMS

- •29. NEURAL NETWORKS

- •29.1 SUMMARY

- •29.2 PRACTICE PROBLEMS

- •29.3 PRACTICE PROBLEM SOLUTIONS

- •29.4 ASSIGNMENT PROBLEMS

- •29.5 REFERENCES

- •30. EMBEDDED CONTROL SYSTEM

- •30.1 INTRODUCTION

- •30.2 CASE STUDY

- •30.3 SUMMARY

- •30.4 PRACTICE PROBLEMS

- •30.5 PRACTICE PROBLEM SOLUTIONS

- •30.6 ASSIGNMENT PROBLEMS

- •31. WRITING

- •31.1 FORGET WHAT YOU WERE TAUGHT BEFORE

- •31.2 WHY WRITE REPORTS?

- •31.3 THE TECHNICAL DEPTH OF THE REPORT

- •31.4 TYPES OF REPORTS

- •31.5 LABORATORY REPORTS

- •31.5.0.1 - An Example First Draft of a Report

- •31.5.0.2 - An Example Final Draft of a Report

- •31.6 RESEARCH

- •31.7 DRAFT REPORTS

- •31.8 PROJECT REPORT

- •31.9 OTHER REPORT TYPES

- •31.9.1 Executive

- •31.9.2 Consulting

- •31.9.3 Memo(randum)

- •31.9.4 Interim

- •31.9.5 Poster

- •31.9.6 Progress Report

- •31.9.7 Oral

- •31.9.8 Patent

- •31.10 LAB BOOKS

- •31.11 REPORT ELEMENTS

- •31.11.1 Figures

- •31.11.2 Graphs

- •31.11.3 Tables

- •31.11.4 Equations

- •31.11.5 Experimental Data

- •31.11.6 Result Summary

- •31.11.7 References

- •31.11.8 Acknowledgments

- •31.11.9 Abstracts

- •31.11.10 Appendices

- •31.11.11 Page Numbering

- •31.11.12 Numbers and Units

- •31.11.13 Engineering Drawings

- •31.11.14 Discussions

- •31.11.15 Conclusions

- •31.11.16 Recomendations

- •31.11.17 Appendices

- •31.11.18 Units

- •31.12 GENERAL WRITING ISSUES

- •31.13 WRITERS BLOCK

- •31.14 TECHNICAL ENGLISH

- •31.15 EVALUATION FORMS

- •31.16 PATENTS

- •32. PROJECTS

- •32.2 OVERVIEW

- •32.2.1 The Objectives and Constraints

- •32.3 MANAGEMENT

- •32.3.1 Timeline - Tentative

- •32.3.2 Teams

- •32.4 DELIVERABLES

- •32.4.1 Conceptual Design

- •32.4.2 EGR 345/101 Contract

- •32.4.3 Progress Reports

- •32.4.4 Design Proposal

- •32.4.5 The Final Report

- •32.5 REPORT ELEMENTS

- •32.5.1 Gantt Charts

- •32.5.2 Drawings

- •32.5.3 Budgets and Bills of Material

- •32.5.4 Calculations

- •32.6 APPENDICES

- •32.6.1 Appendix A - Sample System

- •32.6.2 Appendix B - EGR 345/101 Contract

- •32.6.3 Appendix C - Forms

- •33. ENGINEERING PROBLEM SOLVING

- •33.1 BASIC RULES OF STYLE

- •33.2 EXPECTED ELEMENTS

- •33.3 SEPCIAL ELEMENTS

- •33.3.1 Graphs

- •33.3.2 EGR 345 Specific

- •33.4 SCILAB

- •33.5 TERMINOLOGY

- •34. MATHEMATICAL TOOLS

- •34.1 INTRODUCTION

- •34.1.1 Constants and Other Stuff

- •34.1.2 Basic Operations

- •34.1.2.1 - Factorial

- •34.1.3 Exponents and Logarithms

- •34.1.4 Polynomial Expansions

- •34.1.5 Practice Problems

- •34.2 FUNCTIONS

- •34.2.1 Discrete and Continuous Probability Distributions

- •34.2.2 Basic Polynomials

- •34.2.3 Partial Fractions

- •34.2.4 Summation and Series

- •34.2.5 Practice Problems

- •34.3 SPATIAL RELATIONSHIPS

- •34.3.1 Trigonometry

- •34.3.2 Hyperbolic Functions

- •34.3.2.1 - Practice Problems

- •34.3.3 Geometry

- •34.3.4 Planes, Lines, etc.

- •34.3.5 Practice Problems

- •34.4 COORDINATE SYSTEMS

- •34.4.1 Complex Numbers

- •34.4.2 Cylindrical Coordinates

- •34.4.3 Spherical Coordinates

- •34.4.4 Practice Problems

- •34.5 MATRICES AND VECTORS

- •34.5.1 Vectors

- •34.5.2 Dot (Scalar) Product

- •34.5.3 Cross Product

- •34.5.4 Triple Product

- •34.5.5 Matrices

- •34.5.6 Solving Linear Equations with Matrices

- •34.5.7 Practice Problems

- •34.6 CALCULUS

- •34.6.1 Single Variable Functions

- •34.6.1.1 - Differentiation

- •34.6.1.2 - Integration

- •34.6.2 Vector Calculus

- •34.6.3 Differential Equations

- •34.6.3.1.1 - Guessing

- •34.6.3.1.2 - Separable Equations

- •34.6.3.1.3 - Homogeneous Equations and Substitution

- •34.6.3.2.1 - Linear Homogeneous

- •34.6.3.2.2 - Nonhomogeneous Linear Equations

- •34.6.3.3 - Higher Order Differential Equations

- •34.6.3.4 - Partial Differential Equations

- •34.6.4 Other Calculus Stuff

- •34.6.5 Practice Problems

- •34.7 NUMERICAL METHODS

- •34.7.1 Approximation of Integrals and Derivatives from Sampled Data

- •34.7.3 Taylor Series Integration

- •34.8 LAPLACE TRANSFORMS

- •34.8.1 Laplace Transform Tables

- •34.9 z-TRANSFORMS

- •34.10 FOURIER SERIES

- •34.11 TOPICS NOT COVERED (YET)

- •34.12 REFERENCES/BIBLIOGRAPHY

- •35. A BASIC INTRODUCTION TO ‘C’

- •35.2 BACKGROUND

- •35.3 PROGRAM PARTS

- •35.4 HOW A ‘C’ COMPILER WORKS

- •35.5 STRUCTURED ‘C’ CODE

- •35.7 CREATING TOP DOWN PROGRAMS

- •35.8 HOW THE BEAMCAD PROGRAM WAS DESIGNED

- •35.8.1 Objectives:

- •35.8.2 Problem Definition:

- •35.8.3 User Interface:

- •35.8.3.1 - Screen Layout (also see figure):

- •35.8.3.2 - Input:

- •35.8.3.3 - Output:

- •35.8.3.4 - Help:

- •35.8.3.5 - Error Checking:

- •35.8.3.6 - Miscellaneous:

- •35.8.4 Flow Program:

- •35.8.5 Expand Program:

- •35.8.6 Testing and Debugging:

- •35.8.7 Documentation

- •35.8.7.1 - Users Manual:

- •35.8.7.2 - Programmers Manual:

- •35.8.8 Listing of BeamCAD Program.

- •35.9 PRACTICE PROBLEMS

- •36. UNITS AND CONVERSIONS

- •36.1 HOW TO USE UNITS

- •36.2 HOW TO USE SI UNITS

- •36.3 THE TABLE

- •36.4 ASCII, HEX, BINARY CONVERSION

- •36.5 G-CODES

- •37. ATOMIC MATERIAL DATA

- •37. MECHANICAL MATERIAL PROPERTIES

- •37.1 FORMULA SHEET

- •38. BIBLIOGRAPHY

- •38.1 TEXTBOOKS

- •38.1.1 Slotine and Li

- •38.1.2 VandeVegte

- •39. TOPICS IN DEVELOPMENT

- •39.1 UPDATED DC MOTOR MODEL

- •39.2 ANOTHER DC MOTOR MODEL

- •39.3 BLOCK DIAGRAMS AND UNITS

- •39.4 SIGNAL FLOW GRAPHS

- •39.5 ZERO ORDER HOLD

- •39.6 TORSIONAL DAMPERS

- •39.7 MISC

- •39.8 Nyquist Plot

- •39.9 NICHOLS CHART

- •39.10 BESSEL POLYNOMIALS

- •39.11 ITAE

- •39.12 ROOT LOCUS

- •39.13 LYAPUNOV’S LINEARIZATION METHOD

- •39.14 XXXXX

- •39.15 XXXXX

- •39.16 XXXXX

- •39.17 XXXXX

- •39.18 XXXXX

- •39.19 XXXXX

- •39.20 XXXXX

- •39.21 SUMMARY

- •39.22 PRACTICE PROBLEMS

- •39.23 PRACTICE PROBLEM SOLUTIONS

- •39.24 ASSGINMENT PROBLEMS

- •39.25 REFERENCES

- •39.26 BIBLIOGRAPHY

continuous sensors - 14.20

14.2.5 Liquids and Gases

There are a number of factors to be considered when examining liquids and gasses.

•Flow velocity

•Density

•Viscosity

•Pressure

There are a number of differences factors to be considered when dealing with fluids and gases. Normally a fluid is considered incompressible, while a gas normally follows the ideal gas law. Also, given sufficiently high enough temperatures, or low enough pressures a fluid can be come a liquid.

PV = nRT

where,

P = the gas pressure

V = the volume of the gas

n = the number of moles of the gas

R = the ideal gas constant =

T = the gas temperature

When flowing, the flow may be smooth, or laminar. In case of high flow rates or unrestricted flow, turbulence may result. The Reynold’s number is used to determine the transition to turbulence. The equation below is for calculation the Reynold’s number for fluid flow in a pipe. A value below 2000 will result in laminar flow. At a value of about 3000 the fluid flow will become uneven. At a value between 7000 and 8000 the flow will become turbulent.

continuous sensors - 14.21

VDρ

R = -----------

u

where,

R = Reynolds number

V = velocity

D = pipe diameter

ρ = fluid density u = viscosity

14.2.5.1 - Pressure

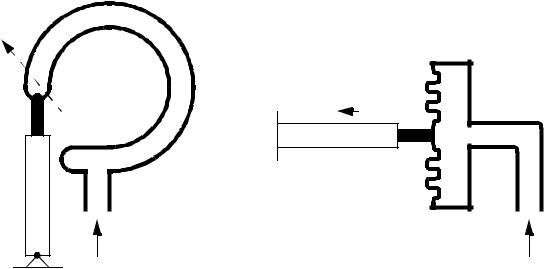

Figure 14.22 shows different two mechanisms for pressure measurement. The Bourdon tube uses a circular pressure tube. When the pressure inside is higher than the surrounding air pressure (14.7psi approx.) the tube will straighten. A position sensor, connected to the end of the tube, will be elongated when the pressure increases.

pressure |

pressure |

increase |

increase |

|

position sensor |

positionsensor |

pressure |

pressure |

|

a) Bourdon Tube |

b) Baffle |

Figure 14.22 Pressure Transducers

continuous sensors - 14.22

These sensors are very common and have typical accuracies of 0.5%.

14.2.5.2 - Venturi Valves

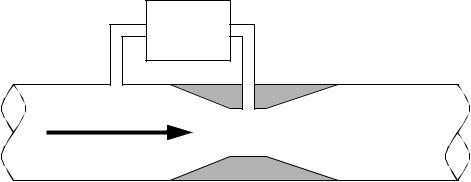

When a flowing fluid or gas passes through a narrow pipe section (neck) the pressure drops. If there is no flow the pressure before and after the neck will be the same. The faster the fluid flow, the greater the pressure difference before and after the neck. This is known as a Venturi valve. Figure 14.23 shows a Venturi valve being used to measure a fluid flow rate. The fluid flow rate will be proportional to the pressure difference before and at the neck (or after the neck) of the valve.

differential |

pressure |

transducer |

fluid flow

Figure 14.23 A Venturi Valve

continuous sensors - 14.23

Aside: Bernoulli’s equation can be used to relate the pressure drop in a venturi valve.

p |

v2 |

+ gz = C |

-- + ---- |

||

ρ |

2 |

|

where,

p = pressure

ρ= density

v= velocity

g = gravitational constant

z = height above a reference

C = constant

Consider the centerline of the fluid flow through the valve. Assume the fluid is incompressible, so the density does not change. And, assume that the center line of the valve does not change. This gives us a simpler equation, as shown below, that relates the velocity and pressure before and after it is compressed.

pbefore |

|

2 |

|

|

|

pafter |

|

vafter |

2 |

|

+ |

vbefore |

+ gz = C = |

+ |

+ gz |

||||||

---------------ρ |

-----------------2 |

------------ρ |

--------------2 |

|||||||

|

|

|

|

|

|

|||||

pbefore |

|

2 |

|

pafter |

|

2 |

|

|

|

|

+ |

vbefore |

= |

vafter |

|

|

|

||||

---------------ρ |

-----------------2 |

------------ρ |

+ -------------- |

2 |

|

|

|

|||

|

|

|

|

|

|

|||||

|

|

|

|

vafter |

2 vbefore |

2 |

|

|

||

pbefore – pafter = ρ |

-------------- |

– |

----------------- |

|

|

|||||

2 |

|

|

|

|||||||

|

|

|

|

2 |

|

|

|

|

||

The flow velocity v in the valve will be larger than the velocity in the larger pipe section before. So, the right hand side of the expression will be positive. This will mean that the pressure before will always be higher than the pressure after, and the difference will be proportional to the velocity squared.

Figure 14.24 The Pressure Relationship for a Venturi Valve

Venturi valves allow pressures to be read without moving parts, which makes them very reliable and durable. They work well for both fluids and gases. It is also common to use Venturi valves to generate vacuums for actuators, such as suction cups.

14.2.5.3 - Coriolis Flow Meter

Fluid passes through thin tubes, causing them to vibrate. As the fluid approaches the point of maximum vibration it accelerates. When leaving the point it decelerates. The