reading / British practice / Vol D - 1990 (ocr) ELECTRICAL SYSTEM & EQUIPMENT

.pdf

|

|

Low voltage switchgear, controlgear and fusegear |

|

|

|

|

|

|

|

neutral current, for example, where the load is wholly |

|

|

|

or predominantly fluorescent lighting, the neutral is |

|

|

|

assigned a rating equivalent to that of the phase |

|

|

|

conductors. |

|

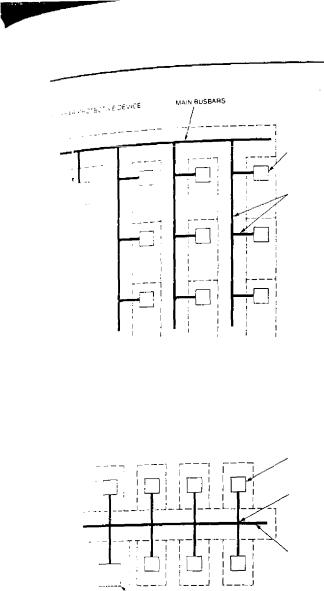

CiFICuiT PROTECTIVE |

Except in the case of orifices (spouts) protected by |

||

DEVICE |

shutters, e.g., at disconnecting (isolating) contacts, |

||

|

|

||

|

|

access to busbar circuits may be gained only by the |

|

EE-OFF BJSEARS |

removal of covers secured by fastenings requiring the |

||

|

|

use of tools, e.g., spanners, screwdrivers, to release. |

|

|

|

Each cover must be clearly and indelibly marked |

|

|

|

BUSBARS in red. Shutters protecting orifices are pro- |

|

|

|

vided with facilities for padlocking closed — for use |

|

|

|

(for example) when a withdrawable part is removed. |

|

|

|

The short-circuit withstand |

strength of busbar sys- |

|

|

tems is described in Section |

6.1 of this chapter. |

|

|

However, for the lower circuit (functional unit) cur- |

|

|

rent ratings, it is often necessary to reduce the cross- |

|

|

sectional area of the tee-off busbars at the point of |

|

|

attachment to the terminals of the circuit short-circuit |

|

|

protective device, to dimensions compatible with those |

|

|

terminals. To maintain, as far as practicable, the se- |

|

|

curity of the busbar system at this point, such reduc- |

|

|

tion in section must not extend for a distance exceeding |

|

CIRCUIT PROTECTIVE |

40 mm from the terminals of the protective device |

|

unless the conductors are insulated for the rated insu- |

|

|

DE ViCE |

|

|

|

|

|

|

lation voltage, and supported in a mechanically robust |

|

TEE OFF BUSRARS |

manner. Where so insulated and supported, the occur- |

|

|

|

|

|

rence of short-circuit earth faults is unlikely. |

|

|

Main circuit fuselinks are to BS88 and of the gen- |

|

MAN 8USBASS |

eral purpose or motor circuit type, as appropriate. |

|

Similarly, fuse holders are to BS88. However, having |

|

|

|

|

|

|

regard to the 1 2 t let-through of large fuse-links at high |

|

|

prospective fault currents, the maximum rating allowed |

BuSRAP RCTECTIvE DEVICE |

|

mounted in fuse holders is 100 A. Fuselinks rated above |

|

100 A are mounted in fuse switches or similar devices. |

|

|

|

I It.. 5_55 Typical busbar circuits

. 'iirminilinsz' through loss of adhesion, taping of

I |

t1 |

toriN not accepted |

for any purpose. |

I |

IL |

iNko husbar circuits in busbar sectioning/inter- |

|

|

|

equipments must |

be segregated from each |

|

|

by carthed metal or |

approved fire-resistant in- |

|

|

For withdrawable equipment, the segregation |

|

[.. quired io extend up to, and including, the fixed

... oluicciinu contacts. This |

segregation is necessary |

||||

rcrruit |

\k ork anywhere on one set of bars whilst |

||||

,!iler |

remains live provided the busbar sectioning |

||||

opc n . |

|

|

|

|

|

.11low freedom in the |

positioning of circuits in |

||||

ri aboard, busbars are specified to have a con- |

|||||

. 'lii rating throughout |

their length; such re |

qui |

rement |

||

k1, of value should |

|

|

|

||

extension become necessary. |

|||||

general rule, neutral |

conductors are required |

||||

|

current carrying capability of not less than |

||||

holf that of the associated phase conductor. How- |

|||||

%t here the connected |

loads result in abnormal |

||||

6.2.6 Earthing of structures

Each switchboard i provided with a main earth bar (protective conductor), usually and preferably on the outside of the enclosure, extending throughout the length of the switchboard. Subsidiary (tee-off) bars are provided as necessary. The bars may be of copper, aluminium or aluminium alloy. To facilitate the attachment on site of earth bonding cables, a clearance of not less

of the main earth bar and the adjacent surface of the switchgear enclosure.

All joints are bolted. Because of problems at the interface of aluminium cable lugs bolted directly to tinned copper surfaces, bars are plain finish, i.e., untinned. Joints in aluminium bars have the oxide film removed by steel wire brush; the surfaces so cleaned are then coated with petroleum jelly or other approved compound immediately before assembly. For outdoor installations, the completed joint is sealed by the application of an overall coating. Provision is made at each end of each main earth bar for connection to the station main earthing system. To assist achievement of

403

Switchgear and controlgear |

Chapter 5 |

|

|

|

|

a satisfactory connection, a flat area of not less than 50 x 50 mm must be provided.

Earth bars of copper are dimensioned as shown in Table 5.3.

(f)To prevent connection to the supply of main Circui t parts to which access has been gained as in (e).

However, whilst a defeat feature is provided fo r use when the door is open, it is not possible to

TABLE 5.3

Copper earth bar dimensions

|

Main earth bar |

Subsidiar y (tee-off) |

|||

|

earth bar |

||||

Busbar system |

|

|

|

||

|

|

|

|

|

|

short-circuit |

Cross- |

|

|

Cross- |

|

protection |

|

Minimum |

Minimum |

||

sectional |

|

sectional |

|||

|

2 |

width, mm |

width, mm |

||

|

area, mm |

area, mm 2 |

|||

|

|

|

|

|

|

Fuse |

150 |

|

25 |

75 |

25 |

Circuit-breaker |

300 |

|

50 |

150 |

25 |

(3 s rated) |

|

|

|

|

|

|

|

|

|

|

|

Earth bars of aluminium alloy must have a width not less than that required for copper, and possess electrical and mechanical properties not inferior to those of copper.

Single main circuit equipments are provided with an earth terminal.

Withdrawable parts are, when in the connected position, bonded to the equipment earth bar or terminal through contacts designed specifically for the purpose. Such contacts must establish the earth connection before the contacts of the main circuit connect.

The neutral points of transformers are earthed at the switchgear through removable links.

6.2.7 Mechanical interlocks

Mechanical interlocking is of the preventive type, i.e., designed to prevent as opposed to correct an improper action, and effective as close as practicable to the point at which force is applied.

Essentially, such interlocks are provided:

(a)To prevent the closure of a switching device incorporated in a withdrawable part, unless the withdrawable part is located correctly in the connected, disconnected or, where appropriate, test position.

(b)To prevent the opening or closing of 'off-load' disconnecting (isolating) devices unless the associated switching device is open.

(c)To prevent the simultaneous closure of 'forward' and 'reverse' or 'low speed' and 'high speed' contactors.

(d)To prevent the simultaneous closure of both contactors or both switches of a changeover arrangement.

(e)To prevent access to main circuit parts through doors unless such parts have been isolated from all sources of supply.

close the door unless the interlock is restored. Pro , vision is made for padlocking the interlock against defeat.

Additionally, where for reasons of safety it is essential to prevent the inadvertent starting of a drive by closure of the circuit isolating device in the presence of a welded contactor.

(g)To prevent the closure of the disconnecting (isolating) device in motor starters unless the associated contactor is open.

6.2.8 Coded-key devices

Coded-key operated devices are provided where necessary in a scheme of system interlocking whereby:

•A key, when inserted, permits a circuit-breaker (or other switching device) to be closed, and is free only when the circuit-breaker is open. Attempted removal of the key when the circuit-breaker is closed must not cause tripping of the circuit-breaker.

•A key is free only when a circuit-breaker is removed from the connected position. It must not be possible to place the circuit-breaker in the connected position with the key removed, but it is possible to place and operate the circuit-breaker in the disconnected position.

6.2.9 Protective systems components

Each component of the protective system, e.g., current transformers, relays, etc., must be capable of withstanding, without damage, the passage of the shortcircuit currents available from the busbars for the short-time rating of the equipment or, in the case of fuse protected equipment, be capable of withstanding

404

Low voltage switchgear, controlgear and fusegear

The let-through current of the highest rated fuselink

hiJi may be fitted in the associated main circuit.

,,■

6 2 10 Current transformers

rrcnut |

transformers dre normally fitted on the side of |

||

0.5itching device remote from the busbars. |

|||

|

|

||

nic |

secondary ‘vindings of each single-phase current |

||

|

and the star-point of the secondary wind- |

||

|

|

||

of each three-phase group are normally earthed

:one point only through a removable link. Where

(ratisformers are not readily visible, e.g., in circuitduplicates of the rating plate are

kcr

in a more convenient position.

6.2.11Ammeters and voltmeters

Vninelers and voltmeters |

mounted on the switchgear |

|

,, r c of the back-connected, |

flush type. Ammeter scales |

|

, e ,c.) |

chosen that full-load current produces approxi- |

|

TJ;ek |

75tro full scale deflection. |

|

\\ here there is no requirement for indication at a

... mote point, those at the switchgear may be con-

ced |

in circuits of ratings up to the order |

|

|

. , t to A. |

|

All ammeters Must be capable of carrying rated

..irrent continuously, be suitable for use with direct- He started motors where appropriate and able to

.,, t ih,tand without damage the passage of fault current he operation of the main circuit protection.

6 2.12 Control switches

on(roI switches for circuit-breakers are of the pistol-

..:r!p |

|

(rotary) |

type; for contactor gear, pushbuttons |

|||||||

ire |

the norm. |

Facilities are provided for padlocking |

||||||||

!,11- ■ |

selector |

devices in all positions, and rotary con- |

||||||||

|

devices in |

the neutral position. Pushbuttons are |

||||||||

|

|

|

and coloured in accordance with Table 5.4. |

|||||||

|

|

|

|

|

TABLE |

5.4 |

|

|

|

|

|

|

|

Mo./dm/toil inscriptions and colour coding |

|||||||

|

|

|

|

|

|

|

|

|

||

|

|

|

Duty |

Inscription |

Colour |

|||||

|

|

|

|

|

|

|

|

|||

|

|

|

1._ mtlir tioual motor |

Start |

Green |

|||||

|

|

|

|

|

|

Stop |

Red |

|||

|

|

|

1- Slai2 |

motor |

|

Forward |

Green |

|||

|

|

|

|

|

|

Reverse |

Green |

|||

|

|

|

|

|

|

Stop |

Red |

|||

|

|

|

1,ike or damper |

|

Open |

Black |

||||

|

|

|

|

|

|

Close |

Black |

|||

|

|

|

|

|

|

Stop |

Red |

|||

|

|

|

F. nicrgency Slop |

|

Stop |

Red |

||||

" |

|

|

|

|

||||||

t,tri. buttons are |

placed to the right of or above |

|||||||||

':op |

buttons. Control devices are located to the right |

|||||||||

,! or below selector switches. |

|

|

|

|

||||||

For the purpose of identification, switchboards, circuits, control equipment, etc., are provided with labelling and coloured symbols largely in line with the requirements specified for 3.3 kV and 11 kV switchgear.

6.2.13 Fuses

Fuselinks in both main (i.e., power) and control/ auxiliary circuits are of the cartridge type.

Main circuit fuselinks are to B588 and of the general purpose or motor circuit type, as appropriate. Control/auxiliary circuit fuselinks may be to BS88 or to Defence Standard DEF 59-96: Part 1. Fuseholders are to BS88 or DEF 59-100: Part 1, as appropriate.

Fuses in control/auxiliary circuits are grouped to assist circuit identification and to provide convenient points of isolation. Wherever practicable, fuses to BS88 are used in preference to the DEF type. The preference stems largely from the provision in BS88 holders of better shrouding of the contacts and a generally greater suitability for use as points of isolation.

6.2.14 Circuit-breaker equipments

Circuit-breakers are specified basically to B54752: Part 1, but with the following additional capabilities:

•A rated asymmetrical breaking current equivalent to the rated symmetrical breaking current plus, in

one phase at the instant of contact separation, a DC component of not less than 50 07o of the AC

component in that phase (see Fig 5.24).

•Breaking a current equivalent to 100% of the sym-

metrical breaking current applied to an outer pole, without the unbalance forces produced under these conditions adversely affecting correct operation.

Where required for a triple-pole and neutral installation, the neutral connection is established through a bolted link.

Circuit-breaker operating mechanisms are of the dependent power solenoid or stored-energy motor chargedspring type, complying basically with the requirements outlined for 3.3 kV and 11 kV equipment. Whilst both types are equally acceptable from the point of view of performance, the latter, although of somewhat greater complication constructionally, does not require the provision of a relatively heavy DC closing supply. Thus, this mechanism can be of advantage in installations where the provision of a heavy battery Source of supply could present a problem — technically and/or economically.

In basic concept, all low voltage switchgear assemblies incorporating circuit-breakers are of the metalclad type in accordance with the definition of the term `rnetalclad' outlined for 3.3 kV and 11 kV equipment. Thus, disconnection (isolation) facilities for main and auxiliary circuits, and also the provision of shutter gear protecting busbar and circuit contacts (spouts)

405

Switchgear and controlgear |

Chapter 5 |

|

|

in the cubicle, follow the arrangements established for the higher voltage equipment. However, it may be helpful to recall that the requirement described in Section 1.3 of this chapter to the effect that work on current carrying parts is permitted only when such parts are earthed, is pertinent only at high voltage. Accordingly, no provision is made for the deliberate earthing of current carrying parts of low voltage equipment.

6.2.15 Contactor controlgear

Motor circuits account for the bulk of the contactor type controlgear used in the power station. Essentially,

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

P |

0 |

|

|

|

|

|

|

P 9-7,4A |

|

|||||

Y |

0 |

|

|

|

|

|

|

|

|

|||||

5 |

0 |

|

|

|

|

|

|

|

|

61=. |

|

|

||

|

|

|

|

|

|

|

|

|

||||||

R 0 |

|

|

|

|

COM |

|

|

|

||||||

|

|

|

|

|

|

|

|

|||||||

Y 0 |

|

|

|

Cl= |

|

|

|

|||||||

|

|

|

|

|||||||||||

B |

0 |

|

|

CM= |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

• |

a |

4 |

—) |

, |

-ire |

|||||||||

|

|

|

|

|

|

|

Com 0 |

|||||||

Y 0 |

|

|

|

|||||||||||

|

|

|

|

|

|

|||||||||

0CM.

•0—(1= Y 0

•0

I I

l fl

E-1

FUSES TO 5558

FOR TYPE C EQUIPMENT THE MAIN CIRCUIT

FUSE LINKS ARE MOUNTED ELSEWHERE

FOR TYPED EQUIPMENT THE MAIN CIRCUIT

FUSE L NKS MUST NOT EXCEED 100A RATING

each circuit comprises a contactor in association with

high breaking capacity (HBC) fuselinks, together with means for disconnecting the main and auxiliary circuits

from their respective incoming supplies. The basic arrangements recognised are as follows and depicted diagrammatically in Fig 5.56:

Type A Non-withdrawable type with operational/ maintenance disconnection by fuse-switch.

Type 13 Withdrawable type having off-load plug and socket devices for maintenance disconnection and a switch within the fuse protected

N> - - TYPE A'

L.. TYPE "El' --' ALTERNATIVE

ARRANGEMENT

-TYPE C'

-- TYPE '0

FIG. 5.56 Alternative arrangements for contactor fuses and isolating devices

406

|

|

Low voltage switchgear, controlgear and fusegear |

|

|

|

|

|

|

zone for operational disconnection. The |

erational disconnection are provided with auxiliary |

|

|

withdrawable assembly also accommodates |

switches driven positively in each direction. |

|

|

the main circuit fuselinks. |

Largely to minimise the risk of operator mistake, |

|

|

Non-withdrawable type with operational/ |

particularly in an emergency, the operating handles of |

|

|

devices for operational disconnection are arranged uni- |

||

|

maintenance disconnection by a switch. |

||

|

formly to close the device with an upward movement. |

||

|

|

||

|

Non-withdrawable type with a switch, within |

Handles operating in a plane parallel to the front of the |

|

|

equipment have a full movement not exceeding 60 0 |

||

|

the fuse protected zone, for operational |

||

|

either side of the horizontal. Mechanisms are of the |

||

|

disconnection. |

||

|

independent manual type. It must not be possible to |

||

|

|

||

pes A, B and C are equally acceptable. Type D is |

leave an operating handle in an intermediate position. |

||

Padlocking facilities are provided as follows: |

|||

permitted only for fuse-fed switchboards. In Type D |

|||

• For locking the handles of devices for operational |

|||

quipment, the fuses are mounted on the busbar side |

|||

o', f the circuit disconnecting device. There is therefore, |

disconnection in the open position — it being pos- |

||

sible to maintain such locking of the device against |

|||

he possibility that their replacement after operation |

|||

t |

closure when access to the interior has been gained |

||

eould be attempted before the abnormality causing the |

|||

operation has been corrected. The act of attempted |

for maintenance purposes. |

||

-ement in such circumstances could initiate an |

• For locking withdrawable contactor equipment as- |

||

r eplacementL |

|||

arc at the fuse carrier/holder contacts. Restriction of |

semblies in the connected position. |

||

the use of Type D equipment to fuse-fed switchboards, |

|||

|

|||

i.e., switchboards for which the busbar system is |

• For locking shutters in the closed position. When |

||

itself fuse-fed, is considered to reduce substantially |

padlocked, the shutters prevent access to the fixed |

||

anv risk arising from this cause. |

isolating contacts which they shroud. Whilst the |

||

The several devices comprising the main circuit, e.g., |

shutters are locked closed, it must not be possible |

||

the contactor, fuse-switch, etc., are usually manufac- |

for the isolating contacts on the withdrawable part |

||

tured by specialist component manufacturers and thus |

of the equipment to make contact with the shutters |

||

may have performance ratings against specific duties. |

should an attempt be made to place it in the con- |

||

Consequently , it is required that each 'circuit' corn- |

nected position. |

||

prising a combination of disconnecting device, fuses, |

• For locking disconnection (isolation) devices of |

||

contactor, power terminals and associated internal con- |

|||

the withdrawable/removable type in the connected |

|||

nections be assigned a rated operating current by the |

|||

position. |

|||

manufacturer of the combination, i.e., the manufac- |

|||

|

|||

turer of the circuit assembly. |

Each circuit is provided with a visual indicating device |

||

As in circuit-breaker equipment, any neutral links |

|||

to show whether the contactor is 'open' or 'closed', |

|||

are of bolted type. |

|||

which must be effective in both the 'circuit connected' |

|||

As a general guideline and to allow for contin- |

|||

and 'circuit disconnected' positions. The device may be |

|||

et-teies, the circuit minimum rating for direct-to-line |

|||

.larted motors is usually specified to be not less than |

either mechanically or electrically operated. The ori- |

||

ginating action must be driven positively in the direction |

|||

120 per cent of the nominal full load current of the |

|||

of closing the main contacts and must not impede |

|||

motor. |

|||

operation of the contactor. Alternatively, and usually |

|||

Filch fuse-switch and switch has a current making |

|||

in the case of separately-mounted (i.e., Type C) units, |

|||

and breaking capacity not less than the value derived |

|||

the indication may be by lamps. If so, lenses are white |

|||

from I3S5424: Part Clause 4.3.5 when based on |

|||

for ON, green for OFF, the green lens being placed |

|||

ilie assigned rated current of the circuit. In addition, |

|||

to the right of, or above, the white lens. The white |

|||

•th..1) switches must be capable of making a current |

|||

lens is identified by the legend 'ON'. |

|||

cninsalent to the supply source prospective short- |

|||

Electrically operated devices other than indicator |

|||

...tr am current as limited in magnitude and duration |

|||

lights must adopt a non-definite indication on loss of |

|||

hs the highest rated fuselink which is permissible in |

|||

an operating signal. |

|||

:hie circuit. |

|||

Each contactor is provided with four normally open |

|||

Where connection to the source of supply, e.g., |

|||

and four normally closed auxiliary contacts, except |

|||

Imsbars, is by plug and socket contacts, apertures |

|||

that for the electrically-held type below 40 A rating, two |

|||

ing access to the supply side are shrouded or shut- |

|||

normally open and two normally closed contacts may |

|||

iered. Shutters must operate automatically on insertion |

|||

be accepted in conjunction with a repeat relay. |

|||

,iiid removal of the withdrawal assembly, and are |

|||

Auxiliary contacts are driven as follows: |

|||

Identified as in circuit-breaker equipment, albeit the |

|||

|

|||

iering is, of necessity, usually smaller. |

• Block type — positively driven in the direction of |

||

or the purpose of indication, if required at a |

closing the main contacts, but may be spring- |

||

point(s) remote from the switchgear, devices for op- |

returned to the open position. |

||

407

Switchgear and controlgear |

Chapter 5 |

|

|

Note: a 'block' type contactor is one in which the contact system is carried in an enveloping case of moulded insulation material. The moving contact assembly operates usually with a parallel motion in a horizontal plane.

•Clapper type — positively driven in both directions.

Note: a 'clapper', or 'bar', type contactor is one in which moving contacts are carried on an insulated bar and engage with stationary contacts mounted (usually) on a flat base of insulation material.

The trip circuit auxiliary switch on latched contactors must close before the main circuit contacts touch.

Means are provided which:

(a)On latched contactors de-energise the closing coil when the contactor has closed and latched.

(b)On both electrically-held and latched contactors prevent reclosure in the event of failure to close, or automatic opening, whilst the closing signal is maintained.

Each contactor is provided with facilities for maintenance testing the opening and closing operations of the contactor by the use of the pushbuttons mounted on the enclosure front. The arrangements are such that the testing can be carried out only when the contactor is disconnected from the busbars.

Control circuits function at the following voltages:

•Contactor closing mechanisms, 110 V AC nominal, derived from 415/110 V control circuit transformers.

•Trip circuits (of latched contactors), 110 V DC nominal.

Control circuit transformers are 415/110 V, noninherently short-circuit proof, to 8S3535, Section F, but having an earthed metallic interwinding screen.

'Non-inherently short-circuit proof' transformers will, if short-circuited at the output terminals, be damaged unless disconnected by an overcurrent device. Such transformers are well suited to the operation of solenoid mechanisms in that, provided the overcurrent protective device (e.g., a fuse) exhibits a suitable time/ current characteristic, advantage may be taken of the 'short-time' capability (of the transformer) to satisfy the relatively heavy transient (inrush) current taken by the solenoid coil at energisation. Duty for duty, a transformer 'inherently short-circuit proof' would need to be of appreciably higher rating.

Fuselinks are fitted in both poles of the input connections to the transformer. These may be mounted either in a fuse-switch or in fuseholders. The output connections are protected by a fuselink in one pole and a solid link in the earthed pole. The non-fused output terminal of the secondary winding is connected to earth through a removable bolted link.

6.2.16 Fusegear

Fusegear is used primarily to distribute supplies rather than control specific items of plant directly, e.g., t o provide supplies to the smaller switchboards, separately mounted motor starters, valve actuators, etc. An important aspect of this role is the provision inherently of short-circuit protection.

Fusegear may be built into and thus form an integral part of multi-motor control switchboards; these may constitute switchboards consisting wholly of fuse gear, or may comprise single circuit feeding units. Where, in addition to circuit disconnection (isolation) a switching facility is required, fuse-switches are employed. Where there is no switching requirement, distribution fuseboards are used.

Fuse switches are basically to BS5419, double-pole, three-pole or three-pole and neutral as necessary. Neutral links may be either bolted or switched. Where switched, the neutral connection must be established before the phases 'make', and 'broken' after the phases 'break'.

To preserve uniformity with the manner of operation of the handles of devices for the disconnection of contactor controlgear, those for fuse-switches are arranged to close the switch with an upward movement. For handles operating with a rotary action in a plane parallel to the front of the equipment, the full movement of the handle shall not exceed 60 ° either side of the horizontal.

Mechanisms are of the independent manual type. It must not be possible to leave the operating handle in an intermediate position.

Note: an independent manual mechanism is one in which manual energy is stored and released in one continuous operation, such that the speed and force of the operation are independent of the action of the operator.

Mechanical indication of the operating positions of the switch handles is provided to show when the switch is ON or OFF.

When necessary, fuse-switches have provision for operating auxiliary switches.

Where fuse-switches are of the withdrawable type, any main circuit parts which may remain live and become exposed upon removal of the withdrawable assembly are shrouded or shuttered. Such shutters operate automatically on insertion and removal of the withdrawable assembly.

Distribution fuseboards may be of the wall-mounted box pattern, of the free-standing cubicle type, or may, where expedient, be incorporated in 'main' switchboards.

Padlocking facilities are provided for:

•Locking fuse-switch handles in the open position. It must be possible to keep the fuse-switch locked . against closure when access to the interior has been gained for maintenance purposes. Only in excep-

408

Fuses

|

tional circumstances, e.g., where continuity of supply |

|

|

|

|

|

|

|

|

|

is an overriding consideration, is provision made |

-41 |

|

14100m, APPIROX |

|

||||

|

|

|

|

|

|

|

|

||

|

for padlocking handles in the closed position. |

|

|

|

|

|

|

|

|

|

king shutters in the closed position. Whilst |

|

|

MAIN LABEL. |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

• |

c oc |

|

|

|

|

|

|

|

|

shutters are locked closed, it must not be possible |

|

|

|

|

|

|

|

|

|

|

ror the isolating contacts on the withdrawable part |

|

|

|

|

|

|

|

|

|

o f I he equipment to make contact with the shutters |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

should an attempt be made to place it in the con- |

|

|

|

|

|

|

|

|

n,:cted position.

•Locking fuse-switches of the withdrawable/removable type in the connected position.

6.2.17 Specialised switchboards/units

In addition to the traditional switchboards described |

|

ON |

ON |

|

|

APPRO% |

|

earlier, certain specialised formations/units have been |

|

|

|

||||

|

|

|

|

|

|||

do eloped. An example of such development is the |

|

OFF |

OFF |

|

|

215Ornm |

|

.actuator power/control distribution board' for the |

|

|

|

|

|

||

|

|

|

|

|

|

||

ji N tribution of power and control supplies to actua- |

|

|

|

|

|

|

|

jars, e.g., valve and damper actuators. The basic intent |

|

|

|

|

|

|

|

al the arrangement is: |

|

|

|

|

|

|

|

• |

The provision from a single location of both power |

|

|

|

|

|

|

|

and control supplies. |

|

|

|

|

|

|

• |

The provision of alternative/standby power supply |

|

|

|

|

|

|

|

via changeover switches. |

|

|

|

|

|

|

• |

To facilitate the use of 'composite' cable, i.e., cable |

|

|

|

|

|

|

|

containing screened power cores, together with con- |

|

|

|

|

|

|

|

trol cores, within an overall sheath. |

|

|

|

|

|

|

The equipment of the switchboards — the busbar

• tem, contactors, fuse-switches, control switches, ca- Mimi facilities, etc. — is generally required to comply ith the design and performance requirements specified for the more traditional switchboards. Figure 5.57

depicts a typical arrangement.

A complementary development, but usable in its own right, is the 'actuator disconnection box'. This

comprises, in effect, a wall or steelwork mounted junc- tion box serving as the interface between the station

\ed' cabling and the flexible power and control leads I rom the actuator. The connection to the box is es-

tablished through plugs and sockets. The plug and

socket concept |

serves the dual role of providing for |

ready removal |

of the actuator and also 'at plant' |

electrical isolation — the latter being a mandatory

requirement within the CEGB. A padlocking facility is provided to prevent engagement of the plugs to en! oree a disconnected (isolated) condition. A typical actuator box is shown in Fig 5.58.

Power supplies for equipment primarily of a port- able nature, e.g., welding plant, bolt heating equip-

ment, portable pumps, etc., are provided by wall or

,,teelwork mounted socket outlets. The outlets are triple-pole and neutral, rated 16, 32, 63 or 125 A

at 41 .5 V. All ratings are switched, and feature short- circuit and earth leakage protection — the latter pri-

FIG. 5.57 Actuator power/control distribution board

— general arrangement

manly for the safety of personnel. The short-circuit protection is provided by fuselinks in the 16, 32 and 63 A units, and the earth leakage feature by residual current circuit-breaker (RCCB). Currently, a mouldedcase circuit-breaker provides the switching, short-circuit and earth leakage functions in the 125 A rating.

To prevent the making and breaking of load current on the plugs and sockets, a mechanical interlock is provided on all ratings whereby plant may be connected, i.e., a plug inserted or withdrawn, only when the outlet is switched off. A test facility is provided to enable the user to check the earth leakage protection. Figure 5.59 shows a typical unit.

7 Fuses

7.1 Introduction

With the possible exception of specialised control and instrumentation circuitry, for which the reader is referred to Volume F, the fuselinks used in the fusing

409

Switchgear and controlgear |

Chapter 5 |

|

|

470mm APPROX

FIG. 5.58 Actuator power/control local disconnection box

arrangements of main, i.e., power and auxiliary circuits, are of the cartridge type. The design of the modern cartridge fuselink, particularly for very high breaking capacities, is too complex a subject for discussion in detail here. However, the following may help towards the understanding of the philosophy of their use in power station applications in the UK.

7.2 Definitions

Fuse A device that, by the fusion of one or more of its specially designed and proportioned components,

opens the circuit in which it is inserted and breaks the current when this exceeds a given value for a sufficient time. The fuse comprises all the parts that form the complete device.

Cartridge fuselink A device comprising a fuse element, or several fuse elements connected in parallel, enclosed in a cartridge usually filled with an arcextinguishing medium and provided with terminals. The fuselink is the part of a fuse which requires replacing after the fuse has operated. Typical LV fuselinks at ratings up to 800 A to BS88:1975 are shown in Fig 5.60.

410

Fuses

Fiu. 5.59 415 V, 63 A socket outlet

Fuse element A part of a fuse designed to melt when

he fuse operates. |

|

Fuseiink contact |

A conducting part of a fuselink |

deigned for the |

purpose of connecting the fuselink |

into a circuit. The conducting parts are, essentially, the cartridge body and end caps together with any tttached fittings — lugs, tags, necessary to provide adequate terminal arrangement. As a general rule,

FIG. 5.60 Typical HBC fuse links to BSS: 1975

fuselinks for use in high prospective current circuits are provided with terminals designed for connection into equipment by screw/stud type fastenings.

Current-limiting fuse/ink A fuselink which, during and by its operation in a specified current range, li mits the current to a substantially lower value than the peak value of the prospective current (see cut-off current).

Prospective current of a circuit The current that would flow in a circuit if a protective device, e.g., fuse or circuit-breaker, situated therein were replaced by a link of negligible impedance.

Prospective breaking current The prospective current measured at a time corresponding to the instant of the initiation of the arc in a fuse during the breaking operation.

Rated breaking capacity The maximum prospective breaking current that a fuse is stated to be capable of breaking at a stated recovery voltage under specific conditions.

Cut-off current The maximum instantaneous value reached by the current during the breaking operation of a fuselink when the fuselink operates in such manner as to prevent the current from reaching the otherwise attainable value. In other words, cut-off occurs when the fuse operates, i.e., interrupts the circuit before sufficient time has elapsed for the current to reach the prospective value.

Cut-off characteristic A curve giving the cut-off current under stated conditions of operation. In the case of AC, the values of cut-off currents are the maximum values reached whatever the degree of asymmetry (of the current). In the case of DC, the values of the cut-off currents are the maximum values reached related to the time-constant as specified.

411

Switchgear and controlgear

Pre-arcing time The time between the commencement of a current large enough to cause the fuse element(s) to melt and the instant when an arc is initiated.

Arcing dine The interval of time between the instant of the initiation of the arc and the instant of final arc extinction.

The sum of the pre-arcing time and

A curve giving I 2 t values (pre-arcing 1 2 t and/or operating [ 2 0 as a function of prospective current under stated conditions of operation.

Virtual time The I 2 t value divided by the square of the prospective breaking current. The virtual times usually stated for fuselinks are pre-arcing time and operating time.

Time/current characteristic The curve giving the virtual time (e.g., pre-arcing time or operating time) as a function of the prospective breaking current under stated conditions of operation.

7.3 Required performance

Figure 5.61 illustrates 'cut-off', and Figs 5.62 and 5.63 'ti me/current' and c1 2 t let-through' characteristics of cartridge fuselinks to BS88:1975.

The current-limiting capability of HBC fuselinks is a particularly attractive feature in high fault level circuits, in that the circuit equipment need be designed to withstand only the thermal and mechanical stresses associated with the value attained by the current at cutoff. In the absence of a current-limiting performance, the whole circuit must be capable of withstanding the very much higher stresses which would otherwise be set up by the passage of the circuit prospective current. Thus, where it is possible and practicable to take advantage of the current-limiting performance of fuses, the circuit equipment may be of appreciably lighter construction, smaller physically and less costly than where the short-circuit protection must, of necessity, be provided by non-current-limiting means, e.g., circuit-breakers.

The role of fuses in the applications described in Sections 5 and 6 of this chapter is primarily the provision of short-circuit protection. Where in addition it is necessary to provide protection against more modest values of overcurrent — the protection of motor circuits against overload being a particular instance — the circuit switching device, e.g., the contactor, is designed and equipped to perform that function.

As a generality, fuselinks are 'general purpose' or tack-up', or a derivative known as a 'motor circuit

|

Chapter 5 |

VALUES GIVEN AP 1"Ly AT .115V |

|

65 650 ■vi VA L IUJ E S AR E ULI P |

EATER |

|

TO 1150: GGRREATER |

10 -

CUTOFF CURRENT PEAK. kA

1 0-

0.1

0 |

100 |

|

FIG. 5.61 Cut-off current characteristics

fuselink' which, as the name implies, is intended primarily for motor duty. Essentially, a motor circuit fuselink is a general purpose fuselink with a dual basis of rating; namely, a given current rating with respect to its ability to carry current continuously and a higher current rating with respect to its time/current characteristic. The concept permits exploitation of the ability of a fuselink of compact dimensions to withstand, for a limited duration, circuit overloads such as occur during motor starting — particularly where the drive is switched direct-on-line. By way of example, a fuselink to BS88: Part 1: 1975 rated 63M100 has a continuous current rating of 63 A — and hence a body of dimensions commensurate with that rating — but a time/current characteristic of a 100 A rated fuselink. Thus where, as is usually the case, the rating of the fuselinks required by a given drive is dictated by the magnitude and duration of the starting current, rather than by the steady state running value, a space saving becomes possible. The letter 'M' appearing between the two values of rating serves merely to confirm the motor circuit application.

Whilst it is important to note that a dual rated fuselink should not be run continuously at a current exceeding the lower value, e.g., 63 A in the case of a 63M100 rating, it is vital that the circuit in which it

412