- •The citole project

- •Warning: This page is horrifically graphically intensive (about 200 images at the moment). It will take a long time to load everything.

- •In Adam Davie's "Life of Alexander" from the 14th century, we read "At the feste was trumping,/ Piping and eke taborying,/ Sytolyng and eke harpyng."

- •I have a mini-lathe that I then used to turn the blocks to cut two pegs out of each one. Top here is the rough block, below is the block after being through the lathe.

- •I was happy with how it came out, and worked out the problems that I wanted to.

- •In the interim, working on the soundboard, since carving out the rosette takes a bit of time. This is the design for the rosette.

- •It will also have a carved pegbox with an animal head, only this time the animal will be a lion, based roughly on Celtic designs.

- •Vincenzo cipriani in Italy does another version of the cantiga style citole. See his website for more views of the instruments - very cute animal heads! No prices anywhere that I can find.

I was happy with how it came out, and worked out the problems that I wanted to.

CITOLE NUMBER THREE Yes, there is another one. This one has a couple of different features worth exploring. First it's going to have a scroll-like pegbox more like a violin, and will have a figurehead of a dog (specifically a greyhound) on it. Next it's going to have a full-sized fleur on the tail to which the tailpiece will be attached. So a couple of experiments to work out. This one is going to be made from cherrywood, like Citole Number Two, as that is much easier to carve, especially for the more intricate fleur and pegbox.

This

is the starting plan. It is a fairly close variant of the Queen Mary

Psalter citole above, only with a dog's head rather than a horse's.

The fitting will be made from walnut.

This

is the starting plan. It is a fairly close variant of the Queen Mary

Psalter citole above, only with a dog's head rather than a horse's.

The fitting will be made from walnut.

The

block has been roughed out with handsaws. I'm always amazed how fast

the saws go through the cherry vs. the hard maple.

The

block has been roughed out with handsaws. I'm always amazed how fast

the saws go through the cherry vs. the hard maple.

Block

has now been cleaned up a bit on the outside. The body has been

shaped, and the fleur has been shaped for the full thickness of the

body, though it will eventually be shaped narrower. The peg-block has

been left large until I work out the exact dimensions of the dog

head. I'm doing a model of the head in clay to work from (to have a

3-D model to carve from is much easier than trying to work from 2-D

drawings), so once that has been worked out, I'll carve down the

peghead to a more reasonable size. You can also see the start of the

guide lines for the drilling out of the body.

Block

has now been cleaned up a bit on the outside. The body has been

shaped, and the fleur has been shaped for the full thickness of the

body, though it will eventually be shaped narrower. The peg-block has

been left large until I work out the exact dimensions of the dog

head. I'm doing a model of the head in clay to work from (to have a

3-D model to carve from is much easier than trying to work from 2-D

drawings), so once that has been worked out, I'll carve down the

peghead to a more reasonable size. You can also see the start of the

guide lines for the drilling out of the body.

In the interim, working on the soundboard, since carving out the rosette takes a bit of time. This is the design for the rosette.

The

soundboard is the other half of the Carpathian white spruce (a master

grade piece, very nice, from LMII

that I got for Citole One. The guitar soundboard wood is sold in

pairs for joining to make a jumbo-sized guitar, but these little

instruments only require 1/2 the width, so one guitar soundboard

makes two citoles, or three rebecs, or two oval fiddles, etc. The

basic outline has been traced onto the board from the body block, and

the rosette has been lined up on it for cutting.

The

soundboard is the other half of the Carpathian white spruce (a master

grade piece, very nice, from LMII

that I got for Citole One. The guitar soundboard wood is sold in

pairs for joining to make a jumbo-sized guitar, but these little

instruments only require 1/2 the width, so one guitar soundboard

makes two citoles, or three rebecs, or two oval fiddles, etc. The

basic outline has been traced onto the board from the body block, and

the rosette has been lined up on it for cutting.

The

body block now has had all the holes drilled into the area that will

be the cavity. This particular piece of cherry was a bit harder than

the one used for Citole 2.

The

body block now has had all the holes drilled into the area that will

be the cavity. This particular piece of cherry was a bit harder than

the one used for Citole 2.

Starting

to hack out the body cavity, though its a little hard to tell from

this image exactly how much has been removed (about half at this

point). This particular block is a little "shaggier" in

grain than the previous block, which makes me nervous about the block

splitting as I'm working on it. But so far everything has gone well.

Starting

to hack out the body cavity, though its a little hard to tell from

this image exactly how much has been removed (about half at this

point). This particular block is a little "shaggier" in

grain than the previous block, which makes me nervous about the block

splitting as I'm working on it. But so far everything has gone well.

This

is the sculpted (in clay) model head for the greyhound pegbox,

showing side, top and front views. He ends up pretty small to fit

into the height of the wood for the block - about 2 1/2 inches from

nose to ears - but shouldn't be too difficult to work. This isn't an

exact version of the final appearance - mostly just a shape guide.

The eyes, nose and mouth will be cut more cleanly in the wood than

just scratched onto the surface as they are here for reference.

This

is the sculpted (in clay) model head for the greyhound pegbox,

showing side, top and front views. He ends up pretty small to fit

into the height of the wood for the block - about 2 1/2 inches from

nose to ears - but shouldn't be too difficult to work. This isn't an

exact version of the final appearance - mostly just a shape guide.

The eyes, nose and mouth will be cut more cleanly in the wood than

just scratched onto the surface as they are here for reference.

Having

the model for how large the head will end up, I was now able to cut

the sickle peg-head into rough shape. Overall body as it stands now.

I've finished the rough-out of the body cavity, though now the walls

need to be thinned to appropriate thickness (a somewhat careful

process, as the shaggy grain of this particular block of cherry is

prone is splitting - hmm, I notice I say that alot with this piece).

Having

the model for how large the head will end up, I was now able to cut

the sickle peg-head into rough shape. Overall body as it stands now.

I've finished the rough-out of the body cavity, though now the walls

need to be thinned to appropriate thickness (a somewhat careful

process, as the shaggy grain of this particular block of cherry is

prone is splitting - hmm, I notice I say that alot with this piece).

Side

view of the rough out of the sickle peghead, before even I rounded

off the neck. Getting into the space under the chin is going to be

annoying.

Side

view of the rough out of the sickle peghead, before even I rounded

off the neck. Getting into the space under the chin is going to be

annoying.

3/4

views of the peghead being carved. The first shows the block just

starting to be shaped, the ears cut out, and the chin thinned down.

The neck of the instrument (as opposed to the dog) has be rounded off

at this point, so you can see the wide corner of the pegbox. The

second image shows the final shaping of the head, but before the

eyes, nose, and mouth have been cut into the surface. The dog's neck

has been thinned considerably, and the nose is quite narrow, though

that is a little difficult to make out from this angle. The large

ears are folded back along the back of the head. The carving was

mostly done with the mini-chisels (brown handle above), whose marks

can still be seen under the chin a bit and on the front corner of the

pegbox as I was softening the sharp front corner. Next I have to

hollow out the channel in the pegbox. I have the impression it most

likely will have to be open to the bottom of the box, as threading

the strings under the dog's nose may prove too annoying.

3/4

views of the peghead being carved. The first shows the block just

starting to be shaped, the ears cut out, and the chin thinned down.

The neck of the instrument (as opposed to the dog) has be rounded off

at this point, so you can see the wide corner of the pegbox. The

second image shows the final shaping of the head, but before the

eyes, nose, and mouth have been cut into the surface. The dog's neck

has been thinned considerably, and the nose is quite narrow, though

that is a little difficult to make out from this angle. The large

ears are folded back along the back of the head. The carving was

mostly done with the mini-chisels (brown handle above), whose marks

can still be seen under the chin a bit and on the front corner of the

pegbox as I was softening the sharp front corner. Next I have to

hollow out the channel in the pegbox. I have the impression it most

likely will have to be open to the bottom of the box, as threading

the strings under the dog's nose may prove too annoying.

The

rest of the pegbox has been carved out now. The box has been hollowed

(done entirely with chisels) starting from the end of the nut down as

far under the dog's nose as was reasonably able to be reached. I

wanted to give the pegs as much clearance space as I could. The holes

for the pegs were initially drilled with the finger drills, and then

widened with a normal hand drill. Finally a peg reamer was used to

taper the holes to fit the pegs. The pegs themselves will be added

later. The peg diameters are slightly narrower than violin pegs, but

not by much. Overall the pegbox region is about the size of violin,

but a bit wider across, as the neck of the citole is significantly

wider than the violin neck. You can also see the prep for the final

carving of the dog features, as I mark out where the nose, eyes, and

mouth are going to be.

The

rest of the pegbox has been carved out now. The box has been hollowed

(done entirely with chisels) starting from the end of the nut down as

far under the dog's nose as was reasonably able to be reached. I

wanted to give the pegs as much clearance space as I could. The holes

for the pegs were initially drilled with the finger drills, and then

widened with a normal hand drill. Finally a peg reamer was used to

taper the holes to fit the pegs. The pegs themselves will be added

later. The peg diameters are slightly narrower than violin pegs, but

not by much. Overall the pegbox region is about the size of violin,

but a bit wider across, as the neck of the citole is significantly

wider than the violin neck. You can also see the prep for the final

carving of the dog features, as I mark out where the nose, eyes, and

mouth are going to be.

Side

view of the neck and peghead. The neck has now been thinned down to

its final thickness of about 1/2 inch at the nut. The fingerboard is

about 3/16 inch thick on top of that, which should be far more than

enough strength for the low tension gut strings that will be on the

instrument.

Side

view of the neck and peghead. The neck has now been thinned down to

its final thickness of about 1/2 inch at the nut. The fingerboard is

about 3/16 inch thick on top of that, which should be far more than

enough strength for the low tension gut strings that will be on the

instrument.

Starting

the carving of the trefoil tailpiece. The block is visible here, cut

down to about 1/2 of the thickness of the body. The three "circles"

of the tail will be each rounded off more into a ball, with the joint

to the body dramatically thinned, and around which the tail-gut will

wrap to support the tailpiece.

Starting

the carving of the trefoil tailpiece. The block is visible here, cut

down to about 1/2 of the thickness of the body. The three "circles"

of the tail will be each rounded off more into a ball, with the joint

to the body dramatically thinned, and around which the tail-gut will

wrap to support the tailpiece.

Starting

to round off the "balls" of the tailpiece. This is done

entirely with the chisels at first, to rough shape the balls into

form, though ultimately will be smoothed down with the files.

Starting

to round off the "balls" of the tailpiece. This is done

entirely with the chisels at first, to rough shape the balls into

form, though ultimately will be smoothed down with the files.

The

end trefoil has been finally shaped with the small chisels and the

medium files. These images are from top and underside behind, to give

an idea of the thickness of the endball.

The

end trefoil has been finally shaped with the small chisels and the

medium files. These images are from top and underside behind, to give

an idea of the thickness of the endball.

The

carving for the rosette. Many little holes are drilled in the opening

with the micro finger drills. The center block is cut out with an

exacto knife, and then the final shaping of the opening is done with

the micro diamond files. In the left image, you can see a couple of

the holes untouched, some of the inner circle with the drilled holes,

the cardinal four inner ones with the center area cut out, and the

outer three cardinals more or less finished. The rosette is about two

inches across. The second image shows the inner space fully complete.

The rightmost image shows the final rosette. The carpathian spruce

has a very large differential in hardness between its grains, so is a

little more difficult to work. But it is significantly stronger and

lighter than the sitka spruce.

The

carving for the rosette. Many little holes are drilled in the opening

with the micro finger drills. The center block is cut out with an

exacto knife, and then the final shaping of the opening is done with

the micro diamond files. In the left image, you can see a couple of

the holes untouched, some of the inner circle with the drilled holes,

the cardinal four inner ones with the center area cut out, and the

outer three cardinals more or less finished. The rosette is about two

inches across. The second image shows the inner space fully complete.

The rightmost image shows the final rosette. The carpathian spruce

has a very large differential in hardness between its grains, so is a

little more difficult to work. But it is significantly stronger and

lighter than the sitka spruce.

Back

to the main body cavity. The floor has been leveled and thinned down

to its final thickness. The walls have been thinned down until I

could flex them with one hand spanning the waist (the side walls are

about 1/8 inch thick plus or minus). The front wall connecting to the

neck has been left thicker to avoid the potential problem with citole

number two. In citole two, when I thinned down the front wall to the

same thickness as the others, I could actually flex the neck a bit.

It hasn't yet affected the action on the instrument, but I decided I

didn't want to take a chance with this one. Still, the whole block

weighs less than a pound at this point. The cherry is definitely much

lighter than the maple. A little sanding cleanup is necessary at the

edges where you can still see the chisel marks as I cleaned up the

floor around the newly thinned walls. I honestly have no idea what

the dark flecks are. They randomly appear in the wood as paper-thin

bits - they aren't knots. There is one knot in the body, a little off

center in the widest portion of the back area. You can just make it

out in the picture.

Back

to the main body cavity. The floor has been leveled and thinned down

to its final thickness. The walls have been thinned down until I

could flex them with one hand spanning the waist (the side walls are

about 1/8 inch thick plus or minus). The front wall connecting to the

neck has been left thicker to avoid the potential problem with citole

number two. In citole two, when I thinned down the front wall to the

same thickness as the others, I could actually flex the neck a bit.

It hasn't yet affected the action on the instrument, but I decided I

didn't want to take a chance with this one. Still, the whole block

weighs less than a pound at this point. The cherry is definitely much

lighter than the maple. A little sanding cleanup is necessary at the

edges where you can still see the chisel marks as I cleaned up the

floor around the newly thinned walls. I honestly have no idea what

the dark flecks are. They randomly appear in the wood as paper-thin

bits - they aren't knots. There is one knot in the body, a little off

center in the widest portion of the back area. You can just make it

out in the picture.

Time

now to start the actual assembly. This is the bracing bar that goes

underneath the widest portion of the soundboard, just off the

location of the bridge. It is made from red cedar, and is shaped like

an upside-down T in cross-section. First it must be glued to the

underside of the soundboard before the soundboard is attached to the

main body.

Time

now to start the actual assembly. This is the bracing bar that goes

underneath the widest portion of the soundboard, just off the

location of the bridge. It is made from red cedar, and is shaped like

an upside-down T in cross-section. First it must be glued to the

underside of the soundboard before the soundboard is attached to the

main body.

The

start of the fingerboard. It has been cut to shape and thinned down

to appropriate thickness. Once I get a clean measurement of the nut

to bridge position on the basic body (block and soundboard), I'll add

the frets to it.

The

start of the fingerboard. It has been cut to shape and thinned down

to appropriate thickness. Once I get a clean measurement of the nut

to bridge position on the basic body (block and soundboard), I'll add

the frets to it.

The

tailpiece, cut to shape and thinned down to final thickness. This one

is not like the rebec or fiddle tails in that it is perfectly flat,

not arched. The holes will be drilled once I have the body together

and can space everything cleanly.

The

tailpiece, cut to shape and thinned down to final thickness. This one

is not like the rebec or fiddle tails in that it is perfectly flat,

not arched. The holes will be drilled once I have the body together

and can space everything cleanly.

Starting

the actual assembly now. The first piece on is the brace for the

soundboard. Back to using my handweight method to attach this to the

soundboard. The attached piece is shown next.

Starting

the actual assembly now. The first piece on is the brace for the

soundboard. Back to using my handweight method to attach this to the

soundboard. The attached piece is shown next.

Attaching

the soundboard to the body. Again with the trusty handweights, this

was lined up very carefully and glued down. The next picture shows

the closed body as I'm fitting the fingerboard for trimming.

Attaching

the soundboard to the body. Again with the trusty handweights, this

was lined up very carefully and glued down. The next picture shows

the closed body as I'm fitting the fingerboard for trimming.

The

fingerboard is next. The frets are made by taking a thin sheet and

functionally turning it into a comb by cutting slots in it, and then

cutting off the teeth. The teeth then become the square frets. The

fret distances are determined by a fret calculator, such as this one

at the Manchester

Guitar Tech, though there are others. I used a 13 7/8

inch scale here. The slots are cut first with a fret saw, and then a

square file is used to broaden the cut into a V shape. The frets are

then laid into the slots and glued in place one at a time. Once all

the frets are placed and dry, the overhanging edges are trimmed off

using a coping saw, and the edges are beveled inward. In the previous

instrument I used constrasting wood for the frets, this time I

decided to keep it monochrome, as it were, and used the same wood

from which the fretboard was made.

The

fingerboard is next. The frets are made by taking a thin sheet and

functionally turning it into a comb by cutting slots in it, and then

cutting off the teeth. The teeth then become the square frets. The

fret distances are determined by a fret calculator, such as this one

at the Manchester

Guitar Tech, though there are others. I used a 13 7/8

inch scale here. The slots are cut first with a fret saw, and then a

square file is used to broaden the cut into a V shape. The frets are

then laid into the slots and glued in place one at a time. Once all

the frets are placed and dry, the overhanging edges are trimmed off

using a coping saw, and the edges are beveled inward. In the previous

instrument I used constrasting wood for the frets, this time I

decided to keep it monochrome, as it were, and used the same wood

from which the fretboard was made.

Last

bit of actual carving done on the dog's head to finish off the

features, and clean up the shape. This took several reference

pictures of greyhounds to get something akin to correct. And yes,

they really do have that line ridge all the way down their skulls.

Last

bit of actual carving done on the dog's head to finish off the

features, and clean up the shape. This took several reference

pictures of greyhounds to get something akin to correct. And yes,

they really do have that line ridge all the way down their skulls.

The

carving done, the fingerboard is attached to the body in the typical

hand-weight clamping method and let dry. Both the bottom of the

fingerboard and the neck of the instrument are given some skuffing so

that the glue has a place to hold, and so that it is less likely to

slide around as it is drying.

The

carving done, the fingerboard is attached to the body in the typical

hand-weight clamping method and let dry. Both the bottom of the

fingerboard and the neck of the instrument are given some skuffing so

that the glue has a place to hold, and so that it is less likely to

slide around as it is drying.

Once

the fingerboard is dry, the final sanding and shaping of the body is

done. This takes quite a while, and is probably the most tedious

portion of the whole instrument making process. I start off with the

carbide files, and work down to very fine sandpaper. This is about

halfway through the process here. Once in place, the frets are also

flattened using a fine grit long flat file to level them, and remove

any sharp edges that might cut into the gut strings. The micro files

are also used to straighten the edges a bit, and to remove any glue

that might have gotten onto the fingerboard proper.

Once

the fingerboard is dry, the final sanding and shaping of the body is

done. This takes quite a while, and is probably the most tedious

portion of the whole instrument making process. I start off with the

carbide files, and work down to very fine sandpaper. This is about

halfway through the process here. Once in place, the frets are also

flattened using a fine grit long flat file to level them, and remove

any sharp edges that might cut into the gut strings. The micro files

are also used to straighten the edges a bit, and to remove any glue

that might have gotten onto the fingerboard proper.

All

the sanding done, the finishing is added. In this case, I used a

rubbed oil finish. Three coats of linseed oil were applied and rubbed

and cleaned between each application. This brings out the rich color

of the wood (the cherry turned a very nice golden red color, which

probably explains its brittleness - the board already had aged some,

I think, before I acquired it). It is hung from its peg holes

inbetween coats in a well ventilated area. Linseed oil doesn't run

the risk of dust settling into the finish like varnishes or laquers,

but is EXTREMELY flamable, and requires very good venting to keep

from buring (rags saturated in oil have been known to spontaneously

combust as the oil vaporizes off of them) or simply getting way too

toxic.

All

the sanding done, the finishing is added. In this case, I used a

rubbed oil finish. Three coats of linseed oil were applied and rubbed

and cleaned between each application. This brings out the rich color

of the wood (the cherry turned a very nice golden red color, which

probably explains its brittleness - the board already had aged some,

I think, before I acquired it). It is hung from its peg holes

inbetween coats in a well ventilated area. Linseed oil doesn't run

the risk of dust settling into the finish like varnishes or laquers,

but is EXTREMELY flamable, and requires very good venting to keep

from buring (rags saturated in oil have been known to spontaneously

combust as the oil vaporizes off of them) or simply getting way too

toxic.

The

body is now done. Final reaming for the pegs is done to fit the pegs

very precisely. I used unmodified rosewood violin pegs on this one as

they matched the color of the fingerboard and other fitting almost

exactly. The bridge and nut are lowered and slotted for the strings,

and adjusted until the action is satisfactory.

The

body is now done. Final reaming for the pegs is done to fit the pegs

very precisely. I used unmodified rosewood violin pegs on this one as

they matched the color of the fingerboard and other fitting almost

exactly. The bridge and nut are lowered and slotted for the strings,

and adjusted until the action is satisfactory.

The

finished instrument, from top, 3/4 view, bottom and close-up of the

dog-head on the pegbox. Overall I'm satisfied with it, and the pegbox

was not nearly as annoying to do as I imagined it would be. It

presently is with its new owners!

The

finished instrument, from top, 3/4 view, bottom and close-up of the

dog-head on the pegbox. Overall I'm satisfied with it, and the pegbox

was not nearly as annoying to do as I imagined it would be. It

presently is with its new owners!

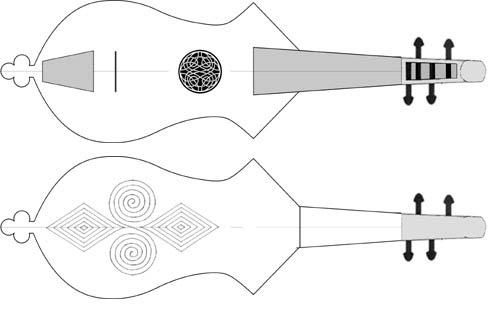

CITOLE NUMBER FOUR

This

one is a requested design, based more on the Cantiga style, using

older celtic geometric patterns as the carved decorations. The basic

layout design is below:

Showing

top and bottom view. This one will have a tail trefoil with loop much

like the dog-headed one above. . The idea here is to carve the

instrument out of maple (like citole one), but to have a Spanish

cedar soundboard. The back geometric design will be carved into the

body, and there will also be a carved geometric design down the sides

of the instrument, as in citole one. The top will have an edge

binding, and the intention at this point is to have an inset ivory

rosette, though I am presently having a hard time finding another

piece of ivory large enough.

Showing

top and bottom view. This one will have a tail trefoil with loop much

like the dog-headed one above. . The idea here is to carve the

instrument out of maple (like citole one), but to have a Spanish

cedar soundboard. The back geometric design will be carved into the

body, and there will also be a carved geometric design down the sides

of the instrument, as in citole one. The top will have an edge

binding, and the intention at this point is to have an inset ivory

rosette, though I am presently having a hard time finding another

piece of ivory large enough.