Chemical Tankers / Day 3 / Day 3 Topic 4 Wall-Wash & Analysis

.pdf

CHLORIDES:

A standard solution of varying amounts of chloride levels may be prepared from the standard chloride solution which should be included with the Methanol Test Kit. As chloride specifications vary from

0.3ppm to 8ppm for various charterers/suppliers, it will be necessary to gauge cleaning procedures with regard to various chloride levels.

more >>>

CHLORIDES:

The most effective method for reducing chlorides is to flush with copious amounts of chloride free water. The preferred source is ships produced water via the D.I. Filter if required as availability of chloride free water in large quantities is often expensive, restricted or impossible.

CHLORIDES:

Standard chloride solutions can be supplied with test kits to make a chloride standard tube for comparison. Add 1 ML of the chloride standard to the tube of 25 ML pure methanol and 75 ML of D.I. Water, this solution will the have turbidity equivalent to 1ppm of chlorides. To make a higher chloride standard, repeat the procedure and increase increase chloride solution e.g. 2ML Chloride Solution gives a 2ppm standard.

more >>>

CHLORIDES:

CHLORIDES:

CHLORIDES:

Standard chloride solutions can be supplied with test kits to make a chloride standard tube for comparison. Add 1 ML of the chloride standard to the tube of 25 ML pure methanol and 75 ML of D.I. Water, this solution will the have turbidity equivalent to 1ppm of chlorides. To make a higher chloride standard, repeat the procedure and increase increase chloride solution e.g. 2ML Chloride Solution gives a 2ppm standard.

Wall Wash Techniques and Sample Analysis

Permanganate Fade Time Test

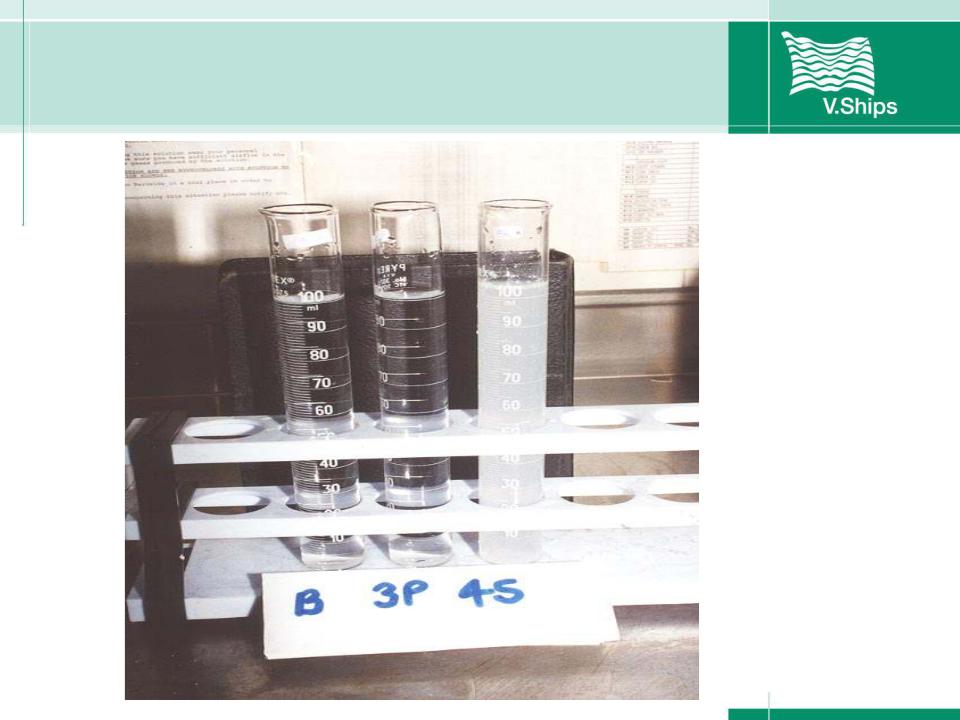

Permanganate Fade Time:

Of all the tests performed on board, this one is most subject to error due to it’s complexity. Basically permanganate solution will fade (change colour from deep purple to nearly clear) at a set rate if there are no impurities. When the solution is added to the wall wash sample, the rate of change of colour will increase if there are any impurities in the sample.

Permanganate Fade Time:

If a customer requires a permanganate fade time of say 50 minutes, then the “pinkish” colour of a pure solution after 50 minutes is known as the “end colour” and can be compared with the ships permanganate test samples after 50 minutes. If after 50 minutes the ships samples fade to clear, or a lighter colour, than the end colour then the sample has failed the test. “End Colour Tubes” are available from laboratories.

Permanganate Fade Time:

Ideally, Nessler test tubes will have been thoroughly cleaned with Hydrochloric acid (observe personal protection), rinsed 3 times with tap water, twice with D.I. Water and twice with methanol. 50 ML of wall wash sample is added to previously labeled test tubes. To this, add 2 ML of previously mixed permanganate solution. Use a thoroughly cleaned pipette or a dispensette (a bottle with a pump top, calibrated for 2 ML delivery). A sterile 2ML syringe can also be used.