- •Copyright Notice

- •Table of Contents

- •Chapter 1. Introduction

- •I. Basic Concepts

- •Examples:

- •Why Finite Element Method?

- •Applications of FEM in Engineering

- •Examples:

- •A Brief History of the FEM

- •FEM in Structural Analysis (The Procedure)

- •Example:

- •Available Commercial FEM Software Packages

- •Objectives of This FEM Course

- •II. Review of Matrix Algebra

- •Linear System of Algebraic Equations

- •Matrix Addition and Subtraction

- •Scalar Multiplication

- •Matrix Multiplication

- •Transpose of a Matrix

- •Symmetric Matrix

- •Unit (Identity) Matrix

- •Determinant of a Matrix

- •Singular Matrix

- •Matrix Inversion

- •Examples:

- •Solution Techniques for Linear Systems of Equations

- •Positive Definite Matrix

- •Differentiation and Integration of a Matrix

- •Types of Finite Elements

- •III. Spring Element

- •One Spring Element

- •Spring System

- •Checking the Results

- •Notes About the Spring Elements

- •Example 1.1

- •Chapter 2. Bar and Beam Elements

- •I. Linear Static Analysis

- •II. Bar Element

- •Stiffness Matrix --- Direct Method

- •Stiffness Matrix --- A Formal Approach

- •Example 2.1

- •Example 2.2

- •Distributed Load

- •Bar Elements in 2-D and 3-D Space

- •2-D Case

- •Transformation

- •Stiffness Matrix in the 2-D Space

- •Element Stress

- •Example 2.3

- •Example 2.4 (Multipoint Constraint)

- •3-D Case

- •III. Beam Element

- •Simple Plane Beam Element

- •Direct Method

- •Formal Approach

- •3-D Beam Element

- •Example 2.5

- •Equivalent Nodal Loads of Distributed Transverse Load

- •Example 2.6

- •Example 2.7

- •FE Analysis of Frame Structures

- •Example 2.8

- •Chapter 3. Two-Dimensional Problems

- •I. Review of the Basic Theory

- •Plane (2-D) Problems

- •Stress-Strain-Temperature (Constitutive) Relations

- •Strain and Displacement Relations

- •Equilibrium Equations

- •Exact Elasticity Solution

- •Example 3.1

- •II. Finite Elements for 2-D Problems

- •A General Formula for the Stiffness Matrix

- •Constant Strain Triangle (CST or T3)

- •Linear Strain Triangle (LST or T6)

- •Linear Quadrilateral Element (Q4)

- •Quadratic Quadrilateral Element (Q8)

- •Example 3.2

- •Transformation of Loads

- •Stress Calculation

- •I. Symmetry

- •Types of Symmetry:

- •Examples:

- •Applications of the symmetry properties:

- •Examples:

- •Cautions:

- •II. Substructures (Superelements)

- •Physical Meaning:

- •Mathematical Meaning:

- •Advantages of Using Substructures/Superelements:

- •Disadvantages:

- •III. Equation Solving

- •Direct Methods (Gauss Elimination):

- •Iterative Methods:

- •Gauss Elimination - Example:

- •Iterative Method - Example:

- •IV. Nature of Finite Element Solutions

- •Stiffening Effect:

- •V. Numerical Error

- •VI. Convergence of FE Solutions

- •Type of Refinements:

- •Examples:

- •VII. Adaptivity (h-, p-, and hp-Methods)

- •Error Indicators:

- •Examples:

- •Chapter 5. Plate and Shell Elements

- •Applications:

- •Forces and Moments Acting on the Plate:

- •Stresses:

- •Relations Between Forces and Stresses

- •Thin Plate Theory ( Kirchhoff Plate Theory)

- •Examples:

- •Under uniform load q

- •Thick Plate Theory (Mindlin Plate Theory)

- •II. Plate Elements

- •Kirchhoff Plate Elements:

- •Mindlin Plate Elements:

- •Discrete Kirchhoff Element:

- •Test Problem:

- •Mesh

- •III. Shells and Shell Elements

- •Example: A Cylindrical Container.

- •Shell Theory:

- •Shell Elements:

- •Curved shell elements:

- •Test Cases:

- •Chapter 6. Solid Elements for 3-D Problems

- •I. 3-D Elasticity Theory

- •Stress State:

- •Strains:

- •Stress-strain relation:

- •Displacement:

- •Strain-Displacement Relation:

- •Equilibrium Equations:

- •Stress Analysis:

- •II. Finite Element Formulation

- •Displacement Field:

- •Stiffness Matrix:

- •III. Typical 3-D Solid Elements

- •Tetrahedron:

- •Hexahedron (brick):

- •Penta:

- •Element Formulation:

- •Solids of Revolution (Axisymmetric Solids)

- •Axisymmetric Elements

- •Applications

- •Chapter 7. Structural Vibration and Dynamics

- •I. Basic Equations

- •A. Single DOF System

- •B. Multiple DOF System

- •Example

- •II. Free Vibration

- •III. Damping

- •IV. Modal Equations

- •V. Frequency Response Analysis

- •VI. Transient Response Analysis

- •B. Modal Method

- •Cautions in Dynamic Analysis

- •Examples

- •Chapter 8. Thermal Analysis

- •Further Reading

Lecture Notes: Introduction to Finite Element Method |

Chapter 2. Bar and Beam Elements |

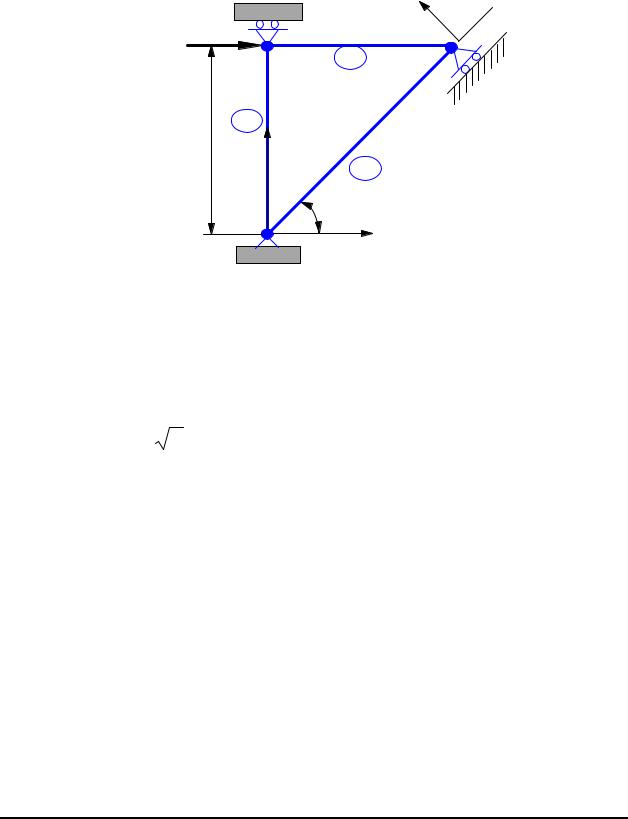

Example 2.4 (Multipoint Constraint)

y’

x’

x’

P |

|

3 |

|

2 |

2 |

L |

1 |

Y |

|

|

3 |

|

1 |

45o |

|

X |

|

|

|

For the plane truss shown above,

P = 1000 kN, L = 1m, E = 210GPa,

A = 6.0 ×10−4 m2 |

for elements 1 and 2, |

A = 6 2 ×10−4 m2 |

for element 3. |

Determine the displacements and reaction forces.

Solution:

We have an inclined roller at node 3, which needs special attention in the FE solution. We first assemble the global FE equation for the truss.

Element 1:

θ = 90o , l = 0, m = 1

© 1997-2002 Yijun Liu, University of Cincinnati |

47 |

Lecture Notes: Introduction to Finite Element Method |

Chapter 2. Bar and Beam Elements |

|

|

|

u1 |

|

|

|

0 |

k1 |

= |

(210 ×109 )(6.0 ×10−4 ) |

0 |

1 |

|

||

|

|

0 |

|

|

|

|

|

|

|

|

0 |

Element 2:

θ = 0o , l = 1, m = 0

|

|

|

u2 |

|

|

|

|

1 |

|

k2 |

= |

(210 ×109 )(6.0 ×10−4 ) |

|

0 |

1 |

|

|

||

|

|

−1 |

||

|

|

|

|

0 |

|

|

|

|

|

Element 3:

θ = 45o , l = 12 , m = 12

|

|

|

|

|

u1 |

|

|

|

|

|

0.5 |

k 3 = (210 ×10 |

9 |

|

|

−4 |

|

|

)(6 |

2 ×10 |

|

) 0.5 |

|

|

|

2 |

|

|

− 0.5 |

|

|

|

|

|

|

|

|

|

|

|

− 0.5 |

v1 |

u2 |

v2 |

|

|

0 |

0 |

0 |

|

|

1 |

0 |

−1 |

(N / m) |

|

0 |

0 |

0 |

|

|

|

|

|||

−1 |

0 |

1 |

|

|

|

|

|||

v2 |

u3 |

v3 |

|

0 |

−1 |

0 |

|

0 |

0 |

0 |

(N / m) |

0 |

1 |

|

|

0 |

|

||

0 |

0 |

|

|

0 |

|

v1 |

u3 |

v3 |

|

0.5 |

− 0.5 |

− 0.5 |

|

0.5 |

− 0.5 |

− 0.5 |

|

− 0.5 |

0.5 |

0.5 |

|

|

|||

− 0.5 |

0.5 |

0.5 |

|

|

|||

(N / m)

© 1997-2002 Yijun Liu, University of Cincinnati |

48 |

Lecture Notes: Introduction to Finite Element Method |

Chapter 2. Bar and Beam Elements |

The global FE equation is,

0.5 0.5 |

0 |

0 |

−0.5 |

||

|

15. |

0 |

−1 |

−0.5 |

|

|

|||||

|

1 |

0 |

−1 |

||

1260 ×105 |

|

||||

|

|

|

1 |

0 |

|

|

|

|

15. |

||

|

|

|

|

||

|

|

|

|

|

|

Sym. |

|

|

|

|

|

Load and boundary conditions (BC):

u1 = v1 = v2 = 0, and v3' = 0,

F2 X = P, F3x' = 0.

−0.5 u1 |

|

F1X |

|||

|

|

|

|

|

|

−0.5 v1 |

|

F1Y |

|||

0 |

u2 |

|

F2 X |

||

0 |

v |

2 |

|

= F |

|

|

|

|

2Y |

||

05. |

|

|

|

|

|

u3 |

|

F3 X |

|||

05. |

v3 |

|

F3Y |

||

From the transformation relation and the BC, we have

' |

|

2 |

2 |

u3 |

|

= |

2 |

(−u3 |

+ v3 ) = 0, |

v3 |

= − |

2 |

2 |

|

|

2 |

|||

|

|

v3 |

|

|

|

|

that is,

u3 −v3 = 0

This is a multipoint constraint (MPC).

Similarly, we have a relation for the force at node 3,

|

2 |

2 |

F3 X |

|

2 |

|

F3x' = |

2 |

2 |

F |

= |

2 |

(F3 X + F3Y ) = 0, |

|

|

|

3Y |

|

|

|

that is,

© 1997-2002 Yijun Liu, University of Cincinnati |

49 |

Lecture Notes: Introduction to Finite Element Method |

Chapter 2. Bar and Beam Elements |

F3 X + F3Y = 0

Applying the load and BC’s in the structure FE equation by ‘deleting’ 1st, 2nd and 4th rows and columns, we have

|

1 |

−1 0 u |

2 |

|

P |

|

|

1260 ×105 |

−1 |

15. |

|

|

|

|

|

0.5 u3 |

|

= F3 X |

|||||

|

0 |

0.5 |

0.5 v |

3 |

|

F |

|

|

|

|

|

|

3Y |

||

Further, from the MPC and the force relation at node 3, the equation becomes,

1 1260 ×105 −1

0

which is

1 1260 ×105 −1

0 The 3rd equation yields,

−1 |

0 u2 |

|

|

P |

|

|

15. |

|

|

|

|

F3 X |

|

0.5 u3 |

|

= |

|

|||

0.5 |

0.5 u |

3 |

|

− F |

|

|

|

|

|

|

3 X |

||

−1 |

|

|

|

|

P |

|

|

2 |

u2 |

|

= |

|

F |

|

|

|

|

|

|

|

|

3 X |

|

1 |

|

|

|

− F |

|

||

u3 |

|

||||||

|

|

|

|

|

|

3 X |

|

F3 X = −1260 ×105 u3

Substituting this into the 2nd equation and rearranging, we have

1260 ×105 |

1 |

−1 u |

2 |

|

P |

|||

−1 |

3 |

|

|

= |

0 |

|

||

|

u3 |

|

|

|||||

Solving this, we obtain the displacements,

© 1997-2002 Yijun Liu, University of Cincinnati |

50 |

Lecture Notes: Introduction to Finite Element Method Chapter 2. Bar and Beam Elements

u2 |

|

|

1 |

3P |

|

0.01191 |

|

||||

|

u |

|

|

= |

|

|

P |

|

= |

|

(m) |

|

2520 ×105 |

||||||||||

|

3 |

|

|

|

|

0.003968 |

|

||||

|

|

|

|

|

|

|

|||||

From the global FE equation, we can calculate the reaction forces,

F1XF1Y

F2Y

F3 X

F

3Y

|

0 |

−0.5 |

−0.5 |

|

−500 |

|

||||

|

|

0 |

−0.5 |

|

|

|

|

−500 |

|

|

|

|

−0.5 u2 |

|

|

|

|||||

= 1260 ×105 0 |

0 |

0 |

|

|

0.0 |

(kN) |

||||

|

u3 |

|

= |

|

||||||

|

|

|

15. |

05. |

|

|

|

|

|

|

|

−1 |

v3 |

|

−500 |

|

|||||

|

|

0 |

05. |

05. |

|

|

|

500 |

|

|

|

|

|

|

|

|

|

||||

Check the results!

A general multipoint constraint (MPC) can be described as,

∑Aj uj = 0

j

where Aj’s are constants and uj’s are nodal displacement components. In the FE software, such as MSC/NASTRAN, users only need to specify this relation to the software. The software will take care of the solution.

Penalty Approach for Handling BC’s and MPC’s

© 1997-2002 Yijun Liu, University of Cincinnati |

51 |