- •Contents

- •1 An introduction to Phast

- •What to Expect of this Tutorial

- •Starting the program running

- •The main window

- •Opening the Phast example file

- •The Study Tree pane

- •The Models tab section

- •Level 1: the Workspace

- •Level 2: the Study

- •Level 3: the Equipment item

- •Level 4: the Scenario

- •The Weather tab section

- •The Parameters tab section

- •The Materials tab section

- •Pure Components

- •Mixtures

- •Warehouse Materials

- •The Map tab section

- •Bund types

- •Terrain types

- •Building types and Buildings

- •Raster Image Set

- •Viewing input data

- •The input dialog for the Chlorine tank Equipment item

- •The Grid View allows you to work on input data for multiple items

- •Running the calculations and viewing the results

- •Viewing the graphs for the LPG sphere Scenarios

- •Viewing results on the GIS, against the background of map images

- •Viewing the Reports for the Catastrophic rupture Scenario

- •Summary group: Consequence Summary Report

- •Input group: Input Report

- •Equipment group: Discharge Report

- •Equipment group: Dispersion Report

- •Equipment group: Commentary Report

- •Equipment group: Averaging Times Report

- •Equipment group: Dynamic Fireball Report

- •Equipment group: Explosion Report

- •Viewing the results for other types of Scenario

- •The Standalone flammable Scenarios

- •The Standalone explosion Scenarios

- •2 Setting up your own analysis

- •The form of the analysis

- •The Equipment and Scenarios defined in the analysis

- •Creating a new workspace

- •Saving the workspace

- •The contents of a new workspace

- •Setting up the map image

- •Inserting the raster image

- •Ensure that there is a Raster Image Set in the Map tab section

- •Insert a Raster Image inside the Set

- •Placing the image in the GIS Input View

- •Setting the co-ordinates and size of the image

- •The location of the site on the map

- •3 Performing the consequence analysis

- •Making sure the Run mode is set to Consequence

- •Defining the pressure vessel that contains a toxic material

- •Turn on the option to insert Equipment on the GIS

- •Insert a Pressure Vessel Equipment item

- •Setting the input data for the vessel

- •The Material tab section

- •The Toxic parameters tab section

- •The Geometry tab section

- •A Summary of the Input Data

- •Defining a catastrophic rupture scenario

- •Inserting the Scenario

- •Setting the input data

- •Elevation in Scenario tab section

- •Toxic parameters tab section

- •Run the calculations for the Scenario and view the results

- •Viewing the set of Graphs

- •Viewing outdoor toxic lethality results against the map

- •Defining the second scenario: a liquid release from pipework

- •Insert a Time varying short pipe Scenario

- •Supplying the tank shape data for the Pressure Vessel

- •Setting the input data for the Scenario

- •Scenario tab section

- •Material tab section

- •Short pipe tab section

- •Time varying releases tab section

- •Running the discharge calculations

- •Using the averaged discharge results to create a User-defined source Scenario

- •Inserting a Short pipe Scenario and set up the equivalent input data

- •Run the consequence calculations for the Short pipe and view the results

- •Defining the third scenario: toxic vapour from pipework

- •Defining three flammable releases

- •Setting the input data for the propane Equipment item

- •Copying the Equipment item

- •Changing the Material selection

- •Changing the coordinates

- •Setting the input data for the fire modelling

- •Running the consequence calculations and viewing the results

- •Jet Fire Graphs

- •Pool Fire Graphs

- •Fireball Graphs

- •Explosion Graphs

- •Flash Fire Graph

- •Alternative methods for modelling explosions

- •Creating a Folder and Scenarios for the other methods

- •Setting the inputs for the TNT explosion method

- •Setting the inputs for the Multi-Energy explosion method

- •Setting the inputs for the Baker-Strehlow-Tang explosion method

- •Running the calculations and viewing the results

- •Flammable releases from a rail tank wagon

- •Defining a folder and creating the Equipment data node for the wagon

- •Setting the Elevation for the Rupture Scenarios

- •Defining the Leak from the liquid side of the wagon

- •Defining the Fireball Failure under Flame Impingement

- •Defining a Standalones Equipment item

- •Defining a Fireball Scenario

- •Running the calculations and viewing the results

- •Saving the workspace

- •What next?

Material tab section

The value that you set for Release height from vessel bottom is below the Tank liquid level that the program calculated when you completed the tank shape data. This means that the initial phase released will be liquid, so the Calculated phase to be released is given as Liquid (release below liquid level).

Short pipe tab section

The Short pipe tab section contains details for the modelling of frictional losses. Leave the pipe roughness with the default value taken from the Parameters, and leave the numbers of valves as zero. There is one bend in the 9 m of pipework, so you should set the Frequency of bends in pipe to 0.11 per m.

Time varying releases tab section

For a newly-inserted Time varying Scenario, the Method for calculating the average rate is set to Average between 2 times, with the times set to 0 s and 20 s.

Leave the tab section with these values. You will perform an initial run of the discharge calculations, then examine the results and decide on the most appropriate way to represent the behaviour for the rest of the consequence analysis, which may involve changing these settings.

This completes the input data for this stage, and you can click on OK to close the input dialog.

Running the discharge calculations

Before you run the calculations, use the Mode option in the Home tab of the Ribbon Bar to change the run mode from Consequence to Discharge. With this setting, the program will run the discharge calculations only, and will not then proceed to the dispersion and effects calculations.

Select the time-varying Scenario and then click on Run to perform the calculations. For some Scenarios the time-varying discharge calculations can be time-consuming, but for this Scenario they should run in about a minute.

When the results are complete, view the Graphs. The Flowrate Graph shows that the rate drops by about 1% in an hour of release, which means that the time-varying behaviour can be ignored for this release.

If the time-varying discharge calculations for a Scenario are time-consuming, you can make the analysis easier to work with if you bypass the time-varying discharge modelling for the hazardous event. There are two possibilities in this situation:

Using the averaged discharge results to create a User-defined source Scenario

Most of the Scenarios for a Pressure Vessel perform in-built discharge calculations to determine the state of the material after expansion to atmospheric pressure, which is the state required for the start of the dispersion calculations. However, the User-defined source Scenario is also available: this Scenario does not perform discharge calculations, but instead allows you to specify directly the state of the material after expansion to atmospheric pressure. You use it if you want greater control over the inputs to the dispersion and effect calculations, as will be described later in this chapter.

| PHAST | April 2018 | www.dnvgl.com/software |

Page 32 |

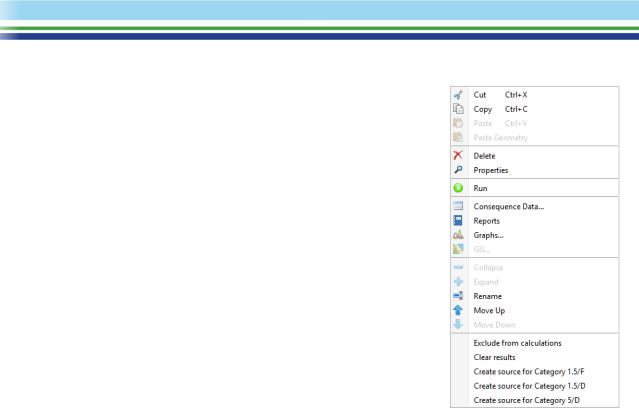

When you performed the discharge calculations, the program calculated the average rate over the first 20 s, and this is the representative rate given in the Discharge Report. If you decide that you want to use this average rate rather than the initial rate, you should right-click on the Scenario, and then select the first Create source option from the bottom of the right-click menu as shown.

There is a separate Create source option for each Weather for which you performed the discharge calculations. For this Scenario, the results will be the same for all Weathers, and when you select the Weather the program will create a User-defined source Scenario with the name User defined source for Category 1.5/F .

The dialog for the User-defined source Scenario does not include the Short pipe or Time varying release tab sections, and instead of containing fields for the pipe diameter and length, the Scenario tab section contains a Release segments table in which you specify the discharge rate and conditions directly, since the User-defined source Scenario does not perform any discharge modelling itself. The Scenario

will be created with discharge data taken from the averaged results from the Time varying Scenario, but you can edit these values if you choose.

Inserting a Short pipe Scenario and set up the equivalent input data

The Short pipe Scenario models the same type of hazardous event as the Time-varying short pipe release Scenario, but it calculates the initial discharge rate, without performing any time-varying discharge modelling. Inserting this Scenario involves repeating some of the data-input, but this is the approach taken in this tutorial as it will make the analysis clearer and easier to maintain: if you need to change some aspect of the input data you can edit the Scenario and rerun the calculations, whereas if you used a User-defined release Scenario you would have to edit and rerun the Time-varying Scenario first, then create a new User-defined release Scenario, and delete the previous User-defined release Scenario.

Before you insert the Short pipe Scenario, rename the Time varying Scenario to add “- time-varying not needed” at the end of the name, and then right-click on the Scenario and select Exclude from calculations from the menu. The Scenario will become greyed out in the tree and will not be included if you run the calculations for the Pressure Vessel or Study, which will make the calculations quicker.

| PHAST | April 2018 | www.dnvgl.com/software |

Page 33 |