reading / British practice / Vol D - 1990 (ocr) ELECTRICAL SYSTEM & EQUIPMENT

.pdf

System choice

SOURCE

GRID

Zg d

zst

FiG. 1.24 Impedance diagram for a station system

39.4 kA with an enhanced making capability of 121 kA first peak. These values equate to 750 MVA break and 900 MVA make, symmetrical, but will be tested to the current value. The combination of power sources which may be paralleled is limited by these ratings. The system must be examined for the proposed operating conditions and the fault contributions determined.

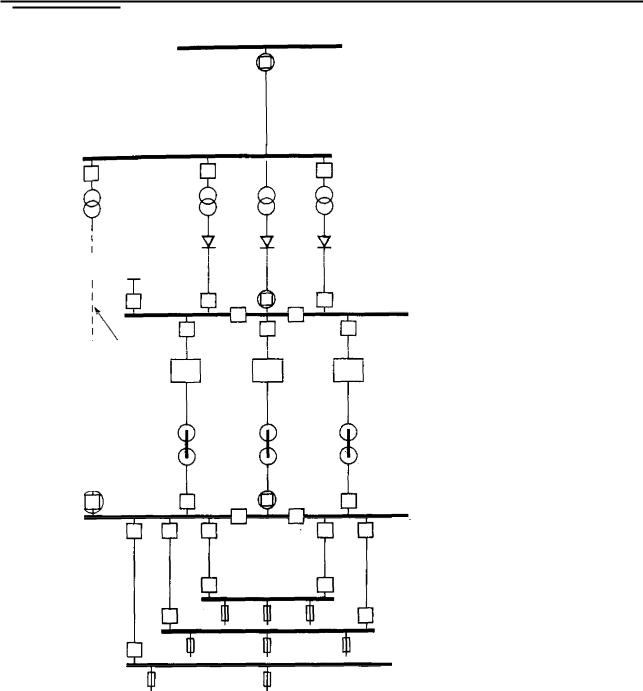

An example of one of the most onerous operating conditions is when the unit board is paralleled with the station board during start-up and shutdown. For this condition the infeeds from contributions (1.1) to (1.5) (inclusive) are summated and may be shown diagrammatically as in Fig 1.25.

UNIT

TRANSFORMER

a lower fault contribution. Therefore choosing 400 kV

w ill give the worst case.

Station transformer impedance (Zst) — assumed to be 18 070 on rating of 60 MVA:

18 |

WO |

x 0.9 (assuming 10°7o negative |

Zst — x |

60 |

|

100 |

tolerance) |

|

= 0.27 p.u. |

|

|

3 3kV

(UNIT)

Total impedance = 0.27 + 0.0029 p.u. =- 0.273 p.u.

3.3kV

(STN,

Fault contribution from station transformer |

|

||

100 |

— 366 MVA |

(1.4) |

|

|

|

||

0.273 |

|

|

|

contribution Assuming a station load of 5 MVA on the 3.3 kV system, starting MVA (assuming a starting MVA/MW rating ratio of 5.5) = 5 x 5.5 MVA = 27.5 MVA

Assuming a 12.5 MVA unit auxiliary transformer feed to the station auxiliaries load (at 123/4 on rating),

the 3.3 kV station auxiliaries motor fault contribution is:

|

100 |

|

MVA |

|

12 |

100 |

100 |

||

|

||||

|

x |

+ |

|

|

100 |

12.5 |

27.5 |

|

|

21.7 MVA |

(1.5) |

|||

The resultant fault level of the 11 kV board being considered is 388 MVA.

Fic. 1.25 Fault contributions from various sources in MVA

'Breaking' fault level = 367 + 366 MVA

=733

'Making' fault level = 733 + 137 + 25 + 22

=917 MVA

This 'make' fault level figure is in excess of the symmetrical fault level rating of 900 MVA. A significant contribution is made by the motor infeeds which are based on pessimistic values.

In reality the values used have not taken account of the initial decrement caused by the X/R ratios during the first half cycle which have a modifying effect by a factor of the order 0.9. Also, no allowance has been made for the additional impedance presented by the connecting cables. This again would justify a reduction by a factor of 0.95. Therefore the motor contribution value is more realistically:

(137 + 25 + 22) x 0.9 x 0.95 = 157 MVA

Calculation of fault infeed for various conditions |

The total 'make' fault level therefore becomes: |

|

The maximum symmetrical fault level rating of 11 kV |

||

|

||

switchgear approved for use on the CEGB system is |

(157 + 733) = 890 MVA |

43

Electrical system design |

Chapter 1 |

|

|

This value is very close to the maximum switchgear rating and would require corroboration by computer system studies as described previously.

When carrying out the initial hand calculations, if it is found that the fault levels are considerably greater than the capabilities of the system components, then a review of the influencing parameters should be carried out. Amongst these are the transformer impedances and tolerances applied. This may result in specifying closer impedance tolerances when purchasing the transformers.

Auxiliary generation

Auxiliary generation may be required, for example, to start up the station without external supplies, i.e., 'black start'.

In this case, the auxiliary generator is assumed to be connected to the station 11 kV board. The impedance diagram is therefore as shown in Fig 1.26.

SOURCE

GRID

Flo. 1.26 Impedance diagram for an auxiliary generator connected to the station board

Assume auxiliary generator (GT) having a rating of 30 MVA at 15 070 sub transient reactance:

ZGT |

1 00 |

= - X 0.15 p.u. |

|

|

30 |

|

= 0.5 p.u. |

Zgrid |

= 0.0029 (from previous) |

Zst |

= 0.27 (from previous) |

0.2729 x 0.5

Total impedance P.U. (0.2729 + 0.5)

= 0.176 p.u.

Fault contribution — |

100 |

MVA |

|

|

0.176 |

= 566 MVA

Therefore, there is no problem in paralleling the auxiliary generator with the grid when restoring the system to grid-fed station transformers.

5.5 Maintenance and safety

Safety of plant and personnel, which assumes prime i mportance in power stations, may be considered under two plant states, i.e., operational and maintenance. Section 8 of this chapter describes in more detail the methods adopted to achieve the objectives, but the considerations can be outlined as follows.

5.5.1 Operational

The main concerns under this mode of activity are:

•Avoiding damage to the plant. This can be caused by putting the plant into a state whereby continued operation or the response to a fault condition would cause permanent damage to the plant. An example of this would be the paralleling of two electrical supplies which would subject the switchgear to short-circuit conditions outside its rating, were it asked to clear a fault.

•Avoiding hazards to personnel. In the example quoted above, there is also a danger to personnel operating the plant and hence another fundamental reason for protecting against it.

Protection is primarily afforded by interlocking, generally referred to as operational interlocking, and is achieved by either an electrical relay scheme or a computer based scheme.

The choice is largely based on the complexity of the system being interlocked, as the electrical relay based scheme becomes extremely ponderous and difficult to design when there are a large number of possible operational configurations to consider.

5.5.2 Maintenance

The concern under this mode is essentially personnel safety. Plant damage is of course possible and must be considered, but less likely due to the plant being nonoperational during maintenance.

Essentially, the objective is to allow safe access for maintenance purposes to electrical equipment, which is normally alive. Access is controlled by a rigid set of safety rules specifically drawn up and controlled by the CEGB, under a formal 'Permit for Work' system. To ensure that access is denied until all electrical apparatus has been switched off, isolated and earthed,

44

System choice

it is normal to apply a coded key system designed for

each application.

5.5.3 Other safety interlocking

During normal operation it is imperative that all equipment which contains live metal must be designed such that access is denied at all times whilst the equipment is enei c;ised. Typical examples of this are switchgear cubicle where internal access is prevented when the isolator is ION', done by ensuring that the isolator interlocks with the door opening mechanism. Although these requirements are written in the equipment specification, there are several ways they may be achieved. The choice must be one of a balanced design while ensuring safety allows equipment operation without undue restriction.

5.5.4 Nuclear safety

Although the above requirements apply equally well to nuclear plant, the systems which have nuclear safety connotations will be designed with a higher integrity than their fossil equivalents. In many cases, however, this does not lead to the scheme being more complex, as the simplest and most cost effective way of achieving the operational and personnel safety requirements will often prove to be robust enough to withstand a higher analysis standard.

5.6 Quality assurance

Quality assurance (QA) may be considered in two parts, there being design quality and product quality.

5.6.1 Design quality

Quality assurance structure

The CEGB has always taken great care in the design of its power stations, with due regard for the specified requirement of a 30 year life from the plant. This is based on the cost of ensuring high reliability and availability, compared with the economic penalty of a high merit unit outage. More importantly, the design of nuclear plant has been given even more rigorous scrutiny in order to attain the high standards required to satisfy the Nuclear Installations Inspectorate (NII).

In order to improve further the quality of the design, the CEGB has adopted the requirements of BS5882 (Nuclear) and BS5750 (Conventional) to formalise its approach to quality assurance.

To manage the design process on the current nuclear projects (e.g., PWR), a set of auditable project procedures have been written to cover all the activities of the project team and any design/supply support required from outside the team. Each person involved in a particular activity will be issued with the relevant procedures relating to it and will be required to work

to them. Fossil fuel plant design will be covered in a similar manner, but to an appropriate and less rigorous standard.

The design process

The essence of controlling the design process is to ensure that:

•All specialist and interface departments have an opportunity to input to the design where their disciplines are involved.

•The design proceeds in accordance with the laid down design strategy.

•The design can be completed within the project programme.

•The design selected is economically justified.

•All aspects of the design process are documented and made available for the life of the station.

To achieve the above, it is necessary that for each topic a design strategy is in place, so that each designer has a common design base from which to proceed. At each stage of the design, the design statement, be it document or drawing, will need to be verified. This will be achieved by the 'verification process'.

Verification is achieved by initially circulating a 'plan' of who will be required to review the document or drawing. The plan will be created at an early stage and will be with the document or drawing throughout the whole life of the design. The document or drawing is circulated to each reviewer identified on the plan. Comments received from reviewers must be considered by the originator, who must agree with the reviewer how to resolve the comment. Each document or drawing will have a 'Fitness for Purpose' reviewer, who has the job of ensuring that the document or drawing fulfils the intended purpose and follows the laid down project strategy. Each document or drawing will have a record sheet indicating the reviewers involved who will sign the sheet after agreement is reached. In this way each stage of the design is reviewed, with any issues which are unresolved being identified clearly at each stage.

Periodically the QA of each section of the project will be audited to identify whether the procedure is being violated and point out any corrective measures necessary.

Independent design audits will be carried out at regular intervals to ensure that the design is proceeding at the required standard. Any corrective measures would be suggested at this point.

Coding and numbering

The development of modern computer databases has led to much more flexible data handling systems being available. The large number of items of plant, docu-

45

Electrical system design |

Chapter |

|

|

ments and drawings associated with modern power plant has led to a need for quick and accurate identification of plant and documents. A system is therefore required which will uniquely 'number' and also 'identify' the plant/documentation. Identification of plant items will use system based codes, with additional coding to identify function, location, separation group, etc.

Several numbering/coding systems are used both in Europe and the USA. The CEGB is developing a 'next generation' system which will employ the best features of the existing systems, with due regard to the power of the computer systems available.

5.6.2 Product quality

The quality of the manufactured product supplied by CEGB contractors for many years has been very high. This is ensured by constantly monitoring the performance of contractors, the use of an 'approved list of tenderers' and, where appropriate, developing designs and specifications jointly with prospective tenderers.

New products, if being considered, are assessed by the CEGB on a technical and commercial basis as are the manufacturers concerned. All vendor assessments of this nature are strictly confidential to the CEGB.

The quality of the product is largely dependent on the quality of the technical specification and the ability of the manufacturer to adhere to it. The CEGB operates a very comprehensive product inspection procedure during manufacture which ensures that the product quality is satisfactory.

The technical specification will call for all necessary routine and type testing of equipment to ensure that it meets the technical requirements. Standard technical clauses have been developed by the CEGB to ensure that the product quality is repeatable, whichever contractor is chosen for a particular piece of plant.

6 Uninterruptable power supply ( UPS) systems

6.1introduction

The UPS systems, formerly known as guaranteed instrument supplies (GIS) or no-break supplies, are designed to provide battery-backed AC supplies of better quality and continuity of service compared with the supplies available from the electrical auxiliary system. They are provided for essential instruments, controls and computers, which are associated with the safe and reliable operation of the plant under all normal and abnormal operating conditions. The following loads are usually supplied from the UPS systems:

•Those which are required for post-incident monitoring and recordings following a main unit trip and loss of station AC supplies.

•Those which because of stringent supply requirements would not give an adequate level of reliability if operated from the electrical auxiliary system only.

•Those which are required for the main unit shutdown. DC supplies are preferred for this purpose because they offer better reliability.

•Those which are essential for 'black start', i.e., in the absence of normal AC supplies.

6.2 Earlier UPS and GIS schemes

Before 1978 both battery-backed motor-generator sets and static inverters were used at various power stations to provide the UPS systems. Both types of system were generally unreliable and the various problems experienced can be summarised as follows.

6.2.1 Motor- generator (MG) set schemes

A typical motor-generator scheme is shown in Fig

1.27.The disadvantages which emerged in service were:

•Frequent maintenance required, e.g., shutdown and inspection every 3 months.

•Excessive brush wear.

•Parallel operation difficult at low loading.

•Unreliable frequency locking to the station master clock.

•Too many components used, resulting in high failure rates (MTBF of 2 years for a single MG set).

6.2.2 Static inverter schemes

Static inverters have been in use for over 17 years on large CEGB power stations for supplying power to instrumentation, controls, computers, alarms, etc.

The subsequent developments of schemes used before 1978 were based on the shortcomings which appeared during their operational years, namely:

•Too many components used, resulting in high failure rates (MTBF of 2 months for a single inverter).

•Ferro-resonance problems when switching transformers onto inverters.

•Load sharing difficulties as well as single inverter failure caused tripping of all inverters and a total loss of instrument supplies.

•Excessive component temperature rise leading to premature failures.

•Poor short-circuit capability.

Each of these early schemes, illustrated in Figs 1.28 to 1.32, is described briefly as follows with details of shortcomings:

46

Uninterruptable power supply (UPS) systems

BATTERY

STANDBY MAINS

SUPPLY

1

I (SEE NOTE) 1 /

CD NORMALLY OPEN

415V 3 PHASE STATION SERVICES BOARD

415V 3 PHASE UNIT BOARD

TRANSFORMERS

RECTIFIERS

BATTERY

11

110VDC

MOTOR STARTERS

MOTOR GENERATORS

110V AC SINGLE PHASE

SUB-BOARDS

OR RING MAINS

(NUMBER OFF DEPENDS

ON SITE LAYOUT)

ilJ

NOTE: CIRCUIT BREAKER CAN ONLY BE CLOSED IF THE THREE MG SET CIRCUIT-BREAKERS ARE OPEN

Fic. 1.27 Motor generator scheme — single line diagram of connections

(a) One inverter per 500 MW generating unit The |

ing solenoids, etc. |

load was normally supplied from the unit electrical |

(b) Two inverters per 500 MW generating unit One |

auxiliary system via a step-down 415 V/110 V |

inverter supplied the load with the other on 'cold' |

single-phase transformer shown in Fig 1.28. In the |

standby as shown in Fig 1.29. |

event of mains failure the load was transferred to |

The DC system was dedicated to the inverters. |

the inverter. The scheme did not prove reliable due |

In the event of mains failure the load was fed from |

to inverter failures. |

the inverter, which was supplied from the battery. |

The 240 V DC supply was derived from the |

If the inverter failed, the changeover contactors |

240 V DC station system used to supply emergency |

transferred the load to an alternative supply derived |

DC drives, emergency lighting, switchgear and clos- |

from the electrical auxiliary system. |

47

Electrical system design |

Chapter 1 |

|

|

TO UNIT 1

C & I SWITCHBOARD

FIG, 1.28 Static inverter scheme (one inverter per main unit)

The scheme proved reasonably reliable, but over-elaborate and consequently more expensive compared with present practice.

(c) |

Four inverters per 660 MW generating unit |

Three |

|

inverters operate normally in parallel and one on |

|

|

standby as shown in Fig 1.30. The scheme was |

|

|

designed such that two inverters could supply the |

|

|

total load. |

|

|

The DC system was dedicated to inverters and |

|

|

was on a per unit basis. |

|

|

The inverters proved very unreliable and the |

|

|

design did not achieve inverter redundancy, i.e., |

|

|

on failure of one inverter the other inverters could |

|

|

trip. The standby supplies derived from the elec- |

|

|

trical auxiliary system had to be used on many |

|

|

occasions due to tripping of all inverters. |

|

|

The equipment was eventually disconnected and |

|

|

a new development single UPS installed. |

|

(d) |

One inverter per 660 MW generating unit |

A DC |

|

system was dedicated to it as shown in Fig 1.31. |

|

In the event of inverter failure the load was transferred to an alternative supply using changeover contactors. The main disadvantages of this scheme were:

• Interruption of supply on transfer from the

inverter to the alternative supply and vice versa.

•On transfer from the alternative supply to the inverter large inrush currents occur on the load side. Low inrush transformers were subsequently fitted to avoid the problem, i.e., to prevent inverter ferro-resonance and trips.

•The scheme reliability was not adequate.

(e) One inverter per 500 MW generating unit A DC system was dedicated to it as shown in Fig 1.32.

The scheme offered considerably improved reliability compared with the previous scheme (Fig 1.31), because a static switch was provided to transfer the load without interruption on inverter failure; also on re-transfer from the alternative supply to the inverter.

A number of inverter trips occurred during grid disturbances. However, the present version of this type of equipment has given very little trouble.

6.3 Development of UPS systems

In order to overcome the previous service difficulties a 30 kVA, 415 V single-phase development static UPS system (Fig 1.28) was commissioned in May 1978 at

48

Uninterruptable power supply (UPS) systems

|

|

■■■=, |

. |

■•■■■••■■••■•■• |

FIG. 1.29 Static inverter scheme (two inverters per main unit)

Drax Power Station together with low inrush (S- li mes full load current) 8 kVA, 415/110 V distribution transformers.

The system has proved entirely satisfactory. Further identical UPS systems have been commissioned at Littlebrook D and Drax power stations and similar 3-phase and single-phase systems have been commissioned at Heysham 2.

For the Littlebrook D and Drax systems, the inverter alone is capable of clearing a short-circuit fault of a 415 V branch circuit protected by a 25 A fuselink to BS8802, Class Q1 , within 4-5 cycles.

The static switch is double-pole and is rated at 1000 A RMS for five cycles. With assistance from the bypass supply, the above fuselink can be operated in less than 5 ms when clearing a branch short-circuit.

The rotary maintenance bypass switch is solenoid bolt-interlocked to prevent out of synchronous transfer.

The complete equipment was type tested; the tests included vibration tests, dry heat, damp heat and low temperature tests, followed by a 200 hours long term stability test on full load.

The step-down transformers have the following basic parameters:

•I mpedance 2%.

•Flux density of approximately 0.75 T.

•Inrush current when energised from mains of approximately 100 A peak at 415 V, decaying to full load current in 10-12 cycles. The inrush current was obtained using a point-on-wave static switch.

A high performance lead-acid Plante battery is rated for 30 minutes' standby duty at 15 ° C ambient temperature.

6.3.1 Littiebrook D power station schemes

Unit GIS system

There are three 660 MW oil-fired units at this station. Each unit has an inverter system including a lead-acid battery, 415 V unit GIS switchboard and a distribution network as indicated on Fig 1.33. Only the unit loads

49

Electrical system design |

Chapter 1 |

|

|

415V 50Hz

STAND-BY

BATTERY CHARGER

415V 50Hz |

415V 50Hz |

STA NO-BY |

STAND-BY |

SUPPLY |

SUPPLY |

415V 50Hz

415V110V

FIG. 1.30 Static inverter scheme (four inverters per main unit)

are connected to this system. (In order to minimise discharging the battery, the charger is normally supplied from the essential/station system on more recent schemes.)

Each inverter system has the following main components:

•Charger.

•Battery (rated for a 30 min standby duty).

•Inverter.

•Static switch.

•Maintenance bypass switch as shown on Fig 1.34.

The charger supply is derived from the 415 V unit switchboard A. The inverter bypass supply is derived

from the 415 V unit switchboard B. Under normal operating conditions the power flow to the loads connected to the GIS switchboards is as follows:

•415 V unit switchboard A.

•Charger.

•Inverter.

•415 V unit GIS switchboard.

•Step-down transformer.

•Changeover contactor.

In the event of failure of the charger supply, the load continues to be supplied by the battery. If the supply to the charger is not restored within approximately

50

Uninterruptable power supply (UPS) systems

FIG. 1.31 Static inverter scheme with an electromechanical changeover switch

half an hour, the inverter system is arranged to transfer he load to the inverter bypass supply automatically and without interruption upon detection of the low battery voltage.

The load is also transferred automatically from the inverter to the bypass supply under any of the following conditions, providing the inverter is synchronised in both phase and frequency to the bypass supply:

•Inverter failure or output voltage outside the set tolerances.

•Excessive inverter overload or load inrush current.

•Short-circuit on the load side.

A break in the supply is expected when transfer is caused by a fault on any of the outgoing feeders. The GIS system is designed to minimise the break (less than 10 ms), except on the rare occasions when changeover contactors are used at the load centres.

Under normal operating conditions the inverter is synchronised in both phase and frequency to the bypass supply to enable an interruption-free transfer to take place.

|

|

415V 50Hz |

415V 50Hz |

REGULATING

TRANSFORMER

1 1 0 V 5 H

FIG, 1.32 Static inverter scheme with regulating transformer

Local distribution units are provided for each 110 V single-phase supply point, each comprising two singlephase main and standby transformers, changeover contactors, switches and distribution switchboard as indicated on Fig 1.35. These are located around the station, in the control block, etc., at suitable load centre positions.

Each 110 V AC GIS switchboard has an automatically connected standby supply arranged via changeover contactors.

Changeover contactor units comprise two adjacent circuits, arranged to give the highest practicable intercircuit segregation to permit work in safety on one circuit whilst the other remains live. The contactors are capable of picking up and sealing home with any incoming supply voltage between 75% and 110% of the rated value. The voltage limits apply over a frequency range between 47 Hz and 51 Hz. Breaks in supply of up to 10 milliseconds should not cause the contactors to drop-out.

The two contactors are interlocked to give either a 'main' supply or a 'standby' supply, i.e., avoid parallel operation of the two supplies. Transfer from the 'main' supply to the 'standby' supply is initiated and completed automatically for 'main' supply voltages below 80% of the setting value. An undervoltage relay is provided for each load centre for this purpose and its

51

Electrical system design |

Chapter 1 |

|

|

415V STATION BOARD

1 415V 50Hz

LOAD CENTRE

|

|

|

|

110V 50Hz |

|

|

110V 50Hz |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

FIG, 1,33 Littlebrook D power station — unit GIS

operating characteristics are such that the minimum operating time at zero voltage is not less than 10 ms. The voltage setting range is adjustable in seven equal steps between 40 07o and 80 07o of the nominal voltage.

On complete loss of the 'main' supply for longer than 10 milliseconds, the transfer to the 'standby' supply takes place such that the total voltage break time on the load side does not exceed 100 ms.

Transfer from the 'standby' back to the 'main' supply is manually initiated following the 'main' supply restoration. The initiation is from the 415 V unit GIS switchboard location and is made in stages to avoid excessive inverter overload, which may arise due to inrush current of the step-down transformers. The total voltage break time on the load side does not exceed 100 ms.

The standby supply is derived from the 415 V station switchboard. This supply is also used for those unit loads which require two AC inputs from diverse sources combining them within the equipment in DC form.

The 415 V bus section switch is intended to be closed

only if a prolonged outage of the incoming 415 V unit GIS is expected.

The system is designed to give acceptable security even during the inverter outage for repair, i.e., two diverse AC supplies are normally available. The computer system is not designed to tolerate 100 ms breaks, but it is not essential for unit operation. All other loads are either designed to tolerate a 100 ms break in supply or have duplicate AC inputs and power packs to achieve the high level of reliability required.

The GIS system is designed to achieve a reliability target of no more than one main generating unit trip in 30 years of operation.

Only one inverter system is provided on each unit GIS system, but in the event of inverter failure automatic transfer to another AC supply occurs, i.e., a standby redundancy is provided. The standby supply is not battery-backed.

The outage time for an inverter is small and it was not considered necessary to provide a second inverter to cover for the small outage times involved. These are based on pessimistic figures of the mean repair time

52