Ceramic Technology and Processing, King

.pdf

Ceramic Property Measurements 413

Figure 11.20: Viscosity/Shear Rate. The up curve is on the left and the down curve on the right of the diagram.

Spindle

Select a spindle with enough drag to put the measurements on midscale. As expected, large rotors have more drag than small ones. Typical configurations are shown in Figure 11.21. (Courtesy Brookfield)

Sample viscosity is instrumental in rotor selection. With experience, one can select the right rotor after one or two trials. Keep the rotor clean and handle it with gloves. Discard the rotor when it becomes dinged or bent since it will produce false readings. Rotors thread onto the shaft with a lefthanded thread; keep this in mind to avoid torquing it the wrong direction and damaging the innards of the instrument.

414 Ceramic Technology and Processing

Figure 11.21: Viscometer Rotors. The rotor is selected to place the measurements on scale. (Courtesy of Brookfield)

Rotors should be inserted into the slip at an angle to prevent entrainment of air bubbles. Then, thread them onto the shaft. Viscosity usually changes for a time as the rotor starts to revolve so it is a good idea to wait for the measurement to stabilize. This does not apply when using the spiral adapter for thixotropic measurements. In this case, avoid disturbing the slip at the slowest speed and watch the readings as they quickly maximize. Then turn to rotation off at once.

Figure 11.22 is of a spiral adapter attachment that can be used for pastes and for approximate thixotropic measurements.

Ceramic Property Measurements 415

Figure 11.22: Spiral Adaptor. Useful for thick pastes and can be used for thixotropic measurements. (Courtesy of Brookfield)

416 Ceramic Technology and Processing

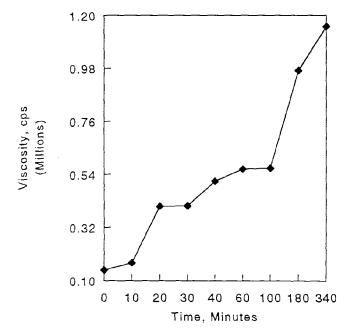

Figure 11.23 is of a thixotropic slip measured with the spiral adapter. A wet cloth covers the slip to prevent evaporation.

Figure 11.23: Thixotropic Data. There is a very large increase in viscosity over time.

The data jumps around somewhat but the thixotropic nature of the slip is clearly seen, with the viscosity rising from about 0.1 to 1.2 million cps over a period of 340 minutes. The helipath stand is even better for thixotropic data. This stand has a drive that slowly raises the rotor up through the mix, thereby supplying fresh slip with a minimum of disturbance. Run the test by taking a measurement and turning the drive off for an interval depending on the rate at which the slip develops thixotropy.

Ceramic Property Measurements 417

Stress Controlled Viscometers

In a stress-controlled viscometer, the rotor speed is set by the instrument based on the stress it senses. Usually, this instrument is used for fine-grained slips with a cone and plate sample holder. Plate and cone configurations require a very small sample of slip. This can be advantageous in some instances, such as when the slip or paste is comprised of precious metals. Figure 11.24 is of a stress-controlled viscometer.

Figure 11.24: Viscometer, Stress-controlled. Stress is set and the strain necessary to attain that stress is measured. (Courtesy of TA Instruments)

The instrument has accessories for controlling the temperature and an enclosure for inhibiting evaporation of the slip's liquid. Enclosures are

418 Ceramic Technology and Processing

especially important when the test interval is long or the liquid has a high vapor pressure. Of particular importance is the capability for measuring viscosity at very low strain rates. Data at low strain rates provides information on processes such as leveling, sag, and behavior at slow flow rates. This type of information cannot be extrapolated from higher strain rate data as the viscosity often departs from the extrapolation path.

Orifice Flow Viscometers

These are simple cylinders with a hole in the base. The test is run by filling the tube with slip, opening the hole, and measuring the time it takes for the stream to break. This number is valid when calibrated with standards, but no information is available at various strain rates. The Zahn viscometer is of this type and is useful for quality control when other equipment is not available. The device is inexpensive and thus is advantageous for the tightlybudgeted. Figure 11.25 is a sketch of this apparatus.

Figure 11.25: Zahn Cup Viscometer. Useful for QC in the plant.

Ceramic Property Measurements 419

Zeta Potential

Zeta potential is measured by the velocity of the ceramic particles in an electric field. This is often accomplished by direct observation, but becomes difficult if more than one phase is present. Given that a ceramist ordinarily works with only a few materials at a given time, it is easier to send the samples out for measurement. One inexpensive instrument has been around for a while but, unfortunately, does not work. Be sure that instruments are always demonstrated on your materials before purchasing.

pH

To use a pH meter, simply follow the instructions on the box. Keep the instrument calibrated, and keep the electrode clean and wet in the storage solution. Dried-out, dirty electrodes are the principle cause of instrument failure.

Check List, Slip Properties

• Strain Rate Controlled Viscometers Spindle type

Spindle speed Measure up and down

Measurement procedure Curve fit

Thixotropic: spiral adaptor, Helipath

•Stress Controlled Viscometers Plate and cone

Accessories: temperature control, evaporation control

•Orifice Flow Viscometers

Lacks strain rate data QC

Inexpensive

420 Ceramic Technology and Processing

• Zeta Potential

Usually better to farm work out

•pH: Care for Electrodes

4.0MICROSCOPY

This section discusses both optical and electron microscopes. Both microscopes have their particular limitations and advantages. While there are a wide variety of optical microscopes, those usually encountered in the ceramic lab are either stereo-binocular or petrographic/metallographic. Most likely, the microscope is a universal microscope, having both transmitted and reflected light capability. The various uses of microscopy include particle size measurement, dimensions, grain size, microstructure, morphology, phase identification, stress measurement, chemical composition (electron microscopes), and crystal type identification (TEM). TEMs have also been used successfully for defect structure analysis.

They are also used to examine surfaces of fired ceramics for cracks, chips, spots, interfaces and other properties.

Many of the attributes for study are too small to be observed without magnification. But microscopes do more than just magnify, as seen in the foregoing partial list of uses.

Optical Microscopes

This section describes two types of optical microscopes, stereobinocular and universal. Many other types exist for specialized uses, and there are many other instruments that use optical microscopes as part of their design. Because the stereo-binocular and universal microscopes are most common in the ceramics lab, the discussion will be limited to these.

Ceramic Property Measurements 421

Stereo-Binocular

These are commonly used to look at the surface of ceramics and other materials where the view is similar to that produced by a magnifying glass, but at magnifications up to about 40X. Illumination is oblique; the light source illuminates the surface without going through the optics. These common microscopes are quite useful. Flexible fiber illuminators with an intensity control are preferred. Photographic capability is also useful for specialized cases. Being stereo, there are two objective and two ocular lenses. This is a substantial advantage over single lens configurations as depth perception helps in visualizing the surface and, perhaps even more importantly, prevents eye strain. Ocular focus is adjustable by turning a sleeve on the lens. High eye point oculars allow the ceramist to wear glasses while using the microscope. Focus allows individual adjustment of the oculars to suite one's eyes.

To focus both eyes, first focus on the stage with one ocular, using the rack and pinion. Using the other ocular, turn the sleeve on the lens to where the same spot is in focus. Each individual must adjust the lens for his/her eyes.

It is unwise to purchase a microscope with sub-standard optics since its use will be limited.

A stand with an extended arm is useful for observing large objects. Ordinary stands are limited to about 100mm working distance, limiting the sample size that can be observed.

Zoom is available as standard equipment but is not essential. However, three choices of magnification are useful. When zoom is included, ensure that the sample stays in focus as the magnification is changed. If the focus changes, try another brand.

Figure 11.26 is of a stereo-binocular microscope.

422 Ceramic Technology and Processing

Figure 11.26: Stereobinocular Microscope. Very useful for looking at sample surfaces up to about 40X. (Courtesy of Fryer-Nikon)

Universal Microscopes

Universal microscopes are usually binocular and equipped for transmitted and vertical illumination, both of which can be polarized. Like the stereo binocular, oblique illumination can be used to moderate