N.L. NIKULSHINA, O.A. GLIVENKOVA,

T.V. MORDOVINA

LEARN TO WRITE SCIENTIFIC PAPERS IN ENGLISH

FSBEI HPE “TSTU Publishing House“

Министерство образования и науки Российской Федерации

Федеральное государственное бюджетное образовательное учреждение высшего профессионального образования

“ Тамбовский государственный технический университет“

Н.Л. Никульшина, О.А. Гливенкова, Т.В. Мордовина

УЧИСЬ ПИСАТЬ НАУЧНЫЕ СТАТЬИ

НА АНГЛИЙСКОМ ЯЗЫКЕ

Рекомендовано Ученым советом университета в качестве учебного пособия для аспирантов естественнонаучных и технических направлений

Тамбов Издательство ФГБОУ ВПО “ ТГТУ“

2012

1

УДК 802.0 (076)

ББК Ш13(Ан)я923

Н654

Р е ц е н з е н т ы:

Доктор педагогических наук, профессор ФГБОУ ВПО “ ТГУ им. Г.Р. Державина“

Р.П. Мильруд

Доктор педагогических наук, профессор ФГБОУ ВПО “ ТГТУ“

О.А. Артемьева

|

Никульшина, Н.Л. |

|

Н654 |

Учись писать |

научные статьи на английском языке |

|

[Электронный ресурс] : учебное пособие / Н.Л. Никульшина, |

|

|

О.А. Гливенкова, Т.В. Мордовина. – Тамбов : Изд-во ФГБОУ ВПО |

|

|

“ ТГТУ“, 2012. – 172 |

с. |

Пособие ориентировано на формирование навыков научного изложения на английском языке в соответствии с требованиями, предъявляемыми в международном научном сообществе. Содержит образцы научно-экспериментальных статей из зарубежных периодических изданий и разработанный на их основе комплекс заданий на анализ и синтез письменных речевых произведений с учетом стилистических, композиционных и лексико-грамматических особенностей научного текста.

Предназначено для обучения аспирантов естественнонаучных и технических направлений университетов написанию и оформлению научно-экспериментальных статей на английском языке. Может быть рекомендовано широкому кругу научных работников, самостоятельно изучающих английский язык.

УДК 802.0 (076)

ББК Ш13(Ан)я923

©Федеральное государственное бюджетное образовательное учреждение высшего профессионального образования

“ Тамбовский государственный технический университет“ ( ФГБОУ ВПО “ ТГТУ“), 2012

2

CONTENTS

ORGANIZATIONAL FORMAT OF AN EXPERIMENTAL |

|

RESEARCH PAPER …………………………………………………..... |

4 |

Chapter 1. PRELIMINARY SECTIONS OF AN |

|

EXPERIMENTAL RESEARCH PAPER ………………... |

23 |

Unit 1. Title ………………………………………………….. |

23 |

Unit 2. Abstract ……………………………………………… |

30 |

Chapter 2. MAJOR SECTIONS OF AN EXPERIMENTAL |

|

RESEARCH PAPER ………………………………………. |

45 |

Unit 3. Introduction ………………………………………….. |

45 |

Unit 4. Methods and Materials ………………………………. |

67 |

Unit 5. Results and Discussion ……………………………… |

94 |

Unit 6. Conclusion …………………………………………... |

129 |

Chapter 3. SUPPORTING SECTIONS OF AN EXPERIMENTAL |

|

RESEARCH PAPER ………………………………………. |

135 |

Unit 7. References …………………………………………… |

135 |

Chapter 4. USEFUL TIPS FROM SCIENTIFIC STYLE |

|

SPECIALISTS ……………………………………………... |

141 |

VOCABULARY …………………………………………………………. |

152 |

LIST OF JOURNAL ARTICLES USED ……………………………… |

155 |

LIST OF REFERENCES ……………………………………………….. |

160 |

APPENDICES …………………………………………………………… |

161 |

3

ORGANISATIONAL FORMAT

OF AN EXPERIMENTAL RESEARCH PAPER

“ Knowledge is no more important, than the way in which it is presented.”

M. Clyne

THE AIMS OF THIS UNIT

to make you think what an experimental research paper is;

to get you acquainted with basic format designed for research papers;

to help you learn the qualities of a good paper structure;

to practise in recognizing typical sections of a research paper.

STARTING POINT

An experimental research paper is a paper written by a scientist to present the objectives, methods, results, and conclusions of the study he/ she has performed. The paper is usually published in a professional scientific journal and often needs to be peer reviewed. It has much in common with other types of scientific writing, such as a monograph, a thesis or dissertation.

The term “experimental research” used here is refer red to any kind of study in which a scientist states a problem, moves a hypothesis as a possible way to solve the problem, collects, processes and interprets research data which will either support or reject the hypothesis.

A paper which describes experimental research differs from a review paper in one major way: it is not limited to the description of the state of knowledge in a given topic area; here the author is expected to create an entirely new work based on his own experimental findings, their interpretation and evaluation.

FOCUS ON STRUCTURING INFORMATION

The organizational format for all experimental research papers is generally the same, regardless of the field of study in which the scientist is working. Some of the research fields treated here are: Agricultural Water Management, Applied Thermal Engineering, Chemical Engineering, Civil Engineering, Ecological Engineering, Environmental Sciences, Mechanical Engineering, Nanotechnology, Powder Technology.

A typical experimental research paper contains the following sections in the order they are listed:

•Preliminary sections:

Title Abstract

4

Keywords

Nomenclature

•Major sections:

Introduction

Methods and Materials Results and Discussion Conclusion

•Supporting sections:

Acknowledgements References Appendices

TASK 0.1. Following is an experimental research paper published in a professional journal “Advanced Powder Technology” ( 2001, vol. 12, no. 2, pp. 255-260). The authors of the article describe a method which they have devised to evaluate the component uniformity of a powder mixture.

Scan the article and answer the questions:

1.What preliminary sections does the paper include?

2.How many major sections does the paper contain?

3.How are these sections headed?

4.Which heading is not standard?

5.Which of the sections are further subdivided? Why?

6.What do you think the subheadings contribute to?

7.Which of the sections contain figures?

8.Which section is the most detailed? Why?

9.What supplementary sections does the paper include?

10.Do you observe any deviations from the general organization format presented above?

A METHOD FOR EVALUATION OF THE COMPONENT UNIFORMITY OF A POWDER MIXTURE BY MICRO FOURIER TRANSFORM INFRARED SPECTROMETRY1

AKIRA T S U G E 1, K I Y O S H I N A K A N E 1, YOSHINORI UWAMINO1, HISASHI MORIKAWA1, TOSHIOI SHIZUKA2 AND MUTSUO SANDO1

1National Industrial Research Institute, 1-1 Hirate-cho, Kita-ku, Nagoya, 462-8510, Japan

2Faculty of Science University, Niigata 8050 Ikarashi 2-no-machi, Niigata-shi 950-2181, Japan

ABSTRACT—A method for evaluating the uniformity of a small volume of components of four kinds of zirconia and silica powder mixture in the range of 10~3 to 10^5 mm3 was investigated using micro-Fourier transform infrared

5

(micro-FTIR) reflectance spectrometry. Reflectance spectra (spot size 250 x 250 дт2) were taken from 10 different locations within a sample and the relative standard deviation (RSD) of the peak height ratio (1100 cm-1: assign to Si–O vibration/600 cm-1: assign to Zr-0 vibration) was calculated for each sample. If the RSD value was below the error that accompanied the measuring method (about 3%), the sample was regarded as uniform. The above operation was repeated with diminishing spot size (80 x 80 and 25 x 25 /tm2) for each sample, and the relationship between the RSD values and measuring volume, which was estimated from spot size, was obtained. The least volumes (regarded as uniform) were obtained for each sample.

Keywords: Fourier transform infrared; powder mixture; component uniformity.

1. INTRODUCTION

In industry, it is common practice that different component powders are mixed to produce a uniform component mixture. Uniformity of the mixture is usually evaluated as follows: a large number of samples is collected from different locations in the mixture and the ratio of components is measured by counting the particles or by chemical analysis. The uniformity is then calculated from the standard deviation of the ratios of each component and described as 'mixedeness', meaning the degree of the random arrangement of particles [1, 2].

Recently, in order to obtain more uniform mixtures, smaller particles of mixing powder are employed or the component mixed particle is synthesized from a liquid mixture such as an alkoxide mixture by the hydrolysis reaction. In order to evaluate the uniformity of these mixtures, the amount of collected sample must be very small. However, for common chemical analysis, more than several milligrams of material is required, so that the evaluation of uniformity in small domains is limited by using chemical analysis.

Local analysis methods are able to measure the concentration, or the concentration ratio, of components in small domains. These methods use light, electrons or ions as a probe, which is focussed on a small domain in the sample, and a signal is generated by the interaction between the probe and the components in the sample [3]. Therefore, the evaluation of uniformity of small domains in a mixture may be possible by using these methods.

In this report, micro-Fourier transform infrared (micro-FTIR) spectrometry was selected from the local analysis methods to evaluate the uniformity of the small domains in a mixture, because this method has several merits such as easy handling, rapid measurement, use under atmosphere and it is a nondestructive technique. It is shown that micro-FTIR is useful for evaluation of the uniformity of a small domain in a mixture. Furthermore, to describe the level of uniformity of the sample as a numerical value, the local analysis measurements were repeated with different spot sizes and the 'least volume (regarded as uniform)' was defined.

This 'least volume' means the minimum volume at which the component ratio in the collecting sample can be considered to be the same as that in the whole mixture.

6

2. EXPERIMENTAL

2.1. Sample

Three kinds of commercial silica powders (specific surface area: 200 m2/g, Hokkoukakgaku Ltd.; 79 m2/g, Yoneyamakagaku Ltd.; and 1.4 m2/g, Katayamakagaku Ltd.) were each mixed with 4 g of commercial zirconia powder (specific surface area 26 m2/g, Daiichikigenso Ltd.). These mixtures were named Ml, M2 and M3, respectively. The silica and zirconia powder were put into bottles (polystyrene, 50 ml) with three polymethylmethacrylate balls and vibrated for 30 min using a mixer mill (model 8000; Spex Ltd.). A silicon alkoxide and zirconium alkoxide mixture was hydrolyzed and heated at 600°C, and a silica and zirconia mixture (the component ratio nearly same to the above mixture) was obtained. This mixture was named Al.

2.2. Test apparatus and measuring condition

The apparatus used for the test was a micro-FTIR spectrometer (Janssen; Jasco Ltd.). About 20 mg of the sample was put into a 5 mm die and pressed at 19.6 MPa.

Infrared radiation, focused by a x l 6 Cassegrain mirror, was irradiated on to the sample surface, and the reflection was collected by the same mirror and detected by a mercury-cadmium-tellurium (MCT) semiconductor detector following passage through an aperture to limit the measuring spot size. An aluminum mirror was used for a reference sample. The measurement spot size was changed from 250 x 250, 80 x 80 and 25 x 25 ji m by changing the aperture size. Ten spectra were measured at different locations in the sample pellet for each spot size.

The chemical analysis of silicon and zirconium in the samples was measured by inductively coupled plasma (ICP) emission spectrometry (wavelength: Si I 251.611 nm and Zr II 343.823 nm, respectively, model ICAP 1000 s; Nihon Jurrel Assu Ltd.). The sample solution was prepared by decomposing 100 mg of the mixture with 5 ml of hydrochloric acid and hydrofluoric acid in a PTFE vessel for 3 h at 170 °С and diluting to 100 ml with distilled water. The concentration ratio between silica and zirconia was calculated from the concentration of Si and Zr in the solution.

3. RESULT AND DISCUSSION

3.1. Estimation of measuring volume

In this test, in order to evaluate the uniformity of the mixture in a small domain by many measurements of local analysis, the measuring volume of the measurement must be estimated. By ICP analysis, the 100 mg collecting mixture divided by 5 g/cm2 (specific gravity of mixture) gives about 20 mm3 volume, because the components in the collecting sample were homogenized by dissolving. By microFTIR analysis, the 250 x 250, 80 x 80 and 25 x 25 дт aperture size measuring volumes were estimated at 6 x 10"4, 6 x 10~5 and 6 x 10~6 mm3, because the influential thickness in infrared reflectance is estimated to be about 10 дт which is nearly half of the infrared wavelength.

7

3.2. Infrared spectra

One of the infrared reflectance spectra is showed in Fig. 1. Peaks were observed at 1100, 750, 600, and 500 cm-1. These peaks occurred by the changing of the refractive index of the sample with the infrared wavenumber range [4]. The change of the refractive index occurs due to the sample having infrared absorbability, which is called 'abnormal dispersion'. The peaks of reflectance are influenced not only by this absorbability, but also by the sample surface roughness, so that a quantitative comparison of the absorbability is difficult between the different spectra. However, the ratio between the peak heights in one spectrum indicates the ratio between infrared absorbability (i.e. concentration) of components in the sample [5]. Therefore, the dispersion of the ratio of peak height between the 1100 cm-1 (assign to Si-0 vibration) and 600 cm-1 (assign to Zr-O vibration) was used to evaluate for the uniformity of the mixture.

3.3. Evaluating for uniformity

Figure 2 shows the relationship between relative standard deviation (RSD) value and measuring volume.

The RSD value of the four kinds of mixtures by ICP analysis were less than 2%, which is less than the error associated with the measuring operation (sample preparation and measurement). Therefore, the four mixtures are considered uniform when the collecting size is over 20 mm3 (or 100 mg).

By micro-FTIR analysis using the 250 x 250 /xm measurement, a RSD value of more than 30%, was obtained for the M3 mixture, while the values of the other mixtures were less than 3%. To compare the common error of microFTIR, four RSD values of 10 peak height ratios between 750 cm-1 (assign to Zr-O vibration) and 600 cm-1 were calculated, and were less than 3%. Therefore, when the collecting volume is over 6 x 10~4 mm3, the M3 mixture is not uniform and the other mixtures are uniform. In the same way, when the collecting volume is over 6 x 10 5 mm3, the M2 and M3 are both considered not uniform, and Al is the only uniform mixture when the collecting volume is over 6 x 10~6 mm3.

The results show that the evaluation for uniformity of small domains in the mixture is possible by considering the relationship between the RSD value from a number of micro-FTIR measurements and the measuring volume.

30

Figure 1. Micro-FTIR reflectance spectrum of ZrCb / SiCb powder mixture

(spot size 250 x 250 дт).

8

Figure 2. Relationship |

|

|

80 |

|

|

between RSD value and |

|

|

|

|

|

|

measuring volume. |

|

|

|

|

|

|

|

|

Q 60 |

|

|

|

|

|

20 |

|

О |

1000 |

-1 |

|

500 |

lxlO41 1x10" lxlO"! 1x10° lxlO 2 |

1500 |

Wavenumber (cm |

|

) |

|

Measureing volume (mm3) |

3.4. Least volume regarded as uniform

From the above, the uniformity level, i.e. the degree of small volume, can be described by repeating the measurements with different measuring volumes. Then, a 'least volume (regarded as uniform)' can be defined as the smallest volume of material required for collection, such that the sample mixture can be assumed to be uniform. That is, when the volume of collected sample is equal to or greater than this value, the component ratio in the bulk sample is considered to be the same as that in the collected sample. The 'least volume' of the samples certified by this test are 6 x 10"6 mm3 for Al, 6 x 10" mm3 for Ml, 6 x 10"1 mm3 for M2 and 20 mm3 for M3, respectively.

3.5. Least volume and number of particles

The powder mixture cannot be uniform when the volume is as small as one particle. Therefore, the uniformity of a powder mixture is described as 'mixedeness', meaning the degree of the random arrangement of the particles. The mixedeness is a useful index for the evaluation of the capacity of the mixing instrument or of the mixing method. However, in order to evaluate for uniformity in very small domains, information of particle distribution of the powder is required with the mixedeness value.

For example, the particle size diameters of Ml, M2 and M3 (calculated from the specific surface areas) are about 0.02, 0.05 and 3 /xm, respectively. The number of silica particles in the calculated least volumes for these materials is in the range 108–109 particles and mixedness values (meaning the degree of random arrangement of particles) of the three mechanically mixed samples were nearly the same. The difference in least volumes is caused by the difference in the particle size of si/xca powder.

Since each particle in the Al mixture included two components, the mixedness value was not described. The least volume may be useful to describe the domain size regarded as uniform.

In industry, the practical domain size regarded as uniform is requested from the product size, etc. However, the practical domain size was not requested as the numerical value, because a difinite term describing the

9

domain size was absent. The mixing condition and the particle size of each single component powder were selected experimentally.

From this point of view, we believe that the 'least volume (regarded as uniform)' is a useful description.

4. CONCLUSIONS

Evaluation of the uniformity of the components of four kinds of zirconia and silica powder mixture (three kinds of mixture were mixed by mechanical procedures and one kind of mixture was mixed by chemical procedure) was attempted using microFTIR reflectance spectrometry, which is one of the local analysis methods. The following results were obtained:

(1)The evaluation of uniformity on small domains from 10~3 to 10~5 mm3 is possible by using micro-FTIR reflectance spectrometry,

(2)The uniformity level can described as 'least volume (regarded as uniform)'. When the amount of collected sample is greater than this volume, the component ratio in the whole mixture can be considered to be the same as that of the collected sample.

REFERENCES

1.K. Terashita, Funryutai kongougijutsu to souch, Bessatsu Kagakukougyou 33, 273 (1989).

2.T. Yamaguch, Kotaikongou ni tsuite, Bessatsu Kagakukougyou 32, 16

(1988).

3.Nihon-gakujutsu-shinkoukai (Ed.), in: Microbeam Analysis, p. 3. Asakurashoten (1985).

4.Nihonkakakukai (Ed.), Jikken-Kagaku-Kouza 6, 230 (1991).

5.Tsuge, K. Nakane, Y. Uwamino, T. Ishizuka and K. Watari, Determination of «-component in sintered silicon-ni tride by Micro FT-IR, in:

Preprint of 42th Congr. Soc. of Analytic Chemistry, Hiroshima, p. 599 (1993).

2. Structuring the content of a research paper, a scientist uses two types of headings: standard headings like Introduction, Methods and Materials, Results and Discussion, Conclusion and non-standard headings which contain title words. Standard headings simply indicate the location and function of a section. Non-standard headings are more meaningful: they help the reader navigate inside the paper and identify author’s scientific contribution. The structure has to expand to match the level of detail by offering more subheadings to help organise these details in a logical order.

TASK 0.2. Following is a complete research paper from the field of Materials Science. It is reproduced here as it appeared in a journal. However, the headings are omitted. Scan the paper and decide where each major section begins. Use standard headings to label each section except Section 2 which the author called EXPERIMENTS.

10

EFFECT OF ADDITIVES ON MELTING POINT AND VISCOSITY

OF RH REFINING SLAG2

Xiaoping Liang1, Yang Jin2 and Yu Wang1

1 College of Materials Science and Engineering, Chongqing University, Chongqing, 400044, China

2 Steelshop of Forging Factory of China National Erzhong Group Co., Deyang, 618013, China

Abstract: To get suitable ladle slag which can avoid slag sticking onto the RH immersion tube during RH refining process of IF steel, the effect of composition on melting point and viscosity of RH refining ladle slag was studied by different additives which is based on CaO. The results of melting point and viscosity testing experiments indicate that the melting point and viscosity of RH refining ladle slag would decrease effectively with the add of experimental additives. During RH refining process of IF steel, adjusting the basicity to 4~5, and the content of Al2O3 to 14%~15% by adding additives, it can avoid slag sticking onto the RH immersion tube efficiently, for the reason that the melting point of ladle slag is about 1280 °C, and the viscosity is only 0.65 Pa·s.

Keywords: RH immersion tube, slag buildup, viscosity, melting point, additives.

RH, acting as one of the most important secondary refining processes, has been paid considerable attention in the production of high quality clean steel. The refining slag produced in the steelmaking process may have the features of high oxidizability and crystallinity, one case in point is the RH refining slag of China Panzhihua Iron & Steel Co., which is a short slag with high melting point and strong oxidizing property because of containing much TiO2, V2O5 and FeO [1]. Its melting point is 1350-1400 °C, which may be 100 °C higher than common refining slag. What's more, the temperature interval from good fluidity to no fluidity is only 20-30 °C [2]. For this slag has high crystallinity, the high melting point phase maybe precipitate form molten slag during refining process. It might bond onto refractory of steelmaking device, which has many unfavorable impacts on refining operation [3]. The common solution is that altering chemical composition of ladle slag for adjusting physicochemical properties of ladle slag by additives [4 – 9]. When determining the viscosity of this kind of slag, it may have a lot of shortcomings by using the rotating cylinder method. Such as the slag may bond onto the refractory equipment and erode it in the laboratory, which may lead to the failure of experiment.

This article devises several kinds of additives mainly based on CaO aimed at the high crystallinity and strongly oxidizability refining slag sticking onto the RH immersion tube during RH refining process, and suitable method for viscosity determination is taken to this kind of slag. In order to get suitable ladle slag which can avoid slag sticking onto the RH immersion tube during RH refining process of IF steel, the effect of composition on melting point and viscosity of RH refining ladle slag was studied by different additives.

11

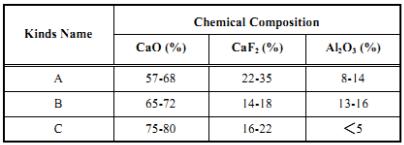

Composition of Additives and Slag

Three kinds of ladle slag additives were devised which is based on CaO, showing in Table 1. Composition of the slag shows in Table 2. Production practice showed that the No.1 slag, which is the basic slag, can easily stick onto the RH immersion tube during RH refining process. No.2- No.10 slag were obtained by adding different quantity of additives into the basic slag No.1 so as to study the effect of additives on the properties of RH refining slag. No.2, No.3 and No.4 slag added 10% of A, B and C respectively; No.5, No.6 and No.7 slag s added 20% of A, B and C respectively; No.8, No.9 and No.10 slag added 30% of A, B and C respectively. The basicity of slag showing below,

R=[CaO%+(56/78)CaF2%)]/SiO2% |

(1) |

where R is the basicity of slag in equation (1).

Table 1. Chemical Composition of Additives

Test Method of Slag Melting Point

The hemisphere point temperature, considered as melting point, was measured by RH-05 melting point detector.

Test Method of Slag Viscosity

Based on the characteristics of slag composition, the fluid length of refining slag was measured firstly, then the viscosity was obtained with the help of relationship between viscosity and fluidity.

Fig. (1) shows the testing device for slag fluid length. Firstly, furnace temperature was held in a fixed value. Secondly, the samples were put into the furnace for a few minutes. Finally, taking out the samples and measuring its fluid length. The experimental temperature was 1500 °C.

12

Fig. (1). Schematic of testing for slag fluid length.

Experimental Plans

Fixing Experiment Conditions

The influencing factors on fluid length are complicated, such as rake angle, samples quality, holding time and so on. For measurement purposes, it is appropriate that the fluid length of molten slag is 1/3 to 2/3 of porcelain boat length. Base on this request, the experiment conditions were fixed by many experiments.

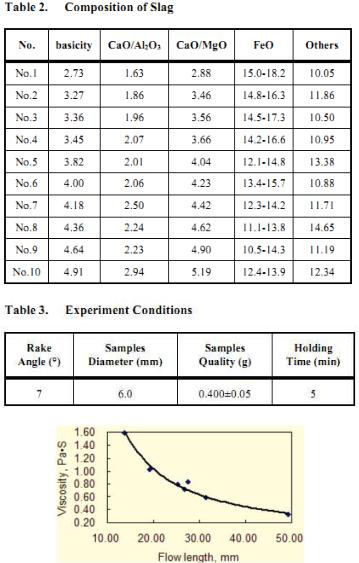

Relationship of Viscosity and Flown Length

Measuring fluid length of the slag whose viscosity was known and similar to the refining slag in above experiment conditions, then the relationship between fluid length and viscosity is built by regression analysis.

Viscosity and Melting Point Measurement of the Slag

Firstly, on the normal operation conditions, slag was taken from the ladle before the RH refining. The slag had been picked up from many different refining ladles. Following the additives with different contents of CaO and flux were proportionally added to the slag, followed by pre-melting the mixture for homogenizing. Finally, measuring the melting point and viscosity.

The effect slag composition on melting point and viscosity were studied with above experiments for reducing the slag buildup. The composition of additives were shown in Table 1. The slag was prepared by adding different additives to refining slag picked up in production field, and then measuring its melting point and viscosity.

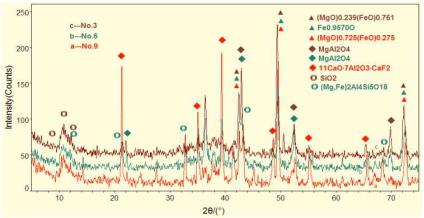

The XRD Analysis of Slag

First were the fragmentation of slag and preparation of powder test sample, then was the XRD analysis.

13

Relationship Between Viscosity and Flown Length

Table 3 shows the experiment conditions under the request of fluid length. Fig. (2) shows the relationship of viscosity and flown length under conditions in Table 2.

Fig. (2). The relationship of flow length and viscosity.

14

The relational expression built by regression analysis is |

|

η= 36.849 x L-1.1935 |

(2) |

where L is fluid length(mm), η is viscosity (Pa·s). The variance of equation (2) is 0.974, indicating that this equation can appropriately describe the relationship between fluid length and viscosity.

The Effect of Additives on Melting Point and Viscosity of Refining

Slag

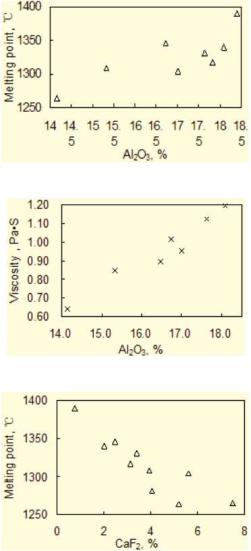

Fig. (3) shows the measured melting point of slag. Fig. (4) shows the viscosity of slag, which is calculated by the measured flow length L and equation (2).

Figs. (3, 4) show that No.1 slag has a higher melting point and viscosity. However, slag have a lower melting point and viscosity after adding additives, the more additives adding in the slag, the lower melting point and viscosity have. Especially for No. 8, No. 9 and No. 10 slag, their melting point are less than 1300 °C. Obviously it is very favorable for avoiding slag sticking onto the RH immersion by reducing the melting point and viscosity of the slag.

Fig. (3). Melting point of slag.

Fig. (4). Viscosity of slag.

15

Fig. (5). XRD pattern of No. 1 slag.

Fig. (6). XRD pattern of No. 2, No. 3 and No. 4, slag.

Figs. (5 – 7) show the XRD pattern of slag samples. Table 4 shows the analysis results of phase composition of slag. The melting point and viscosity of the slag have changed after adding additives because there is a direct relationship to the slag phase. Fig. (5) shows that MA exists in No. 1, which is a phase with high melting point. However, a large number of 11CaO·7Al2O3·CaF2 appear in No. 9-obtained by adding 30% additives B into No. 1, which is a phase with low melting point. Physical properties of slag changed with the adding of additives, that is why No. 1 has a higher melting point and viscosity than No. 9.

16

Fig. (7). XRD pattern of No. 3, No. 6 and No. 9 slag.

Fig. (6) shows that when the same amount of additives is added, the MA reduces and 12CaO·7Al2O3(or11CaO·7Al2 O3·CaF2), non-crystalline substance increase with the increase of CaO content.

Fig. (7) shows that when the same content of additives is added, the MA reduces with the increase of additives amount. MgO combines with FeO to form oxide solid solution, and Al2O3 forms 12CaO·7Al2O3 mainly. Especially, 12CaO·7Al2O3 or 11CaO·7Al2O3·CaF2 increases and the non-crystalline substance increase Significantly in the slag with the increase of slag basicity. As stated previously, the composition of RH slag can adjust by adding additives, then the precipitation phases of MA can be efficiently inhibited, so as to improve the physical properties related to the slag sticking. It can be concluded that No. 4, No. 7, No. 9 and No. 10 have a better property-changing.

The Effect of Basicity on Melting Point and Viscosity of Refining Slag

Fig. (8) shows the effect of basicity on melting point, and Fig. (9) shows the effect of basicity on viscosity at 1500 °C.

It can be found that, with slag basicity increasing, melting point and viscosity would decrease deeply. The main reason is that the activity of O2rises sharply with the contents of CaO increasing. This change is good for the dissolution of Al2O3, which can remarkably decrease the slag melting point and viscosity. Under the present condition, the slag basicity is about 2.7, its melting point is about 1400 °C and viscosity is about 1.10 Pa·s at 1500 °C respectively. However, the refining slag melting point and viscosity has a large decrease when adjusting the basicity to 4-5 by additives which is a benefit for reducing immersion tube buildup.

17

Fig. (8). Effect of basicity on slag melting point.

Fig. (9). Effect of basicity on slag viscosity.

The Effect of Al2O3 on Melting Point and Viscosity of Refining Slag

Fig. (10) shows the effect of Al2O3 on melting point, and Fig. (11) shows the effect of Al2O3 on viscosity at 1500°C. We can see from those two figures that, with the contents of Al2O3 increasing, slag melting point and viscosity would rise sharply. The primary reason is that, with the contents of Al2O3 increasing, the crystallizing rate of high melting point phase, such as CaO·Al2O3 and CaO·6Al2O3, would increase and may generate many multiple oxides. Therefore, the contents of Al2O3 should be appropriate for reducing amount of slag building-up. As can be seen from Figs. (10, 11), slag has proper melting and viscosity when the mass fraction of Al2O3 is 15%.

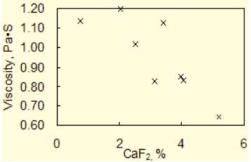

The Effect of CaF2 on Melting Point and Viscosity of Refining Slag

Fig. (12) shows the effect of CaF2 on melting point, and Fig. (13) shows the effect of CaF2 on viscosity at 1500 °C. It can be found from Figs. (12, 13) that, with slag basicity increasing, melting point and viscosity would decrease sharply. The reason is that CaF2 has a low melting point. Meanwhile, some low melting point eutectics would appear by the reaction of CaF2 and other oxides.

18

For example, one of these eutectics is CaF2·Al2O3, whose eutectic temperature

is about 1400 °C. The appearance of these low melting point eutectic can reduce the free high melting point phases, at the same time, F- can improve the slag fluidity by spuring the composite anion on to decomposing.

Fig. (10). Effect of Al2O3 on slag melting point.

Fig. (11). Effect of Al2O3 on slag viscosity.

Fig. (12). Effect of CaF2 on slag melting point.

19

Fig. (13). Effect of CaF2 on slag viscosity.

However, the mass fractions of CaF2 should be no more than 5%, for guaranteeing refining effectiveness, and considering manufacture cost and environmental protection.

(1) The melting point and viscosity of high oxidizability refining slag can be easily determinated. The relationship between viscosity η and fluid length L

is |

η= 36.849 x L-1.1935 |

(2)It is found that, within the composition range determined by the experiment, the added additives based on CaO can effectively reduce the melting point and viscosity of RH refining ladle slag, so as to improve slag sticking onto the RH immersion tube.

(3)For the problem of slag building-up onto RH immersion tube of Panzhihua Steel during RH refining process, the results of experiments indicate that, altering the basicity to 4-5, mass fractions of Al2O3 to 15% by additives

under present condition, the refining slag melting point is 1280 °C, and the viscosity is 0.65Pa·s at 1500 °C. The slag has a lower melting point and good fluidity which can reduce amount of slag building-up effectively.

[1]Li J. Adhesion and corrosion mechanism and improvement of material properties of Panzhihua Iron & Steel (Group) Co. Master thesis, Wuhan university, Wuhan, china; 2001.

[2]Bai CG. Study on some physical chemistry problems of blast furnace

slag-bearing titania. PhD dissertation, Chongqing university, Chongqing, China; 2003.

[3]Yao JF. Slag Buildup In Ladle And Countermeasures. Iron Steel 2002;

37:70 – 72.

[4]Wang HM, Li GR, Xu MX., Li B, Zhang XJ, Shi GM.. Effect of Additives on Viscosity of LATS Refining Ladle Slag. Chin J Process Eng 2006; 6: 227 – 230.

[5]Behera RC, Mohanty UK. Viscosity of Molten Al2O3–Cr2O3–CaO– CaF2 Slags at Various Al2O3/CaO Ratios. ISIJ Int 2001; 41: 834 – 843.

[6]Park JH, Min DJ, Song HS. The effect of CaF2 on the viscosities and structures of CaO-SiO2 (-MgO) -CaF2 slags. Metal Mater Trans B 2002; 33B: 723 – 728.

20

[7]Li GR. Effect of Strong Basic Oxide (Li2O, Na2O, K2O and BaO) on Property of CaO-Based Flux. J Iron Steel Resh Int 2003; 10: 6 – 9.

[8]Wang HM, Li GR, Ding ZT. Effect of Additives on Melting Point of LATS Refining Ladle Slag. J Iron Steel Res Int 2007; 14: 25 – 29.

[9]Huang H, Jin ST. Study on the Relationship between Viscosity and Fluidity of Mold Flux. Steel Making 2003; 19: 43 – 46.

Notes:

additive – добавка, присадка, примесь melting point – точка плавления

viscosity – вязкость, липкость, клейкость, тягучесть refining slag – рафинировочный шлак

immersion tube – труба с погруженным концом

FOCUS ON LANGUAGE USE

3. The requirements of a good structure are: 1) author’s scientific contribution should be located under the heading that has the largest number of subheadings; 2) title keywords should be repeated in headings and subheadings; 3) headings at the same indentation level or subheadings under the same heading should adopt a parallel syntax.

TASK 03. Following is the structure from the paper published in Advanced Powder Technology journal. Analyze the title and the structure and answer the questions below:

A NEW SPHERICALLY AGGLOMERATED DRUG COMPOSITE SYSTEM

WITH LACTOSE FOR DRY POWDER INHALATION3

1.INTRODUCTION

2.MATERIALS AND METHODS

2.1.Preparation of spherical agglomerates of KSR-592

2.2.Measurement of the particle size of agglomerates and primary

crystals

2.3.Observation of the morphology of the agglomerates

2.4.Preparation of DPI formulations with KSR-592 agglomerates for evaluation of inhalation properties

2.5.Evaluation of inhalation properties of DPI formulation of KSR-592

2.6.Measurement of the drug and lactose particle sizes in the formulation

3.RESULTS

3.1.Preparation of the agglomerate of KSR-592

3.2.Inhalation properties of the DPI formulation prepared with agglomerates of KSR-592

3.3.Effect of the particle size of lactose on inhalation properties

4.DISCUSSION

5.CONCLUSION

21

Notes:

agglomerated – агломерированный

drug – лекарственный препарат, медикамент inhalation – ингаляция, вдыхание

composite – композитный; композиционный; сложный, составной lactose – лактоза, молочный сахар

1.How many sections does the structure of the paper include?

2.Do any of the headings contain title words?

3.Which of the sections are further subdivided?

4.Which title words are repeated in the subheadings of a structure?

5.According to the number of subheadings, under which heading can contribution be found?

6.Is a structure consistent at the syntax level?

7.Are there any words from the title which are missing in the structure?

8.Do you find the structure quite informative and logical?

SELF-CHECK QUESTIONS

1.What is an experimental research paper?

2.What kinds of studies fall under the umbrella of experimental

research?

3.What does a research paper differ in from a review paper?

4.What does the organizational format for all experimental research papers include?

5.What two types of headings does a scientist use?

6.What is the purpose of standard headings?

7.What do non-standard headings contribute to?

8.Which section should be the most detailed?

9.What is the purpose of subheadings?

10.What are the requirements of a good paper structure?

22

Chapter 1

WRITING PRELIMINARY SECTIONS OF

AN EXPERIMENTAL RESEARCH PAPER

U n i t 1. TITLE

THE AIMS OF THE UNIT:

to make you think about the purpose of titles;

to inform on the structure of a title;

to present information on qualities of a good title;

to get you acquainted with techniques to improve titles;

to analyse language features of a title;

to provide practice in estimating the qualities of titles;

to practise in writing titles of your own.

STARTING POINT

A title of the paper is a brief statement of the problem being investigated. It contains the key words or concepts underlying the research.

The title helps the reader decide whether the paper satisfies his/ her scientific needs and is worth reading. Therefore, it should be clear, concise and representative of the contribution (a new method, mechanism, process, algorithm, etc.) the researcher has made.

With a catchy, unique title the author has more chances to interest the reader.

FOCUS ON STRUCTURING INFORMATION

1. The title is composed of two parts: contribution and background. Remember that contribution (what is new) comes at the beginning of the title.

Unlike a full sentence (containing a verb), where new information usually appears at the end (stress position) and old information at the beginning (topic position), in a verbless title new information (i.e. the contribution) appears at the beginning; and the known, less specific informat ion, at the end.

Compare the following two titles:

“Highly efficient waveguide grating couplers using silicon-on-insulator” and “Silicon-on-insulator for high-output waveguid e grating couplers”.

Are they both claiming the same thing? Apparently, they are not.

If the contribution of the author is the development of highly efficient waveguide grating couplers, then the first title is correct. If, however, the paper

23

is mostly about the use of silicon-on-insulator, then the first title should be changed into the second one.

Notes:

waveguide grating coupler – волноводный решёточный ответвитель silicon-on-insulalor – полупроводниковая структура (типа) "кремний

на диэлектрике", КНД-структура

high-output – мощный, высокопроизводительный

TASK 1.1. Following are the titles to the papers written in the field of Powder Technology. Read and translate the titles. Identify author’s contribution. Put the bar | separating the contribution from the context like in the example below:

E.g.: Numerical simulation of the velocity and stress fields | for a flowing powder using the smoothed particle method and experimental verification.1

1.In vitro inhalation behavior of spherically agglomerated steroid particles with carrier lactose.2

2.Energy monitoring in distinct element models of particle systems.3

3.Theoretical analysis of electrostatic forces between coated particles.4

4.Advanced measurement methods for particle size distribution by means of backward sampling.5

5.Evaluation of the inner structure of fiber-powder composite prepared by different granulation processes using a drilling tester.6

6.Effects of grinding condition on synthesis of forsterite.7

7.Rapid size classification of ultrafine particles using surface characteristics.8

Notes:

powder technology – порошковая технология numerical simulation – численное моделирование stress field – поле напряжений

particle size distribution – гранулометрический состав in vitro – в лабораторных условиях

carrier – переносчик, носитель sampling – взятие образцов drilling – бурение

grinding – измельчение, размол, размалывание forsterite – форстерит

FOCUS ON LANGUAGE USE

2. The translation of titles from Russian into English often results in abundant use of the preposition of. E.g.: методы измерения размера частиц (*techniques of measurement of the size of particles).

24

There are three ways to overcome this shortcoming:

1. Use of modified nouns. E.g.:

immobilization of enzymes vs. enzyme immobilization deposition of chemical vapour vs. chemical vapour deposition

techniques of measurement of the size of particles vs. particle size measuring techniques

2.Use of gerundive and infinitive verbal forms. Addition of verbal forms makes a title shorter and more dynamic. E.g.:

Assessing the potential of a fine powder to segregate using laser diffraction and sieve particle size measuring techniques9;

The method to determine the optimum refractive index parameter in the laser diffraction and scattering method.10

3.Replacement of the preposition of, where possible, by another, more specific preposition. E.g.:

Constructing an engineering model for moisture migration in bulk solids as a prelude to predicting moisture migration caking.11

Studies on potential applications of biomass for the separation of heavy metals from water and wastewater.12

TASK 1.2. Translate the following modified nouns into Russian. particle reflection coefficient

particle size analysis amplitude balance equation fluid flow equation

metal powder spray process surface modification method finite element design package risk assessment technique color correction matrix online keyword search reliability study algorithm instrument security factor

nonlinearity compensation techniques 3-phase power line disturbance analyzer

TASK 1.3. What do we call these things, people and processes? Use the structure noun + noun.

E.g.: an engineer specializing in hardware design is a hardware design engineer.

an increase in drilling rate is ……….. .

somebody whose job is to inspect safety is ……… . the process of describing environment is ……… .

25

method used in construction works to control quality is ……….

equipment used for gas processing purposes is ………. |

. |

algorithm developed for integration is …………….. |

|

technology used to produce molded powder is ………… |

|

simulation of climate with the help of a computer is … |

|

treatment by heat in vacuum is …………. |

|

detection of molecules on the surface is ……….. |

|

extraction by acid at room temperature is ………… |

|

cutting by means of oxygen using metal powder is … |

…. |

processing of data obtained as a result of search is …… |

|

TASK 1.4. Using noun + noun structures, translate the following

Russian word combinations into English.

алгоритм обработки данных анализ эффективности затрат

многокритериальный метод проектирования параллельный механизм управления моделирование шаровой мельницы файл описания объекта алгоритм распознавания неисправностей

технология массового производства коэффициент динамического усиления система оптического распознавания символов уравнение теплового баланса система регулирования давления план оптимального поиска плотность магнитного потока

TASK 1.5. In the word combinations below replace abstract nouns by gerund form. Remember that Gerund is not used with an article, has no plural form and cannot take an object with the preposition of.

E.g.: visualization of brain activity vs. visualizing brain activity

measurements of gas porosity estimation of biomass growth velocity

construction of electronic devices with atomic dimensions improvement of automotive efficiency

protection of the greenback

treatment of diabetes with transplanted cells evaluation of three-dimensional particle shape calculation of the production rate by fragmentation determination of the thermodynamic properties of P taxonomic method of presentation of language

26

TASK 1.6. In the word combinations below replace abstract nouns by Infinitive form:

a model of assessment of the validity of the proposed constructs an approach to the simulation of the nervous system

a systematic method of computation of the truth value of any statement models of description of the two-dimensional properties of solid surfaces technology of increasing labour efficiency

method of determining the optimum refractive index parameter

an integrated framework of evaluation of water allocation strategies new methods and models of improving understanding of processes

TASK 1.7. In the titles below replace the preposition of marked with * by another, more specific preposition:

experimental study *of predicting service life of concrete an algorithm *of deriving a transducer from a set of rules

development of rigorous techniques *of the description of language model *of emulating in real time

research *of herbs and their effects

technique *of studying attitudes towards school subjects strategies *of evaluating and improving scientific prose advanced system *of data analysis

technology *of producing metal-oxide-semiconductors theoretical and descriptive research *of such phenomena system of energy management

study *of changes in water situation

method *of the fine-pitch tooth profile optimization investigation *of the interaction of secondary current pulses novel strategies *of combatting the disease

3. Titles have to be clear to all, experts and non-experts. Therefore, avoid long (fiveor six-word) modified nouns. Their clarity is often inversely proportional to their length.

Phrases like “ adult sheep muscle protein iron” are difficult to understand. They should be broken up by inserting verbal forms and prepositions: “ protein iron found in the muscle tissue of adult sheep”.

TASK 1.8. Change long modified nouns below to make them clearer. Modify the order of words, insert verbal phrases and/or prepositions where necessary:

trading partners community virtual integration

kinetic analysis of electric stimulus responsive hydrogels silicone oil-gibbsite suspension properties study gas-solid fluidized bed porosity measurements

surface corona discharge-induced plasma chemical process

27

ultrasonic spray pyrolysis-synthesized lithium manganate microscopic surface bumps formation research

particle size distribution measurement method fibrous material powder mixture granulation

4. Readers find new articles through online keyword searches therefore the choice of effective keywords is very important for a title.

Keywords are divided into three categories: general, intermediate and specific. General keywords, like simulation, model, physical are used to describe the domain or the type of your paper. Intermediate keywords, such as fast Fourier transform, clustering, microarray are usually associated with methods common to several fields of research or to l arge subdomains. Specific keywords are such as plate-like gel particles, plasmid gene. It is these keywords that help readers to retrieve your articles.

A good title is the title which has keywords from more than one category. If the title is too specific, it will only be found by a handful of experts in your field; if the title is too general, it will not be f ound by experts.

Notes:

fast Fourier transform – быстрое преобразование Фурье clustering – создание кластеров (групп)

microarray – микромассив

plate-like gel particles – пластинчатые частицы геля plasmid gene – плазмидный ген

TASK 1.9. Following are the titles to the papers published in the areas of Ecological Engineering, Environmental Sciences, Chemical Engineering Science, Powder Technology, etc. Categorize the keywords which make them up: G (general), I (intermediate), S (specific).

Theoretical and experimental study of multi-compression particle breakage.13

Factors affecting the tensile strength of hot-gas filter cakes.14

Effect of light exposure and ultrasound on the formation of porous silicon.15

Experimental and numerical study on bar-reinforced concrete filled steel tubular columns under axial compression.16

Cutting geometry and base-cone parameters of manufacturing hypoid gears by generating-line method.17

Notes:

particle breakage – измельчение частиц tensile strength – прочность на растяжение filter cake – фильтровальная лепешка bar-reinforced concrete – железобетон

28

tubular column – трубчатая колонна axial compression – осевое сжатие

cutting geometry – геометрия движений при резании; hypoid gear – гипоидная передача; гипоидная шестерня

generating method – метод обката

TASK 1.10. On the basis of the titles below, can you define the type of journal papers: experimental research article (A), review article (B) or popular science article (C).

Chemical powder technology – a new insight into atomic processes on the surface of fine particles.18

AIDS and population “control”.19

Performance and exhaust emissions of a diesel engine fuelled with Croton megalocarpus (musine) methyl ester.20

The terror birds of South America.21 Electrostatics of particles.22

Application of magnetic particles modified with amino groups to adsorb copper ions in aqueous solution.23

Will robots inherit the earth?24

Studies on potential applications of biomass for the separation of heavy metals from water and wastewater.25

Notes:

exhaust emissions – выхлопные газы

musine – кротон крупноплодный (Croton megalocarpus) methyl ester – метиловый эфир

TASK 1.11. Look through a professional journal in your field of study. Analyze the titles to the published papers in terms of conventions described before.

PRACTICE IN WRITING YOUR PAPER

TASK 1.12. Following the rules you have learned in this unit, formulate a title to your own experimental research paper.

To make your title effective:

−place contribution upfront in a title;

−use keywords of different categories,

−make use of verbal forms to add energy;

−use adjectives and numbers to describe the strong aspect of a contribution;

−avoid long modified nouns leading to uncertainty.

29