- •Rig types & components rig processes

- •June, 2002 Contents

- •Drilling programme

- •Casing and cementing programme

- •Bits and Hydraulics programme

- •Mud programme

- •Drilling procedures programme

- •Figure 02

- •Semi-submersibles

- •Figure 03

- •Drill ships

- •D. Platform rigs

- •The drilling types

- •Rotary drilling:

- •Cable tool drilling:

- •Land rig components

- •1. Mast or Derrick

- •Figure 07

- •2. Substructure

- •Figure 08

- •1 0. Tongs

- •11. Prime Movers (Engines )

- •12. Transmission

- •13. Draw Works

- •Figure 12

- •Figure 13

- •14. Drilling Line

- •15. Rotary Table

- •Figure 14

- •19. Top drive

- •20. Heave (Motion) Compensation

- •Drill string Compensator:

- •Riser and Guideline Tensioners

- •Figure 18

- •21. Drill String

- •Figure 19

- •Figure 20

- •Figure 21

- •I) Hole Openers

- •Figure 22

- •22. Casing head

- •23. Mud pumps (Slush Pumps)

- •24. Kelly Line-Rotary Hose (Mud Hose)

- •25. Shale Shaker

- •26. Desanders and Desilters

- •27. Degassers

- •28. Mud Pits

- •29. Bop’s (Blow-Out Preventers)

- •Figure 25

- •Figure 26

- •Rig personnel

- •List of Common Drilling Terms

- •3.The drilling mud

- •Composition and nature of drilling muds

- •Types of mud

- •Mud Properties Termenology

- •De nsity

- •Gel strength:

- •Filtration

- •Alkalinity

- •Chloride Content

- •Installing Christmas Tree

- •Directional Drilling

- •Drilling to total depth (td)

- •Conventional coring:

- •Sidewall coring

- •Tripping

- •Figure 27

- •Stuck pipe

- •1. Differential sticking

- •2. Mechanical sticking

- •Fishing

- •Wireline logging (electric) logging

- •Cement Figure 30

- •(Figure 31)

- •Completing the well & Setting Production Casing

- •Perforating production casing

- •Drill Stem Test (dst)

- •Acidizing

- •Fracturing

- •Installing the Christmas Tree

- •5.Mud Logging Definition

- •Types of mud logging units

- •Duties & responsibilities

- •I) mud logging unit captain

- •6.The mud logging theory & lag

- •Answers

- •Trip-out monitoring procedures

- •7.Sample collection and description

- •Preparation for collection of cutting sample

- •Shaker Samples

- •Sample Descriptions

- •Rock Types

- •Describing and logging oil shows

- •Acetone Test

- •Heat Test

- •Hot Water Test

- •Acid Test

- •Some Criteria & Procedures For Rock & Mineral Identification Testing Methods:

- •General remarks on sample escription

- •Contamination of cuttings

- •8.Gas system

- •Gas Curve

- •Types of recorded gases

- •1) Cuttings gas (formation gas)

- •2) Background gas

- •3) Trip gas

- •4) Connection gas

- •4) Circulation gas

- •Gas detection and analysis monitoring equipment

- •Gas trap assembly

- •Fid gas detector

- •Fid gas chromatograph

- •9.Sensors

- •Sensors specifications

- •1.Hook load sensor

- •2.Torque sensors Electric torque type:

- •Mechanical torque type:

- •3.Standpipe and choke pressure sensors

- •1. Strain gauge type:

- •2. Current loop type:

- •7.Analog rotary speed sensor

- •8.Pit volume sensors

- •9.Flow out sensors

- •10.Mud temperature sensors

- •11 .Mud density sensor

- •12. Mud conductivity sensor

- •13. Depth sensor

- •14. Pump stroke sensor

- •15. Digital rotary speed sensor

- •16.Gas trap assembly

- •17. Hydrogen sulphide gas detector - h2s

- •Basic Mud Logging

Figure 14

Figure 15

16. Kelly

This is the topmost joint in the drill string and is 40-45 feet in length. It is commonly square or hexagonal. The kelly passes through the rotary table and transmits the table rotation to the drill string via the kelly bushing. (Figure 15)

17. Kelly Bushing

This engages with master bushing either by having a square lower section or by four pins fitted into holes around the central opening. This transmits the rotations to the kelly. (Figure 15)

18. Master Bushings

Through the master bushings, the rotary table transmits rotary motion to the kelly drive bushings and the kelly. They are also the connecting link between the rotary table and the slips which support the pipe during trips.

18. Swivel

Figure 16

The swivel supports the drill string and allows rotation at the same time. It also allows the passage of drilling fluid from the rotary hose into the drill string. The swivel performs a very tough job supporting a load that can be measured in hundreds of tons. This string could also be rotating at 200 or more revolutions per minute. Abrasive drilling fluids are often pumped through it at the rate of perhaps a thousand gallons a minute at a pressures that can exceed 3,000 psi.

The swivel is hung from the hook by the swivel bail and is connected to the rotary hose by the goose neck. Inside the housing just below the goose neck is the wash pipe. This is made of the strongest material known to the industry. The wash pipe is stationary and is joined to the rotating swivel stem. Special packing to seal this rotating joint is contained in the stuffing box. The bearings run in an oil bath. (Figure 16)

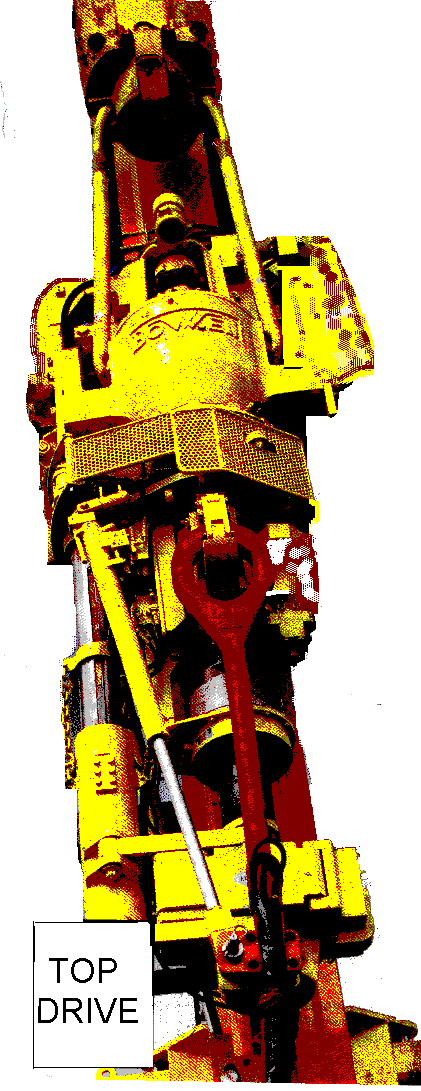

19. Top drive

This is a specially designed electric or hydraulic motor installed on the drill lines that replaced kelly and kelly bushing and it rotates the string as well.

Using the top drive enables drilling to be carried out stand by stand instead of joint by joint. This reduces the number of connections to be made while drilling. (Figure 17)

Unlike the kelly, Top drive is not removed during trips.

20. Heave (Motion) Compensation

Heave Compansators are used on semisbus and float ships rigs. The two basic types of motion compensators are:

Drill string compensator

Riser and guideline tensioner.

Drill string Compensator:

The drill string motion Compensator system is designed to nullify the effects of rig heave on the drill string or other hook-supported equipment. (Figure 18)

Mounted between the hook and travelling block, the compensator is connected to deck mounted air pressure vessels via a hose loop and standpipe and is controlled and monitored from the driller’s control console.

While drilling, the drill string compensator controls the weight on the bit. The driller lowers the travelling block to account for drill-off and to maintain the compensator cylinder within its stroke capacity while the drill string compensator automatically maintains the selected bit weight.

As the rig heaves upward, the compensator cylinders are retracted and the hook moves downward to maintain the selected loads.

Actually, the hook remains fixed relative to the seabed; the rig and compensator move, producing relative motion between the hook and rig.

The motion of both the kelly and drill string is relative to the rotary table.