- •Rig types & components rig processes

- •June, 2002 Contents

- •Drilling programme

- •Casing and cementing programme

- •Bits and Hydraulics programme

- •Mud programme

- •Drilling procedures programme

- •Figure 02

- •Semi-submersibles

- •Figure 03

- •Drill ships

- •D. Platform rigs

- •The drilling types

- •Rotary drilling:

- •Cable tool drilling:

- •Land rig components

- •1. Mast or Derrick

- •Figure 07

- •2. Substructure

- •Figure 08

- •1 0. Tongs

- •11. Prime Movers (Engines )

- •12. Transmission

- •13. Draw Works

- •Figure 12

- •Figure 13

- •14. Drilling Line

- •15. Rotary Table

- •Figure 14

- •19. Top drive

- •20. Heave (Motion) Compensation

- •Drill string Compensator:

- •Riser and Guideline Tensioners

- •Figure 18

- •21. Drill String

- •Figure 19

- •Figure 20

- •Figure 21

- •I) Hole Openers

- •Figure 22

- •22. Casing head

- •23. Mud pumps (Slush Pumps)

- •24. Kelly Line-Rotary Hose (Mud Hose)

- •25. Shale Shaker

- •26. Desanders and Desilters

- •27. Degassers

- •28. Mud Pits

- •29. Bop’s (Blow-Out Preventers)

- •Figure 25

- •Figure 26

- •Rig personnel

- •List of Common Drilling Terms

- •3.The drilling mud

- •Composition and nature of drilling muds

- •Types of mud

- •Mud Properties Termenology

- •De nsity

- •Gel strength:

- •Filtration

- •Alkalinity

- •Chloride Content

- •Installing Christmas Tree

- •Directional Drilling

- •Drilling to total depth (td)

- •Conventional coring:

- •Sidewall coring

- •Tripping

- •Figure 27

- •Stuck pipe

- •1. Differential sticking

- •2. Mechanical sticking

- •Fishing

- •Wireline logging (electric) logging

- •Cement Figure 30

- •(Figure 31)

- •Completing the well & Setting Production Casing

- •Perforating production casing

- •Drill Stem Test (dst)

- •Acidizing

- •Fracturing

- •Installing the Christmas Tree

- •5.Mud Logging Definition

- •Types of mud logging units

- •Duties & responsibilities

- •I) mud logging unit captain

- •6.The mud logging theory & lag

- •Answers

- •Trip-out monitoring procedures

- •7.Sample collection and description

- •Preparation for collection of cutting sample

- •Shaker Samples

- •Sample Descriptions

- •Rock Types

- •Describing and logging oil shows

- •Acetone Test

- •Heat Test

- •Hot Water Test

- •Acid Test

- •Some Criteria & Procedures For Rock & Mineral Identification Testing Methods:

- •General remarks on sample escription

- •Contamination of cuttings

- •8.Gas system

- •Gas Curve

- •Types of recorded gases

- •1) Cuttings gas (formation gas)

- •2) Background gas

- •3) Trip gas

- •4) Connection gas

- •4) Circulation gas

- •Gas detection and analysis monitoring equipment

- •Gas trap assembly

- •Fid gas detector

- •Fid gas chromatograph

- •9.Sensors

- •Sensors specifications

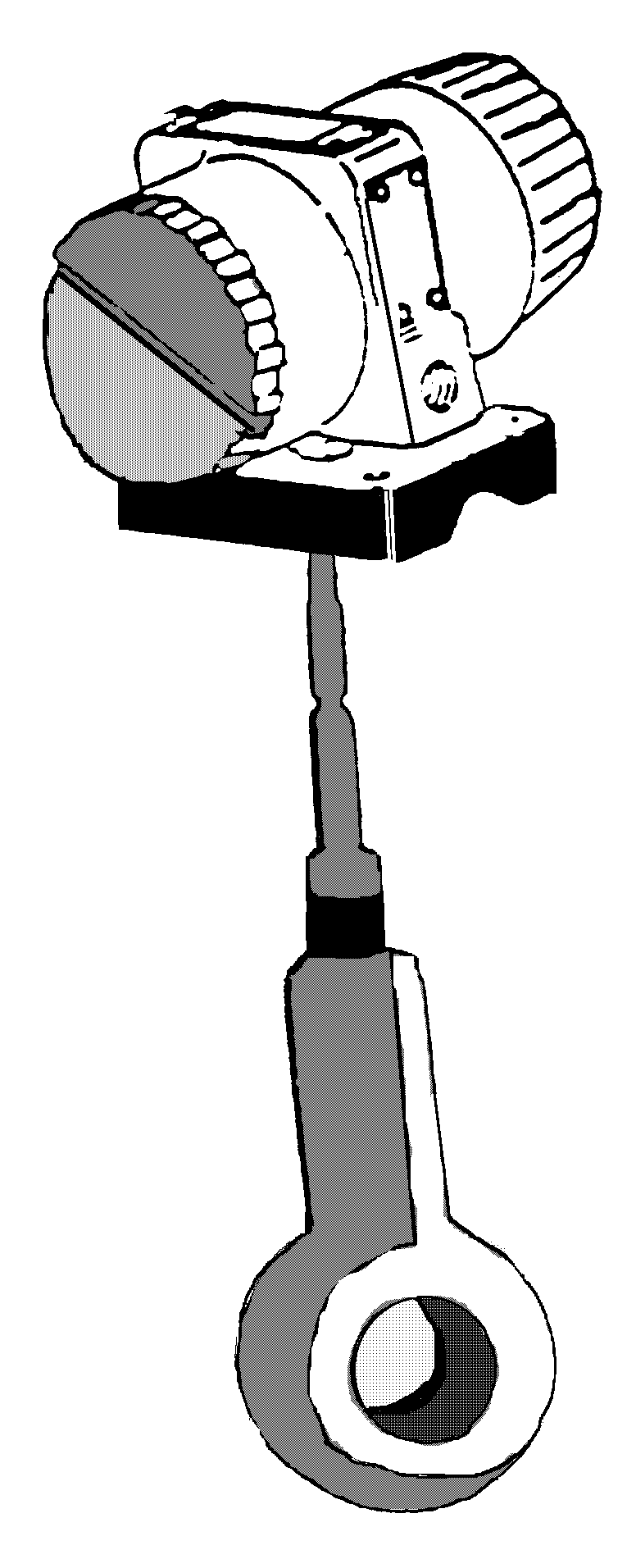

- •1.Hook load sensor

- •2.Torque sensors Electric torque type:

- •Mechanical torque type:

- •3.Standpipe and choke pressure sensors

- •1. Strain gauge type:

- •2. Current loop type:

- •7.Analog rotary speed sensor

- •8.Pit volume sensors

- •9.Flow out sensors

- •10.Mud temperature sensors

- •11 .Mud density sensor

- •12. Mud conductivity sensor

- •13. Depth sensor

- •14. Pump stroke sensor

- •15. Digital rotary speed sensor

- •16.Gas trap assembly

- •17. Hydrogen sulphide gas detector - h2s

- •Basic Mud Logging

10.Mud temperature sensors

Tw o

types of temperature sensor are in use. Either semiconductor

thermistor transducers or platinum resistance elements (PRT) are

used. These are mourned in a protective cage at the end of all sensor

poles.The Temperature-In

sensor is mounted in the suction pit and the Temperature-Out

sensor

in the shaker header box.

o

types of temperature sensor are in use. Either semiconductor

thermistor transducers or platinum resistance elements (PRT) are

used. These are mourned in a protective cage at the end of all sensor

poles.The Temperature-In

sensor is mounted in the suction pit and the Temperature-Out

sensor

in the shaker header box.

The thermistor sensor is supplied with an 8.5 volt excitation voltage. The current output of the sensor is dependent on temperature and varies linearly between 270 and 370 microamps. This signal is converted by the signal conditioner card into a 0-10 VDC analog signal for input into the computer.

The Platinum Resistance element has a 4-20 m.a. converter in the sensor head and uses a 24 VDC excitation voltage from the signal conditioner.

11 .Mud density sensor

The Mud density sensor is of the differential pressure type. Two silicon oil filled diaphragms are placed one foot apart in the drilling mud and a highly accurate differential pressure transducer interrogates the readings and transmits a 4-20 m.a. signal to the computer.

The sensors are mounted in the suction pit and in the shaker header box to provide the density In&Out measurements.

The span can be adjusted over the desired range through calibration at the sensor head.

The sensor is supplied with 24 VDC excitation supply and produces a 4-20 m.a. signal. This enters a signal conditioner card and is fed to the computer as a 0-10 VDC signal.

For long term rig installations we recommend the resonant density sensors. Their superior accuracy and reliability give an on-line density reading that can be used with confidence by the customer and rig operator.

These sensors can be mounted in the mud pump suction lines. This allows the sensors to pick up the density of the fluid being pumped. The sensors rapidly detect the presence of the wrong fluid being pumped and can save rig time and money by early detection of miss-aligned pits. Unlike differential pressure sensors they are unaffected by turbulence in the pits and they maintain accurate calibration over long periods.

12. Mud conductivity sensor

The

sensor is a new 4-20 m.a. type which has all the electronics in the

sensor head and gives a 4-20 m.a. signal to the unit. This signal is

then put through a density (or new conductivity) signal conditioner

card (both are exactly the same) to produce a 0-10 VDC signal for the

computer.

The

sensor is a new 4-20 m.a. type which has all the electronics in the

sensor head and gives a 4-20 m.a. signal to the unit. This signal is

then put through a density (or new conductivity) signal conditioner

card (both are exactly the same) to produce a 0-10 VDC signal for the

computer.

Principle of operation:

The sensor works on the principle of the toroidal coupling effect. The sensor contains two coils, known as the primary and secondary coils. AC current is fed to the primary coil by a Oscillator. The magnetic effect caused by this current is transmitted to the secondary coil by the medium surrounding the coils. This produces a current in the secondary coil, whose phase difference is related to the resistivity of the medium. The phase difference by a demodulation unit and then amplified to a 4-20 m.a. signal. The sensor also contains a thermistor for temperature compensation, so that the actual value given is at it’s 20° equivalent.

The 4-20 m.a. signal from the sensor is conditioned through a density/conductivity signal conditioner and then fed to the computer as a 0-10 VDC.