- •Rig types & components rig processes

- •June, 2002 Contents

- •Drilling programme

- •Casing and cementing programme

- •Bits and Hydraulics programme

- •Mud programme

- •Drilling procedures programme

- •Figure 02

- •Semi-submersibles

- •Figure 03

- •Drill ships

- •D. Platform rigs

- •The drilling types

- •Rotary drilling:

- •Cable tool drilling:

- •Land rig components

- •1. Mast or Derrick

- •Figure 07

- •2. Substructure

- •Figure 08

- •1 0. Tongs

- •11. Prime Movers (Engines )

- •12. Transmission

- •13. Draw Works

- •Figure 12

- •Figure 13

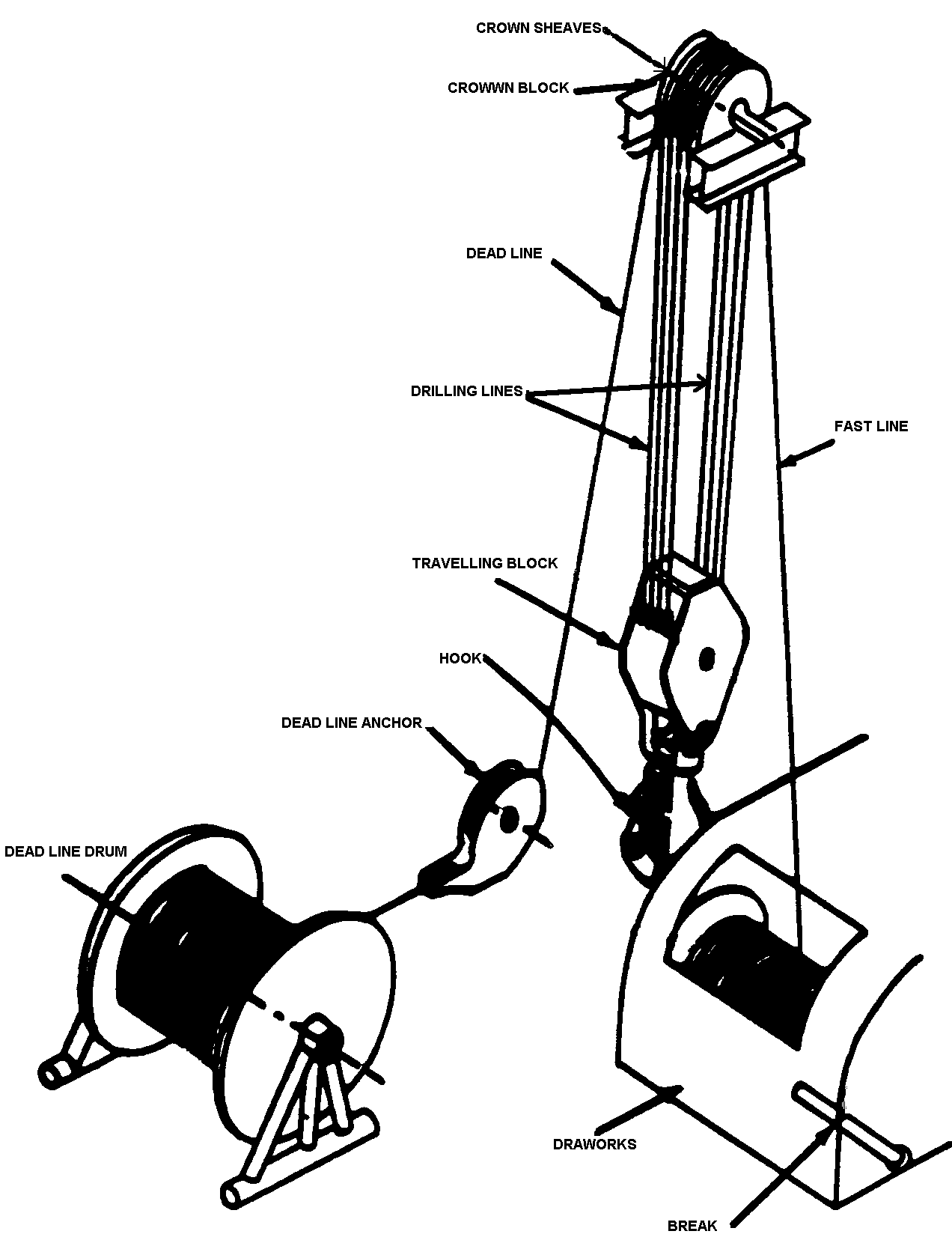

- •14. Drilling Line

- •15. Rotary Table

- •Figure 14

- •19. Top drive

- •20. Heave (Motion) Compensation

- •Drill string Compensator:

- •Riser and Guideline Tensioners

- •Figure 18

- •21. Drill String

- •Figure 19

- •Figure 20

- •Figure 21

- •I) Hole Openers

- •Figure 22

- •22. Casing head

- •23. Mud pumps (Slush Pumps)

- •24. Kelly Line-Rotary Hose (Mud Hose)

- •25. Shale Shaker

- •26. Desanders and Desilters

- •27. Degassers

- •28. Mud Pits

- •29. Bop’s (Blow-Out Preventers)

- •Figure 25

- •Figure 26

- •Rig personnel

- •List of Common Drilling Terms

- •3.The drilling mud

- •Composition and nature of drilling muds

- •Types of mud

- •Mud Properties Termenology

- •De nsity

- •Gel strength:

- •Filtration

- •Alkalinity

- •Chloride Content

- •Installing Christmas Tree

- •Directional Drilling

- •Drilling to total depth (td)

- •Conventional coring:

- •Sidewall coring

- •Tripping

- •Figure 27

- •Stuck pipe

- •1. Differential sticking

- •2. Mechanical sticking

- •Fishing

- •Wireline logging (electric) logging

- •Cement Figure 30

- •(Figure 31)

- •Completing the well & Setting Production Casing

- •Perforating production casing

- •Drill Stem Test (dst)

- •Acidizing

- •Fracturing

- •Installing the Christmas Tree

- •5.Mud Logging Definition

- •Types of mud logging units

- •Duties & responsibilities

- •I) mud logging unit captain

- •6.The mud logging theory & lag

- •Answers

- •Trip-out monitoring procedures

- •7.Sample collection and description

- •Preparation for collection of cutting sample

- •Shaker Samples

- •Sample Descriptions

- •Rock Types

- •Describing and logging oil shows

- •Acetone Test

- •Heat Test

- •Hot Water Test

- •Acid Test

- •Some Criteria & Procedures For Rock & Mineral Identification Testing Methods:

- •General remarks on sample escription

- •Contamination of cuttings

- •8.Gas system

- •Gas Curve

- •Types of recorded gases

- •1) Cuttings gas (formation gas)

- •2) Background gas

- •3) Trip gas

- •4) Connection gas

- •4) Circulation gas

- •Gas detection and analysis monitoring equipment

- •Gas trap assembly

- •Fid gas detector

- •Fid gas chromatograph

- •9.Sensors

- •Sensors specifications

- •1.Hook load sensor

- •2.Torque sensors Electric torque type:

- •Mechanical torque type:

- •3.Standpipe and choke pressure sensors

- •1. Strain gauge type:

- •2. Current loop type:

- •7.Analog rotary speed sensor

- •8.Pit volume sensors

- •9.Flow out sensors

- •10.Mud temperature sensors

- •11 .Mud density sensor

- •12. Mud conductivity sensor

- •13. Depth sensor

- •14. Pump stroke sensor

- •15. Digital rotary speed sensor

- •16.Gas trap assembly

- •17. Hydrogen sulphide gas detector - h2s

- •Basic Mud Logging

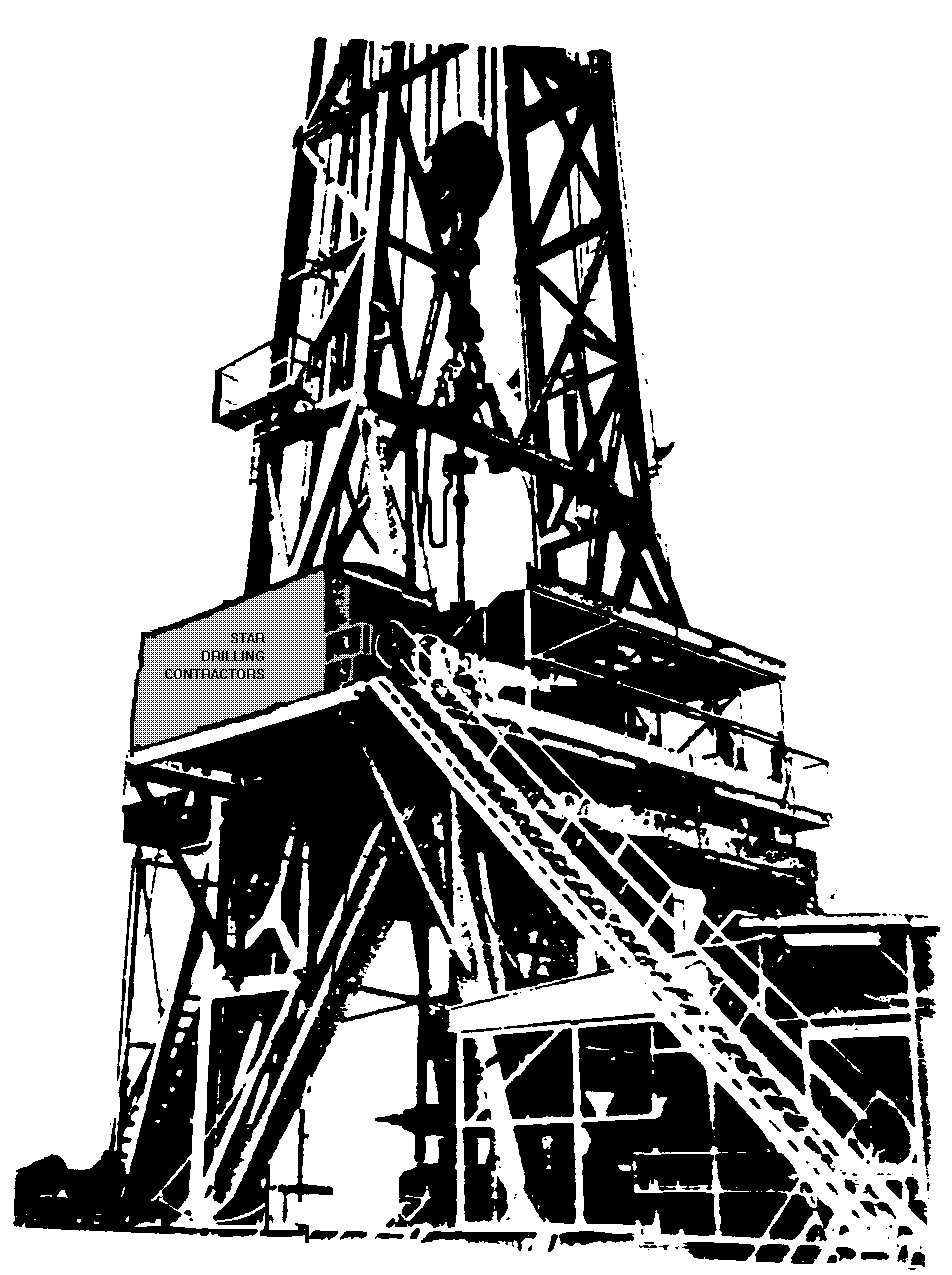

Figure 07

b) Derricks

There is no clear-cut distinction between a mast and a derrick. Often, the two terms are used interchangeably.

To keep things simple we will regard a derrick as the framework-tower type of support usually associated with oil well drilling. Typically derricks are assembled on-site bolting individual pieces together. The rigging-up time for this method is of course, longer than for a cantilever mast. (Figure 07)

2. Substructure

This is the support on which the derrick rests. It also acts as a support for the heavy equipment on the rig floor. The top of the substructure varies in height from 10-30 feet above the ground. This clearance is provided so that wellhead equipment can be installed underneath the rig floor. (Figure 08)

3. V-Door

This is a triangular opening on the front of the derrick to allow drill pipe and equipment to be picked up from the catwalk and brought into the derrick.

4. Monkey Board

This is a platform situated at a specific height from the rig floor, typically 60 to 90 feet, on which the derrickman works during trips. This platform also supports the fingers that are used to rack the stands of drill pipe .

Figure 08

5. Crown and Crown Blocks

The top of the derrick is known as the crown, it is usually a small platform designed to carry the crown blocks. The crown blocks are the uppermost set of sheaves on which the drilling line is strung, most crowns of recent manufacture have from four to six sheaves. (Figure 09)

6. Travelling Block

This is merely the travelling pulley (sheave) assembly that is slung from the crown blocks by the drilling line. It connects the drilling line to the hook and swivel. (Figure 09)

7. Hook

This is suspended directly from the block. It is composed of a main hook which carries the swivel bail and two smaller offset hooks carrying the elevator arm bails. The hook can rotate in the axis of the travelling block, limited by a lock device ; it is also sprung. (Figure 09)

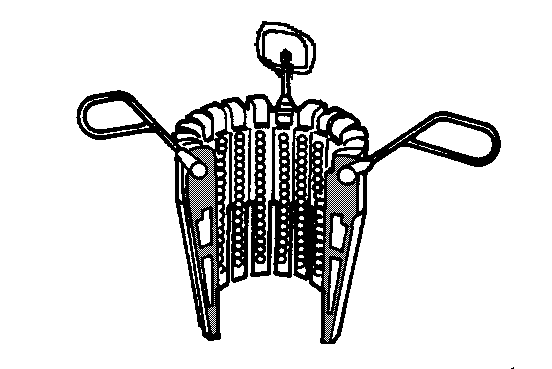

8. Elevators

Elevators

Two elevators are hung from the hook on the elevator bails and are used for latching around the drill pipe in order to lift it. Elevators are of many slightly differing designs and sizes for use with different pipe sizes, drill collar and casing sizes. They are not used during the drilling operation but are necessary for lifting the pipe during a trip. Figure 10)

9. Slips

Th ese

devices are used to hold the weight of the drill string when it is

not supported by the hook (during connections or tripping time).

Slips are made of hinged sections with a single opening. They are

placed around the pipe, their tapered outer sections fitting against

either the inside surface (bowl) or the master bushing or against the

inserts. As the pipe is lowered, the slips tapered section causes

them to close tightly around the pipe. (Figure

11)

ese

devices are used to hold the weight of the drill string when it is

not supported by the hook (during connections or tripping time).

Slips are made of hinged sections with a single opening. They are

placed around the pipe, their tapered outer sections fitting against

either the inside surface (bowl) or the master bushing or against the

inserts. As the pipe is lowered, the slips tapered section causes

them to close tightly around the pipe. (Figure

11)

1 0. Tongs

A pair of special type of spanners is used to breakout and; or to tighten the pipe connections. One of the tongs is called “Back-up” and is attached to the drill pipe and is anchored to the derrick structure by a chain.

The other one is attached by to the connected pipe box or saver sub to be unscrewed and is connected via a chain to the Cat-head of the draw works. The rotation power of the draw works is used to breakout or tighten the connection.

On most modern rigs “Power Tongs” are used instead, They are hydraulically self operated able to breakout the connection without the use of chains. These are safer devices. (Figure 11)