- •Rig types & components rig processes

- •June, 2002 Contents

- •Drilling programme

- •Casing and cementing programme

- •Bits and Hydraulics programme

- •Mud programme

- •Drilling procedures programme

- •Figure 02

- •Semi-submersibles

- •Figure 03

- •Drill ships

- •D. Platform rigs

- •The drilling types

- •Rotary drilling:

- •Cable tool drilling:

- •Land rig components

- •1. Mast or Derrick

- •Figure 07

- •2. Substructure

- •Figure 08

- •1 0. Tongs

- •11. Prime Movers (Engines )

- •12. Transmission

- •13. Draw Works

- •Figure 12

- •Figure 13

- •14. Drilling Line

- •15. Rotary Table

- •Figure 14

- •19. Top drive

- •20. Heave (Motion) Compensation

- •Drill string Compensator:

- •Riser and Guideline Tensioners

- •Figure 18

- •21. Drill String

- •Figure 19

- •Figure 20

- •Figure 21

- •I) Hole Openers

- •Figure 22

- •22. Casing head

- •23. Mud pumps (Slush Pumps)

- •24. Kelly Line-Rotary Hose (Mud Hose)

- •25. Shale Shaker

- •26. Desanders and Desilters

- •27. Degassers

- •28. Mud Pits

- •29. Bop’s (Blow-Out Preventers)

- •Figure 25

- •Figure 26

- •Rig personnel

- •List of Common Drilling Terms

- •3.The drilling mud

- •Composition and nature of drilling muds

- •Types of mud

- •Mud Properties Termenology

- •De nsity

- •Gel strength:

- •Filtration

- •Alkalinity

- •Chloride Content

- •Installing Christmas Tree

- •Directional Drilling

- •Drilling to total depth (td)

- •Conventional coring:

- •Sidewall coring

- •Tripping

- •Figure 27

- •Stuck pipe

- •1. Differential sticking

- •2. Mechanical sticking

- •Fishing

- •Wireline logging (electric) logging

- •Cement Figure 30

- •(Figure 31)

- •Completing the well & Setting Production Casing

- •Perforating production casing

- •Drill Stem Test (dst)

- •Acidizing

- •Fracturing

- •Installing the Christmas Tree

- •5.Mud Logging Definition

- •Types of mud logging units

- •Duties & responsibilities

- •I) mud logging unit captain

- •6.The mud logging theory & lag

- •Answers

- •Trip-out monitoring procedures

- •7.Sample collection and description

- •Preparation for collection of cutting sample

- •Shaker Samples

- •Sample Descriptions

- •Rock Types

- •Describing and logging oil shows

- •Acetone Test

- •Heat Test

- •Hot Water Test

- •Acid Test

- •Some Criteria & Procedures For Rock & Mineral Identification Testing Methods:

- •General remarks on sample escription

- •Contamination of cuttings

- •8.Gas system

- •Gas Curve

- •Types of recorded gases

- •1) Cuttings gas (formation gas)

- •2) Background gas

- •3) Trip gas

- •4) Connection gas

- •4) Circulation gas

- •Gas detection and analysis monitoring equipment

- •Gas trap assembly

- •Fid gas detector

- •Fid gas chromatograph

- •9.Sensors

- •Sensors specifications

- •1.Hook load sensor

- •2.Torque sensors Electric torque type:

- •Mechanical torque type:

- •3.Standpipe and choke pressure sensors

- •1. Strain gauge type:

- •2. Current loop type:

- •7.Analog rotary speed sensor

- •8.Pit volume sensors

- •9.Flow out sensors

- •10.Mud temperature sensors

- •11 .Mud density sensor

- •12. Mud conductivity sensor

- •13. Depth sensor

- •14. Pump stroke sensor

- •15. Digital rotary speed sensor

- •16.Gas trap assembly

- •17. Hydrogen sulphide gas detector - h2s

- •Basic Mud Logging

29. Bop’s (Blow-Out Preventers)

Th e

main function of the blow-out preventers is to furnish a means of

closing-off the annular space between the drill pipe and casing. Most

preventers are either hydraulically or pneumatically controled with

manual operation available as a safety precaution. Blow-out

preventers are rated according to their working pressure and their

inner diameter. There are many design variations of BOP’s; however,

they fall essentially into two categories :

e

main function of the blow-out preventers is to furnish a means of

closing-off the annular space between the drill pipe and casing. Most

preventers are either hydraulically or pneumatically controled with

manual operation available as a safety precaution. Blow-out

preventers are rated according to their working pressure and their

inner diameter. There are many design variations of BOP’s; however,

they fall essentially into two categories :

A) Annular Preventers:- This type seal by closing a circular packing element around the drill pipe; this element is made of rubber one most types will also seal the annulus with virtually anything or nothing in the bore. (Figure 24)

B) Ram Preventers:- These derive their name from the hydraulic cylinders and ram shafts that move the two sealing ram blocks. (Figure 25)

Unlike annular preventers, this type will only seal around a specific pipe size; to accommodate different pipe sizes the ram elements are changeable.

A set of rams and annual preventers, when assembled, is known as the Blow-Out Preventer Stack; commonly referred to as the stack or BOP’s (Figure 26).

Ram Type BOP

Figure 25

Example of BOP Stack Arrangement

Figure 26

Rig personnel

Company Man or Company Representative:

The operator representative usually a drilling engineer employed by the oil company engaged in drilling.

Tool Pusher:

A drilling foreman or rig superintendent.

Driller :

Employee in charge of the “brake” responsible for making hole as quickly as possible.

Assistant Driller:

Assists driller in “making hole” and general jobs around the rig.

Derrick Man:

Responsible for stacking pipe in derrick during trips. Operates from monkey board attached by safety harness. Assist mud engineer to mix mud.

Roughnecks/ Floor hands:

General workers under supervision of the driller.

Rig Mechanic :

Keeps the rig running smoothly. Controls maintenance of rig.

Motorman Rig Electrician Rig Welder:

Keep the motors running.

Mud Engineer:

Controls properties of drilling fluid within limits specified by operator.

Mud Loggers :

Produce mud log of the well. Responsible for detecting changes in volume of surface mud, changes of drilling parameters and the presence of hydrocarbons.

Offshore Personnel

Captain :

Responsible for the rig as a marine vessel. He will hole a masters certificate, and is in command during rig moves.

Crane Operators:

Re sponsible

for loading and unloading of supply boats. Usually doubles as a

roustabout supervisor.

sponsible

for loading and unloading of supply boats. Usually doubles as a

roustabout supervisor.

Barge Engineers:

Responsible for the vessels stability and rig move.

Radio Operator

Operates radio to communicate rig to town.

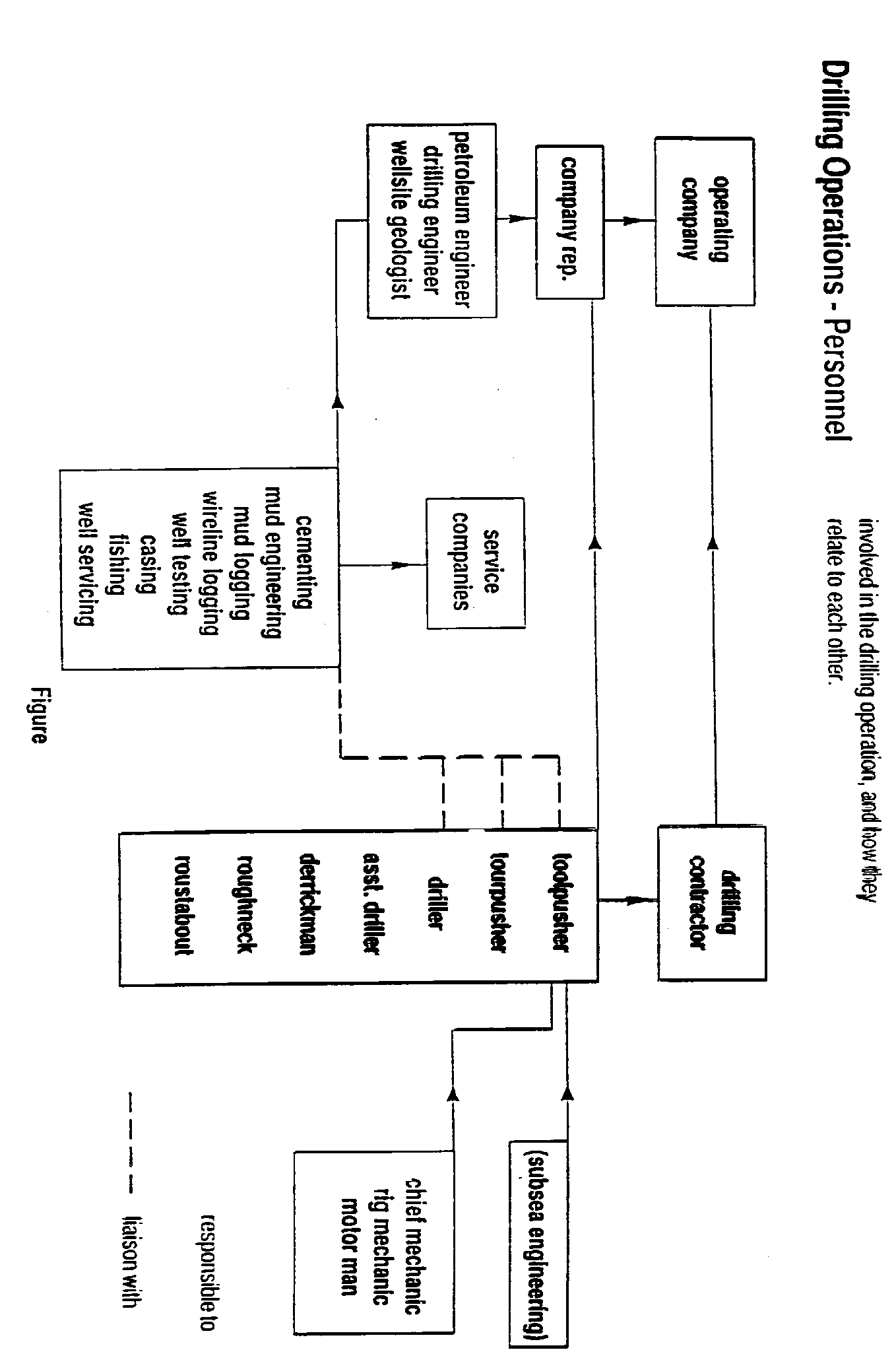

The relationships between all of the previous mentioned personnel can be explained by using a simple organization chart. On the chart on the next page, the solid lines show lines of responsibility. The broken lines show where there is liaison between the companies or departments.

It is realised that this organization chart is a hypothetical one, actual company organisation may vary slightly from this.

The services provided by the service companies which are listed in the chart will be covered through the rest of the units.