- •Rig types & components rig processes

- •June, 2002 Contents

- •Drilling programme

- •Casing and cementing programme

- •Bits and Hydraulics programme

- •Mud programme

- •Drilling procedures programme

- •Figure 02

- •Semi-submersibles

- •Figure 03

- •Drill ships

- •D. Platform rigs

- •The drilling types

- •Rotary drilling:

- •Cable tool drilling:

- •Land rig components

- •1. Mast or Derrick

- •Figure 07

- •2. Substructure

- •Figure 08

- •1 0. Tongs

- •11. Prime Movers (Engines )

- •12. Transmission

- •13. Draw Works

- •Figure 12

- •Figure 13

- •14. Drilling Line

- •15. Rotary Table

- •Figure 14

- •19. Top drive

- •20. Heave (Motion) Compensation

- •Drill string Compensator:

- •Riser and Guideline Tensioners

- •Figure 18

- •21. Drill String

- •Figure 19

- •Figure 20

- •Figure 21

- •I) Hole Openers

- •Figure 22

- •22. Casing head

- •23. Mud pumps (Slush Pumps)

- •24. Kelly Line-Rotary Hose (Mud Hose)

- •25. Shale Shaker

- •26. Desanders and Desilters

- •27. Degassers

- •28. Mud Pits

- •29. Bop’s (Blow-Out Preventers)

- •Figure 25

- •Figure 26

- •Rig personnel

- •List of Common Drilling Terms

- •3.The drilling mud

- •Composition and nature of drilling muds

- •Types of mud

- •Mud Properties Termenology

- •De nsity

- •Gel strength:

- •Filtration

- •Alkalinity

- •Chloride Content

- •Installing Christmas Tree

- •Directional Drilling

- •Drilling to total depth (td)

- •Conventional coring:

- •Sidewall coring

- •Tripping

- •Figure 27

- •Stuck pipe

- •1. Differential sticking

- •2. Mechanical sticking

- •Fishing

- •Wireline logging (electric) logging

- •Cement Figure 30

- •(Figure 31)

- •Completing the well & Setting Production Casing

- •Perforating production casing

- •Drill Stem Test (dst)

- •Acidizing

- •Fracturing

- •Installing the Christmas Tree

- •5.Mud Logging Definition

- •Types of mud logging units

- •Duties & responsibilities

- •I) mud logging unit captain

- •6.The mud logging theory & lag

- •Answers

- •Trip-out monitoring procedures

- •7.Sample collection and description

- •Preparation for collection of cutting sample

- •Shaker Samples

- •Sample Descriptions

- •Rock Types

- •Describing and logging oil shows

- •Acetone Test

- •Heat Test

- •Hot Water Test

- •Acid Test

- •Some Criteria & Procedures For Rock & Mineral Identification Testing Methods:

- •General remarks on sample escription

- •Contamination of cuttings

- •8.Gas system

- •Gas Curve

- •Types of recorded gases

- •1) Cuttings gas (formation gas)

- •2) Background gas

- •3) Trip gas

- •4) Connection gas

- •4) Circulation gas

- •Gas detection and analysis monitoring equipment

- •Gas trap assembly

- •Fid gas detector

- •Fid gas chromatograph

- •9.Sensors

- •Sensors specifications

- •1.Hook load sensor

- •2.Torque sensors Electric torque type:

- •Mechanical torque type:

- •3.Standpipe and choke pressure sensors

- •1. Strain gauge type:

- •2. Current loop type:

- •7.Analog rotary speed sensor

- •8.Pit volume sensors

- •9.Flow out sensors

- •10.Mud temperature sensors

- •11 .Mud density sensor

- •12. Mud conductivity sensor

- •13. Depth sensor

- •14. Pump stroke sensor

- •15. Digital rotary speed sensor

- •16.Gas trap assembly

- •17. Hydrogen sulphide gas detector - h2s

- •Basic Mud Logging

Rig types & components rig processes

June, 2002 Contents

1. WELL PLANNING 3

1. Operating company 4

2. Drilling contractor 4

3. Drilling service companies 4

4. Logistical support services 4

5. DRILLING PROGRAMME 4

2. RIG TYPES & COMPONENTS 6

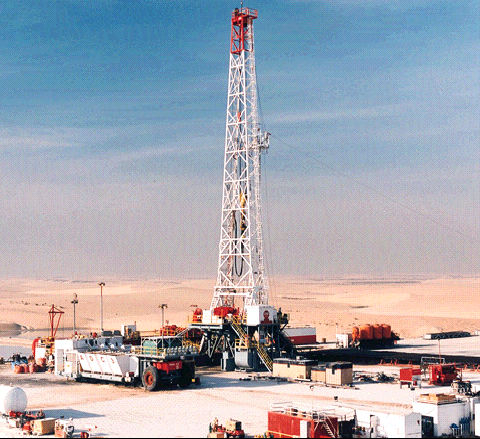

6. LAND RIGS 6

7. OFFSHORE RIGS 7

a)JACK-UP RIGS 7

b)SEMI-SUBMERSIBLES 8

c)DRILL SHIPS 9

8. D. PLATFORM RIGS 10

9. THE DRILLING TYPES 11

10. LAND RIG COMPONENTS 11

11. RIG PERSONNEL 35

3. THE DRILLING MUD 41

12. TYPES OF MUD 45

13. Mud Properties Termenology 45

Density 45

Rheology 46

Funel Viscosity 46

Plastic viscosity: 46

Yield point: 46

Gel strength: 47

pH : 47

Filtration 47

Alkalinity 48

Chloride Content 48

Calcium 48

4. RIG PROCESSES 48

14. Drilling 49

a) Normal drilling : 49

(b)Directional Drilling 50

(c)Drilling to total depth (TD) 51

15. Coring 51

(a)Conventional coring: 51

(b)Sidewall coring 51

16. Tripping 51

17. STUCK PIPE 58

18. Fishing 62

19. Wireline logging (electric) logging 64

20. Casing 64

21. Cement 67

22. Completing the well & Setting Production Casing 69

23. Perforating production casing 69

24. Drill Stem Test (DST) 69

25. Acidizing 70

26. Fracturing 70

27. Installing the Christmas Tree 70

5. Mud Logging Definition 72

28. TYPES OF MUD LOGGING UNITS 73

29. DUTIES & RESPONSIBILITIES 75

6. THE MUD LOGGING THEORY & LAG 81

7. Sample collection and description 80

30. Preparation for collection of cutting sample 80

31. Shaker Samples 80

32. Sample Descriptions 83

Rock Types 85

33. DESCRIBING AND LOGGING OIL SHOWS 90

34. Some Criteria & Procedures For Rock & Mineral Identification 95

Testing Methods: 95

35. GENERAL REMARKS ON SAMPLE ESCRIPTION 99

36. CONTAMINATION OF CUTTINGS 99

8. GAS SYSTEM 102

37. Gas Curve 103

38. TYPES OF RECORDED GASES 104

39. GAS DETECTION AND ANALYSIS 106

MONITORING EQUIPMENT 106

GAS TRAP ASSEMBLY 106

40. FID GAS DETECTOR 106

41. FID GAS CHROMATOGRAPH 109

9. SENSORS 110

42. SENSORS SPECIFICATIONS 110

1.HOOK LOAD SENSOR 112

2.TORQUE SENSORS 112

Electric torque type: 112

Mechanical torque type: 113

3.STANDPIPE AND CHOKE PRESSURE SENSORS 113

7.ANALOG ROTARY SPEED SENSOR 114

8.PIT VOLUME SENSORS 115

9.FLOW OUT SENSORS 118

10.MUD TEMPERATURE SENSORS 119

11.MUD DENSITY SENSOR 119

12. MUD CONDUCTIVITY SENSOR 120

13. DEPTH SENSOR 121

14. PUMP STROKE SENSOR 121

15. DIGITAL ROTARY SPEED SENSOR 122

16.GAS TRAP ASSEMBLY 122

17. HYDROGEN SULPHIDE GAS DETECTOR - H2S 123

1.WELL PLANNING

Before a new well is drilled a well plan has to be developed. There is a number of different companies involved in making the hole and a well plan requires close liaison between them.

A little later we will look at the relationship between the different companies but let’s first consider the major bodies involved in the operations.

Operating company

The operating company is the oil or gas company which has a licence to drill for and produce petroleum within a specified area. The actual licence may be held by a number of companies who are working as a partnership. in such a case one of the partners is usually nominated as “the operator”.

Drilling contractor

To do the actual drilling of the well the operator will employ a drilling contractor. Usually, the contractor is the owner of the drilling rig and is responsible for providing the personnel who make up the drilling crew.

Drilling service companies

As you will shortly see, there are many special drilling services required during the drilling of the well. It is the responsibility of the operator to engage these companies and coordinate their activities.

Logistical support services

Supply of equipment, materials and personnel to and from the drill site has to be arranged and coordinated. In offshore, this will involve the use of aircraft, helicopters and supply boats. In Onshore, conventional land transport will be required. Once again it is the responsibility of the operator to organize all this.

The well is drilled in a series of stages. At each stage, different kinds of problems are encountered. It is crucial to try to anticipate these problems in order for the drilling crew to take the necessary measures to minimize their effect.

In order to do this, the operator’s drilling department will collect as much information as possible about the nature of the formations through which the well will be drilled. This information should include:

Expected total depth of the well.

Types and thicknesses of different rock formations to be drilled.

Expected formation pressures.

Depth and nature of any troublesome formations that may be encountered.

If the well is being drilled as a development well in an area where there are other wells, this information is readily available. However, if the well is an exploration well in a new area, the information is scarse and hence, much has to be inferred from the seismic surveys.

Having collected and collated all available data, the drilling department of the operating company will develop the drilling programme.