- •Unit 5 Panelling

- •Unit 6 Tunnel

- •1.1 Read the text title and hypothesize what the text is about. Write down your hypothesis.

- •1.2 What do you know concerning this issue? List your ideas in the table left column “I know”.

- •If you know answers to these questions write them down in the space given after each question.

- •Circle in the list the words and expressions you know. Write down their translation in the table and calculate the percentage of your lexical competence.

- •Unit 7 Types of Tunnels

- •Circle in the list the words and expressions you know. Write down their translation in the table and calculate the percentage of your lexical competence.

- •Immersed tube tunnels, sunk into a body of water and sit on, or are buried just under, its bed.

- •Unit 8 Tunnel Planning

- •1.4 Circle in the list the words and expressions you know. Write down their translation in the table and calculate the percentage of your lexical competence.

Unit 5 Panelling

Introduction

1.1 Read the text title and hypothesize what the text is about. Write down your hypothesis.

…………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………

1.2 What do you know concerning this issue? List your ideas in the table left column “I know”.

I know |

I have learnt |

|

|

|

|

|

|

|

|

If you know answers to these questions write them down in the space given after each question.

1 |

What can panelling bring to your house? |

|

|

2 |

How many types of panelling are there? |

|

|

3 |

When was panelling created? |

|

|

4 |

What internal fittings does joinery include? |

|

|

5 |

What does external cladding refer to? |

|

|

6 |

What type of cladding is used for a less extreme climate? |

|

|

7 |

What is an integral part of the overall building design? |

|

|

Circle in the list the words and expressions you know. Write down their translation in the table and calculate the percentage of your lexical competence.

1 |

internal fittings |

|

9 |

protective coating |

|

2 |

fabrics |

|

10 |

business setting |

|

3 |

versatility |

|

11 |

sturdy materials |

|

4 |

to break up |

|

12 |

ceiling linings |

|

5 |

deterioration |

|

13 |

comprehensive |

|

6 |

correct installation |

|

14 |

an external cladding |

|

7 |

modern finishes |

|

15 |

mould fabrication |

|

8 |

rigid components |

|

16 |

weather resistant |

|

P anelling

is a wall covering constructed from rigid or semi-rigid components.

Panelling can bring a new look and style to your home. The main

purpose of panelling is putting together numerous small pieces of

whatsoever material you wish to apply for a more alluring

effect. There are many types of panelling but brick

panelling is quite easy and convenient. Brick panelling provides the

same result of brick masonry but at a lower cost. In panelling, a

number of bricks are placed on top of one another, set symmetrically

to generate a comfortable impression. Brick wall panelling and faux

brick panelling are types of brick panelling.

anelling

is a wall covering constructed from rigid or semi-rigid components.

Panelling can bring a new look and style to your home. The main

purpose of panelling is putting together numerous small pieces of

whatsoever material you wish to apply for a more alluring

effect. There are many types of panelling but brick

panelling is quite easy and convenient. Brick panelling provides the

same result of brick masonry but at a lower cost. In panelling, a

number of bricks are placed on top of one another, set symmetrically

to generate a comfortable impression. Brick wall panelling and faux

brick panelling are types of brick panelling.

Brick panelling system also has durability and unmatched stylishness of brick; however, panelling makes best use of time, space and weight. The materials produced are called brick panels generally assembled in a factory. A brick panel weighs one fifth of the full weight of the full-size brick. Brick panelling presents such versatility, which is hard to attain with any other element.

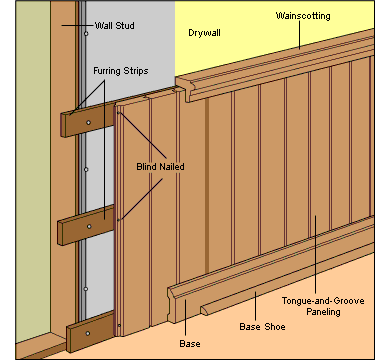

Panelling comes in three main types: surface panelling, backing and grooves.

Surface panelling refers to the surface material the paneling offers. This can be real wood or veneer, vinyl covered or printed-paper.

Backing material can be plywood, particleboard or hardboard.

Grooves can be real grooves in the wood or painted-on grooves to give the illusion of real. Touch the wood to tell if grooves are real or painted.

W all

panels serve many functions, from providing descriptions of exhibits

in museums and galleries to hiding away electronics such as stereo

speakers. As a decor element, wall panels are an excellent way to

break up wall space. This can be achieved by panelling the upper or

lower half of the wall, installing wainscoting, creating a faux

finish, or one of several other methods.

all

panels serve many functions, from providing descriptions of exhibits

in museums and galleries to hiding away electronics such as stereo

speakers. As a decor element, wall panels are an excellent way to

break up wall space. This can be achieved by panelling the upper or

lower half of the wall, installing wainscoting, creating a faux

finish, or one of several other methods.

In the business setting, there are portable or temporary wall panels that can be used to divide a space into cubicles. Modular wall panels may be constructed of wood or metal and are often covered with textured materials, fabrics, paneling or wallpaper to make them more aesthetically pleasing. There are also acoustical and sound absorbing wall panels that are perfect for the studio.

Panelling was developed in antiquity to make rooms in stone buildings more comfortable. The panels served to insulate the room from the cold stone. In more modern buildings, such panelling is often installed for decorative purposes.

A ppearance

products that are used as lining for walls or ceilings, usually with

no structural performance requirements. Panelling can be made from

board-type products such as plywood, or from tongue and groove or

lapped timber pieces. Wood panelling can be used as wall or ceiling

linings or for built-in features and furniture.

ppearance

products that are used as lining for walls or ceilings, usually with

no structural performance requirements. Panelling can be made from

board-type products such as plywood, or from tongue and groove or

lapped timber pieces. Wood panelling can be used as wall or ceiling

linings or for built-in features and furniture.

Board panelling. Decorative board panelling used internally would not be structural in most cases, and because of the internal application, an internal grade would be appropriate. Only one surface is exposed to view. Colour matching will be important.

Decorative board panelling used externally is often exposed to the weather. The glues used in manufacture must be weather resistant and hence an exterior grade of plywood must be specified. The protective coating on these panels must be much tougher than that used on the inside of the building.

Types of Ceiling Panelling. Ceilings do not have to be plain, painted or textured drywall. There are varieties of ceiling panels that can bring attention to the ceiling. Different materials and styles can help create a room that is modern, rustic or elegant. There are options of heated panels or those that provide sound barriers.

Choosing a ceiling material means deciding between aesthetic appeal and practical functionality. Strictly speaking, a ceiling could be made out of almost any type of material. Each has its pros and cons when it comes to visual appeal and work capacity.

D rywall.

Buildings commonly use it for the walls, but ceilings employ

drywall material in the form of tiles. Drywall is a material composed

of a naturally occurring mineral called gypsum. The benefits of using

drywall are that it is water resistant and is resistant to fire.

Since drywall resists water so well, it is good practice to use a

grid system with drywall ceiling tiles in order to check for any

hidden water damage. Its fire resistance retards the spread of fire

within a building. Drywall also has cosmetic benefits and comes in a

variety of textures.

rywall.

Buildings commonly use it for the walls, but ceilings employ

drywall material in the form of tiles. Drywall is a material composed

of a naturally occurring mineral called gypsum. The benefits of using

drywall are that it is water resistant and is resistant to fire.

Since drywall resists water so well, it is good practice to use a

grid system with drywall ceiling tiles in order to check for any

hidden water damage. Its fire resistance retards the spread of fire

within a building. Drywall also has cosmetic benefits and comes in a

variety of textures.

Lumber. Wood ceiling materials offer another option with a more rustic appeal. Most wooden ceiling materials are made of pine and are a light brown color, but they can also be painted. Often, the wood has tongue and groove patterns that allow the materials to fit tightly next to one another. This creates the illusion that the ceiling finish is more complete throughout the room.

Acoustical Material. Acoustical ceiling materials are a good option if noise reduction is a priority in a house or other building. The acoustical materials absorb sound and are usually composed of a fiberglass and starch blend. Some acoustical ceiling materials are made of wood fibers, but this type of material is not practical in humid climates. Noise reducing tiles come in a variety of types that offer different sound protection qualities.

Other Kinds of Ceiling Materials. There are many other kinds of materials used for ceilings, each of which presents different benefits. A more cost effective option is to use plastic tiles. Plastic is inexpensive to produce, and therefore inexpensive for the consumer to purchase. Metal, such as tin or copper, are also viable materials to use in a ceiling. One disadvantage of a metal ceiling is that is more difficult to cut. Cork is another option to use for ceilings. It is environmentally friendly and easy to install.

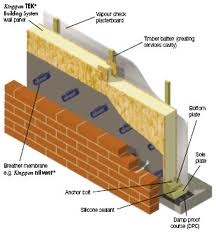

External Cladding. It is a wonderful choice for protecting the average home from the external elements, such as rain, snow, extreme heat and so forth. As many know external cladding simply refers to any material used to cover another material on the interior and exterior of a building. Metal cladding is an excellent choice for any homeowner who faces seasonal extremes from desperately cold winters to hot summers. With such a range of temperatures the building materials of a house often flex, expand, shrink and distort over the course of a year.

With metal external cladding this is not the case and these will withstand the extremes of temperatures over the years, however its crucial to mention that certain types of aluminium cladding do not fair very well in areas that have considerable hail. In fact with serious hail they are easily dented and distorted.

Wood external cladding. A great type of cladding for a less extreme weather system is wood. Wood external cladding is flexible, and it has insulation properties which are not found in metal claddings.

External cladding is an exterior grade material. The availability of a wide range of timber cladding products provides designers with many possibilities. Timber clad buildings can be designed to suit any environment and fit any site. Appropriate protective coating systems are required to prevent deterioration of timber surface from exposure to the weather.

Modern finishes give a long lasting and attractive appearance to timber cladding and can be used to quickly and effectively change the colour and style of a timber clad building. Timber clad buildings offer excellent thermal performance all year round. Obtaining the best performance depends on good design, proper construction practice and correct installation. Cladding should be considered an integral part of the overall building design as it can contribute to aesthetics, comfort and structural adequacy.

Steel cladding systems.

Exterior Cladding Products. Colourcoat exterior steel cladding products have been developed specifically to support the aesthetic and functional requirements of modern architecture.

Colourcoat includes roof and wall cladding products with unique coating formulations, offering long-term performance and the most comprehensive guarantees available.

Interior Cladding Products. Colourcoat products are also available for interior cladding applications. The products included have been specifically developed for the internal sheets of building envelope systems and where greater protection is required on the internal surface

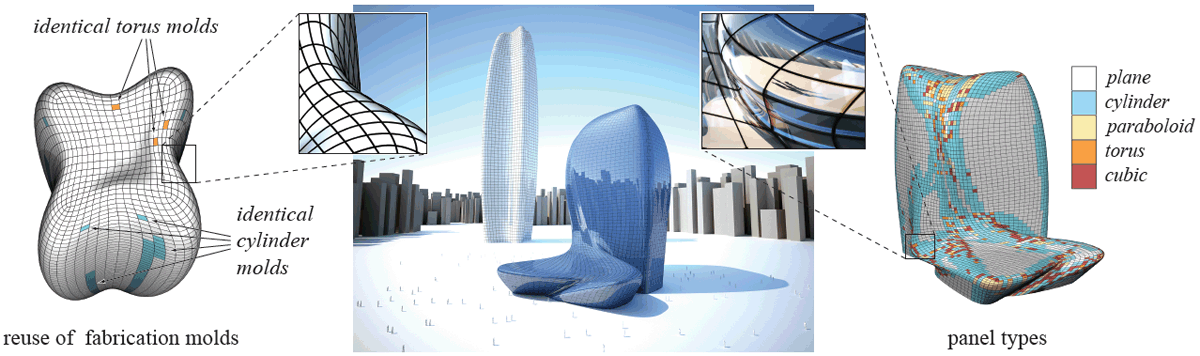

The emergence of large-scale freeform shapes in architecture poses big challenges to the fabrication of such structures. A key problem is the approximation of the design surface by a union of patches, so-called panel, that can be manufactured with a selected technology at reasonable cost. The production of curved panels is mostly based on moulds. Since the cost of mould fabrication often dominates the panel cost, there is strong incentive to use the same mould for multiple panels.