- •Application of paint. Table of Content.

- •7. Application of paint.

- •7.1. Application methods – Introduction.

- •Figure 7.1. A ll methods have their good and bad points.

- •7.1.1. Brush application

- •Figure 7.2. A paint brush is an excellent tool for stripe coating

- •7.1.2. Roller application

- •Paint glove.

- •7.1.3. Application by spraying

- •7.1.4. Application technique - airless spray.

- •7.2. How does spray equipment function ?

- •7.2.1. Low pressure spray equipment

- •7.2.2. High pressure spray equipment

- •7.2.3. Plural component spraying (Two component spraying)

- •7.2.4. Float coating

- •7.2.5. Paint-drum pump

- •7.3. Treatment of equipment before and after application

- •7.3.1. Before application

- •7.3.2. After application

- •7.4. Application and curing conditions

- •Ventilation

- •Figure 7.6

- •Good ventilation is essential to have good drying and curing conditions.

- •G ood practice

- •B ad practice

- •7.5. Safety aspects during application

- •Figure 7.7. A iless spraying can be dangerous

7.1.3. Application by spraying

A paint brush is not a very practical choice when painting large areas. Here paint spraying equipment is a more effective alternative. The most important advantages of spray-application are:

It gives a very high production rate and is suitable for large jobs.

All coats, including the first, may be applied by airless spraying.

Airless spraying, when used correctly, offers the advantages of giving a higher film thickness per coat. Consequently, fewer coats would be needed with an airless spray than with, for example a roller, to obtain the same total film thickness.

A much more even film thickness is obtained. This is very important as thin parts are recognised as the weak points of the paint film and consequently a decisive factor for the durability of the corrosion protective system. An even film thickness depends on the application technique used.

The major disadvantages of spray- application are:

It requires a lot of training / practice to apply an even film to a pre-determined thickness, with no defects and a smooth surface.

It is not suitable for application in narrow gaps or areas with difficult access (Like rat holes, behind corners etc.)

Location and surrounding environment may be affected.

The two most common methods of paint spray application are “air spray” and “airless spray”. The air spray method (also called conventional air spray) uses compressed air to atomise the paint as it exits the spray gun. The airless spray method uses a pump to pressurise the paint to a high pressure and force it through a small orifice as it exits the spray gun, causing the paint to atomise (hydraulically).

A much better finish is obtained by using low pressure than by airless spraying. It is very easy to regulate, making it most suitable for jobs requiring high standards such as the application of car enamels or furniture lacquers.

On the other hand, air spraying use large amounts of air which may cause a portion of the paint to be blown away by the continuous stream of air coming from the spray-gun. It is apparent that low pressure spray will lead to dust formation and high paint loss.

Normally, the addition of a thinner to the paint is done to adjust the paint to a correct spray viscosity. Information about thinners to be used and the level of thinning is found in the Technical data sheet.

7.1.4. Application technique - airless spray.

High-pressure spraying is used for application of most types of coating used to protect ships, offshore structures and industrial plants. Paint application using airless spraying must be carried out correctly in order to obtain satisfactory results.

Always remember to start the movement of the spray-gun before pressing the trigger. Release the trigger before having reached the end of the next band, the flow of paint should be stopped. Otherwise, there will be too high a wet-film thickness at the point where the spray-gun is turned / stopped.

It is very important that the spray-gun is kept in constant motion. So much paint is passing through the nozzle (about 1.2 litres per minute using 0.021” nozzle) that only a short stop or speed reduction will result in a much too thick paint film.

The spray-gun must be held at the correct distance from the substrate, i.e. about 30-60 cm (12-24 inches). Strong wind, excessive good ventilation and high temperature during application may influence the distance that should be used.

The gun should be held perpendicular to the substrate and it should remain so throughout the stroke. It has been proven that too long a distance between the spray-gun and the surface, will cause dry spraying, pinholes, entrapped air and heavy dusting resulting in loss of paint and uneven film thickness. By correct use of airless spray equipment it is possible to carry out the spray application with hardly any dust formation at all.

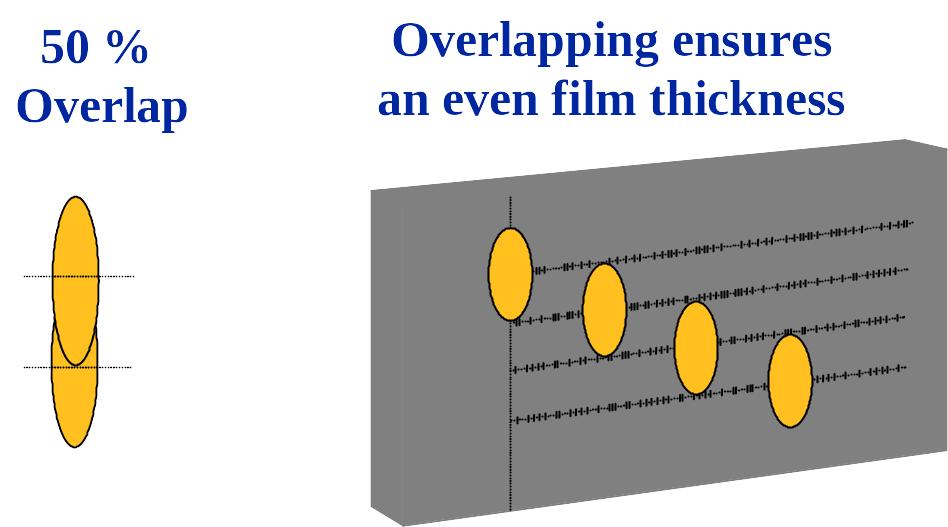

Each stroke should overlap the previous stroke by 50% or cross application. Using correct overlapping and the correct rate of movement of the spray-gun, an even film thickness will be obtained over the whole construction. At the same time minimum dust formation is obtained.

Difficult areas such as profiles, corners, edges, etc. are sprayed first. The other surfaces are subsequently sprayed.

The wet film thickness should be controlled continuously during spraying. With a little practice the correct film thickness can easily be obtained. When new equipment is to be used, or a new paint is to be applied for the first time it is wise to “calibrate” the applicator. Apply the paint on a test piece or plate and measure the wet film thickness. If necessary adjust the equipment or the speed of the movement until the desired thickness is achieved.

Always remember to choose the correct nozzle for the job. The user-instructions for most paints will indicate the type/size of nozzle recommended for the individual paints. These indications can be a good guide; however, often it may be wise to experiment to find alternative nozzles which give the best result under prevailing conditions.

It should always be born in mind that the nozzle will gradually wear out thus changing the dimensions of the opening and, thus, the spray pattern. As a rule of thumb: Change the nozzle for every 400-500 litres of paint applied.

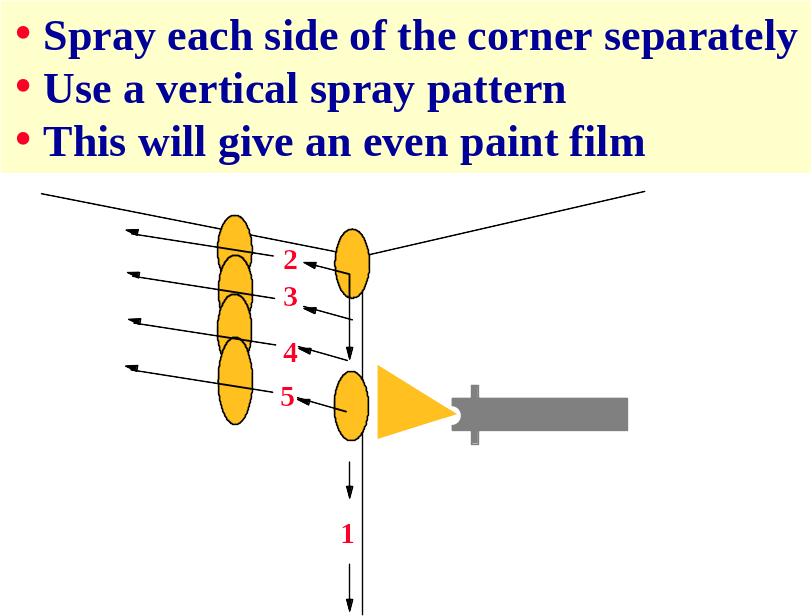

Figure 7.3.

Stroke and triggering with at spray application

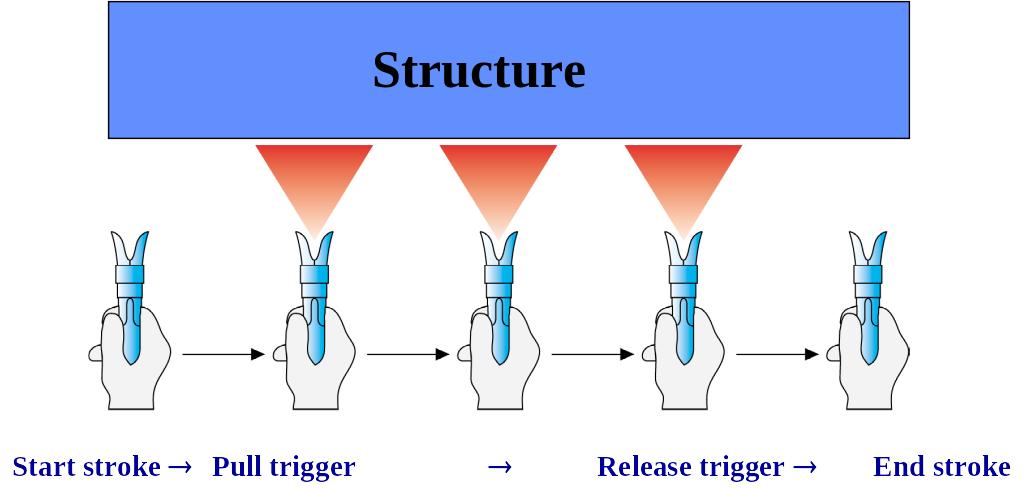

Figure 7.4.

A irless

spraying with overlap.

irless

spraying with overlap.

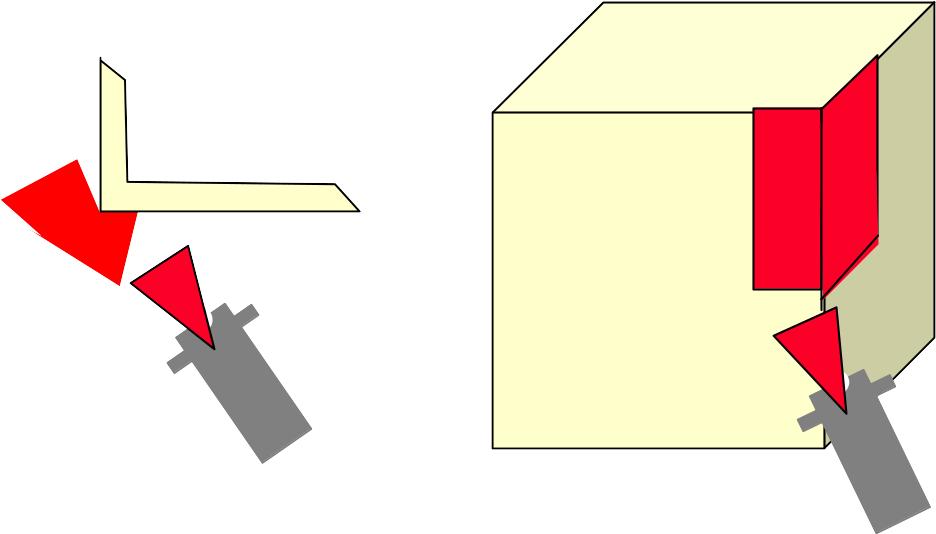

Figure 7.5.

Correct application of corners

Outside corner Inside corner