- •Surface Preparation and Cleaning. Table of content

- •5.1.1.Hand tool cleaning.

- •6.5.1.2.Power tool cleaning.

- •6.5.2. Blast-cleaning.

- •Figure 6.2.

- •Illustration of various blasting methods

- •6.5.2.1.Centrifugal abrasive blast-cleaning

- •6.5.2.2.Compressed-air abrasive blast-cleaning.

- •Figure 6.3 Effect of nozzle pressure on cleaning rate

- •6.5.2.3.Vacuum or suction-head abrasive blast-cleaning.

- •6.5.2.4.Moisture-injection abrasive blast-cleaning (compressed-air moisture- injection abrasive blast-cleaning)

- •6.5.2.5.Wet abrasive blast-cleaning (Compressed-air wet abrasive blast-cleaning).

- •6.5.2.6. Other methods

- •6.6. Abrasives.

- •Table 6.1. Abrasive / Profile Comparative Chart

- •Table 6.2. How to specify Blasting

- •Table 6.3. Examples of production rates to a Sa 2 ½ condition.

- •Table 6.4

- •Table 6.5. Consumption rates at different Nozzle pressures.

- •6.6.1. Metallic abrasives.

- •Table 6.6.

- •6.7. Water jetting and hydro blasting

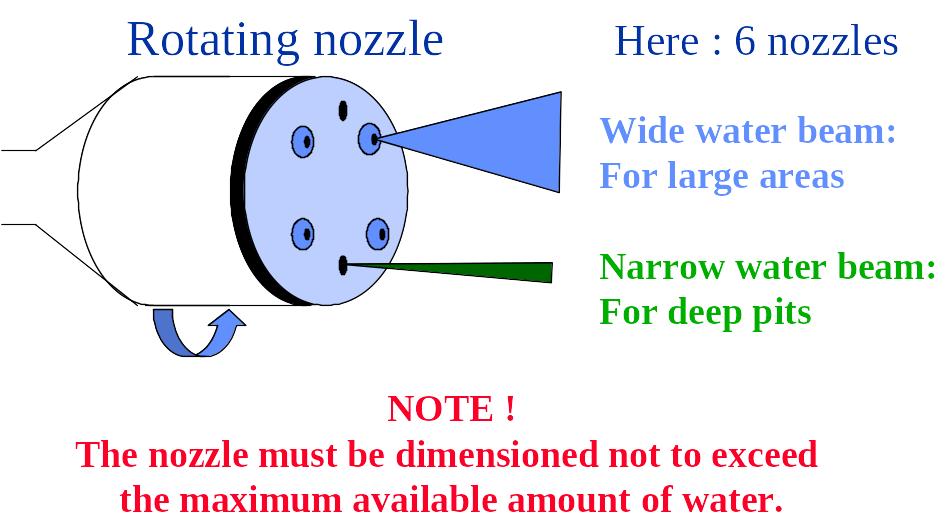

- •Figure 6.6 Rotating nozzles must be designed to fit the purpose

- •Figure 6.7 The water used must be free from impurities, which may contaminate the surface.

- •6.8. Electrolytic descaling with magnesium strips

- •Figure 6.8 Principle of electrolytic descaling

- •6.9. Preparation between paint coats

Figure 6.6 Rotating nozzles must be designed to fit the purpose

Over the past years it gradually became apparent that water jetting is very suitable for maintenance work. The method provides a number of environmental, economical and technical advantages:

Soluble salts are removed very effectively from the surface

No dust contamination of areas to be painted

No dust contamination of the surrounding environment

Easier, faster and lower cost for removal of waste after cleaning

Lower cost disposal of waste after cleaning

Sensitive areas (e.g. valves) can be cleaned without special protection

No risk of electrical sparks by cleaning

These features make water jetting an attractive surface preparation method in many repair yards, and for on-board maintenance. Seen from the paint-manufacturer’s side, however, cleaning by water jetting has five immediate limitations:

No roughness is created.

The cleaned surface will flash rust.

Water quality and imposed impurities.

Water, rust and old paint may contaminate surrounding areas.

Water fog is created in closed compartments.

Water jetting (as blast cleaning) can be a dangerous process.

Figure 6.7 The water used must be free from impurities, which may contaminate the surface.

The three first limitations can in most cases be overcome by a suitable choice of coating and by proper planning of the job. Only rarely is additional alternative treatment necessary.

There are now even more effective wet processes using low-pressure water added to a high-pressure air stream containing sand. The addition of the abrasive, generally sand, to the water gives a considerable improvement in cleaning at lower water pressures. Since all wet processes leave a wet surface, these will soon form a powdery film of rust which, although it is generally iron oxide rather than iron sulphate or chloride, would be an undesirable surface to paint over because of its powdery nature. Some wet processes use inhibitors in the water to prevent such rusting. However, it is important to establish that any traces of such inhibitors is compatible with the subsequent paint and does not cause any blisters.

If surface preparation is done by water jetting, the surface will at the time of application be characterised by:

The original roughness profile or profile created by a corrosion process

A certain cleaning degree, according to ISO 8501

Wet or dry surface, depending on environmental conditions and time to dry.

A certain flash rust degree, according to agreed acceptance criteria

The flash rust and the low roughness call for a first coating with good wetting and penetration properties. Well-known examples of such coatings are:

Epoxy mastics

Coal tar epoxies

The shape of the surface and the penetrating properties of the selected paint determines whether the first coat must be thinned or not. A coating with good penetrating property needs no thinning. If the coating is high build also a thick layer can be applied. Other products may require thinning and to be applied in a low dry film thickness, say 30 - 50 microns.

The general rule is that paint application shall be made on a dry surface. On the other hand application should preferably be done before humidity develops flash rust on the steel surface. Facing these two evils the surface tolerant paints on the market today prefer flash rust to humidity as the coatings are surface tolerant and not tolerant to humidity. The general rule is therefore to wait until the surface has dried and accept some flash rust.

In some rare cases the surface may be damp wet at the time of application. Most products, except the ones containing tar, have some tolerance towards damp surfaces, but often specially designed products must be chosen. (e.g. wet blast primers)

If in particular the cleaning is organised to allow application of a fast drying holding primer shortly after drying, but prior to formation of flash rust, the choice of products can be made much more freely.

When using a holding primer, this must be applied in a low film thickness, 30 - 50 microns. Furthermore, the holding primer must be of a type which can tolerate water for 10 - 20 minutes after application.