- •Surface Preparation and Cleaning. Table of content

- •5.1.1.Hand tool cleaning.

- •6.5.1.2.Power tool cleaning.

- •6.5.2. Blast-cleaning.

- •Figure 6.2.

- •Illustration of various blasting methods

- •6.5.2.1.Centrifugal abrasive blast-cleaning

- •6.5.2.2.Compressed-air abrasive blast-cleaning.

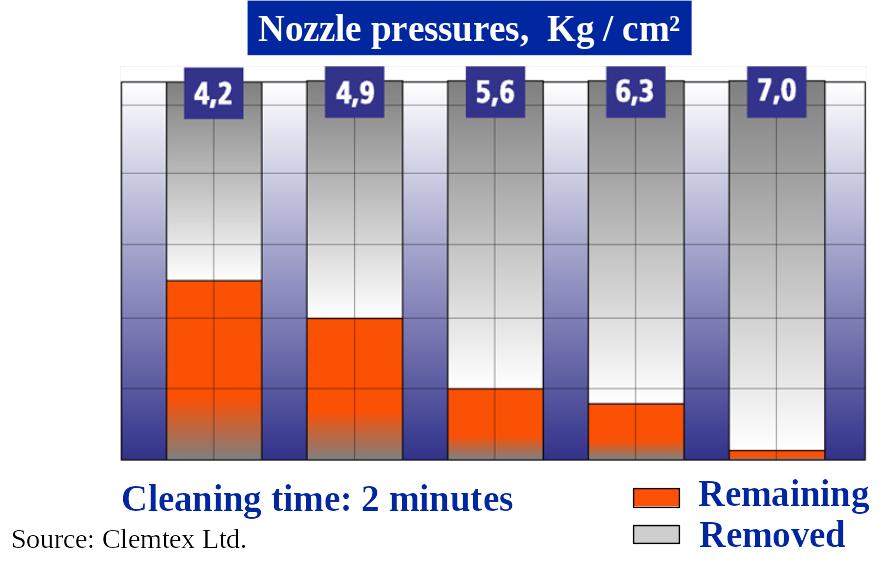

- •Figure 6.3 Effect of nozzle pressure on cleaning rate

- •6.5.2.3.Vacuum or suction-head abrasive blast-cleaning.

- •6.5.2.4.Moisture-injection abrasive blast-cleaning (compressed-air moisture- injection abrasive blast-cleaning)

- •6.5.2.5.Wet abrasive blast-cleaning (Compressed-air wet abrasive blast-cleaning).

- •6.5.2.6. Other methods

- •6.6. Abrasives.

- •Table 6.1. Abrasive / Profile Comparative Chart

- •Table 6.2. How to specify Blasting

- •Table 6.3. Examples of production rates to a Sa 2 ½ condition.

- •Table 6.4

- •Table 6.5. Consumption rates at different Nozzle pressures.

- •6.6.1. Metallic abrasives.

- •Table 6.6.

- •6.7. Water jetting and hydro blasting

- •Figure 6.6 Rotating nozzles must be designed to fit the purpose

- •Figure 6.7 The water used must be free from impurities, which may contaminate the surface.

- •6.8. Electrolytic descaling with magnesium strips

- •Figure 6.8 Principle of electrolytic descaling

- •6.9. Preparation between paint coats

Figure 6.3 Effect of nozzle pressure on cleaning rate

The nozzles are normally made from tungsten or Boron carbide. As they are continuously exposed to abrasives, they only have a lifetime of approximately 200 - 300 hours. Basically, there are two types of nozzles; straight bore- and Venturi-nozzle. At 7 bars the speed of the abrasive increase from 300 km/h for a straight nozzle to 700 km/h for a Venturi nozzle. The blasting “fan” from the Venturi nozzle covers a larger area and give a more even pattern than straight bore nozzle of the same size. It is easy to understand that these advantages give a higher production rate for the Venturi nozzle.

As is the case when a construction is painted it is important to check/control the environmental conditions during the pre-treatment process. The most important factor is to ensure that the surface temperature of the metal is min. 3 oC above the dew point and that the relative humidity is less than 80 - 85%.

After dry abrasive blast-cleaning, remove loosely adhering dust, debris and abrasive from the surface by vacuum, brushing or by use of compressed air free from oil and moisture.

6.5.2.3.Vacuum or suction-head abrasive blast-cleaning.

This method is similar to compressed-air abrasive blast-cleaning, but with the blasting nozzle enclosed in a suction-head sealed to the steel surface, collecting spent abrasive and contaminants. It is more time-consuming than other blast-cleaning methods and therefore mainly used for small spots and welding seems.

6.5.2.4.Moisture-injection abrasive blast-cleaning (compressed-air moisture- injection abrasive blast-cleaning)

This method is similar to compressed-air abrasive blast-cleaning, but with one exception: A very small amount of liquid (usually clean, fresh water) is added to the air/abrasive stream before the nozzle. The addition of liquid can in extreme cases be controlled to give only droplets out of the nozzle. The liquid binds the dust, meaning that the individual abrasive particles are enveloped with an extremely thin liquid film that, when the particles burst, prevents the formation of dust around the surface being treated. The suspended-particle size is less than 50 µm and the consumption of water is usually in the range of 15 to 25 l/h.

The surface preparation quality achieved by this method differs from that obtained by compressed-air abrasive blast-cleaning by the fact that the prepared surface is initially moist. Normally, the moisture disappears within a few minutes, but the time required for evaporation depends on the ambient conditions. The humidity may cause a light, negligible rust trace on the peaks of the roughened surface. In cases where “flash rusting” occurs, suitable coating systems are necessary.

A suitable rust inhibitor may be added to the water. By using them there is a potential risk of adding/dosing too much and thereby promote osmotic blistering. Thus, the rust inhibitor should be compatible with subsequent coatings and should be tested and approved by the paint supplier prior to use.