Lecture 3. Process of Cargo Transportation

Lecture Outline

3.1. Overview of cargo transportation processes.

3.2. Technological schemes of cargo transportation processes.

3.3. General rules of transportation process technology.

3.4. Basic concepts of cargo transportation process.

3.5. Indicators of transportation process (will be provided during the next lecture)

3.1. Overview of cargo transportation processes

As it was stated earlier, cargo transportation starts at the place of goods production and finishes at the place of their consuming. Process of transportation begins with making up of cargo for transportation (packing, marking, etc.). Process of storing (e.g. at the factory or a plant) is required for getting the necessary amount of goods intended for one consumer. Then the process of loading and transportation by truck transport from the factory to the railway follows.

On railway warehouse, they proceed with the process of documentary processing. Later, the process of storing reoccurs until the goods enough for one railway wagon is stored. That cargo is loaded into the wagon; the wagon is included into a train and dispatched. During transportation from origin point to point of destination, the wagon may again be subject to the process of train collection while the wagon can be transferred from one train into another at the sorting station. Processes of cargo unloading and transfer to road transport are the next in the cargo transportation process follow-up. This way the goods are delivered to the consumer. The consignee unloads the packages or containers.

Thus, cargo transportation process contains a chain of individual processes and operations.

Technological operations which are included into the transportation process differ greatly concerning their duration. Some operations, when united, form certain stages of transportation process. Every stage is intended for reaching an exact objective. For instance, the stage of transshipment cargo from one transport mode to the other in road-railway (waterway) transportation comprises the following operations:

1) unloading of the movable fleet of road transport;

2) moving cargo to the warehouse;

3) warehouse operations (horizontal and vertical stowing of cargo);

4) providing cargo storage / warehousing;

5) execution of documentation at warehouse;

6) saving of goods at the warehouse;

7) operations required for the period of storage (cooling, venting, etc.);

8) preparation of cargo for release from the warehouse;

9) moving of goods to the wagon;

10) cargo loading into the wagon;

11) laying cargo in the wagon and securing / fastening the cargo or closing the wagon doors;

12) processing of required documentation (packing list, bill of lading, certificate of origin, etc.).

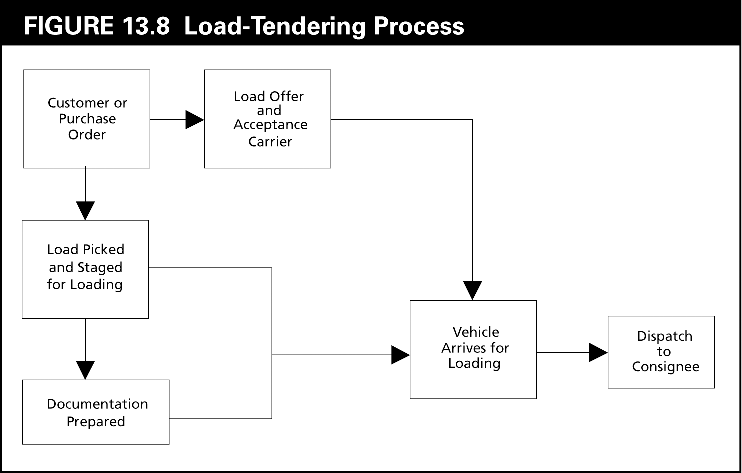

If the goods are transferred directly from the truck to the railway wagon, some of the above-enlisted operations fall out. A figure illustrating the simplest cargo transportation process is suggested below.

During the stage of making up of cargo for transportation at the enterprises of dairy and meet industry, for example, the following operations take place: moving load, unloading, storing and tare decontamination, repair of tare (if necessary), packing of the ready product into tare, storing of packed goods, etc.

Individual operations and stages of transportation process are interdependent (i.e. before moving load it has to be loaded onto transport mode). Therefore, cargo transportation process is a multistage and multioperation process with a large technological, operational and economic variety of operations. Individual stages of cargo transportation process are very often regarded as individual processes.