- •Introduction

- •History

- •Classification of Concretes

- •Materials for Heavy Concrete

- •Properties of Concrete Mixes and Concretes

- •Preparation and Transportation of Concrete Mixes

- •Fig. 3. Continuous concrete mixer

- •Placing Concrete Mixes, Curing Concrete and Quality Control

- •Internal vibrators are used for compacting concrete mixes in massive constructions of great depth (thickness). Used as internal vibrators are:

- •In cold seasons, concrete should be protected against excessive cooling, which slows down hardening, and the more so against freezing.

- •Specific Properties of Concrete

- •Environment and health

- •Building with concrete

- •Concrete as environmentally friendly choice

Properties of Concrete Mixes and Concretes

H eavy

concrete should acquire its design strength at a given time and

possess such qualities that are required of the construction being

manufactured from it (water and frost resistance, density, etc.). In

addition, the concrete mix should have an adequate mobility.

eavy

concrete should acquire its design strength at a given time and

possess such qualities that are required of the construction being

manufactured from it (water and frost resistance, density, etc.). In

addition, the concrete mix should have an adequate mobility.

Strength of concrete. In buildings and installations, concrete may be subjected to various stresses, such as compression, tension, bending, spalling. Concrete is best in compression, this being its basic mechanical property.

Concrete grade is determined by the compressive strength of a cubic specimen with sides measuring 20 cm made from a working concrete mix, after 28 days of hardening under normal conditions.

Properties of concrete mixes. Even with high-quality materials, concrete can be made strong and durable only if the mix is thoroughly compacted when placed into a construction. The moulding capacity of a concrete mix is determined by two factors - mobility and plasticity. Plasticity is an indicator of internal cohesion of a concrete mix, its ability to be moulded and to acquire a prescribed shape without breaks and stratification. The mobility of a concrete mix is evaluated by its ability to flow under its own weight or under vibration.

Choice of concrete mix mobility. Stiff-concrete mixes are more economical because they consume less cement than the mobile ones. The mobility of a concrete mix should be as low as possible, but consistent with adequate placeability. When choosing the mobility of a concrete mix, the size and the character of the construction, the simplicity and easy placing of the reinforcement should be taken into account.

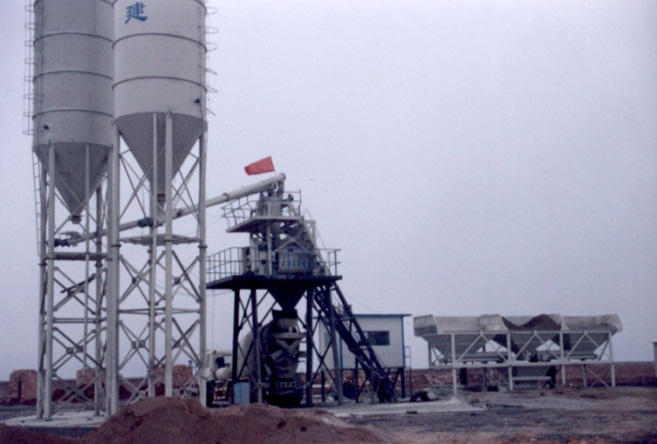

Preparation and Transportation of Concrete Mixes

P

reparation

of concrete mixes.

The main operations in the process of preparing concrete mixes are

proportioning and mixing of ingredients.

reparation

of concrete mixes.

The main operations in the process of preparing concrete mixes are

proportioning and mixing of ingredients.

The main condition for preparing a concrete mix of prescribed properties and for maintaining these properties from batch to batch consists in an accurate proportioning of ingredients in accordance with the working composition of concrete. Materials are proportioned by measuring devices of batch or continuous action. The former may be provided with manual, semiautomatic and automatic controls.

Most efficient are automatic weighers which have high accuracy of proportioning, short weighing time and are easy to control. Volumetric measuring devices are less accurate and are used at small concrete mixing installations, but even in these cases cement is proportioned by weight. At large mixing plants materials are proportioned by weight only. Figure 1 shows an automatic weighing batcher for cement, and Figure 2, the same for aggregates.

In semiautomatic batchers, the gates open and close automatically upon filling the weight-measuring device, the discharge gate being operated by hand. Automatic batchers are controlled from a central control desk. A required amount of material is weighed automatically in two stages, first to about 90%, then topped accurately to a preset mark.

Automatic batchers can also be controlled with the aid of punch cards which carry coded information on the quantities of materials being proportioned. This system allows proportioning of an unlimited amount of mix compositions and repeating a particular proportioning schedule any number of times.

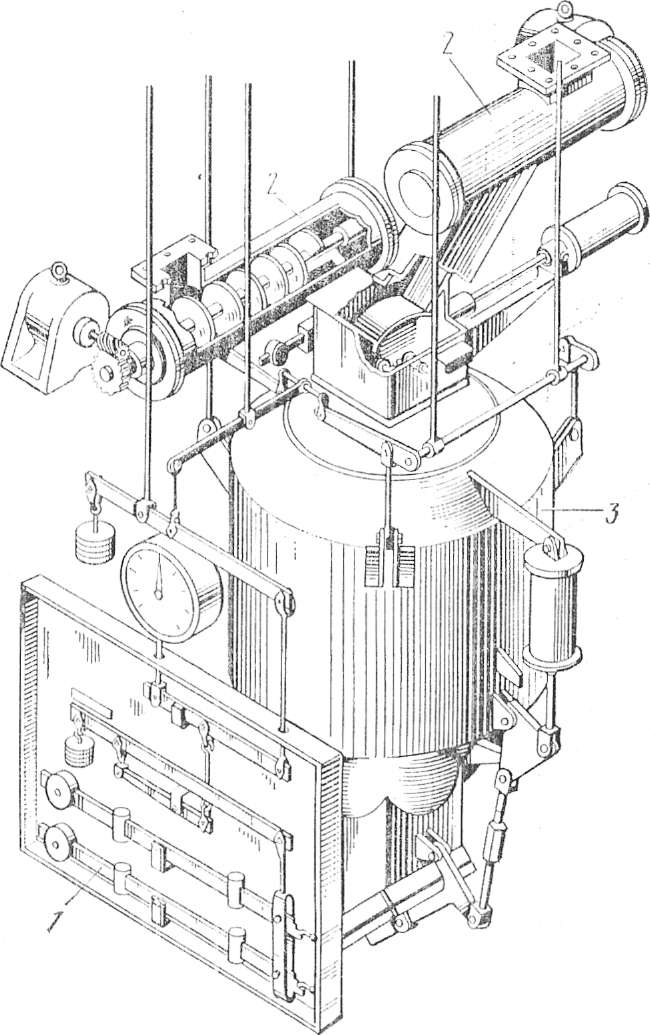

Fig. 1. Automatic weighing batcher for cement

1—automatic scales; 2—screw conveyor; 3—bin

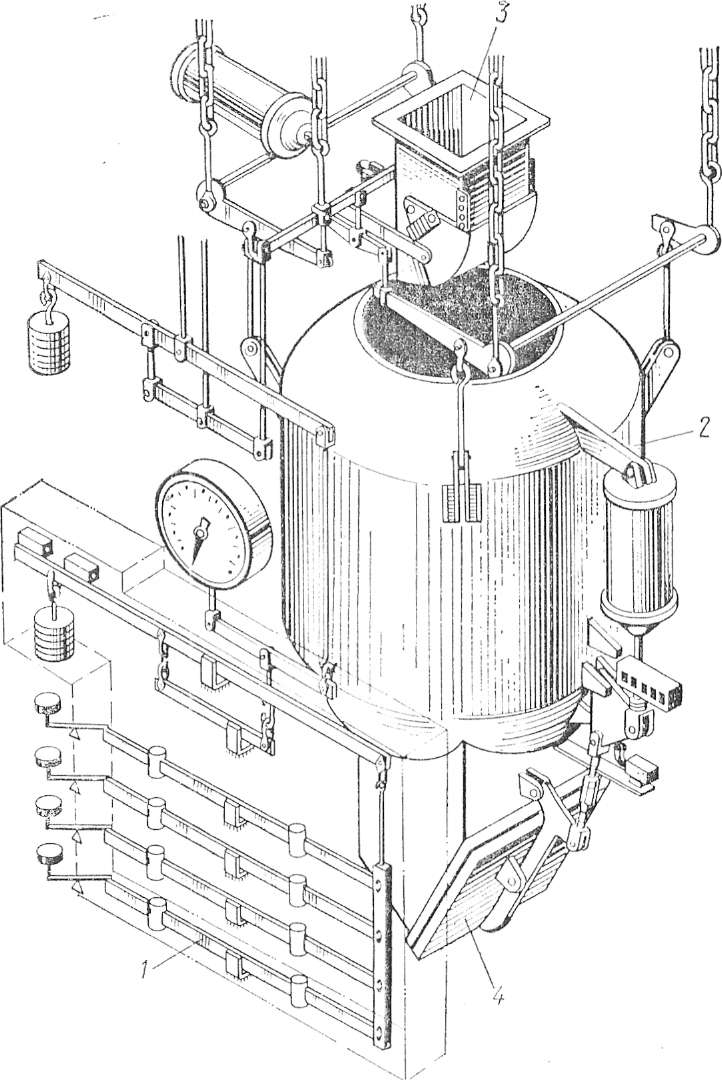

Fig. 2. Automatic weighing batcher tor aggregates

1—atomatic scales; 2—bin; 3—receiving funnel; 4—discharge bottom gate

According to existing norms, the proportioning tolerances are ±1 % by weight for cement and water and ±2% for aggregate. This accuracy can be obtained by weight proportioning only.

Concrete mixes are prepared in batch and continuous concrete mixers. In batch-type concrete mixers the working cycles include pauses during which the mixers are charged at prescribed intervals of time with weighed portions of materials; the latter are then mixed and a finished concrete mix is discharged. In continuous concrete mixers, all three operations are performed continuously (Figure 3).

The mixing time of stiff concrete mixes is about twice as great as compared to that of mobile mixes.