2015 ARKH-P7 Artic P

.pdf

AGENDA

1 Geography and geopolitic

1 Geography and geopolitic

2 Existing facilities

2 Existing facilities

3 Some technical challenges:

3 Some technical challenges:

A Ice and Icebergs

B Winterization

C Arctic Codes

D HSE

4 Shtokman

4 Shtokman

Definitions

Winterization refers to the process of preparing something for an upcoming winter.

Winterization refers to the process of preparing something for an upcoming winter.

Opened module ≠ winterized module ≠ contained module

Opened module ≠ winterized module ≠ contained module

Protecting against cold, icing, snow, wind, rain:

Protecting against cold, icing, snow, wind, rain:

Personnel

Equipment

Asset

Operations

Providing optimum conditions to:

Providing optimum conditions to:

HSE performance

Production, flow assurance

Maintenance

Construction / pre-service phases

Overall winterisation strategy

Project / Company must have an overall winterisation strategy / philosophy i.e

Overall protection

Individual equipment protection

Personal Protective Equipment (PPE) – thermal coverall, breathing apparatus, gloves,..

A Winterization philosophy shall be established and adress requirements discipline by discipline (for instance trace heating)

Needs a Leader ("Mr/Mrs Winterisation")

Winterisation is not a single discipline

Classic "transverse working“

Winterisation = design & installation

Simple

Robust / sturdy

Pipelines, flexibles, risers

Pipes :

Coating

Foundations stability

Expansion loops

Heat tracing, insulation

Flexibles :

Non ferrous material behaviour against cold

Ice in annular due to condensation

Reel laying (radius) during cold weather cold

Storage under extreme cold conditions

Risers protection against ice loads

May be exposed to ridge sail & keels

Wear, shocks, ice gouging

Clamps (neoprene)

Local heating in moon pools

Preservice operations in adverse weather

Lifting in snow storm

Trailers move

MATERIAL ISSUES

All cases must be assessed, not only structural components (pressure vessels – restart after shut down in winter).

T°C Amplitude between winter and summer may generate high loads that could be not taken into account in classical design codes.

AGENDA

1 Geography and geopolitic

1 Geography and geopolitic

2 Existing facilities

2 Existing facilities

3 Some technical challenges:

3 Some technical challenges:

A Ice and Icebergs

B Winterization

C Arctic Codes

D HSE

4 Shtokman

4 Shtokman

ISO 19906 Arctic code for offshore structures

Why an International Standard ?

Race to the Arctic has begun; 25% Yet-To-Find Oil & Gas

Offshore oil and gas E&P operations in ice covered waters are currently underway in nine countries

Currently only four countries have Arctic Codes: Canada, Norway, Russia, United States

wide variation in coverage, methods and age

Contractors working or proposing to work in these areas may not have the necessary experience

Harmonization of current codes, including integration of latest knowledge, will:

Ensure consistent approaches (ice loads, integrity)

Reduce approval times and save design effort

ISO/TC67

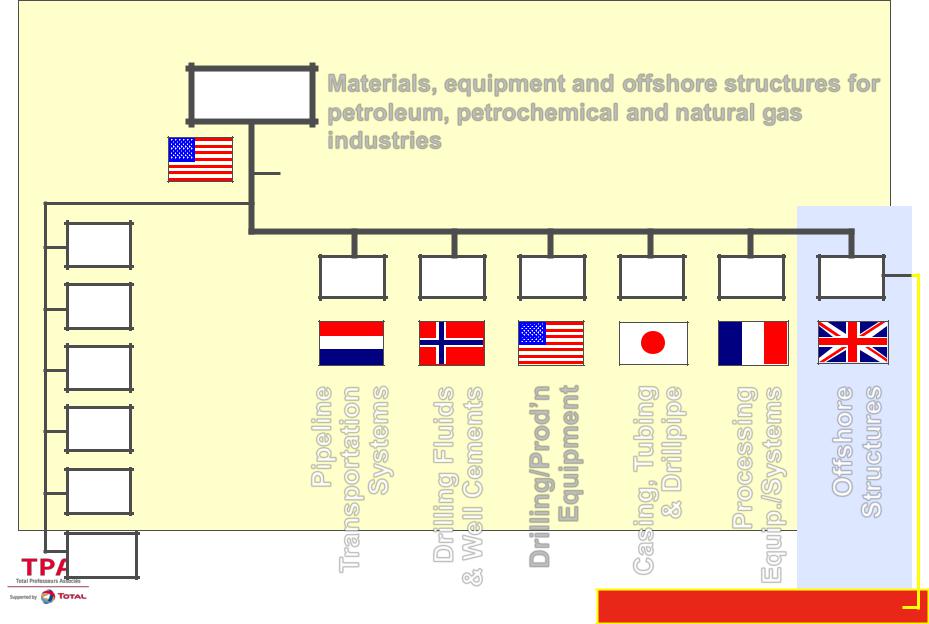

ISO/TC67 Materials, equipment and offshore structures for petroleum, petrochemical and natural gas

industries

|

EC = Executive Committee |

EC/MC |

|

|

MC = Management Committee |

|

WG2 AssessmentConformity |

|

|

|

|

|

|

||

|

|

SC 2 |

SC 3 |

SC 4 |

SC 5 |

SC 6 |

SC 7 |

|

WG4 |

Data |

|

|

|

|

|

|

|

|

Collection |

|

|

|

|

|

|

|

WG5 |

Aluminium |

|

|

|

|

|

|

|

|

Drill Pipe |

Pipeline Transportation Systems |

FluidsDrilling CementsWell& |

Drilling/Prod’n Equipment |

TubingCasing, Drillpipe& |

Processing Equip./Systems |

Offshore Structures |

|

WG7 |

ResistantCorrosion |

|||||||

|

|

|

|

|

|

|||

|

Materials |

|

|

|

|

|

|

|

WG9 |

Life Cycle |

|

|

|

|

|

|

|

|

Costing |

|

|

|

|

|

|

|

WG10LNG systems |

|

|

|

|

|

|

||

|

& equipment |

|

|

|

|

|

|

|

WG8 - Arctic Offshore Structures